Abstract

The use of slurry sampling as the procedure for sample preparation provides simplicity, speed, and low consumption of reagents in analytical methods. In this paper, a method based on slurry sampling for the determination of iron in samples of fortified milk powder by high-resolution continuum source flame atomic absorption spectrometry was developed. Multivariate design techniques were applied for the optimization of experimental conditions of the method for a sample mass of 100 mg, final volume of slurry of 10 mL, and using the absorbance signal as response. Initially, a two-level full factorial design was used for the preliminary evaluation of the variables involved in slurry preparation: concentration hydrochloric acid, Triton X-100 concentration, and sonication time. Then, the Doehlert matrix was applied for the determination of the critical conditions: 2.5 mol L−1 hydrochloric acid and sonication time of 20 min. External calibration technique with aqueous standard was used for the quantification of iron. This way, the method allowed iron determination with limits of detection and quantification of 0.9 and 3.0 μg g−1, respectively. The precision expressed as the relative standard deviation was evaluated under repeatability and reproducibility conditions, being 3.2% and 4.0%, respectively. Addition/recovery test was used for assessing the accuracy of the method, and the recovery values achieved were in the range of 90–110%. The method was applied for iron determination in eight samples of fortified milk powder, and the obtained concentrations varied from 95.4 to 295.6 μg g−1. The results were compared with those obtained after acid digestion, and no significant difference was observed applying t test at the 95% confidence level.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Iron is among the nutrient elements more important to the human diet. It is required for the transport of oxygen and is an essential constituent of numerous enzymes involved in diverse metabolic functions, including the production of metabolic energy, protein and DNA metabolism, collagen synthesis, and metabolism of β-carotene (Saman 2007; Sharma and Singh 2009). Due to their wide metabolic activity, iron deficiency causes serious health problems. The most severe and common form of iron deficiency is anemia, which is associated with weakness and eventually heart failure. Furthermore, iron deficiency is among the most prevalent forms of malnutrition worldwide, and it represents a high overall cost to society (Saman 2007; Kosse et al. 2001; Martínez-Navarrete et al. 2002; Moy 2006). Thus, fortification programs of foods have been created in numerous countries, being an effective means for reducing the prevalence of iron deficiency (Kosse et al. 2001; Martínez-Navarrete et al. 2002; Lamonier et al. 2010).

However, for fortification programs of food to be effective, a consistent and uniform addition of iron compounds to appropriate food vehicles is required, such as flour and milk powder, which are widely consumed by the target population, mainly children (Kosse et al. 2001; Martínez-Navarrete et al. 2002). This way, the development of simple and reliable analytical methods for accurate quantification of iron in fortified foods is of great relevance. Nevertheless, food matrices are complex and usually require a decomposition or extraction step for its analysis, such as milk powder (Soylak et al. 2004; Saracoglu et al. 2007; do Nascimento et al. 2010). Because of this, most of the existing methods for iron quantification in fortified foods are often complicated, time-consuming, and involve the use of potentially hazardous reagents (Kosse et al. 2001). In recent years, the slurry sampling technique has become an interesting alternative for minimizing the manipulation step of samples and reducing the operational work, the analysis time, and the risk of contamination, apart from minimizing or avoiding the loss of volatile analytes and using hazardous reagents (Magalhães and Arruda 1998; Ferreira et al. 2010). Slurry sampling has been successfully applied for the determination of metals and metalloids in a broad range of complex matrices, and several spectrometric techniques have been employed for the detection, such as inductively coupled plasma (ICP) optical emission spectrometry (dos Santos et al. 2010), ICP mass spectrometry (Hsiao et al. 2011), hydride generation atomic absorption spectrometry (AAS; Macedo et al. 2010), electrothermal AAS (Saleh et al. 2009), and flame atomic absorption spectrometry (FAAS; Brandao et al. 2010).

