Abstract

This paper describes an improved process for bioethanol production using a recently developed combined extrusion–saccharification technology. Blue agave bagasse (BAB) was pretreated via a thermo-mechano-chemical process (co-rotational twin-screw, reactive extrusion) to increase the availability of cellulose and hemicellulose for enzymatic saccharification. Then, several commercial enzyme preparations, boosted with accessory enzymes (exoglucanase, endoglucanase, hemicellulase, xylanase, and β-glucosidase), were tested with extruded BAB at 5 % consistency in a stirred vessel. The enzyme blend that produced the highest saccharification yield was evaluated at different BAB consistencies. The obtained concentration of sugars increased up to 69.5 g/L (73 % yield) when a 20 % BAB mixture was used. When the enzyme blend was fed into the extruder and with a residence time of 2 min, the yield reached 15 % of the maximum theoretical of C6 sugars along this step. This extruded and pre-saccharified BAB was further hydrolyzed and used for fermentation. The pre-saccharification step significantly enhanced cellulose degradation and ethanol production. Our results indicate that the enzymatic saccharification of BAB, coupled with reactive extrusion, produces an excellent substrate for bioethanol production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, the continuous depletion of fossil fuels and the need to reduce greenhouse gas emissions to mitigate global warming have generated an increasing worldwide interest in alternative energy sources. Developing biofuels from biomasses is one alternative. In particular, producing bioethanol from lignocellulosic biomasses has emerged as an alternative fuel source that can decrease the depletion of crude oil and alleviate environmental pollution. Countries around the world are interested in the potential of lignocellulosic biomasses as promising feedstocks for ethanol production due to their low cost and wide availability [1]. However, combining effective pretreatment processes with efficient enzymatic hydrolysis to obtain fermentable sugars from lignocellulosic residues remains a major challenge.

Blue agave bagasse (BAB) is a lignocellulosic by-product in the production of tequila, the most important alcoholic beverage produced in Mexico. The annual production of BAB in Mexico is approximately 300 Mton, which represents approximately 40 % of the agave plant [2]. BAB is currently used as animal feed or for composting. However, its potential for saccharification and subsequent bioethanol production has been barely explored. Tequila is produced from Agave tequilana, a plant commonly known as blue agave. Middle-aged agave plants are collected, the leaves removed, and the pinecones cooked in the tequila production process. The juices obtained are then fermented and distilled. However, the amount of bagasse produced exceeds the current demand for such applications. Bagasse composition, on a dry weight basis, is 38.9 % cellulose, 17 % hemicellulose, and 18.4 % lignin. The remaining constituents are proteins, minerals, and other compounds [3]. This composition makes BAB a potential candidate for bioconversion to ethanol.

Lignocellulosic biomasses can be transformed into ethanol via physicochemical or biological processes. Pretreatment is the crucial step in bioethanol production and is needed to remove lignin, reduce cellulose crystallinity, and increase the porosity of the material. This step is required to convert the lignocellulosic materials, which are difficult to process, into cellulose and hemicellulose that can later be hydrolyzed by an enzymatic process into fermentable sugars. Pretreatment processes are considered efficient if they can produce limited amounts of lignin as a by-product and if enzymes can hydrolyze large amounts of cellulose. In addition, the recovery of carbohydrates must be high, the energy input must be low, and the process must be profitable [4]. Currently, there are several reported methods of agave bagasse pretreatment, including dilute acid, dilute alkaline, ionic liquid, and ethanosolv [2, 5–7]. The yield of total sugars obtained after diluted pretreatment and subsequent enzymatic hydrolysis was in the range from 5.2 [5] to 73.6 % (w/w) [2]. For alkaline pretreatment, the yield reached after hydrolysis was 58 % [5], while for ionic liquid and ethanosolv pretreatments the yield of the saccharification was about 85 % [6, 7]. However, one of the drawbacks of these processes is the post-treatment, either washing or neutralization before enzymatic hydrolysis and, in some cases, the generation of by-products.

Size reduction is one of the most effective methods to ease the handling of lignocellulosic materials and to increase their surface area, thus improving enzyme accessibility. Size reduction can be achieved by grinding, milling, or chipping. However, these processes are costly and require substantial energy input [8]. An alternative for size reduction of biomass particles is twin-screw extrusion, a method that is commonly used in the polymer and food processing industries [9]. This method may significantly improve the enzymatic hydrolysis and fermentation stages of bioethanol production because, in principle, it does not generate by-products that may affect the subsequent steps of the process.

