Abstract

In the present work a novel methodology for the determination of Fe, Mn, and Zn by flame atomic absorption spectrometry in samples of spirulina, commercialized as a food supplement, was developed. Variables involved in the sample preparation were optimized using the Doehlert design and desirability function. The developed method presented quantification limits of 18, 5.3, and 8.6 mg kg−1, precision, expressed as repeatability (%RSD, 0.5 mg kg−1, N = 5) of 1.3; 1.8 and 2.3% respectively for Fe, Mn, and Zn. Accuracy was assessed by addition/recovery test, comparison with another method adopted as standard, and analysis of certified reference materials (Apple leaves NIST1515, and Pinus leaves NIST 1575a), showing that the method presents adequate accuracy for the determination of the elements studied. The concentrations of Fe, Mn, and Zn found were in the ranges from 52.5 to 836; 7.50 to 40.2, and 13.7 to 25.0 mg kg−1 respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Arthrospira (Spirulina) platensis is a spiral-shaped filamentous cyanobacterium, classified as a blue-green microalgae. They are microorganisms generally found in tropical and subtropical regions in warm water bodies with a high content of carbonate/bicarbonate compounds, alkaline pH, and salinity. Under ideal physical conditions and in the presence of adequate nutrients, it can proliferate rapidly and generate a large mass of algae. This mass is easily collected from the aqueous medium, which enables its cultivation and commercialization on a large scale [1,2,3].

Spirulina has been used as a food supplement for humans and animals, being adopted as a source of proteins, minerals, B vitamins, iron, and antioxidants, such as phycocyanin and gallic acid. Several benefits of the use spirulina in the diet have been researched, such as the prevention of heart attacks, arteriosclerosis, and stroke. Also, your consumption can avoid allergic rhinitis and diseases linked to obesity (helping with weight loss), allows the treatment of diabetes, combating anemia, and provide muscle mass gain [4,5,6,7]. Spirulina is often marketed in a dried form to prevent the product deterioration and to extend its shelf life. It is available in powder, capsule and tablet form. Ingesting more than recommended amounts of spirulina can cause nausea, vomiting, or diarrhea in some people. Allergic reactions caused by ingestion of large amounts of spirulina are, however, rare [8, 9].

Slurry sampling is a sample preparation technique based on dispersing a finely powdered solid in a liquid and introducing it into equipment aiming at elemental determination. The technique intents to minimize treatment steps and increase the analytical frequency. The following additional advantages are: minimization of the risk of contamination and loss of volatile elements, reduction in the use of corrosive reagents, application to a wide variety of inorganic and organic samples, among others [10, 11].

Slurry sampling has already been applied in the food industry for the determination of Cu, Cd, Pb, and Cr in yogurt by graphite furnace atomic absorption spectrometry (GFAAS) [12], Cd, Pb, and Cr in honey by GFAAS [13], Cr from milk and similar baby food by GFAAS [14], Fe from fortified milk power by high resolution continuous source flame atomic absorption spectrometry (HR-CS FAAS) [15], Ca, Fe, and Zn from coffee by flame atomic absorption spectrometry (FAAS) [16], Ca, Cu, Fe, K, and Mg from sugarcane juice by inductively coupled plasma optical emission spectrometry (ICP OES) [17], 16 metals from plant-based foods by inductively coupled plasma mass spectrometry (ICP-MS) [18], K, Fe, Zn, Cu, Mo, and Cd from wheat flour by ICP-MS [19], As from rice samples by hydride generation atomic fluorescence spectrometry (HG AFS) [20], Arsenic, Cd, Hg, and Pb from herbs by electrothermal vaporization (ETV) ICP OES [21], among other works. Flame atomic absorption spectrometry (FAAS) is a very widespread analytical technique in laboratories due to its versatility, simplicity, and relatively low cost of acquisition and maintenance [22,23,24,25]. Because it is robust, FAAS is very compatible with slurry sampling, providing fast, reliable methodologies with good analytical characteristics.

Multivariate optimization methods have been widely applied in the development of analytical methods in recent years. They are economical, efficient, and allow the evaluation of interactions between variables involved in system performance. Doehlert design is an experimental matrix that has been widely used in response surface methodology in the optimization of various analytical procedures due to its practicality and application versatility [26,27,28,29].

