Abstract

Transitioning from a linear economy to circular economy–based business models can be difficult for small and medium–sized enterprises (SMEs) because of dynamic technological changes and market demands. This transformation is aligned with sustainable development goal 12: responsible production and consumption. In this context, adaptation of digital technologies can be helpful for SMEs to track their resources and energy consumption and optimize logistics and supply chains in new and innovative ways. Also, proper management of these technologies have major implications for organization’s competitiveness. But practices remain limited in SMEs due to lack of technological management and their linkages with other enabling factors to improve competitiveness. Therefore, the present study aims to discuss the enabling factors for digital technologies adaptation in SMEs to facilitate circular economy–based business model and develop a framework. The study utilizes the 183 responses from Indian manufacturing sector using exploratory factor analysis to develop a framework which is further tested by identifying priority order of factors using Bayesian Best–Worst method (B–BWM) approach using a case study. The results indicate that management support and the Internet of Things are the most critical factors for SMEs which facilitates the circular business models and improve market competitiveness, optimize resources and enable product life cycle thinking. Apart from this, study offers managerial implications such as resource efficiency, supply chain visibility, and circular business models, which can guide SMEs to facilitate circular business models and improve competitiveness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The global increase in population and personalized demands has put the pressure on natural resources which particularly affect manufacturing firms that consume substantial global resources (Kirchherr et al., 2017). Government bodies and customer pressure are forcing manufacturing firms to adopt circular economy–based approaches in their business models to address climate change challenges and achieve sustainability (Mhatre et al., 2021; Trevisan et al., 2023). Circular economy initiatives help to promote sustainability by better resource utilization and waste minimization (Kumar et al., 2021; Schöggl et al., 2023). At present, manufacturing sector face an issue of higher pollution generation and carbon emissions, which are major concerns in addressing sustainability and are well discussed in the literature (de Sousa Jabbour et al., 2018). Sustainability generally refers to social growth while implementing sustainable manufacturing practices that have less environmental impact (Haapala et al., 2013). At the same time, the manufacturing sector is undergoing digital transformation, also known as “Industry 4.0”, which includes various digital and physical technologies in manufacturing to complete personalized demands (Kagermann et al., 2011; Kim, 2017). Its vertical and horizontal integration helps manufacturing firms in real–time process monitoring and control, energy management, decentralized decision–making, personalized production and predictive maintenance (Machado et al., 2020). Advanced technologies to support manufacturing sector can be categorized into physical and digital technologies, which include additive manufacturing, robotics, artificial intelligence, the Internet of Things, and augmented and virtual reality (Jamwal et al., 2021). In past few years, technological developments have aligned Industry 4.0 concept with the United Nations SDGs to achieve sustainability in manufacturing (Berndtsson, 2015). Prior studies in this area such as: Dwivedi et al., (2021) also suggest the benefits of digitalization to unlock new opportunities for sustainability and circular economy. However, adopting these practices requires a deep understanding and benefits of these technologies for the circular economy, which will help reduce manufacturing costs, waste, and lead times and increase sustainable value with market competitiveness (Jabbour et al., 2019; Jamwal et al., 2023). Digital technologies are playing an important role in transition to circular economy through resource utilization, data analytics and waste management (Khan et al., 2022; Mhatre et al., 2021). Also, these technologies facilitate the collaboration among the supply chain members to identify new opportunities for continuous improvement in SMEs (Ghadge et al., 2022; Kumar et al., 2021).

The adoption of robotics and sensor technologies helps to streamline manufacturing practices, less exposure of labour to the hazardous environment and reduce defects in manufacturing (Tseng et al., 2018). Despite of these benefits in manufacturing, the practices related to the circular economy are limited in emerging economies due to lack of digital infrastructure, complexities in supply chain, and financial constraints (Yadav et al., 2020a, 2020b). Digital transformation is in its early stages in India due to lower technological maturity as well as lack of understanding about the benefits of these technologies (Luthra & Mangla, 2018). Also, there is need of circular business model in an emerging economy like India due to need to address resource depletion, environmental issues (Dwivedi et al., 2021). In this context, adopting digital technologies and their role in SMEs is important because of their potential to enable better resource management in the system, improve market competitiveness, promote life cycle management and waste tracking in the entire supply chain (Ghadge & Mogale, 2023; Kumar et al., 2021). Digital technologies provide new opportunities for manufacturing sector in terms of optimization, data–driven decision-making, and inventory management (Tseng et al., 2018).