Multivariate design techniques have been widely applied for the optimization of analytical methods in recent years. These allow the simultaneous study of several variables and present advantages such as reduction of the number of required experiments, assessment of the statistical significance of variable effects studied, as well as evaluation of the interaction effects between the variables and the determination of the critical conditions of these variables, being more cost-effective than traditional univariate approaches (Ferreira et al. 2004; Tarley et al. 2009). Multivariate techniques have been extensively used for the optimization of analytical methods involving procedures of preconcentration, sample digestion, ultrasonic-assisted extraction, and microwave-assisted extraction (Soylak et al. 2007; Ferreira et al. 2007; Shah et al. 2009; Khajeh and Sanchooli 2010; Khajeh et al. 2010). However, its use for the optimization of analytical strategies based on slurry sampling has been rarely explored (de Amorim et al. 2011).

Considering all the matters discussed above, this work proposes the development of an analytical method based on slurry sampling for iron determination in fortified milk powder by high-resolution continuum source FAAS (HR-CS FAAS) and application of multivariate design techniques for the optimization of the experimental conditions.

Experimental

Instrumentation

For iron determination, a high-resolution continuum source flame atomic absorption spectrometer model ContrAA 700 from Analytik Jena (Jena, Germany) equipped with a xenon short-arc lamp XBO 301 with a nominal power of 300 W operating in a hot spot mode as a continuum radiation source was used. An air–acetylene flame was used for the atomization of iron at a flow rate of 60 L h−1 using a burner height of 6 mm. All measurements of absorbance were performed in triplicate for blanks, analytical solutions, and samples using the primary line of iron at 248.3270 nm, considering 5 pixels. An Ultrasonic Benchtop Cleaner VWR model 75 D (Cortland, New York, USA) was used for slurry preparation.

Reagents, Solutions, and Samples

All reagents were of analytical grade unless otherwise stated. Ultrapure water was obtained from a Milli-Q system (Millipore, Bedford, MA, USA). Nitric, hydrochloric and sulfuric acids, Triton X-100, and hydrogen peroxide were of suprapur quality obtained from Merck (Darmstadt, Germany). Laboratory glassware was kept overnight in 10% (v/v) nitric acid solution. All glassware was rinsed with deionized water and dried in a dust-free environment before use.

A 50 μg mL−1 iron solution was prepared from 1,000 mg L−1 iron stock solution (Merck) by appropriate dilution with 1% (v/v) hydrochloric acid solution. Calibration solutions in final concentrations of 0.5–3.0 μg mL−1 were prepared by appropriate dilution from 50 μg/mL iron solution with 2.5 mol L−1 hydrochloric acid and 0.1% (w/v) Triton X-100.

The samples of fortified milk powder with iron (whole and skimmed) were locally available brands, purchased in supermarkets from Salvador City, Brazil. The samples were stored in polyethylene pots decontaminated previously and kept in a desiccator.

Procedure for Slurry Preparation

A sample mass of 100 mg was directly weighed in 10-mL volumetric flask. A volume of 1.0 mL of 1% (w/v) Triton X-100 solution was added and the mixture diluted with 2.5 mol L−1 hydrochloric acid solution to 10 mL. Then, the slurries were sonicated for 20 min in an ultrasonic bath; afterwards, the slurries were aspirated directly through the nebulizer for iron determination by HR-CS FAAS. All the samples were analyzed in triplicate, and blank solutions were prepared containing all the reagents used for slurry preparation. External calibration technique was used for iron quantification, and the analytical curves were established using aqueous standards.

Procedure for Digestion of Milk Powder

A sample mass of 100 mg was directly weighed in a digestion tube. About 1.0 mL of concentrated sulfuric acid and 1.0 mL of concentrated nitric acid were added and the mixture heated to 180 °C for 1 h in a digester block. Then, a volume of 1.0 mL of 30% (v/v) hydrogen peroxide was added and the mixture was again heated for 30 min. After cooling to room temperature, the residual solution was transferred to a volumetric flask with ultrapure water and diluted to 10 mL.

Strategy for Optimization of the Method

The optimization of the experimental conditions for slurry preparation was performed using a two-level factorial design and Doehlert matrix involving the following variables: hydrochloric acid concentration, Triton X-100 concentration, and sonication time. The absorbance signal was used as analytical response and the experimental data were processed using the STATISTICA program. All experiments were carried out in random order using a sample mass of 100 mg for a final volume of slurry of 10 mL. Triplicate of the central point was performed for experimental error evaluation. The slurries were prepared from a sample of fortified whole milk powder with iron content of 132.9 ± 7.0 μg g−1 (n = 3, 95% confidence level). It is important remember that the samples were purchased already fortified by the manufacturer.