The present work deals with the development of a method based on slurry sampling for the determination of Fe, Mn, and Zn by flame atomic absorption spectrometry (FAAS) in samples of pulverized spirulina sold as a food supplement. The preparation of the slurry was optimized using multivariate optimization techniques (Doehlert design and desirability function) in order to generate the best possible analytical characteristics for the method.

Experimental

Instrumentation

The metals were determined in the slurries of spirulina samples using a flame atomic absorption spectrometer from Perkin Elmer (Norwalk, CT, USA), model Analyst 200. Absorbance signals for Fe, Mn, and Zn were obtained using hollow cathode lamps operating according to the manufacturer's recommendations, i.e. 1.8, 0.7, and 2.7 for slit, 248.3, 279.5, and 213.9 nm for the wavelengths and 30, 20 and 15 mA for the lamp currents. Background absorbance signals were corrected using a deuterium lamp. The flame was maintained by a gas mixture composed of acetylene (flow rate of 2.0 mL min−1) and air (flow rate of 13.5 mL min−1) and the height of the burner was 13.5 mm. The flow rate used for nebulization was 5.0 mL min−1.

An analytical balance (Sartorius, model BL D105) was used to determine the mass of samples and reagents used to prepare solutions. To increase the slurry formation performance, an ultrasonic bath (Maxclean 1450 model, São Paulo, Brazil) was used. In the samples decomposition process by wet process, a digester block (Tecnal, model TE 0851, Piracicaba, Brazil) was used. An Elga Purelab Classic system (model, High Wycombe, UK) was used to obtain ultrapure water.

Reagents and solutions

All reagents used in this work were analytical grade. The solutions were prepared and the experiments were carried out in cleaned glassware (kept in a 10% (v/v) HNO3 solution for at least 12 h). This material was then rinsed with ultrapure water and dried in a dust-free environment.

Triton X-114 10% m/v solutions (Sigma-Aldrich, Milwaukee, USA) were prepared by diluting 10 g of the surfactant in 100 mL of ultrapure water and sonicating for 10 min to improve its solubilization. HNO3 and HCl solutions were prepared by diluting concentrated solutions of these acids (Merck, Darmstadt, Germany) to the various required concentrations. Iron, Mn, and Zn standard solutions were prepared by diluting volumes of 1000 µg mL−1 stock solutions preserved in 1% chloric acid (Merck, Kenilworth, NJ, USA) to the required concentrations.

Sample collection

Samples of powdered spirulina were purchased from stores specialized in natural feeding in the city of Jequié (Bahia, Brazil) and taken to the laboratory in its packaging. The samples did not need to be comminuted because they already showed fine particles with a size considered adequate for the slurries preparation.

Method optimization

The method based on slurry sampling for the determination of analytes by FAAS was optimized by performing preliminary studies and multivariate optimization methods (Doehlert design and desirability function). In the optimization step, a mixture of several samples of spirulina belonging to different lots and stores was used with the intention of guaranteeing greater representativeness of the matrix.

After optimization, the method was performed as follows: About 0.1 g of the powdered spirulina sample was weighed and transferred to a 50.0 mL volumetric flask. Then, the sample was put in contact with about 5 mL of ultrapure water and then with 7.8 mL of concentrated HNO3 and sonicate for 13 min. The mixture was manually shaken so that the acid attacks the sample and it turns from green to brown. After this process, it was added 625 µL of 10% Triton X-114 solution. Finally, the mixture had the volume completed to 50.0 mL with ultrapure water and taken to the flame atomic absorption spectrometer to perform the determination of the metals.

Sample decomposition

The decomposition method was applied to the spirulina samples in order to compare their results with those obtained by the method that employs slurry sampling. A mass of approximately 0.1 g of the sample was weighed and transferred to a digester tube. Subsequently, about 2 mL of ultrapure water was added to avoid pelletizing the sample at the bottom of the container and 5.0 mL of concentrated nitric acid and 3.0 mL of 30% hydrogen peroxide (vv−1) were added. This mixture was stirred and taken to the digester block for heating at 110 °C until it is completely decomposed.