In this context, adopting digital technologies to promote sustainability practices in supply chain and circular business models will be helpful for Indian SMEs. Therefore, identification and integration of digital technologies enablers which can support circular economy business models in Indian SMEs will be beneficial to improve market competitiveness and enhancing the overall effectiveness of circular business models.

Therefore, the present study aims to identify critical enablers for digital technologies adoption which can support circular business models in SMEs. We use the mix method approach with B–BWM approach for weight prioritization of enablers. The research objectives addressed in the study are as follows:

(1) Identification of criteria for digital technologies–enabled circular economy business models, (2) identification of enabling factors for digital technologies enabled circular economy business models, (3) prioritizing these enablers for circular economy business models in SMEs.

The study findings will be helpful for industry professionals and academia to understand the benefits of digital technologies to support circular economy business models. The paper’s organization is as follows: The Second section discusses the literature review. Third section discusses the research methodology. Fourth section discusses the results and discussion. Finally, the conclusion and future scopes have been discussed.

Literature Review

In this study, comprehensive literature review is done to identify opportunities and research gaps for circular economy. This section discusses the concepts of digital technologies in Industry 4.0 and their benefits for the circular economy.

Industry 4.0 and Digitalization

Digitalization is currently driving through the Industry 4.0 concept in the manufacturing sector (Bag et al., 2022). In this digitalization wave, factors such as personalized production, urbanization, and advanced technologies have forced manufacturing firms to revisit their business models and incorporate digitalization initiatives, i.e., digital technologies (Yadav et al., 2020a, 2020b). Due to growing market competitiveness Indian manufacturing sector is now adopting Industry 4.0 technologies in their business practices to promote flexibility as well as agility in the production systems (de Sousa Jabbour et al., 2018; Raj et al., 2020). In existing literature, the term Industry 4.0 is also referred as “Smart manufacturing” concept. Industry 4.0 integrates both the physical and digital technologies through Cyber physical systems and enable more flexibility and sustainability in the existing business models (Çınar et al., 2020). Therefore, the concept of Industry 4.0 is now popular in both the developing and developed countries due to its benefits for manufacturing sector (Sung, 2018). However, the adoption rate is still lower in the developing countries as compared to developed countries due to lower understanding of technologies and maturity of Industry 4.0 practices (de Sousa Jabbour et al., 2018).

Digital Technologies and Circular Economy

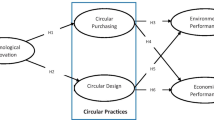

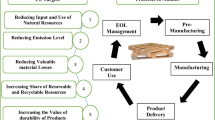

In last few years, adoption of digital technologies in manufacturing sector has gained attention due to their important role to promote circular economy to reduce waste, resource extraction and pollution (Khan et al., 2022). These practices also involves the zero waste philosophy with the consideration of closed loop material flow with in the entire system (Stahel, 2016). In this context, existing studies in literature have discussed the potential benefits of adopting digital technologies in terms of waste reduction, improve organizational performance, improve market competitiveness and improve resource utilization (Rajput & Singh, 2019). As compared to the traditional concept of reusing, reducing and recycling, circular economy approach goes beyond the new strategies like regeneration and restoration in manufacturing (Singhal et al., 2020). Digital technologies in the manufacturing sector support all these approaches by analyzing the large amount of data generated across the supply chain (Pagoropoulos et al., 2017). Despite such benefits, the existing studies in this area show that there is lack of understanding in circularity concept in SMEs due to lack of adequate discussion between role of digital technologies and its benefits for circular economy in developing economies (Chauhan et al., 2022; Jabbour et al., 2019). Due to government pressure and dynamic customer market, SMEs of emerging economies are realizing the need of IoT and AI to improve their resource efficiency, decentralized decision-making and energy management (Rajput & Singh, 2019). These technologies also supports the collaborative environments in supply chain network to facilitate the circularity concept across the supply chain (Giudice et al., 2021). Also, other technologies such as: Blockchain can help to improve the data security, transparency, organizational performance, and sustainable product management in supply chain through technological innovations (Upadhyay et al., 2021). Therefore, it is important to understand the role of these enablers for developing economies. In this context, we have identified the list of enabling factors for digital technologies adoption for circular business models. The list of identified enablers which can support a circular economy is shown in Fig. 1.

