Abstract

Conversations on digital technologies and their use in a circular economy (CE) have proliferated in recent years. The ability to fully use circular resources has become possible with the development of advanced and digital manufacturing technologies. However, there is currently only a limited amount of research that looks at the impact of digital technology on the establishment of a circular economy in a supply-chain context. This study seeks to examine the effect of technological innovation on CE practises, intending to assess their relationship to environmental and economic performance. The authors developed a conceptual framework based on the comprehensive literature review and employed a quantitative method to evaluate the theoretical framework. This research uses survey data of 290 respondents from the small and medium enterprises (SMEs) located in China and Pakistan to explore a model that explains the link between technological innovation, CE practices and performance. The SMART PLS 3.3.3 version was utilized for data analysis. The test findings reveal that technological innovation is positively associated with CE practices and that leads to economic and environmental performance. The findings may assist policymakers and business professionals in taking the appropriate steps to successfully implement and operate circular economy practices. With this connection, this research emphasized that SMEs should integrate their CE practices with digital technology solutions to attain long-term financial and environmental goals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It is becoming more difficult to control the detrimental consequences of unsustainable and environmentally damaging consumption and production practices in a competitive and global business environment (Korhonen et al. 2018; Rajput and Singh 2019). In response to the growing need to decouple economic development from resource use and environmental effects, the circular economy (CE) idea arose and has gained traction in recent years (Mendoza et al. 2017; Demestichas and Daskalakis 2020; Min et al. 2021). This idea is believed to provide a vast commercial potential that, if well-executed, may generate a total economic value of €1800 billion in Europe alone (Bressanelli et al. 2018). Furthermore, according to Gavrilescu et al. (2018) and Yang et al. (2019) estimated that the global economy would gain US$ 4.5 trillion by the end of 2030. To take advantage of this opportunity, businesses will have to reorient themselves around the principles of CE in their supply chains, abandoning the traditional methods of thinking (linear and product-centrism) and embracing the model of service-oriented value generations in their customer interactions (Urbinati et al. 2017). As in the linear economy (take-make-use-dispose), manufacturers produce the goods and eventually sell the product to the end consumers, who then discard it at the end of product life or when it is no longer necessary (Kouhizadeh et al. 2020). CE is thought to repurpose materials or product components and reduce waste by extending the life of goods, thus benefiting both the environment and the economy (Govindan and Hasanagic 2018). The circular economy is often termed a closed-loop supply chain that focuses on restorative and regenerative elements. The explicit application of circular practices like eco-product design and circular procurement allows the industrial system to adopt the idea of 'end-of-life' with restoration, remove hazardous materials, and reduce waste all across the supply chain (Moktadir et al. 2020). Thus the CE's main goal is to make better use of resources and help achieve better environmental outcomes at every step of the supply chain (Heyes et al. 2018). Further, it aims to ensure our present way of life continues to be technically viable for the foreseeable future. This is accomplished by using a closed system, or loop, in which firms reuse materials through a process of decomposition, recovery, and restoration (Demestichas and Daskalakis 2020). Hence, on its most basic level, the circular economy identifies and solves the issue of poor use of resources.

Circular economy practices have been successful at affecting three levels of interventions, including macro (the whole city), meso (at the supply chain level) and micro or company (intra-firm) level (Murray et al. 2017). For instance, H&M, a Swedish fast-fashion business, has built its supply chain in a circular manner (SC). First, H&M selected organic cotton as a raw material for manufacturing garments, thus reducing its adverse environmental effect. The downstream end adds value to the product by instituting a Garment Collecting Program that gathers and repurposes old clothing in three ways: re-wear, reuse, and recycling. Similarly, Dell also aggressively applies CE thinking to their product and service life cycles (Yang et al. 2019). These companies employ eco-friendly materials, efficient designs that use fewer resources, and integrate energy efficiency in their processes (Gavrilescu et al. 2018).

Many studies have identified the necessity and opportunity for uncovering a new route for sustainable development, which includes handling the waste generated by society by employing a circular business model, where this waste is recycled and reused to generate higher-valued products to meet society's current demands (Lieder and Rashid 2016). Industry 4.0 is becoming an increasingly significant facilitator of CE business models, and particularly in this regard, digital technologies are vital (Nascimento et al. 2019; Rosa et al. 2020). In this regard, the CE business models that rely on digital technology have lately been an active study topic (de Sousa Jabbour et al. 2018). Theoretically, sustainability may be accomplished by fusing CE with Industry 4.0. A flurry of new review papers has surfaced on digital technologies' contributions to CE development. In particular, some academics analyse the impact of Industry 4.0 and/or CE at the business and national level. Several studies have examined the factors that influence and/or impede the adoption of Industry 4.0 technologies and the transition to CE (Moktadir et al. 2020; Cantú et al. 2021; Kumar et al. 2021). Some studies are based on systematic review and have attempted to clarify the meaning and connotation of Industry 4.0 or CE (Rosa et al. 2020; Romero et al. 2021), while Kouhizadeh et al. (2020), Khan et al. (2021a, b) and Shojaei et al. (2021) worked on block chain technology to investigate its role in establishing CE. It's worth noting that a growing number of publications are looking into the connections between Industry 4.0 and sustainability (Dev et al. 2020; Luthra et al. 2020; Ranta et al. 2021). However, there is a dearth of empirical research on how adopting digital technologies and various embracing technological innovations may help businesses build a circular economy paradigm across the value chain.

Sustainability based on Industry 4.0 involves protecting the environment while using smarter and more flexible processes and using contemporary technology to advance industrial models and the ways of life (Luthra and Mangla 2018; Luthra et al. 2020). Every country now tries to adjust and become "Industry 4.0-ready," while most economies grapple with digital change. Technological innovation in the era of Industry 4.0 helps businesses keep track of goods and resources and distribute and identify them across their supply chains, making it easier to keep value (Jabbour et al. 2019; Chege and Wang 2020). Several nations, including China, Germany, and Japan, have adapted the CE concepts to their legislation and national development plans with this connection (Rajput and Singh 2019). In 2008, China became the world's first country to put forward laws that supported a circular economy (Nascimento et al. 2019). The Chinese government recently put CE at the heart of its policies, enforcing legislation established in 2008 (Wu et al. 2015; Korhonen et al. 2018). Furthermore, "Made in China 2025", a locally driven initiative to foster the development and implementation of Industry 4.0 technologies, has been put in place to help China achieve its objective of achieving self-sustainability. Hence, it is imperative to study technological innovation under Industry 4.0 and CE practices together and how they influence business sustainable performance. Further, it is important to understand how businesses utilize digital technologies in innovating business processes to help implement circular economy since it is the biggest obstacle in achieving those goals (Geissdoerfer et al. 2018). Therefore, the current study fills the gap to investigate the impact of technological innovation on circular economy practices and consequently on economic and environmental performances in SMEs in China and Pakistan.