Results and discussion

Method optimization

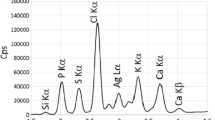

Preliminary studies were carried out to evaluate the diluent and the agitation method. First, 2.0 mol L−1 HNO3 and 2.0 mol L−1 HCl solutions were tested as diluents. The results are shown in Fig. 1a. It was observed that for the metals Mn and Zn, the highest signals were obtained when HNO3 was used as diluent. For Fe, however, HCl have showed a slightly better result compared to HNO3. However, nitric acid was chosen because it generates more satisfactory results considering the three analytes simultaneously.

Preliminary studies on slurry formation. a study of the diluent in the formation of the slurry of the spirulina samples. Experimental conditions: 250 g of the sample, 25 mL of 2.0 mol L−1 acid, Triton X-114 for a final concentration of 2.5%, 30 min of ultrasonic bath; b study of the stirring method. Experimental conditions: 250 mg of the sample, 25 mL of 2.0 mol L−1 HNO3, Triton X-114 for a final concentration of 2.5%

The sample agitation procedure was also studied. The methods used are as follow: (i) ultrasonic bath (10 min), (ii) vortex agitation (60 s), (iii) shaker agitation (30 min) and (iv) vortex agitation (10 s) followed by ultrasound (10 min). The results are shown in Fig. 1b. According to this study, the methods involving sample submission to ultrasound energy present the best results, especially for Fe. As there are practically no differences between treatments i and ii, we chose to use only ultrasonic agitation preceded by a quick manual agitation.

To carry out the simultaneous optimization of the variables involved in the slurry formation (sonication time (ST), concentration of nitric acid (AC) and volume of the 5% Triton X-114 solution (TX)), the surface response methodology was applied using the Doehlert matrix. Table 1 presents the combination between the levels of the variables that make up the 13 experiments necessary for modeling and the responses. For the simultaneous optimization of the three responses (the absorbances obtained for the three metals studied) the desirability function was used. Individual desirabilities (di) were calculated with the aim of maximizing (Eq. 1). Overall desirabilities (D) were obtained by the geometric mean of individual desirabilities according to Eq. 2.

where yi is the response to be transformed, yL is the smallest response (absorbance) obtained for an analyte, ym is the maximum response and m is the number of analytes.

The linear and quadratic functions were adjusted to the overall desirability to describe the behavior of the data. Although both the linear (F = 135 > 2.16) and the quadratic model (F = 41.8 > 2.56) showed a significant lack of fit, the latter was chosen because it presented a better correlation between the observed and predicted values (Fig. 2a and b). The response surfaces obtained by fitting the quadratic function to global desirability are shown in Fig. 2c. The quadratic model indicated as optimal conditions to obtain the maximum simultaneous signals for the extracted metals, the sonication time of 18 min, the nitric acid concentration of 2.5 mol L−1, and the volume of the surfactant solution 10% Triton X-114 of 625 µL. Experiments performed under these optimal conditions showed a response (0.702) very close to the predicted value (0.711) for these conditions. As the maximum response that could be obtained is equal to unity, it is noted that, for the program algorithm to meet the maximum simultaneous extraction for the three metals studied, there was a sacrifice of about 29% of the maximum desirability that could be achieved for each metal individually.

Evaluation of matrix effects

Aiming to evaluate whether spirulina slurries present transport interference in the determination of analytes, matrix effect studies were carried out. For this purpose, analytical curves, performed by external calibration and by standard addition to the sample, were made with the objective of comparing the angular coefficients. The external calibration curves were prepared with the same liquid phase of the slurries without the sample. If these coefficients are not statistically different at a 95% confidence level, it is considered that there is no evidence of a matrix effect. The calibration equations obtained for the two procedures are shown in Table 2.

The equations obtained by the standard addition method show high values for the linear coefficients compared to those obtained in the equations by external standardization. This fact was already expected since the blank of the curve by standard addition is constituted by the own sample. Analyzing the confidence intervals of the slopes, it is noted that, at a confidence level of 95%, they intersect, showing that there are no statistically significant differences between them. This fact demonstrates that these slurries introduced into the equipment, practically do not present matrix effects for the determination of Fe, Mn, and Zn. Thus, calibration by external standardization was chosen to carry out the determinations because it is more practical and simpler to be adopted in routine laboratories in the analysis of a large number of samples.