Results and Discussion

Optimization of Experimental Conditions for Slurry Preparation

Initially, a two-level factorial design was applied for the preliminary evaluation of the variables involved in the slurry preparation: hydrochloric acid concentration (AC), Triton X-100 concentration (TC), and sonication time (ST). The matrix of the factorial design with the obtained results for each experiment is shown in Table 1. The maximum and minimum levels for each variable as well the central point are presented in coded and real values. The result of this design, as Pareto chart (Fig. 1), demonstrates that only hydrochloric acid concentration and sonication time are the variables statistically significant for the slurry preparation into the experimental domains studied. Although the Triton X-100 concentration was not a statistically significant variable, it was observed that the presence of this reagent in a concentration of 0.1% (w/v) provided better homogeneity and stability of the slurries. Thus, this variable was fixed in their maximum level for further studies.

Afterwards, Doehlert matrix was applied for the determination of optimum experimental conditions. This experimental design was chosen because it offers some advantages in relation to central composite and Box–Behnken designs. Doehlert matrix requires fewer experiments, which are more efficient and can move through the experimental domain. Furthermore, the number of levels is not the same for all variables. This property allows a choice of the variables to be assigned to a large or a small number of levels, in accordance with specified criteria (Ferreira et al. 2004). In this study, the HCl concentration was evaluated at five levels and their experimental domain was displaced for higher levels, considering that their effect was higher and positive for slurry preparation. However, the sonication time was evaluated only at three levels. Table 2 shows the Doehlert matrix with the results obtained for each experiment.

A quadratic model involving the two variables was found to adequately describe the data in Table 3. An analysis of variance (ANOVA) demonstrated that the model does not suffer from lack of fit. Furthermore, the ANOVA indicated that only the linear and quadratic terms for HCl concentration were significant at the 95% confidence level. The results of ANOVA are shown in Table 3.

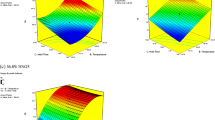

Considering the real values, the relation between the acid hydrochloric concentration, sonication time, and absorbance signal is described by the following equation:

This equation also describes a response surface, shown in Fig. 2, which presents a critical point that it is maximum for a hydrochloric acid concentration of 2.44 mol L−1 and a sonication time of 19.5 min. This way, the experimental conditions established for the method were: hydrochloric acid concentration of 2.5 mol L−1, sonication time of 20 min, and Triton X-100 concentration of 0.1% (w/v).

Validation process

The concentration of Triton X-100 demonstrated to be a robust variable for the interval of 0.02–0.1% (w/v) since this variable was not significant according to the results obtained from the two-level factorial design. Thus, a robustness study was performed only involving hydrochloric acid concentration and sonication time applying a two-level factorial design, considering a variation of ±20% for each variable. The experimental data obtained for this study are shown in Table 4. The Pareto chart obtained (Fig. 3) demonstrates clearly that the hydrochloric acid concentration and sonication time are robust variables for the interval of 2.5 ± 0.5 mol L−1 and 20 ± 4 min, respectively.

Analytical curves were obtained for iron by the analyte addition technique for a sample of fortified skimmed milk powder with iron content of 103.1 ± 6.6 μg g−1 and also for a sample of whole milk powder not fortified with iron. The slopes of these curves were compared with the slope of the analytical curve obtained by external calibration technique using aqueous standard solutions. All these results are shown in Table 5, as confidence intervals. There were no significant differences between the slopes obtained for both systems. This means that the quantification of iron in milk powder slurries can be carried out by external calibration technique and analytical curve established with aqueous standard solutions.

Mass curves were also obtained for samples of whole and skimmed milk powder containing 132.9 ± 7.0 and 103.1 ± 6.6 μg g−1 of iron, respectively. The sample mass was studied in the range of 50–250 mg. The results demonstrated that a sample mass of up to 200 mg can be used for slurry preparation, a linear relation between the absorbance and sample mass being obtained (r > 0.99). However, slurries prepared with a sample mass of 250 mg caused problems of obstruction in the nebulization system of the spectrometer since less homogeneous and stable slurries were obtained using this mass amount for both samples.