Extrusion is a practical mechanical method for the physical or chemical processing of materials and is economically suitable for large-scale production. Some attractive features of extrusion include its excellent temperature control and efficient pulverization caused by high shearing [10, 11].

The goal of using extrusion processes in bioethanol production is to obtain microfibers by weakening the rigid cell wall structure of lignocellulosic materials. This structural change enhances the digestibility of lignocellulosic biomasses: it increases the available surface area for enzyme action and also decreases cellulose crystallinity [4].

After pretreatment, the cellulose present in the biomass is ready for hydrolysis. The use of enzymes as catalysts has important advantages, such as the mild conditions of the process (pH 4.0–7.0 and temperature of 40–60 °C), high yields, specificity, and the fact that reactions with enzymes do not produce by-products that can adversely affect fermentation. A large number of processes for the hydrolysis of cellulose into glucose have been developed over the years. One disadvantage of using enzymes for bioethanol production is their high cost. However, compared with the costs of hydrolysis using sulfuric acid, where corrosion and glucose degradation at the high temperatures required for acid hydrolysis increase costs, enzymatic processes for cellulose hydrolysis are more feasible [12].

Enzymatic degradation of solid cellulose is a process that takes place at the solid–liquid interface where enzymes are the mobile components [13]. The action of cellulase on insoluble cellulosic substrates produces chemical and physical changes in the residual solid phase of cellulose. These changes are caused by primary hydrolysis, which promotes the release of soluble intermediates from the surface of the solid phase. In addition, secondary hydrolysis of these soluble intermediates occurs to produce intermediates of low molecular weights and, ultimately, glucose [14].

Up to now, several commercial enzymes have been used with different substrates, among them some types of agaves and bagasses. Cellic CTec2 (Novozyme) was able to hydrolyze wheat straw with >98 % of yield and Celluclast (Novozyme) with β-glucosidase supplementation reached up to 81 % yield [15]. Mixtures of Novozyme’s preparations Cellic CTec2 and Cellic HTec2 were employed in the hydrolysis of agave bagasse, pretreated with ionic liquid, and the yield obtained was about 50 % of the theoretical C6 yield [6]. Accelerase 1500 and its accessories, XC and XY (Genencor), also were used for wheat straw hydrolysis, with glucose yields about 80 %. Marcos et al. demonstrated that the use of enzyme accessories enhanced glucose and xylose recovery [16].

Celluclast and Viscozyme (Novozyme) have been already used for saccharification of biomass of Salix viminalis, a species of willow native from western Asia and developed as a bioenergy crop (leaves and stem) [17].

In addition, Zymafilt (Enmex), in combination with another cellulase, has been used in hydrolysis reaction for vanilla extraction [18]. Cornejo reported Celluzyme (Enmex) for the hydrolysis of polysaccharides produced by Ustilago maydis [19].

In this study, we evaluated the saccharification of BAB by commercial preparations of enzymes. The election of those enzymes was based on their hydrolysis yield as well as their availability in Mexico City. The effects of alkalinity and thermal conditions in the extrusion-based pretreatment were also analyzed. We obtained enhanced performance with our recently developed combined extrusion–saccharification process [3]. Our results demonstrate that BAB can be saccharified to an extent that provides acceptable yields using commercial enzyme preparations. In addition, the resulting carbohydrates were effectively fermented to ethanol.

Materials and Methods

Enzymes

Enzymes from Genencor, Novozyme, Advanced Enzymes, and Enmex were evaluated. The enzymes used were the following: Accelerase® 1500, Accellerase® XY, Accellerase® XC, and Accellerase® BG (Genecor); Celluclast, Cellic CTec2, Cellic HTec2, and Viscozyme (Novozyme); Cellulase Conc (Advanced Enzymes); and Celluzyme LB, Celluzyme XB, and Zymafilt (Enmex). All enzymatic preparations were generously donated by the corresponding manufacturers.

Dinitrosalicylic acid, sodium sulfite, potassium sodium tartrate salt, and phenol were purchased from Sigma Aldrich. HPLC-grade acetonitrile was purchased from Baker.