Analytical characteristics

Using the optimized conditions for the developed method, experiments were carried out to determine the analytical characteristics of the method. The limits of detection (LOD) and limits of quantification (LOQ) were accessed by performing 15 sample blank determinations. The LODs were obtained by calculating the standard deviations of these values multiplied by 3 and divided by the angular coefficients of the analytical curves (LOD = 3 s/a, where s is the sample standard deviation and a, the slope of the analytical curve). The values found for the LODs were 5.5, 1.6 and 2.6 mg g−1 for Fe, Mn and Zn, respectively. The LOD is an estimate of the analyte concentration that can be detected, but this does not mean that it can be quantified. In order to carry out the quantification, the LOQ must be calculated. It is accessed by calculating the standard deviations of the blank signals, multiplying them by 10 and dividing them by the slopes of the analytical curves (LOQ = 10 s/a). The following values were found for the LOQs: 18, 5.3 and 8.6 mg kg−1 for Fe, Mn and Zn, respectively.

Precision refers to the degree of dispersion of the results and can be accessed by calculating the standard deviation(s) at a given concentration level. For the developed method, precision was estimated as repeatability and expressed as %RSD. Thus, eight slurries of a spirulina mix were prepared and the three analytes were added to a final concentration of 0.5 mg L−1 before determination. The calculated %RSD values were 3.6, 2.9 and 1.8% for Fe, Mn and Zn, respectively.

Sensitivity is a parameter that expresses the ability of the method to distinguish between two very close concentrations. In this work, it was taken as the angular coefficient of the analytical curve. The following values were found: 0.0489; 0.1087 and 0.3477 Abs L mg−1. Thus, the method proved to be more sensitive for Zn.

Accuracy was evaluated using three methodologies: (i) tests of addition/recovery of known amounts of analytes to slurries, (ii) comparison of analyte concentrations obtained with the slurry method with those generated by applying the decomposition method in an acid medium (adopted as standard method) and (iii) determination of metals studied in the slurries prepared with certified reference material of apple and pinus leaves.

The addition tests to the sample allowed the recovery of analytes in the following ranges 94.0 to 108% (Fe), 90.7 to 108% (Mn) and 93.4 to 119% (Zn). There are some criticisms regarding this type of test, as it overestimates the recoveries due to the fact that the added analyte is free in the slurry, as opposed to the analyte present in the sample, which may be bound or strongly interacting with the matrix. The values obtained, however, show that the sample matrix does not affect the accuracy of the method.

Accuracy was also evaluated by comparing the analyte concentrations obtained by the method developed with the concentration values obtained from the method adopted as standard, in this case, acid decomposition in a digester block. The results are shown in Table 3. The paired t-test was used to compare these two data sets with a 95% confidence level. The test revealed that there is no evidence of statistically significant differences between the concentration values obtained by the two methods. (tFe = 0.92; tMn = 0.55 and tZn = 1.52 < tcritical (2.77) for N = 5).

A slurry was prepared, using the optimized conditions, of certified reference material apple leaves (NIST 1515 and pinus leaves (NIST 1575a)). The t-test was applied to compare the certified values with that found by analyzing the slurry. The values obtained (t = -0.127 or 0.589 or -1.60 < 2.78 for Fe, Mn and Zn respectively) are very close to the certified values, showing that there are no statistically significant differences between them, proving that the method is accurate for the analytes evaluated (Table 4).

Al-Dhabi used ICP-MS to determine Ni, Zn, Hg, Pt, Mg, and Mn in 25 Spirulina samples for human consumption which were commercialized in different parts of the world. They found values (mg kg−1) ranging from 0.005 to 2.248 for Mn and 0.530 to 6.225 for Zn [30]. A similar study was conducted in order to determine the metal content in Spirulina-based dietary supplements. They applied a mineralization procedure based on microwave digestion and ICP-MS analysis and the metal concentrations (mg kg−1) ranged from 63 ± 1 to 1066 ± 7 for Fe; 3 ± 0.3 to 57.3 ± 0.6 for Zn [31]. Rzymski et al. has also studied the content of macro and trace elements in 13 Spirulina samples through ICP OES. In this case, they found concentrations (mg kg−1) ranging from 368.5 to 2286.6 for Fe, 26.1 to 109.8 for Mn and 9.6 to 61.4 for Zn [32]. The study carried out by Neher et al. evaluated the metal content in 11 Spirulina samples through the application of an ultrasound-assisted digestion and MPAES. In this case, some of the samples showed a metal content below the LOQ so the concentration (mg kg−1) of the three analytes varied from 856.74 to 905.8 for Fe, 1.46 to 119 for Mn and 2.87 to 8928 for Zn [33]. Thus, our sets of results showed a good agreement with the range observed in previous studies.