The limits of detection and quantification (LOQ), calculated according IUPAC’s recommendation (IUPAC 1978), were 0.9 and 3.0 μg g−1, respectively. The blank was prepared in the same way as the slurries, from a sample of unfortified milk powder with iron content below the limit of quantification of the proposed method.

The precision expressed as the relative standard deviation (RSD) was evaluated under repeatability and reproducibility conditions, being of 3.2% and 4.0%, respectively, for a sample containing 187.1 ± 3.9 μg g−1 of iron. The accuracy was evaluated by the addition/recovery test for all the analyzed samples, and recoveries in the range of 90–110% were achieved.

Application

The method was applied for iron determination in eight samples of fortified milk powder, and the results are presented in Table 6, as confidence intervals. The samples also were analyzed after the acid digestion procedure and iron determined by HR-CS FAAS. A mixture of sulfuric and nitric acid was required because milk powder has fat, a higher temperature being necessary for their decomposition. As the decomposition was performed in an open system (digester block), it was necessary to use an acid with a high boiling point, for example, sulfuric acid. The iron concentrations found in the samples varied from 95.4 to 295.6 μg g−1. Application of a t test at the 95% confidence level demonstrated that there was no significant difference between the results obtained by both methods. However, three samples of different lots of the same manufacturer presented iron contents below the limit of quantification of the proposed method.

Conclusions

Employing the slurry sampling allowed the development of an analytical method which is simple, rapid, and effective for the determination of iron in samples of fortified milk powder by HR-CS FAAS. Furthermore, the developed method provides low risk of sample contamination, uses less corrosive reagents, and involves less operational work.

The possibility of the iron quantification using reference solutions for the calibration provides higher simplicity of the method, which makes the method adequate for routine analysis. The use of multivariate design techniques was useful for suitable optimization of the experimental conditions involved in the slurry preparation. The two-level factorial design allowed evaluating the statistical significance of the variables, while the Doehlert matrix allowed determining the critical conditions for the appropriate preparation of slurries.

Finally, the proposed method was properly validated by means of the assessment of analytical parameters, such as limits of detection and quantification; precision as RSD, under repeatability and reproducibility conditions; and accuracy by the addition/recovery test and comparison between methods. This fact is of great importance for the development of methods involved in food analysis.

References

Brandao GC, de Jesus RM, da Silva EGP, Ferreira SLC (2010) Use of slurry sampling for the direct determination of zinc in yogurt by high resolution-continuum source flame atomic absorption spectrometry. Talanta 81:1357–1359

de Amorim FR, Franco MB, Nascentes CC, da Silva JBB (2011) Direct determination of molybdenum in milk and infant food samples using slurry sampling and graphite furnace atomic absorption spectrometry. Food Anal Meth 4:41–48

do Nascimento IR, de Jesus RM, dos Santos WNL, Souza AS, Fragoso WD, dos Reis PS (2010) Determination of the mineral composition of fresh bovine milk from the milk-producing areas located in the State of Sergipe in Brazil and evaluation employing exploratory analysis. Microchem J 96:37–41

dos Santos EJ, Herrmann AB, Vieira F, Sato CS, Correa QB, Maranhao TA, Tormen L, Curtius AJ (2010) Determination of Hg and Pb in compact fluorescent lamp by slurry sampling inductively coupled plasma optical emission spectrometry. Microchem J 96:27–31

Ferreira SLC, dos Santos WNL, Quintella CM, Neto BB, Bosque-Sendra JM (2004) Doehlert matrix: a chemometric tool for analytical chemistry—review. Talanta 63:1061–1067

Ferreira SLC, Korn MDGA, Ferreira HS, da Silva EGP, Araujo RGO, Souza AS, Macedo SM, Lima DDC, de Jesus RM, Amorim FAC, Bosque-Sendra JM (2007) Application of multivariate techniques in optimization of spectroanalytical methods. Appl Spectrosc Rev 42:475–491

Ferreira SLC, Miro M, da Silva EGP, Matos GD, dos Reis PS, Brandao GC, dos Santos WNL, Duarte AT, Vale MGR, Araujo RGO (2010) Slurry sampling—an analytical strategy for the determination of metals and metalloids by spectroanalytical techniques. Appl Spectrosc Rev 45:44–62