Raw Material

BAB was provided by Patron, a distillery located in Guadalajara, Mexico. BAB was dried over a wide area at environmental conditions and milled to particle sizes smaller than 3 mm prior to extrusion. After extrusion, it was milled into particles approximately 250 μm in size and then stored until use.

X-Ray Diffraction

X-ray diffraction analyses of BAB samples were carried out in an X-ray diffractor (Advance D-8, Bruker AXS, Inc., Madison, WI). A 2θ scan was run from 5° up to 50° at a scan rate of 1°/min. Pure cellulose was used as the internal reference with a diffraction peak at 2θ ≅ 23°, which corresponds to the crystalline region [20]. Untreated BAB was also used as an internal control. The intensity of the diffraction peak at 2θ ≅ 21.5° was measured for extruded samples obtained at 75 °C and 5 % of NAOH. The crystallinity index was calculated according to Segal’s method [21, 22].

Extrusion Pretreatment

The pretreatment stage was carried out in a twin-screw extruder (Clextral Processing Platform Evolum EV25, Clextral, France) composed of ten modules, each 100 mm in length, one with electrical heating (Scheme 1). Module 1 was used for the introduction of raw BAB at a flow rate of 0.23 kg h−1. Two pumps were used to supply aqueous NaOH (5 %, w/v) to module 3. The ratio of the flow rate of aqueous NaOH to the flow rate of BAB (L/S) maintained in the extruder was 3.7. BAB deconstruction took place in modules 4–6. Temperature in this zone was programmed at 50 °C. Module 5 consisted of a compression zone, which was followed by a mixing zone in module 6. Module 7 was used as an in situ neutralization zone; at this stage, aqueous phosphoric acid (5 %, w/v), at L/S = 3.7, was fed into the module. Module 8 was a zone of intensive mixing. Module 9 was used for filtration. Module 10 consisted of two reverse screws, thus acting as a compression zone. The operation conditions were set to achieve a NaOH/dry matter (DM) ratio of 10 % (w/w), a liquid/solid ratio of 7.5, and a rotation speed of 100 rpm. This complex process will be referred to as “extrusion” hereafter. After extrusion, the solid extruded biomass was recovered, dried, and analyzed for carbohydrate and lignin content.

Enzyme Activity Measurement

The activity of the cellulolytic enzymes was measured in filter paper units (FPU) [23]. A strip of Whatman no. 1 filter paper (1 × 6 cm), approximately 60 mg, was added to 1.5 mL of enzyme solution containing 0.05 M of citrate buffer (pH 4.8). The samples were incubated for 1 h at 50 °C. The endo-β-1,4-glucanase was measured adding 0.5 mL of a solution of 2 % (w/v) carboxymethylcellulose (CMC) to 0.5 mL of enzyme solution containing 50 mM of Na-citrate buffer (pH 4.8). The samples were incubated for 0.5 h at 50 °C and the activity of the endo-1,4-β-xylanase was determined as follows: to 1.8 mL of xylan from beechwood (1.0 %, w/v) was added 0.2 mL of enzyme solution containing 50 mM of Na-citrate buffer (pH 4.8). The samples were incubated for 300 s at 50 °C. The activity for cellulase was reported as FPU per milliliter and endoglucanase as endoglucanase units (EGU) per milliliter. Both units are defined as micromoles of reducing sugar from glucose formed during the hydrolysis reaction per minute. Xylanase activity was defined as millimoles of reducing sugar from xylose produced per second (in millikatal per milliliter) [24].

Finally, in all cases, reducing sugars were measured once the reaction had been stopped, which was accomplished by adding 3 mL of DNS solution, boiling for 5 min, and then cooling. Then, 20 mL of distilled water was added to the solution and the absorptivity of the samples was measured at 540 nm in a Genesys 10S UV spectrophotometer.

Enzymatic Hydrolysis

Enzymatic hydrolyses of treated and untreated BAB were undertaken using different enzyme preparations and cocktails obtained from Genencore, Novozyme, Enmex, and Advanced enzymes (19 FPU/g dry matter). Enzymatic hydrolysis was carried out at different concentrations of solids in a 50-mM sodium acetate buffer (pH 5.5) at 50 °C for 72 h with orbital agitation in a 50-mL Erlenmeyer flask. Saccharification was measured by high-performance liquid chromatography (HPLC), as described later, and expressed as carbohydrate content.