Conclusions

The analytical method developed based on slurry sampling allowed the determination of Fe, Mn and Zn by FAAS in spirulina samples in a fast, economical and reliable way. It is not a time-consuming procedure, such as sample digestion, and avoid consuming large amounts of acids to carry out the decomposition. The method proposed in this work showed adequate analytical characteristics for the determination of Fe, Mn and Zn in powdered spirulina samples. The method proved to be accurate, obtaining satisfactory recoveries, generating concentration values of the analytes compatible with the values found by applying the digestion method in an acid medium and with the certified values according to their evaluation by t tests.

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

S. Kouser Ali, A. Mohammed Saleh, Int. J. Pharm. Pharm. Sci. 4(3), 9–15 (2012)

B.W.B. Holman, A.E.O. Malau-Aduli, J. Anim. Physiol. Anim. Nutr. (2013). https://doi.org/10.1111/j.1439-0396.2012.01328.x

B. Raoof, B.D. Kaushik, R. Prasanna, Biomass. Bioenerg. (2006). https://doi.org/10.1016/j.biombioe.2005.09.006

E.W. Becker, Biotechnol. Adv. (2007). https://doi.org/10.1016/j.biotechadv.2006.11.002

M.R. Andrade, J.A.V. Costa, Ciencia Tecnol. Alime. (2008). https://doi.org/10.1590/S1413-70542008000500029

A.S. Babadzhanov, N. Abdusamatova, F.M. Yusupova, N. Faizullaeva, L.G. Mezhlumyan, M.K. Malikova, Chem. Nat. Compd. (2004). https://doi.org/10.1023/B:CONC.0000039141.98247.e8

T. Okamoto, H. Kawashima, H. Osada, E. Toda, K. Homma, N. Nagai, Y. Imai, K. Tsubota, Y. Ozawa, Transl. Vis. Sci. Technol. (2019). https://doi.org/10.1167/tvst.8.6.20

S. Grosshagauer, K. Kraemer, V. Somoza, J. Agric. Food. Chem. (2020). https://doi.org/10.1021/acs.jafc.9b08251

L. Gouveia, A.P. Batista, I. Sousa, A. Raymundo, N.M. Bandarra, in Food Chemistry Research Developments, ed. by K.N. Papadopoulos (Nova Science Publishers, 2008), pp. 1–37.

T.A. Anunciação, W.C. Carvalho, M.G.A. Korn, J.S. Almeida, A.F. Dantas, L.S.G. Teixeira, Food Chem. (2021). https://doi.org/10.1016/j.foodchem.2021.130474

A.S. Silva, G.C. Brandão, S.L.C. Ferreira, A.M.P. Santos, Anal. Lett. (2021). https://doi.org/10.1080/00032719.2021.1991941

C.K. Andrade, P.M.K. Brito, V.E. Anjos, S.P. Quináia, Food Chem. (2018). https://doi.org/10.1016/j.foodchem.2017.07.111

C.K. Andrade, V.E. Anjos, M.L. Felsner, Y.R. Torres, S.P. Quináia, Food Chem. (2014). https://doi.org/10.1016/j.foodchem.2013.09.065

F.R. Amorim, E.A.N. Knupp, J.S.B. Silva, C.C. Nascentes, At. Spectrosc. (2016). https://doi.org/10.46770/AS.2016.06.006

G.C. Brandao, D.P. Gomes, G.D. Matos, Food Anal. Methods (2012). https://doi.org/10.1007/s12161-011-9282-5

A.C. Trindade, S.A. Araújo, F.A.C. Amorim, D.S. Silva, J.P.S. Alves, J.S. Trindade, R.M. Aguiar, M.A. Bezerra, Food Anal. Methods (2020). https://doi.org/10.1007/s12161-019-01578-5