While earlier researches have mainly focused on technological innovations in achieving sustainability on large-scale manufacturing organizations located in developed countries (Nascimento et al. 2019; Rajput and Singh 2019), small and medium businesses (SMEs) and developing economies have been underrepresented in empirical research. Generally, SMEs are frequently labelled as failing to include environmental sustainability in their business operations since they have less involvement in sustainable business practices when compared to standards applied by big corporations. Nevertheless, it's beyond dispute that SMEs play a crucial role in the national economy. Their presence significantly influences the rise of personal income, job creation, and export growth. This research investigates how various technological innovations under the Industry 4.0 paradigm are expected to be used to circular economy practices and performance concerning China Pakistan Economic Corridor (CPEC)' s wide range of manufacturing industries involved. CPEC is a $62 billion worth of multi-dimensional and multi-spectrum project that Pakistan and China collaborated on to create economic synergies and geopolitical benefits for both countries (Abid and Ashfaq 2015; Ali et al. 2018). With the continuous development in the CPEC corridor and growth of manufacturing sectors, there has recently emerged a greater need for circular processes because of the rising reliance on global supply networks that demand facilities for the disposal of products after the end of their useful lives. Hence, it is critical for SMEs in emerging economies like China and Pakistan to take advantage of circular economy practices with technologically advanced solutions because even a small step towards circular thinking in the right direction would majorly affect the future the whole market.

The rest of our paper is structured as follows. First, we conduct a literature review to establish the basis for the theoretical model, with a particular emphasis on the assumptions relating to technological innovation, circular practices, and environmental and economic performance. Next, a description of the methodology and then results are reported. Finally, we analyze and discuss our findings and draw theoretical and managerial conclusions.

2 Literature review and hypotheses development

2.1 Industry 4.0 – technological revolution

I4.0 also known as the fourth industrial revolution, which encompasses a wide range of new technologies aimed at making things better indefinitely (Romero et al. 2021). These include big data analytics, simulations and integration systems, the use of internet of things (IoT) in industrial processes, block chain technology and cloud computing. I4.0 is a concept that integrates information and communication technology (ICTs) with production and manufacturing processes (de Sousa Jabbour et al. 2018). It's no longer a secret that technology is a key factor in the success of sustainable businesses (Dubey et al. 2017). Emerging technologies must be used by organisations in order to make operations both ecologically and economically viable. Industry 4.0-based technologies may help businesses become more sustainable. Cyber-Physical Systems, IoT, Cloud Manufacturing, and Additive Manufacturing are a few examples (Luthra et al. 2020; Romero et al. 2021). Operations management can benefit from I4.0 technologies in a variety of ways, including speeding up production processes, lowering manufacturing costs, improving value chain coordination and increasing process flexibility. They can also improve customer service and enhance product customization (Fettermann et al. 2018; Dev et al. 2020). The use of Industry 4.0-based technologies such as Internet of Things (IoT), machine learning, and blockchain by many Indian companies has been found to enhance the efficiency of business processes. Using real-time data, Tata Power Ltd developed a digital platform to help its clients enhance the efficiency of their power plants and better control their electricity usage. Voltas Ltd uses Internet-of-Things (IoT)-based technologies to provide its customers with better chiller maintenance services (Kumar et al. 2021). Similarly, Imran et al. (2018) investigated Pakistan's textile sector and discovered that big data, smart factories, cyber physical systems and the Internet of things (IoT) are the most important elements for improving performance.

2.2 Circular economy

Circular Economy (CE) is a zero-waste regeneration system founded on the idea that trash generated inside a company may be recycled and used as a useful resource by another company. CE, according to Geng et al. (2016), is the creation of closed-loop material flow throughout the whole economic system. According to Webster (2015), CE is one that is restorative in nature and strives to maintain goods, components, and materials at their maximum usefulness and value at all times. CE defines a paradigm change in the way materials and resources are used and disposed of. It is in direct opposition to our society's long-standing patterns of production and consumption (EMAF 2015). Global industrial growth has been maintained for decades under the present system, which is based on a linear system thinking (Moktadir et al. 2020). Many intergenerational and international problems, such as trash disposal in natural areas, resource shortages, and climate change, are rooted in this style of thinking (Korhonen et al. 2018). This unsustainable system calls for a new approach to resource management, and CE offers an innovative route to sustainable development that introduces a fresh perspective on value generation (Dantas et al. 2021).

The circular economy reduces the extraction of raw materials from nature and the heap of waste in landfills by extending the useful life of materials and goods already in circulation. Since the CE strategy is founded on claims of saving the environment and increasing GDP, it has garnered a lot of interest from industry and policy-makers alike (Ghisellini et al. 2016). Firms must embrace CE principles and make linear models circular and resource-efficient. To be more effective, they must revisit their existing business model. That is, they must reassess their value-creation, delivery, and capture methods (Ranta et al. 2021).

2.3 Circular economy and technological innovations

With the emergence of Industry 4.0, digitalization is generally acknowledged as a vital component in CE expansion. With the increased usage of digital technology and linked devices, resources consumption may be reduced, and circular systems may be easier to implement. The technological advancements in the industry enable fewer resources, thereby reducing the need for materials. Firms can use smarter and advance technological solutions that help reduce energy usage, save on logistical routes, and free up capacity (Antikainen et al. 2018). Technological innovation promotes transparency, which allows the firm to access the information related to the consumption of resources used for the product, helping companies increase product life cycles and advance to CE practices (Kagermann 2015).

Although CE and I4.0 were developed separately, they are now merging into industrial paradigms that emphases a restorative industrial production model. Researchers believe that CE models aim to design and create waste-reducing products and services aided by digital technologies that may assist their sustainable development (Romero et al. 2021). The implementation of these digital technologies is thus aligned with the concept of the circular economy. The extant literature has demonstrated that CE practices and innovation are increasingly affected by the current state of digital technology (Stock et al. 2018; Gligoric et al. 2019). Further, an effort to bring digital technology to the manufacturing sector is simultaneously underway with CE development (Kiel et al. 2020). Pagoropoulos et al. (2017) classify digital technologies used in Industry 4.0 into three functional categories: data collection, data integration, and data analysis. Sensors (e.g., RFID) and gadgets that link products and people to the Internet (e.g., the Internet of things) are data-gathering technologies. Data integration technologies collect and categorize data, while data analysis tools use this information to generate and create new information (Ranta et al. 2021). Cloud and blockchain technologies are mentioned the most for data integration (Khan et al. 2021a). In addition, both big data analytics and artificial intelligence (AI) have come to prominence in the extant literature as critical data analysis tools (O’Leary 2013; Soroka et al. 2017).