Hsiao PK, Jiang SJ, Sahayam AC (2011) Determination of trace elements in silicon powder using slurry sampling eletrothermal vaporization inductively coupled plasma mass spectrometry. J Anal At Spectrom 26:586–592

IUPAC, Analytical Chemistry Division (1978) Spectrochim Acta B 33:242–245

Khajeh M, Sanchooli E (2010) Optimization of microwave-assisted extraction procedure for zinc and iron determination in celery by Box–Behnken design. Food Anal Meth 3:75–79

Khajeh M, Moghaddam ARA, Sanchooli E (2010) Application of Doehlert design in the optimization of microwave-assisted extraction for determination of zinc and copper in cereal samples using FAAS. Food Anal Meth 3:133–137

Kosse JS, Yeung AC, Gil AI, Miller DD (2001) A rapid method for iron determination in fortified foods. Food Chem 75:371–376

Lamonier JA, Capanema FD, Rocha DS, de Oliveira JED, da Silva MC, de Almeida CAN (2010) Iron fortification strategies for the control of childhood anemia in Brazil. J Trop Pediatr 56:448–451

Macedo SM, dos Santos DC, de Jesus RM, da Rocha GO, Ferreira SLC, de Andrade JB (2010) Development of an analytical approach for determination of total arsenic and arsenic(III) in airborne particulate matter by slurry sampling and HG-FAAS. Microchem J 96:46–49

Magalhães CEC, Arruda MAZ (1998) Slurry sampling: the technique employment in the direct samples analysis. Quim Nova 21:459–466

Martínez-Navarrete N, Camacho MM, Martínez-Lahuerta J, Martínez-Manzó J, Fito P (2002) Iron deficiency and iron fortified foods—a review. Food Res Int 35:225–231

Moy RJD (2006) Prevalence, consequences and prevention of childhood nutritional iron deficiency: a child public health perspective. Clin Lab Haem 28:291–298

Saleh MAD, Neves RCF, Silva FA, de Moraes PM, Loureiro VR, Roldan PS, Padilha PM (2009) GFAAS determination of zinc in fish feed and feces using slurry sampling. Food Anal Meth 2:162–168

Saman S (2007) Iron Nutr Diet 64:S126–S130

Saracoglu S, Saygi KO, Uluozlu OD, Tuzen M, Soylak M (2007) Determination of trace element contents of baby foods from Turkey. Food Chem 105:280–285

Shah AQ, Kazi TG, Arain MB, Baig JA, Afridi HI, Jamali MK, Jalbani M, Kandhro GA (2009) Optimization of ultrasonic-assisted acid extraction of mercury in muscle tissues of fishes using multivariate strategy. J AOAC Int 92:1580–1586

Sharma AK, Singh I (2009) Spectrophotometric trace determination of iron in food, milk, and tea samples using a new bis-azo dye as analytical reagent. Food Anal Meth 2:221–225

Soylak M, Tuzen M, Narin I, Sari H (2004) Comparison of microwave, dry and wet digestion procedures for the determination of trace metal contents in spice samples produced in Turkey. J Food Drug Anal 12:254–258

Soylak M, Tuzen M, Souza AS, Korn MGA, Ferreira SLC (2007) Optimization of microwave assisted digestion procedure for the determination of zinc, copper and nickel in tea samples employing flame atomic absorption spectrometry. J Hazard Mater 149:264–268

Tarley CRT, Silveira G, dos Santos WNL, Matos GD, da Silva EGP, Bezerra MA, Miró M, Ferreira SLC (2009) Chemometric tools in electroanalytical chemistry: Methods for optimization based on factorial design and response surface methodology. Microchem J 92:58–67

Acknowledgments

The authors gratefully acknowledge the Brazilian agencies PRONEX/Fundação de Amparo à Pesquisa do Estado da Bahia (FAPESB), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for grants and fellowships.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brandao, G.C., Gomes, D.P. & Matos, G.D. Development of an Analytical Method Based in the Slurry Sampling for Iron Determination in Fortified Milk Powder by HR-CS FAAS. Food Anal. Methods 5, 579–584 (2012). https://doi.org/10.1007/s12161-011-9282-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-011-9282-5