S.O. Souza, S.S.L. Costa, B.C.T. Brum, S.H. Santos, C.A.B. Garcia, R.G.O. Araujo, Food Chem. (2019). https://doi.org/10.1016/j.foodchem.2018.03.060

H. Cui, W. Guo, L. Jin, S. Hu, J. Anal. At. Spectrom. (2020). https://doi.org/10.1039/C9JA00340A

R. Teuma-Castelletti, D. Beauchemin, J. Anal. At. Spectrom. (2020). https://doi.org/10.1039/D0JA00275E

W.N.L. Santos, D.D. Cavalcante, S.M. Macedo, J.S. Nogueira, E.G. Silva, Food Anal. Method. (2013). https://doi.org/10.1007/s12161-012-9519-y

M.L. Lin, S.J. Jiang, Food Chem. (2013). https://doi.org/10.1016/j.foodchem.2013.04.105

M. Asik, U. Ay, Fresen. Environ. Bull. 29, 6591 (2020)

H.A. Ergül, T. Varol, Ü. Ay, Mar. Pollut. Bull. (2013). https://doi.org/10.1016/j.marpolbul.2013.05.018

D. Bingöl, Ü. Ay, S.K. Bozbaş, N. Uzgören, Mar. Pollut. Bull. (2013). https://doi.org/10.1016/j.marpolbul.2012.12.006

Y. Kojuncu, J.M. Bundalesvka, Ü. Ay, K. Cundeva, T. Stafilov, G. Akçin, Sep. Sci. Technol. (2004). https://doi.org/10.1081/SS-200026751

U.M.F.M. Cerqueira, M.A. Bezerra, S.L.C. Ferreira, R.J. Araujo, B.N. Silva, C.G. Novaes, Food Chem. (2021). https://doi.org/10.1016/j.foodchem.2021.130429

C.G. Novaes, R.T. Yamaki, V.F. Paula, B.B. Nascimento Júnior, J.A. Barreto, G.S. Valasques, M.A. Bezerra, Rev. Virtual Quím. (2017). https://doi.org/10.21577/1984-6835.20170070

M.A. Bezerra, V.A. Lemos, C.G. Novaes, R.M. Jesus, H.R. Souza Filho, S.A. Araujo, J.P.S. Alves, Microchem J. (2020). https://doi.org/10.1016/j.microc.2019.104336

M.A. Bezerra, J.T. Castro, R.C. Macedo, D.G. Silva, Anal. Chim. Acta. (2010). https://doi.org/10.1016/j.aca.2010.04.063

N.A. Al-Dhabi, Saudi. J. Biol. Sci. (2013). https://doi.org/10.1016/j.sjbs.2013.04.006

M.V. Principe, I.S. Permigiani, M.C. Della Vedova, E. Petenatti, P. Pacheco, R.A. Gil, J. Pharm. Pharm. Res. 8, 422 (2020)

P. Rzymski, J. Budzulak, P. Niedzielski, P. Klimaszyk, J. Proch, L. Kozak, B. Poniedziałek, J. Appl. Physiol. (2019). https://doi.org/10.1007/s10811-018-1681-1

B.D. Neher, S.M. Azcarate, J.M. Camiña, M. Savio, Food Chem. (2018). https://doi.org/10.1016/j.foodchem.2018.03.011

Acknowledgements

Authors acknowledge the financial support of the Fundação de Amparo à Pesquisa do Estado da Bahia (FAPESB). Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq. Grant Number 304582/2018-2) and Financiadora de Estudos e Projetos (FINEP).

Funding

This research was supported by the Brazilian National Research Council (CNPq) (Grant Number 310949/2021–1).

Author information

Authors and Affiliations

Contributions

UMFMC: Conceptualization, experimental analysis, data analysis, and writing. MAB: Conceptualization, methodology, data analysis, writing, review, and editing. BNS: experimental analysis. CGN: data analysis, writing, review, and editing. ERVA: experimental analysis and writing. SAA: Data analysis, writing, review, and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the research reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cerqueira, U.M.F.M., Bezerra, M.A., Silva, B.N. et al. Multivariate optimization of a method based on slurry sampling for determination of Fe, Mn and Zn in spirulina (Arthrospira sp.) samples. Food Measure 17, 5322–5329 (2023). https://doi.org/10.1007/s11694-023-02034-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02034-z