Further to this, it has been reported that emerging digital technologies like the Internet of things (IoT), such as RFID, Internet of Services (IoS), and cyber-physical systems (CPS) are quickly gaining root in industrial transformation (Dantas et al. 2021). Information gathered by technologies such as RFID is critical in the retailing and back end of the upstream supply chain. Using this data, companies can evaluate the quality of returned goods and optimize the return flows throughout the product life cycle (Antikainen et al. 2018). Similarly, the IoT can prolong the life cycle of goods and allow return at the supply chain by better monitoring, analyzing, and controlling product data (Centobelli et al. 2020). They also demonstrated how cyber-physical systems might help optimize production and maintenance by providing real-time data for decision-making. In addition to this, incorporating those as mentioned above, technological solutions into material processes helps the firm collect, organize, and consume waste as a resource (Wilts and Berg 2017). The fact that digital solutions can implement circular business models by automating resource management, control, and optimization, which also aids in helping businesses to drive cost out of the supply chain.

Meanwhile, Industry 4.0 research has shown that digital technologies help organizations to become more competitive by offering more innovative solutions, lowering costs, increasing equipment effectiveness, and reducing resource consumption (Kiel et al. 2020). Digital technologies help businesses increase value creation and capture, but they also play a role in stimulating resource flow strategies. This is suggested by the recent findings of Rajput and Singh (2019), who found that companies that adopt circular economic principles see significantly increased value creation from Industry 4.0 technologies. Hence based on the arguments mentioned above, it can be inferred that.

H1: Technological innovation significantly influences circular procurement practice.

H2: Technological innovation significantly influences circular design practice.

2.4 Circular economy practices and environmental performance

Environmental initiatives, such as circular design (CD) and circular procurement (CP), are often regarded as excellent ways to dramatically decrease waste generation and reduce the total ecological footprint (Al-Sheyadi et al. 2019). Green products are said to have incremental and positive effects on businesses' long-term survival and have a part to play in the overall effort to develop sustainable competitive advantages in the market. It has been reported that effective green practices through green design and purchasing may decrease the environmental impact of products and processes by 80% (Khan and Qianli 2017). Geffen and Rothenberg (2000) argue that the implementation of CD is an essential first step in implementing a complete green supply chain process. The design and operational methods that favour the environment result in substantial reductions in negative environmental impacts and may contribute to the company's sustainability. With the ecological design, products are more easily disassembled and recycled, which will help the firm cut down on the use of hazardous chemicals and lower its consumption of manufacturing materials. Khan et al. (2020b) examined different elements of environmental performance and found that Eco design is directly and significantly related to socio-environmental sustainability.

The researchers also argue that it is equally important for companies to adopt sustainable green management to choose the right suppliers (Su et al. 2016). In a complex, competitive market, having an exceptionally broad range of environmentally friendly suppliers is essential, influencing manufacturing decisions on both a basic and psychological level. Cousins et al. (2019) studied UK firms and reported a strong and favourable connection between eco-practices and environmental performance. Green practices adopting at different levels of the supply chain may help reduce waste while also boosting processing efficiency, enabling companies to generate more revenue. A company's GSCM procedures include all efforts to minimize the negative environmental impacts of its goods and services. These efforts facilitate decreasing material and water consumption and waste generation to the lowest possible level, as reported by Yildiz Çankaya and Sezen (2019). Hence, based on the explanations mentioned above, it can be inferred that.

H3: Circular procurement practice is positively connected with the environmental performance of SMEs.

H4: Circular design practice is positively connected with the environmental performance of SMEs.

2.5 Circular economy practices and economic performance

On the economic side, incorporating technological solutions to enhance the circular economy helps organizations and their SCs in many business aspects. The increasing research on circular economy indicates that proactive GSCM policies may reduce long-term economic expenses connected with environmental hazards linked with business activities (Al-Sheyadi et al. 2019). CE-accredited processes save unnecessary expenditures and keep money in circulation, while also helping to conserve natural resources and cut down on unnecessary expenses (Khan et al. 2021a). Eco-friendly methods help eliminate waste in whole processes, boosting revenues (Menhas et al. 2019). As reported in the literature, green practices are linked with firm performance. They discovered a strong and favourable link between green approaches and the financial stability of organisations (Zhang et al. 2020). GSCM may help economic performance in two ways: First, firms can get economic advantage by minimizing the use of materials and energy. Second, companies may indirectly receive economic advantages by enhancing their company image and loyalty by using sustainable methods (Schmidt et al. 2017).

These research results show that using GSCM techniques favourably influences overall company productivity (Tang et al. 2012; Yildiz Çankaya and Sezen 2019). Moreover, market-oriented environmental efforts like designing more ecologically friendly goods may open new sales channels and boost profitability (Zhu et al. 2008). It is later confirmed by Zailani et al. (2012), who viewed that eco-design products had a beneficial impact on companies' financial and environmental performance, leading to increased business competitiveness and improved public image. The enhanced public image and reputation via green management practices may also result in a higher demand for goods (Korhonen et al. 2018; García-Sánchez et al. 2021). Meanwhile, it is often believed that an increase in environmental performance via waste reduction would improve operational efficiency, which eventually results in improved financial performance (Feng et al. 2018). Hence based on the arguments above and justification, it is inferred that.

H5: Circular procurement practice is positively connected with the economic performance of SMEs.

H6: Circular design practice is positively connected with the economic performance of SMEs.

3 Research methodology

This section demonstrates the research methodology opted for assessing the relationship that has been framed in the theorized model. We have employed quantitative methodology with a survey tool as a research instrument. The study has been contextualized in China and Pakistan, focusing on Small and medium enterprises (SMEs) manufacturing concerns of these two countries. SMEs are considered to be the backbone and engine of growth in any country's economic development. About 99.8% of companies in China are SMEs and offer a whopping 79.4% of employment opportunities to the workforce countrywide (Khan et al. 2021a; Shah et al. 2021). Additionally, they account for 60% of GDP and almost half of the taxes (Min et al. 2021). The same is the case with Pakistan, in which SMEs offer a massive 78% of the country's employment and contribute 30% to the country's GDP (Shah and Syed 2018). These two countries have had a longstanding relationship since the mid-twentieth century. Furthermore, in recent years, China and Pakistan have taken a concerted effort to rekindle the ancient Silk Road from Kashgar (China) to Gwadar (Pakistan) via a project called the Economic Corridor of China Pakistan (CPEC). CPEC is a multi-billion-dollar endeavour involving capital investment, infrastructure structuring, trade promotion, government-to-government geopolitical support, and people-to-people interaction programs (Menhas et al. 2019; Shah et al. 2021). Not only would the CPEC upgrade Pakistan's insufficient and outdated infrastructure, but it will also generate close to 3 million jobs and contribute an additional 2–3% to Pakistan's GDP growth rate (Abid and Ashfaq 2015). CPEC is also vital for China's geopolitical interests. It offers a safer path to South Asian, African, and Middle Eastern markets. This route poses security concerns due to Malacca Strait's passage and its considerably longer distance of 12,900 km (Shaikh et al. 2016; Ali et al. 2020). In addition to this, China's and Pakistan's economic growth and development have traditionally been concentrated in their eastern regions; CPEC would enable both countries to develop their western provinces. This would escalate the growth of manufacturing sectors in both countries. Hence, with rising manufacturing sectors, incorporating technological innovation to facilitate the circular economic model is the vital component of firm strategy in China and Pakistan.