The experiments were carried out in duplicate. Hydrolysis performance was reported as the enzymatic hydrolysis yield, which is defined as the glucose/xylose released during the reaction divided by the glucose/xylose content of BAB, expressed as a percentage.

Bioextrusion of BAB

Bioextrusion is the coupling of pretreatment in the extruder with the addition (into the extruder) of the enzyme cocktail previously selected. The objective of this procedure was to modify the BAB with a compression and expansion process to facilitate penetration of the enzyme into the biomass matter [3].

The bioextrusion process was undertaken by dividing the extruder into three sections: deconstruction (four modules), neutralization (one module), and bioextrusion (five modules). Deconstruction required the use of NaOH (5 wt%) and neutralization required the use of H3PO4 (10 wt%) to bring the pH to 5.5. Bioextrusion was conducted using the most efficient enzymatic cocktail. The enzyme concentration was adjusted to 10 mg protein/g dry matter. Bioextrusion lasted 2 min with an L/S ratio of 5. The entire process was carried out at 50 °C and 85 rpm.

Carbohydrate Determination

Sugars were analyzed using HPLC equipment with a light scattering detector (HPLC-PR-ELSD). A Luna NH2 column (5 μm, 100 A, 250 × 4.6 mm; Phenomenex, Torrance, CA) was used for the separation and quantification of xylose and glucose. The eluent gradient of acetonitrile/water was 85:15–65:35 over 1 h at a flow rate of 1 mL min−1. The analysis proceeded at 40 °C in the HPLC column. The conditions in the detector were 100 °C in the evaporator and 70 °C in the nebulizer. The nitrogen flow rate was 0.8 mL min−1.

Protein Determination

The protein concentrations of the enzyme preparations were measured using the Bradford protein assay [25]. Bovine serum albumin was used as the standard.

Fermentation of BAB

Thermosacc yeast cells (Saccharomyces cerevisiae, kindly provided by Lallemand Inc., Milwaukee, US) were used for ethanol production. The strain was inoculated for 16 h at 35 °C in fresh medium (all in w/v: glucose 1 %, yeast extract 0.5 %, (NH4)2SO4 0.1 %, KH2PO4 0.1 %, and MgSO4 0.05 %) prior to use in the fermentation experiments.

Fermentations were carried out in a 50-mL flask (30 mL occupied volume) and a 500-mL reactor (420 mL occupied volume). A 20 % solution of extruded BAB hydrolysates was analyzed in duplicate to determine its composition. The hydrolysates in the flask or reactor were allowed to continue the process of hydrolysis for 24 h before adding the yeast to begin fermentation. The yeast concentration was 1 g/g, based on the amount of dry matter. In order to obtain a yeast extract final concentration of 0.2 % (w/v), the necessary solid was added to avoid alterations in the total fermentation volume.

Fermentation proceeded for 72 h at 35 °C. Erlenmeyer flasks were incubated in an orbital shaker at 200 rpm. In the case of the 500-mL jacketed reactor, agitation was supplied by a propeller spinning at 200 rpm. Samples were taken at different times. Ethanol production was evaluated by gas chromatography.

Ethanol Analysis

Aliquots (500 μL) were withdrawn at different times during the fermentations. Samples were centrifuged to remove yeast cells and filtered through 0.22-μm membrane filters. The ethanol produced was quantified using a gas chromatograph equipped with a flame ionization detector and a 3-m × 1/18-in. × 0.085-in. SS Porapak Q 80/100 column.

Results and Discussion

Pretreatment and Selection of Enzymes

The integration of the enzymatic hydrolysis of cellulose and hemicellulose into the extrusion process required the evaluation of commercial enzyme preparations and/or enzymatic cocktails. Because the extrusion process requires a significant amount of BAB, on the order of kilograms, the required amount of enzymes is also high. For this reason, the enzymes were selected based on two criteria: price and activity.

Five commercial enzyme preparations were used (see Table 1). Cellulase activities were measured as the amount of reducing sugars released [23]. The results for saccharifying cellulase (FPU assay) and carboxymethylcellulose for endo-β-1,4-glucanase (CMC assay) are reported.