Based on the comprehensive literature analysis, gaps related to the relationship between digital technologies and the circular economy are as follows:

-

1.

The existing studies present the theoretical understanding of both concepts but lack in empirical research in developing economies, which requires further investigation.

-

2.

Although literature reported on the digital economy enablers, the impact on SMEs to improve organizational performance remains unclear.

-

3.

Existing research overlooks SMEs' perspective in the emerging economy manufacturing sector. Considering the varied levels of adoption and maturities among SMEs, there is a need for a comprehensive understanding of these two concepts.

Research Methodology

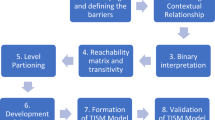

The study adopts a mixed-method approach, which combines literature analysis, expert consultations and inputs from five managers during questionnaire design (See Fig. 2). The study conducts a large–scale survey in the Indian manufacturing sector, which validates these 22 enablers which can support a circular economy through digital technologies adoption.

Questionnaire Design and Data Collection

The survey was conducted in the Indian manufacturing sector, focusing on validating identified enablers as mentioned in the scope of the study. A questionnaire survey based on a 1–5 Likert scale was developed in the initial phase and validated through a pilot study to refine questions. After input from experts, a few modifications were made to the questionnaire per the inclusion criteria shown in Table 1. The questionnaire included a formal cover letter explaining the data collection objectives and a consent form. The final questionnaire was distributed to a sample of 1310 manufacturing firms in India, targeting those with technological maturity and experience in digitalization. We targeted at least 150 responses with an aim to respondent to factor ratio of 5:1 or higher (Reio Jr & Shuck, 2015). After data collection, these responses were cleaned and tested for validity and reliability.

Data Analysis and Results

The identified enablers were finalized with a discussion with a team of five managers from leading SMEs. The list was finalized based on the enabler’s applicability in the SMEs and literature support reported in past studies. Out of 1310 contacted manufacturing firms, only 210 responses were received, of which 27 were incomplete and excluded from the data analysis. The remaining 183 responses were utilized for the reliability and validity tests, which report the Cronbach Alpha value of 0.79, well accepted in the literature (Field, 2013; Hair, 2009). The demographic details of the study are presented in Table 2.

The results of standard deviations and mean obtained from the descriptive analysis are presented in Fig. 3. All the enabling factors related to digital technologies for circular economy show more than 2.5 mean value, which means all the enabling factors reported are somewhat significant for industries. This helps include the variables for the EFA in the next sections.

Exploratory Factor Analysis (EFA)

In the initial step of EFA, inter–related factor correlation was checked. Further, the reliability of all factors was checked. Also, Bartlett’s test was conducted and results found to be significant. This suggests the factors were highly relevant for the exploratory factor analysis. Further, Table A1 as given in supplementary Appendix file shows the total variance of factors under the major groups. In the third step, the number of reduced factors, latent variables, or components was determined, which explains the significant total variance presented in Table A1. The pattern matrix is shown in Table A2 in Appendix. Based on the EFA analysis, all the factors were categorized into major dimensions and a framework is proposed for SMEs (See Fig. 4).

Bayesian Best–Worst Method Approach

The literature on multi–criteria decision–making (MCDM) methods offers various weight computation approaches, including DEMATEL, AHP, Interpretive ranking process, ANP and multi–attribute approaches. The approach used for decision–making depends on the problem's nature and expert selection (Kumar et al., 2017). However, relying solely on the expert decision may result in biased outcomes and decisions. To address this issue, we have used the Bayesian Best–Worst method, which overcomes the limitation of the traditional Best worst approach (Yadav et al., 2020b). The best–Worst method has gained popularity in multi–criteria decision–making in the last few years due to its ability to consider both positive and negative criteria. Unlike other MCDM methods, this method finds out the relative importance of criteria systematically and identifies the best and worst alternatives in the decision–making problem. This helps in robust decision–making over alternative methods. Apart from this, the BWM approach can handle incomplete or imprecise information, which makes it a suitable choice for handling complex decision–making problems. For this reason, the present study adopted a Bayesian–based BWM approach for decision–making.