3.1 Instrument development

We begin by developing a questionnaire and presented to experts (five academicians and five supply chain professionals) to pre-test the instrument. This led to some changes to the measurements to ensure the questions were posed in the context of our study and the language used was clear and accurate. It is then followed by the development of a short covering letter explaining our study aim and ensuring anonymity and confidentiality of their answers to our survey questions. We developed a questionnaire based on the seven-point Likert scale, representing the degree to which respondents agree or disagree with the statement where 1– represents strongly disagree and 7– represents strongly agree. The questionnaire primarily includes two sections–the first section comprises a list of questions from five different constructs which are reflective in nature. The construct of technological innovation is measured through four items are adopted from Kim and Shin (2019); Kouhizadeh and Sarkis (2018) Kim and Shin (2019), Kouhizadeh and Sarkis (2018).

Similarly, we incorporated three-item scales for both circular procurement (Yook et al. 2018; Galeazzo et al. 2021) and circular design practices (Zhu et al. 2008; Liu et al. 2018). Likewise, the three-item scale for both environmental performance was adapted from Seman et al. (2019) and Wong et al. (2020), while economic performance was adapted from Wong et al. (2020). The construction definition is presented in Table 1.

3.2 Sample and data collection

As mentioned earlier, we collected data from SMEs located in both China and Pakistan. Due to the target population size, the number of questions, and the expense involved in contacting respondents. To alleviate privacy concerns, respondents' answers were kept anonymous. Respondents were handed the questionnaires, together with a statement explaining the aim of this study, and were given enough time to finish reading it. A pre-condition for the responses was adequate and relevant knowledge on technological innovations and circular economy practices. Initially, we sorted the list of contacts, and the final online questionnaire link was sent on multiple platforms, including WhatsApp, WeChat, and Emails. Initially, we have contacted 450 potential respondents, and in the first round, 178 responses were obtained. To reach out to the remaining 272 non-respondents, we sent them a follow-up notification. After the second round, we got another 112 responses. In total, we obtained 290 questionnaires from the two rounds, with a response rate of 64.4%, which is suitable for testing hypotheses. These responses were incorporated for data analysis. Table 2 presents the demographic characteristics of the study participants (Table 3).

3.3 Data analysis tool

In this study, SEM (Structural Equation Modelling) technique with the partial least squared (PLS) method was used to examine the inter-relationship among various variables. It has been widely recognized and accepted in green supply chain and sustainability literature to confirm theorized relationships. The literature had reported all of the numerous preliminary factors one should consider while choosing the PLS-SEM approach. It is believed that the PLS-SEM handles many indicator variables effectively, and they assert that it can cope with the problem of non-normal data because of the PLS- SEM's capacity to accept complex models. Further to this, PLS-SEM helps with small sample size and can analyze formative variables. This study utilized the PLS-SEM since the main aim of this research was to predict or analyze the connection between the exogenous and endogenous variables (Hair Jr et al. 2017; Hair et al. 2019), and the rationale to utilize the PLS-SEM technique is the ability to develop composite structures while maintaining predictive accuracy. The SEM assessment using PLS was conducted in two phases: first, using the measurement model, and then the structural model.

4 Results and discussion

4.1 Common method bias assessment

For the research, we collected data for both independent and dependent variables from the same person. Using this technique may lead to the common method bias (CMB). We carried out traditional Harman's one-factor test application on all five constructs (i.e. TI, CPP, CDP, ECO and ENP) with fifteen items and all these items are loaded on a single factor without any rotation The maximum variance found to be 34.2% on a single factor, thus confirming no issues related to CMB in the dataset. In addition to this, we used Smart PLS 3 to conduct a collinearity test on all five constructs. The test results confirm that a CMB problem was found to be non-significant in this research since VIFs for all the latent variables produced showed variance inflation factors (VIFs) being less than 3.3. (Khan et al. 2021a).

4.2 Measurement model analysis

For SEM analysis, we begin with confirmatory factor analysis (CFA) on all the first-order constructs in the research to ensure the measurement model was correct. To gauge the reliability of the measurements, we test for composite reliability and Cronbach's α to check for internal consistency. The coefficients of all the constructs had alphas between 0.7 and 1, indicating that the constructs have met reliability criteria.

The indicator reliability is examined through loadings of each item, which has to be a minimum of 0.6 to establish convergent validity (Hair et al. 2014), and results confirmed that all the items have greater than 0.6 as presented in Table 4. For the validity assessment, construct validity is measured using AVE. AVE values were between 0.549 and 0.734 (more than 0.5), therefore demonstrating construct validity. To examine discriminant validity, we examined the square root of AVE for each construct against all other related constructs' bivariate correlations.

The results demonstrated in Table 5 shows that each Square Root of AVE was greater than all the related correlations, thus establishing discriminant validity (Fornell and Larcker 1981). In addition to this, discriminant validity is also examined using contemporary hetro trait mono triat (HTMT) criteria, and the results indicate that all the constructs have HTMT values of less than 0.9, therefore offers confirmation for discriminant validity (Table 6).

4.3 Structural model analysis

Table 7 shows the findings of the PLS analysis of the research model. To calculate the standard errors and t-values of the path coefficients, a sample of 5000 subsamples was utilized using bootstrapping technique (Hair et al. 2014). The findings show that technological innovation has a statistically significant, direct, and positive connection with SMEs' circular procurement practice (β = 0.198, P < 0.001) and circular design practice (β = 0.221, P < 0.001). Therefore, the findings corroborate H1 and H2, which lends credence to the idea that TI is crucial to enhancing CP and CD for SMEs. In addition to this, the hypothesized connection between circular procurement practices and environmental performance (H4, β = 0.283, P < 0.001), CD and ECO (H5, β = 0.141, P < 0.001), and between CD and ENP (H6, β = 0.289, P < 0.001) are supported, demonstrating that CP helps the firm to achieve sustainable business performance in terms of both reducing cost and flourishing environmental sustainability. However, there is no statistically significant relationship found between CP and ECO, thus rejecting H3. The path results between CP and performance indicate that CP only contributes significantly to ENP alone.