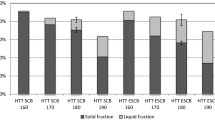

Each enzyme was tested on a raw and pretreated 5 % BAB mixture (w/v) and analyzed after 72 h (Fig. 1). BAB without extrusion produced approximately 40–50 % of the theoretical yield, indicating the need for a pretreatment to increase sugar yield. After extrusion, the release of reducing sugars increased almost twofold (∼80 %). The tendency for this increase in the recovery of sugars is consistent with the degree of disruption of BAB fibers observed in the SEM analyses (see Fig. 2).

The extrusion pretreatment promoted two main changes in the structure and color of BAB. The average particle sizes of pretreated BAB were smaller than those of the raw material, as shown in Fig. 2a, b. This phenomenon was caused by a change in the structure of BAB, which was broken into separate fibers and fiber bundles, as shown in Fig. 2b. Particle reduction increases the surface area, mass transfer, and, therefore, the degradation of cellulose into glucose during enzymatic hydrolysis [26]. BAB changed from light to dark brown after extrusion, and this change in color is related to the chemical breakdown of lignin and the removal of extractives [27]. The use of alkaline pretreatment and subsequent neutralization into the extruder, unlike the alkaline pretreatment in which the substrate must be neutralized and washed before use, does not imply any washing or removing of phosphate salts produced during the neutralization and is compatible with the latter fermentation.

The composition of raw and extruded BAB is shown in Table 2. Cellulose and hemicellulose contents presented a small increase after extrusion, compared with other substrates [3], because the dynamic plug of material formed during the process in the filtration zone absorbs most of the soluble fraction of the destructured BAB. The level of crystallinity of pretreated BAB is also an indicator of enzyme accessibility to the biomass. There was a significant decrease in crystallinity for pretreated BAB compared to the raw BAB value. This result is consistent with the observations of Lamsal et al. [20] who reported a decrease of the crystallinity index for extruded wheat bran, which resulted in greater sugar production than that of the untreated wheat bran. Reduced biomass crystallinity was also present in other instances [28]. An increase in the presence of cellulose revealed that alkaline pretreatments affect the lignocellulosic structure. The morphology of cellulose changes when the concentration of NaOH is increased [29].

Synergism between cellulase, hemicellulase, and some accessory enzymes for the hydrolysis of cellulose has been reported [30]. Selig et al. [31] demonstrated that cellulase activity improves when hemicellulases and accessory enzymes are used for the hydrolysis of hemicellulose. We therefore prepared mixtures of commercial cellulases and accessory enzymes to enhance the hydrolytic capacity of the commercial enzymes and increase the yield. These accessory enzymes were mainly β-glucosidase, β-glucanase, and xylanase. We chose different compositions of enzymes according to the properties of the accessory enzymes (Table 3) and evaluated their effect on the hydrolytic yield (Fig. 3).

Enzymatic hydrolyses of pretreated BAB with the boosted enzyme preparations were performed at 50 °C for 48 h in a reaction volume of 30 mL with a 5 % BAB mixture (w/v) and 10 mg of total protein per gram dry matter. The best hydrolytic yield was achieved by supplementing Cellic CTec2 with 20 % Viscozyme. This mixture of enzymes increased sugar release by 10 % compared with that of Cellic CTec2 alone and resulted in conversions of up to 95 % (in one case) of all available sugars, as shown in Fig. 3.

Cellic CTec2 boosted with Viscozyme (referred to as Cellic 4 hereafter) was used in the remaining experiments because it was the preparation that demonstrated the highest hydrolytic yield of extruded BAB.