5 Discussion

Technological innovation has a substantial impact on CE practices, as shown by the present research findings. The extant literature found that technological innovation is required for establishing a circular economy model, which thus leads to dramatic improvements in value generation and capture (Ranta et al. 2021). This elucidates how businesses' capacity to enhance circularity in their company enables them to get value from new digital technologies while generating and reaping profit. Our study results are congruent with the reasoning presented in the literature. For instance, Bianchi et al. (2019) stated that technological innovations like Artificial intelligence (AI) and robots in a wide range of industries (supply chain, distribution) might have a major effect on the natural environment and reduce pollution, reduce greenhouse gas emissions and energy consumption while increasing profitability at the same time. Likewise, Ranta et al. (2021) conducted a study based on multiple cases and found IoT technologies and AI the greatest driver in enabling CE business model. IoT technologies allow the use of machine data in product creation, producing information that can be used to improve the machine's fuel consumption in order to reduce resource flows while simultaneously making the product more desired and cost-effective for the consumer to purchase. Meanwhile, AI technologies enable the business to better predict the availability of waste materials and the demand for refined goods in the marketplace. It will allow the business to optimise the value chain by eliminating needless storage and possible shortages, thus lowering costs and boosting revenues while closing resource flows. Similarly, Kouhizadeh et al. (2020) linked blockchain technology (BCT) and circular economy and proposed a significant connection between these emergent factors. Likewise, Shojaei et al. (2021) conducted a case study and believe that the use of BCT is the most viable strategy for embracing CE practices. It was later empirically examined by Khan et al. (2021a, b) and found a significant relationship between BCT and circular economy practices. Meanwhile, additional benefits of these technological solutions include increasing the operational capability of the information system and boosting CE performance. The latest industrial revolution has facilitated more integration, automation, and digitalization. Hence, with the advanced technological solutions, firms have the opportunity to implement more advanced CE practices. The incorporation of these practices elevates the sustainability performance.

Furthermore, the results demonstrate that adopting environmental design techniques is a significant contributing factor to organizational success. The outcome of this study effort is contemporaneous with the results of Khan and Qianli (2017), who discovered that the eco-design procedures had a substantial effect on the overall financial success of a company (Khan and Qianli 2017). Furthermore, Feng et al. (2018) and Carter et al. (2000) discovered that CE/Green practises improve firm performance. The implementation of CE standards not only enhances a company's environmental performance, but it also offers the company with economic advantages (Khan et al. 2021a, b). By using green design principles, sustainable company performance is more likely to be realised. Similarly, the concept of environmental sustainability is supported by eco-design, since companies who practice eco-design can efficiently recycle and remanufacture the products after the end of product life (Ali et al. 2020). Another advantage of eco-design is that it encourages environmental sustainability while also helping businesses succeed in their environmental performance, and it will eventually benefit their financial performance (Cousins et al. 2019).

In addition, governments and regulatory bodies were also highlighted as having critical roles. As their role is to advocate and promote eco-design, however, extremely stringent and rigorous regulations are likely to discourage industrialists and business professionals to implement and promote eco-design practices effectively (Wang et al. 2019).

The results also depicted the significant effect of CP on environmental performance but insignificant to economic performance. This suggests that initiatives related to purchasing green goods cannot lead to a company's financial success. The result has been consistent with earlier studies that found green purchasing does not substantially affect economic performance directly (Feng et al. 2018; Yildiz Çankaya and Sezen 2019; Pinto 2020). Likewise, it has been reported that green purchasing may raise the system's total cost, which may sometimes cause performance issues for the business (Younis et al. 2016; Galeazzo et al. 2021). It is also of the view that buying green products is more expensive than purchasing non-green items, which may negatively impact an enterprise's financial results (Yang et al. 2021). In the context of emerging countries, customers in countries like China and Pakistan are far more conscious and aware of the effect of manufacturing firms on the environment, which presents significant challenges to industrial firms. With this notion in mind, customers impose pressure on industrial companies, which compels them to implement green practices. Despite this, government and regulatory agencies, especially in Pakistan, fail to compensate green companies in any meaningful way, offering them no financial assistance, subsidies, or tax breaks, resulting the probability of increasing the cost of green goods. In emerging economies, consumers are unlikely to pay more for environmentally-friendly goods, resulting in missing financial advantages connected with using green procurement practices.

6 Conclusion, implications and limitations

This research aims to assess various technological innovations' roles in adopting CE practices to improve sustainable business performance. A quantitative survey using a questionnaire was administered to 290 Chinese and Pakistani SMEs. A software application known as SMART PLS was used to analyze data and to help us make predictions about technological innovations, CE practices, environmental and economic performance. The measurement model analysis depicted that the constructs used in this study were reliable and valid. The structural model showed that technological innovations have a substantial and favourable impact on CE practices. Specifically, technological innovations are associated with both aspects of CE practices, and specifically, CDP is found to be more significant than CPP. Also, environmental performance is shown to improve from CDP and CPP. However, economic performance is only achieved through CDP. In summary, conforming to what had been predicted, technological innovation may serve as a vital component in promoting CE efforts, resulting in additional increases in sustainable performance.

6.1 Policy implications

Several policy implications were derived from this research for both government and organizations. First, policies and regulations should be centred on indigenization of Industrial 4.0 and CE to match individual country’s capabilities and goals. Due to the fact that every country has varying capacity to prepare and embrace embrace Industry 4.0 and CE, the central government should grasp these concepts and align them with the national and local economic growth targets. As a result, with a clear direction and standard in place, policies may be developed and implemented with more flexibility, increasing the likelihood of a successful implementation of Industry 4.0 and the transition to the country’s CE Framework. Second, at the same time, to fully utilize the benefits associated with technological innovation in achieving sustainability targets, the government should focus on all stakeholders' acceptance and involvement in Industry 4.0 and CE. China has developed national plans for Industry 4.0 adoption and establishing circular economy, and has backed them up with relevant regulations to encourage their implementation. Firms play a significant role in the adoption of Industry 4.0 and CE, since they are responsible for assimilating and driving innovation as well as establishing an appropriate business model under the direction of government policies. The synchronisation of innovation and industry policy with the interests and activities of other stakeholders should be prioritised. Thus, with appropriate government-market connections, advancement in technological solutions and structural transformation induced by Industry 4.0 and CE may positively impact sustainable development.

Further, it has become more important to establish circular practices due to the planned transfer of businesses from China to Pakistan and anticipated industrial expansion. Environmental issues arising from CPEC projects are becoming more problematic for Pakistan. The environmental effect of CPEC projects in Pakistan is also a major issue. As Pakistan's manufacturing sector grows, it will increasingly become a part of global supply chains that need facilities for disposing of goods at the end of their useful lives. Consequently, Pakistan may avoid many of the difficulties that other emerging nations experience. Through the incorporation of green techniques backed by advance technological solutions into CPEC projects, Pakistan will be better prepared for environmental challenges in the future.

The benefits of advanced technological solutions and their impact on green ecosystem, policymakers should focus on developing innovative technologies so as to accelerate the adoption of Industry 4.0 and CE. Industry policy should focus more on driving the transition to a green economy by using state of art technological innovations. Also, the incorporation of sophisticated technology alternatives allows the company to better comprehend circular procurement and circular structure, all-important to long-term success. CE practices backed by technological interventions assist companies in tracking a product throughout its full lifecycle. Furthermore, with the use of advanced technology, CE practices are also beneficial in other regards, such as enhancing resource and waste re-utilization rates. This would enable them to use their resources more effectively and thereby enhances company performance. Finally, the adoption of CE systems may benefit a company by helping it accomplish both environmental and economic goals in the long term. Hence, it is highly suggested that policymakers and regulatory authorities actively encourage business organizations to incorporate technological solutions to assist with implementing a sustainable CE system. It is imperative that firms must seek out all possibilities to pursue the goals of the climate and circular economy. Businesses will only be able to thrive in the long term if they focus on sustainability. The circular economy may help companies succeed financially, as well as meet their environmental goals. Hence, the circular economy model driven through advanced technological means is an increasingly valuable means of achieving enterprise sustainability.

6.2 Limitations and future research directions

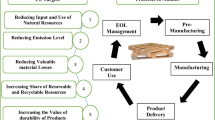

This research has several shortcomings, but on the other hand, several unexplored avenues await investigation. To begin with, the study sample was selected from SMEs that operated in China and Pakistan. Future studies may undertake a worldwide comparison to extend the results' applicability. This study yielded preliminary findings that only serve as a starting point for further investigating the relationship between technological innovations and the circular economy. However, this study has neglected to include many additional factors that could be classified as circular economy practices which include, remanufacturing, reverse logistics, circular packaging, as previously stated. Furthermore, future researchers are required to conduct empirical research to get a better grasp of how various technological options can optimize these circular economy practices. Last, this study used cross-sectional data to reduce causal inference. Panel data may be used in the future to examine how perceptions of technological innovation with CE practices and performance vary over time (Fig. 1).

References

Abid M, Ashfaq A (2015) CPEC: Challenges and Opportunities for Pakistan. J Pakistan vis 16:142–169

Al-Sheyadi A, Muyldermans L, Kauppi K (2019) The complementarity of green supply chain management practices and the impact on environmental performance. J Environ Manage 242:186–198. https://doi.org/10.1016/j.jenvman.2019.04.078

Ali Y, Rasheed Z, Muhammad N, Yousaf S (2018) Energy optimization in the wake of China Pakistan Economic Corridor (CPEC). J Control Decis 5:129–147. https://doi.org/10.1080/23307706.2017.1353929

Ali Y, Bin ST, Sabir M et al (2020) Integration of green supply chain management practices in construction supply chain of CPEC. Manag Environ Qual an Int J 31:185–200. https://doi.org/10.1108/MEQ-12-2018-0211

Antikainen M, Uusitalo T, Kivikytö-Reponen P (2018) Digitalisation as an Enabler of Circular Economy. Procedia CIRP 73:45–49. https://doi.org/10.1016/j.procir.2018.04.027

Bianchi P, Durán C, Labory S (2019) Impact of Industry 4.0 on Manufacturing. Transform Ind Policy Digit Age 11–11. https://doi.org/10.4337/9781788976152.00006

Bressanelli G, Adrodegari F, Perona M, Saccani N (2018) Exploring how usage-focused business models enable circular economy through digital technologies. Sustain 10:639. https://doi.org/10.3390/su10030639

Cantú A, Aguiñaga E, Scheel C (2021) Learning from failure and success: The challenges for circular economy implementation in SMEs in an emerging economy. Sustain 13:1–34. https://doi.org/10.3390/su13031529

Carter C, Kale R, Grimm C (2000) Environmental purchasing and firm performance: an empirical investigation. Transp Res Part E Logist Transp Rev 36:219–228

Centobelli P, Cerchione R, Chiaroni D, Del Vecchiio P, Urbinati A (2020) Designing business models in circular economy: A systematic literature review and research agenda. Wiley Online Libr 29:1734–1749. https://doi.org/10.1002/bse.2466

Chege SM, Wang D (2020) The influence of technology innovation on SME performance through environmental sustainability practices in Kenya. Technol Soc 60:10210. https://doi.org/10.1016/j.techsoc.2019.101210

Cousins PD, Lawson B, Petersen KJ, Fugate B (2019) Investigating green supply chain management practices and performance: The moderating roles of supply chain ecocentricity and traceability. Int J Oper Prod Manag 39:767–786. https://doi.org/10.1108/IJOPM-11-2018-0676

Dantas TET, de-Souza ED, Destro IR et al (2021) How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain Prod Consum 26:213–227. https://doi.org/10.1016/j.spc.2020.10.005

de Sousa Jabbour ABL, Jabbour CJC, Godinho Filho M, Roubaud D (2018) Industry 4.0 and the circular economy: a proposed research agenda and original roadmap for sustainable operations. Ann Oper Res 270:273–286. https://doi.org/10.1007/S10479-018-2772-8

Demestichas K, Daskalakis E (2020) Information and communication technology solutions for the circular economy. Sustain 12:1–19. https://doi.org/10.3390/su12187272

Dev NK, Shankar R, Qaiser FH (2020) Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour Conserv Recycl 153:104583. https://doi.org/10.1016/j.resconrec.2019.104583

Dubey R, Gunasekaran A, Childe SJ et al (2017) Can big data and predictive analytics improve social and environmental sustainability? Technol Forecast Soc Change 144:534–545. https://doi.org/10.1016/j.techfore.2017.06.020

EMAF (2015) Towards a Circular Economy: Business Rationale for an Accelerated Transition

Feng M, Yu W, Wang X et al (2018) Green supply chain management and financial performance: The mediating roles of operational and environmental performance. Wiley Online Libr 27:811–824. https://doi.org/10.1002/bse.2033

Fettermann DC, Cavalcante CGS, de Almeida TD, Tortorella GL (2018) How does Industry 4.0 contribute to operations management?. J Ind Prod Eng 35:255–268. https://doi.org/10.1080/21681015.2018.1462863