The sugar obtained from the enzymatic hydrolysis of extruded BAB was mainly glucose (83 %), as shown by the HPLC analyses (data not shown). As observed in Fig. 4, glucose production was determined at different substrate concentrations over 24 h. The glucose produced from a 2.5 % substrate mixture reached 11.3 g/L (96 % of the theoretical convertible cellulose into glucose), and hydrolysis at higher concentrations (7, 10, 15, and 20 %) showed significant increases in glucose concentration. However, the conversion of cellulose to glucose decreased from 96 to 75 % as the concentration (consistency) of the extruded BAB increased from 2.5 to 20 %. The viscosity of the system increased with the concentration of extruded BAB, and liquefaction of the substrate took longer as a result. One factor that affects digestibility in high-solid samples during the initial stages of reaction is mass transfer. Because there is a small quantity of free water present in the substrate, the hydrolysis rate is slow. According to Qin [32], water is stored in the fiber at high concentrations of substrate and the enzymes are trapped within the fiber structure, thus limiting their mobility. Although the samples with 20 % consistency of extruded BAB showed fluidity after 4 h and hydrolysis was prolonged to 48 h, only a marginal increase in glucose concentration was observed, and the yield achieved was much lower than the maximum obtained earlier (data not shown). This adverse result is caused by several factors, such as end-product inhibition by high glucose concentrations [33–36]. Therefore, the lower yield with a 20 % mixture of extruded BAB (73.6 %), compared with that from a 2.5 % mixture (96 %), is explained by the inhibition effect caused by the high concentration of glucose present in the system after the enzymatic reaction.

Bioextrusion of BAB

Bioextrusion (the combination of the pretreatment extrusion and the enzymatic hydrolysis occurring inside the same extruder) was carried out using 10 mg protein/g DM of Cellic 4. The mean residence time used during bioextrusion was 2–3 min. Saccharification began during this short period of time, reaching a conversion of cellulose to glucose of approximately 15 %, as shown in Fig. 5a. A similar result of significant saccharification achieved in such a short time was also reported by Vandenbossche et al. [3]. The product of the bioextrusion process was immediately fed into a 500-mL jacketed reactor, in a semi-continuous operation mode, to allow saccharification to proceed further. Then, an identical amount of Cellic 4 was added to the reactor for a final protein concentration of 20 mg/g DM and the reaction was allowed to continue for 24 h at 50 °C.

The saccharification yield obtained in that short time results from the close contact between the enzymes and BAB. This close contact is made possible by the different compression, relaxing, and mixing zones [3].

Even when significant saccharification took place over a very short period of time during the bioextrusion step, the overall conversion of cellulose to glucose after 24 h of enzymatic reaction in the jacketed reactor was only 72 %. In contrast, when hydrolysis proceeded only in the reactor, the conversion yield was higher (77 %), as shown in Fig. 5b. This reduced yield is probably caused by the inactivation of the enzyme within the extruder. It should be noted that only part of the additional enzyme is added after extrusion. Therefore, one may assume that, given the harsh conditions, the enzyme added during bioextrusion might be trapped inside the BAB matrix. Thus, the amount of free enzyme in the reactor is insufficient to achieve the yields obtained earlier.

Fermentation of Hydrolysates from Extruded and Bioextruded BAB

The products obtained from the hydrolysis of either extruded or bioextruded BAB carried out over 24 h, with a 20 % consistency, were used without any filtration for the subsequent fermentation experiments. The material obtained after hydrolyses was supplemented with yeast extract (0.2 %, w/v). The initial glucose concentrations were approximately 70.9 and 72.4 g/L for the extruded and bioextruded BAB, respectively. To assure the capacity of the Thermosacc yeast to produce ethanol, a glucose solution (200 g/L) was used as the control. The fermentation experiments proceeded for 100 h. Almost 75 % of the glucose in the pure media was metabolized after 24 h, demonstrating a high fermentation capacity. Ethanol production reached 68 g/L after 24 h (60 % of the theoretical glucose-to-ethanol conversion yield based on 0.51 g ethanol/g glucose). The final ethanol production after 72 h was 87.9 g/L, and the glucose was almost completely consumed.

Our Thermosacc yeast was able to consume the glucose present in the BAB hydrolysate and produce ethanol without any filtration. Depletion of glucose in the fermentation of extruded BAB was not observed in the first 72 h. At this point, approximately 18 % of the total glucose remained in the system. Therefore, the total production of ethanol was 30.8 g/L, equivalent to the use of 78.5 % of the theoretical glucose available for ethanol production (Fig. 6a).

The glucose released in the saccharification stage after bioextrusion was also fermented. The results are shown in Fig. 6b. Depletion of glucose is observed after 72 h and resulted in ethanol production of 32 g/L, which was equivalent to the conversion of 85 % of the glucose present in the media. The final conversion of glucose to ethanol from bioextruded BAB was slightly higher than the conversion achieved from extruded BAB. In addition to glucose, cellulose oligomers were found in the bioextruded BAB (data not shown). These sugars were probably degraded during fermentation by the remaining enzymes and fermented by Thermosacc.