Fornell C, Larcker DF (1981) Evaluating structural equation models with unobservable variables and measurement error. J Mark Res 18(1):39–50. https://doi.org/10.2307/3151312

Galeazzo A, Ortiz-de-Mandojana N, Delgado-Ceballos J (2021) Green procurement and financial performance in the tourism industry: the moderating role of tourists’ green purchasing behaviour. Curr Issues Tour 24:700–716. https://doi.org/10.1080/13683500.2020.1734546

García-Sánchez IM, Gallego-Álvarez I, Zafra-Gómez JL (2021) Do independent, female and specialist directors promote eco-innovation and eco-design in agri-food firms?. Bus Strateg Environ 30:1136–1152. https://doi.org/10.1002/bse.2676

Gavrilescu M, Campean T, Gavrilescu D-A (2018) Extending Production Waste Life Cycle and Energy Saving by Eco-Innovation and Eco-Design: the Case of Packaging Manufacturing 2:611–631. https://doi.org/10.1007/978-3-319-63215-5_42

Geffen CA, Rothenberg S (2000) Suppliers and environmental innovation the automotive paint process. Int J Oper Prod Manag 20:166–186. https://doi.org/10.1108/01443570010304242/FULL/HTML

Geissdoerfer M, Vladimirova D, Evans S (2018) Sustainable business model innovation: A review. J Clean Prod 198:401–416

Geng Y, Sarkis J, Ulgiati S (2016) Sustainability, wellbeing, and the circular economy in China and worldwide. Push boundaries Sci Res 120 years addressing Glob issues 351:76–79

Ghisellini P, Cialani C, Ulgiati S (2016) A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J Clean Prod 114:11–32

Gligoric N, Krco S, Hakola L et al (2019) Smarttags: IoT product passport for circular economy based on printed sensors and unique item-level identifiers. Sensors 19:586

Govindan K, Hasanagic M (2018) A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective. Taylor Fr 56:1–2. https://doi.org/10.1080/00207543.2017.1402141

Hair J, Risher J, Sarstedt M, Ringle C (2019) When to use and how to report the results of PLS-SEM. Eur Bus Rev 31:2–24. https://doi.org/10.1108/EBR-11-2018-0203

Hair J, Sarstedt M, Hopkins L, Kuppelwieser GV (2014) Partial least squares structural equation modeling (PLS-SEM) An emerging tool in business research. Eur Bus Rev 26:106–121

Hair JF Jr, Hult GTM, Ringle C, Sarstedt M (2017) A primer on partial least squares structural equation modeling (PLS-SEM). Sage Publications

Heyes G, Sharmina M, Mendoza JMF et al (2018) Developing and implementing circular economy business models in service-oriented technology companies. J Clean Prod 177:621–632

Imran M, ul Hameed W, ul Haque A (2018) Influence of Industry 4.0 on the production and service sectors in Pakistan: Evidence from textile and logistics industries. Soc Sci 7:246. https://doi.org/10.3390/socsci7120246

Jabbour CJ, Sarkis J, de Sousa L, Jabbour AB et al (2019) Who is in charge? A review and a research agenda on the ‘human side’ of the circular economy. J Clean Prod 222:793–801. https://doi.org/10.1016/j.jclepro.2019.03.038

Kagermann H (2015) Change through digitization–Value creation in the age of Industry 4.0. In: Management of permanent change. Springer, pp 23–45

Khan SAR, Qianli D (2017) Impact of green supply chain management practices on firms’ performance: an empirical study from the perspective of Pakistan. Environ Sci Pollut Res 24:16829–16844. https://doi.org/10.1007/s11356-017-9172-5

Khan SAR, Yu Z, Sarwat S et al (2021a) The role of block chain technology in circular economy practices to improve organisational performance. Int J Logist Res Appl 0:1–18. https://doi.org/10.1080/13675567.2021.1872512

Khan SAR, Zia-ul-haq HM, Umar M, Yu Z (2021b) Digital technology and circular economy practices: An strategy to improve organizational performance. Bus Strateg Dev 1–9. https://doi.org/10.1002/bsd2.176

Kiel D, Müller JM, Arnold C, Voigt K-I (2020) Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0. Digit Disruptive Innov 231–270. https://doi.org/10.1142/9781786347602_0009

Kim J, Shin N (2019) The impact of blockchain technology application on supply chain partnership and performance. Sustain 11:6181. https://doi.org/10.3390/su11216181

Korhonen J, Honkasalo A, Seppälä J (2018) Circular Economy: The Concept and its Limitations. Ecol Econ 143:37–46. https://doi.org/10.1016/j.ecolecon.2017.06.041

Kouhizadeh M, Sarkis J (2018) Blockchain practices, potentials, and perspectives in greening supply chains. Sustain 10:3652. https://doi.org/10.3390/su10103652

Kouhizadeh M, Zhu Q, Sarkis J (2020) Blockchain and the circular economy: potential tensions and critical reflections from practice. Prod Plan Control 31:950–966. https://doi.org/10.1080/09537287.2019.1695925

Kumar P, Singh RK, Kumar V (2021) Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour Conserv Recycl 164:105215. https://doi.org/10.1016/j.resconrec.2020.105215

Lieder M, Rashid A (2016) Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J Clean Prod 115:36–51

Liu Y, Blome C, Sanderson J, Paulraj A (2018) Supply chain integration capabilities, green design strategy and performance: a comparative study in the auto industry. Supply Chain Manag 23:431–443. https://doi.org/10.1108/SCM-03-2018-0095/FULL/HTML

Luthra S, Kumar A, Zavadskas EK, Mangla SK, Garza-Reyes JA (2020) Industry 4.0 as an enabler of sustainability diffusion in supply chain: an analysis of influential strength of drivers in an emerging economy. Int J Prod Res 58:1–18. https://doi.org/10.1080/00207543.2019.1660828

Luthra S, Mangla S (2018) Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf Environ Prot 117:168–179

Mendoza J, Sharmina M, Gallego‐Schmid A, Heyes G, Azapagic A (2017) Integrating backcasting and eco-design for the circular economy: The BECE framework. Wiley Online Libr 21:526–544. https://doi.org/10.1111/jiec.12590

Menhas R, Mahmood S, Tanchangya P et al (2019) Sustainable development under Belt and Road Initiative: A case study of China-Pakistan Economic Corridor’s socio-economic impact on Pakistan. Sustain 11. https://doi.org/10.3390/su11216143

Min Z, Sawang S, Kivits RA (2021) Proposing circular economy ecosystem for chinese smes: A systematic review. Int J Environ Res Public Health 18:1–13. https://doi.org/10.3390/ijerph18052395

Moktadir MA, Ahmadi HB, Sultana R et al (2020) Circular economy practices in the leather industry: A practical step towards sustainable development. J Clean Prod 251. https://doi.org/10.1016/j.jclepro.2019.119737

Murray A, Skene K, Haynes K (2017) The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J Bus Ethics 140:369–380. https://doi.org/10.1007/S10551-015-2693-2

Nascimento DLM, Alencastro V, Quelhas OLG et al (2019) Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J Manuf Technol Manag 30:607–627. https://doi.org/10.1108/JMTM-03-2018-0071

O’Leary D (2013) Artificial intelligence and big data. IEEE Intell Syst 28:96–99

Pagoropoulos A, Pigosso DC, McAloone TC (2017) The emergent role of digital technologies in the Circular Economy: A review. Procedia CRIP 64:19–24

Pinto L (2020) Green supply chain practices and company performance in Portuguese manufacturing sector. Bus Strateg Environ 29:1832–1849. https://doi.org/10.1002/bse.2471

Rajput S, Singh SP (2019) Connecting circular economy and industry 4.0. Int J Inf Manage 49:98–113. https://doi.org/10.1016/j.ijinfomgt.2019.03.002

Ranta V, Aarikka-Stenroos L, Väisänen JM (2021) Digital technologies catalyzing business model innovation for circular economy–Multiple case study. Resour Conserv Recycl 164. https://doi.org/10.1016/j.resconrec.2020.105155

Romero CAT, Castro DF, Ortiz JH et al (2021) Synergy between circular economy and industry 4.0: A literature review. Sustain 13:1–18. https://doi.org/10.3390/su13084331

Rosa P, Sassanelli C, Urbinati A et al (2020) Assessing relations between Circular Economy and Industry 4.0: a systematic literature review. Int J Prod Res 58:1662–1687. https://doi.org/10.1080/00207543.2019.1680896

Schmidt CG, Foerstl K, Schaltenbrand B (2017) The Supply Chain Position Paradox: Green Practices and Firm Performance. J Supply Chain Manag 53:3–25. https://doi.org/10.1111/JSCM.12113

Seman N, Govindan K, Mardani A et al (2019) The mediating effect of green innovation on the relationship between green supply chain management and environmental performance. J Clean Prod 229:115–127

Shah D, Syed A (2018) Framework for SME sector development in Pakistan. Islam Plan Comm Pakistan 1:21–23

Shah SZA, Anwar M, Hussain CM (2021) Top managers’ attributes, innovation, and the participation in China-Pakistan Economic Corridor: A study of energy sector small and medium-sized enterprises. Manag Decis Econ 42:385–406. https://doi.org/10.1002/mde.3242

Shaikh F, Ji Q, Fan Y (2016) Prospects of Pakistan-China energy and economic corridor. Renew Sustain Energy Rev 59:253–263

Shojaei A, Ketabi R, Razkenari M et al (2021) Enabling a circular economy in the built environment sector through blockchain technology. J Clean Prod 294:126352

Soroka A, Liu Y, Han L, Haleem M (2017) Big data driven customer insights for SMEs in redistributed manufacturing. Procedia CIRP 63:692–697

Stock T, Obenaus M, Kunz S, Kohl H (2018) Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf Environ Prot 118:254–267

Su C, Horng D, Tseng M et al (2016) Improving sustainable supply chain management using a novel hierarchical grey-DEMATEL approach. J Clean Prod 134:469–481. https://doi.org/10.1016/j.jclepro.2015.05.080

Tang A, Lai KH, Cheng TC (2012) Environmental governance of enterprises and their economic upshot through corporate reputation and customer satisfaction. Wiley Online Libr 21:401–411. https://doi.org/10.1002/bse.1733

Urbinati A, Chiaroni D, Chiesa V (2017) Towards a new taxonomy of circular economy business models. J Clean Prod 168:487–498. https://doi.org/10.1016/j.jclepro.2017.09.047

Wang Y, Sun X, Guo X (2019) Environmental regulation and green productivity growth: Empirical evidence on the Porter Hypothesis from OECD industrial sectors. Energy Policy 132:611–619

Webster K (2015) A Wealth of Flows

Wilts H, Berg H (2017) The digital circular economy: Can the digital transformation pave the way for resource-efficient materials cycles?. Wuppertal Inst für Klima, Umwelt, Energie

Wong CY, Wong CWY, Boon-itt S (2020) Effects of green supply chain integration and green innovation on environmental and cost performance. Int J Prod Res 58:4589–4609. https://doi.org/10.1080/00207543.2020.1756510

Wu X, Yang Q, Xia X et al (2015) Sustainability of a typical biogas system in China: Emergy-based ecological footprint assessment. Ecol Inform 26:78–84

Yang M, Chen H, Long R et al (2021) Will the public pay for green products? Based on Analysis of the Influencing Factors for Chinese’s Public Willingness to Pay a Price Premium for Green Products Environ Sci Pollut Res. https://doi.org/10.1007/S11356-021-14885-4

Yang Y, Chen L, Jia F, Xu Z (2019) Complementarity of circular economy practices: an empirical analysis of Chinese manufacturers. Int J Prod Res 57:6369–6384. https://doi.org/10.1080/00207543.2019.1566664

Yildiz Çankaya S, Sezen B (2019) Effects of green supply chain management practices on sustainability performance. J Manuf Technol Manag 30:98–121. https://doi.org/10.1108/JMTM-03-2018-0099

Yook K, Choi J, Suresh N (2018) Linking green purchasing capabilities to environmental and economic performance: The moderating role of firm size. J Purch Supply Manag 24:326–337

Younis H, Sundarakani B, Vel P (2016) The impact of implementing green supply chain management practices on corporate performance. Compet Rev 26:216–245. https://doi.org/10.1108/CR-04-2015-0024

Zailani S, Eltayeb T, Hsu C (2012) The impact of external institutional drivers and internal strategy on environmental performance. Int J Oper Prod Manag 32:721–745. https://doi.org/10.1108/01443571211230943

Zhang Q, Pan J, Jiang Y, Feng T (2020) The impact of green supplier integration on firm performance: The mediating role of social capital accumulation. J Purch Supply Manag 26:100579. https://doi.org/10.1016/j.pursup.2019.100579

Zhu Q, Sarkis J, Lai KH (2008) Confirmation of a measurement model for green supply chain management practices implementation. Intern J Prod Econ 111:261–273

Acknowledgements

This research is supported by Beijing Key Laboratory of Urban Spatial Information Engineering (NO. 20210218).

Funding

Beijing Key Laboratory of Urban Spatial Information Engineering,20210218,Syed Abdul Rehman Khan

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, S., Piprani, A.Z. & Yu, Z. Digital technology and circular economy practices: future of supply chains. Oper Manag Res 15, 676–688 (2022). https://doi.org/10.1007/s12063-021-00247-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12063-021-00247-3