Conclusions

BAB contains a high concentration of cellulose, which can be converted into fermentable sugars. BAB is not used for human consumption. Its use as animal feed is negligible. Moreover, its availability as a by-product of tequila production is guaranteed throughout the year. Glucose yields of ∼96 and ∼77 % of the theoretical maximal conversion of 5 and 20 % consistencies, respectively, were obtained in this study by using several commercial enzymes and accessory enzymes. The enzymatic hydrolysis results suggest that the pretreatment used in this study, which consisted of an extrusion process combined with an alkaline treatment at 50 °C followed by neutralization, plays an important role in fiber deconstruction. Coupling this extrusion pretreatment to an enzymatic pre-hydrolysis process inside the same extruder increased the initial rate of saccharification. However, an important fraction of the enzyme seems to have been inactivated. On other hand, the combination of the extrusion pretreatment followed by the addition of fresh cellulolytic enzymes resulted in a higher yield of saccharification and higher ethanol production. These results suggest that BAB is an excellent candidate for ethanol production when used in combination with an adequate extrusion pretreatment and the correct saccharifying enzymes.

References

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod Biorefin 2:26–40

Saucedo-Luna J, Castro-Montoya AJ, Martínez-Pacheco MM, Sosa-Aguirre CR, Campos-García J (2011) Efficient chemical and enzymatic saccharification of the lignocellulosic residue from Agave tequilana bagasse to produce ethanol by Pichia caribbica. J Ind Microbiol Biotechnol 38:725–732

Vandenbossche V, Brault J, Vilarem G, Hernández- Meléndez O, Vivaldo-Lima E, Hernández-Luna M, Bárzana E, Duque A, Manzanares P, Ballesteros M, Mata J, Castellón E, Rigal L (2014) A new lignocellulosic biomass deconstruction process combining thermo-mechano-chemical action and bio-catalytic enzymatic hydrolysis in a twin-screw extruder. Ind Crop Prod 55:258–266

Singh R, Shukla A, Tiwari A, Srivastava M (2014) A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew Sust Energ Rev 32:713–728

Hernández-Salas JM, Villa-Ramírez MS, Veloz-Rendón JS, Rivera-Hernández KN, González RA, Plascencia-Espinosa MA, Trejo-Estrada SR (2009) Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour Technol 100:1238–1245

Perez-Pimienta JA, López-Ortega MG, Chavez-Carvayar JA, Varanasi P, Stavila V, Chen G, Singh S, Simmons BA (2015) Characterization of agave bagasse as a function of ionic liquid pretreatment. Biomass Bioenerg 75:180–188

Caspeta L, Caro-Bermúdez MA, Ponce-Noyola T, Martínez A (2014) Enzymatic hydrolysis at high-solids loading for the conversion of agave bagasse to fuel ethanol. Appl Energy 113:277–286

Maurya DP, Singla A (2015) An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5:597–609

Lee SH, Teramoto Y, Tanaka N, Endo T (2007) Improvement of enzymatic saccharification of woody biomass by nano-fibrillation using extruder. In: The 57th Annual Meeting of The Japan Wood Research Society

Pilli TD, Severini C, Baiano A, Derossi A, Arhaliass A, Legrand J (2005) Effects of operating conditions on oil loss and properties of products obtained by co-rotating twin-screw extrusion of fatty meal: preliminary study. J Food Eng 70:109–116

Thymi S, Krokida MK, Pappa A, Maroulis ZB (2005) Structural properties of extruded corn starch. J Food Eng 68:519–526

Mosier NS, Wyman CE, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Balat M, Balat H (2008) Progress in bioethanol processing. Prog Energy Combust Sci 34:551–573

Mosier NS, Ladisch CM, Ladisch M (2002) Characterization of acid catalytic domains for cellulose hydrolysis and glucose degradation. Biotechnol Bioeng 79:610–618

Rodrigues AM, Ostergaard Haven M, Lindedam J, Felby C, Gama M (2015) Celluclast and Cellic CTec2: saccharification/fermentation of wheat straw, solid–liquid partition and potential of enzyme recycling by alkaline washing. Enzym Microb Technol 79:70–77

Marcos M, García-Cubero MT, González-Benito G, Coca M, Bolado S, Lucas S (2013) Optimization of the enzymatic hydrolysis conditions of steam-exploded wheat straw for maximum glucose and xylose recovery. J Chem Technol Biotechnol 88:237–246

Kim HG, Son HJ, Jeong MJ, Sim SJ, Park DJ, Yang JK, Yoo SB, Yeo JK, Karigar CS, Choi MS (2011) Enzymatic saccharification of Salix viminalis cv. Q683 biomass for bioethanol production. J For Sci 27:143–149

Ovando LS, Waliszewski KN, Pardio VT (2005) The effect of hydration time and ethanol concentration on the rate of hydrolysis of extracted vanilla beans by commercial cellulase preparation. Int J Food Sci Technol 40:1011–1018

Cornejo-Mazón M, Hernández-Sanchez H, Gutiérrez-López GF, Dorantes-Alvarez L, Cortés-Sanchez AJ, Jiménez-Aparicio A, Gimeno-Seco M, Moreno A, Jaramillo-Flores ME (2012) Production and partial characterization of an exopolysaccharide from Ustilago maydis in submerged culture. Afr J Biotechnol 11:7079–7087

Lamsal B, Yoo J, Brijwani K, Alavi S (2010) Extrusion as a thermo-mechanical pre-treatment for lignocellulosic ethanol. Biomass Bioenerg 34:1703–1710

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Zhu JY, Wang GS (2009) Specific surface to evaluate the efficiencies of milling and pretreatment of wood for enzymatic saccharification. Chem Eng Sci 64:474–485

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340:97–106

Kumar R, Wyman CE (2009) Does change in accessibility with conversion depend on both the substrate and pretreatment technology? Bioresour Technol 100:4193–4202

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I to cellulose II. Cellulose 9:17–18

Gusakov AV, Salanovich TN, Antonov AI, Ustinov BB, Okunev ON, Burlingame R, Emalfarb M, Baez M, Sinitsyn AP (2007) Design of highly efficient cellulase mixtures for enzymatic hydrolysis of cellulose. Biotechnol Bioeng 1:1028–1038

Selig MJ, Knoshaug EP, Adney WS, Himmel ME, Decker SR (2008) Synergistic enhancement of cellobiohydrolase performance on pretreated corn stover by addition of xylanase and esterase activities. Bioresour Technol 99:4997–5005

Qin E (2010) High consistency enzymatic hydrolysis of lignocellulose. Dissertation, The University of British Columbia, Vancouver

Ioelovich M, Morag E (2012) Study of enzymatic hydrolysis of pretreated biomass at increased solids loading. Bioresources 7:4672–4682

Hodge DB, Karim MN, Schell DJ, MacMillan JD (2008) Soluble and insoluble solids contributions to high-solids enzymatic hydrolysis of lignocellulose. Bioresour Technol 99:8940–8948

Xiao Z, Zhang X, Gregg DJ, Saddler JN (2004) Effects of sugar inhibition on cellulases and beta-glucosidase during enzymatic hydrolysis of softwood substrates. Appl Biochem Biotechnol 115:1115–1126

Tengborg C, Galbe M, Zacchi G (2001) Reduced inhibition of enzymatic hydrolysis of steam-pretreated softwood. Enzym Microb Technol 28:835–838

Acknowledgments

This work was funded by the European Community, Seventh Framework Program, under grant agreement no. 227498 (BABETHANOL PROJECT). It is also part of a research project carried out through the Bioenergy Thematic Network (“Red Temática de Bioenergía”) with partial support from the Mexican Council for Science and Technology (CONACYT), grant no. 260457. The authors wish to thank Advanced Enzyme Technologies, Novozyme, Enmex, Genecore, and Lallemand for kindly supplying enzymes and yeast. We also thank PATRON Spirits Company and Consejo Regulador del Tequila (CRT) for the supply of raw BAB. Technical training and discussions with several members of the BABETHANOL team (INPT, CIEMAT, INSA, and VTT, mostly) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Montiel, C., Hernández-Meléndez, O., Vivaldo-Lima, E. et al. Enhanced Bioethanol Production from Blue Agave Bagasse in a Combined Extrusion–Saccharification Process. Bioenerg. Res. 9, 1005–1014 (2016). https://doi.org/10.1007/s12155-016-9747-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-016-9747-x