For the framework validation proposed after EFA, we have done a case study in the automotive firm in which eight experts were considered to provide their inputs on a 1–5 Likert scale and analyzed using the Bayesian BWM approach, which is discussed below:

-

Step 1:

In the initial step, a set of decisions for the criteria is provided:

C = {C1, C2,….,Cn}

-

Step 2:

In this step, input for best criteria \(\left({C}_{B}\right)\) and worst criteria \(\left({C}_{W}\right)\) from criteria C is provided by a group of decision–makers. Here, the best criteria are the most desirable criteria or most important, while the worst criteria are the least important.

-

Step 3:

In this, a pairwise comparison is made between other criteria C and best criteria \(\left({C}_{B}\right)\). The “best–to–others” vector is presented by \({A}_{B}\) and can be calculated as:

$${A}_{B}=\left({a}_{B1},{a}_{B2},\dots .,{a}_{Bn}\right)$$(1)Here, in Eq. 1\({a}_{Bj}\) represent \({C}_{B}\) which is the preference of best criteria over the \({c}_{j}\in C\)

-

Step 4:

In this, a pairwise comparison worst criteria \(\left({C}_{W}\right)\) from criteria C is provided by a group of decision–makers. The “worst–to–others” vector can be represented by \({A}_{w}\) and can be calculated as:

$${A}_{w}={\left({a}_{1w},{a}_{2w},\dots .,{a}_{nw}\right)}^{T}$$(2)Here, in Eq. 2\({a}_{jw}\) represent the preference of \({c}_{j}\in C\) over worst criteria \({C}_{w}\)

-

Step 5:

The optimal weights can be calculated as:

$${w}^{*}=\left({w}_{1}^{*},{w}_{2}^{*},\dots .,{w}_{n}^{*}\right)$$(3)Using the following equation, we can find the weight vector \({w}^{*}\)

$$\underset{w}{{\text{min}}}\underset{j}{{\text{max}}}\left\{\begin{array}{cc}\left|\frac{{w}_{B}}{{w}_{j}}-{a}_{Bj}\right|,& \left|\frac{{w}_{j}}{{w}_{w}}-{a}_{jW}\right|\end{array}\right\}$$subject to:

$$\sum_{j=1}^{n}{w}_{j}=1, {w}_{j}\ge 0 \forall j=\mathrm{1,2},\dots .,n$$(4)The consistency ratio (CR) can be checked by:

$$CR=\frac{{\xi }^{*}}{CI}$$(5)Here optimal value obtained in Eq. 3 can be represented by \({\xi }^{*}\) with a fixed value of CI (value of \({a}_{Bw})\)

The credal ranking in the BWM approach is used to calibrate the degree that one criterion in any problem is superior to the other criteria. The definitions for Credal ordering and Credal ranking are represented below:

Definition 1 (Credal ordering):

Let us consider, \({c}_{i} and {c}_{j}\) are the pair of criteria, then credal ordering can be represented by O and computed as:

Here,

R represents the relationship between the \({c}_{i} and {c}_{j}\) criteria i.e., \(=;<,>\)

The confidence in the relationship can be represented by \(d\in \left[\mathrm{0,1}\right]\)

Definition 2 (Credal ranking):

Here we considered criteria C = {C1, C2,….,Cn}

and Credal ranking can be calculated as:

(Ci, Cj), where Ci, Cj ∈ C

If the \({c}_{i}\) is superior to \({c}_{j}\)

Then, confidence \(P\left({c}_{i}>{c}_{j}\right)\) can be computed as:

\(P\left({w}^{agg}\right)\) can be represented as the posterior distribution of \({w}_{j}^{agg}\)

If there are Q samples, then confidence, as well as posterior distribution, can be computed as:

The weight of all enabling factors with their ranking is shown in Table 3.

Results and Discussions

Initially, the EFA approach was used to categorize these enablers into the respective groups, i.e., technological, environmental, manufacturing systems, organizational, and people. The priority order of major groups in enabling factors for digital economy–based circular economy business model is as follows: (a) organizational (0.2490); (b) technological (0.2438); (c) manufacturing systems (0.2102); (d) environmental (0.1539); (e) people (0.1429).

It is found that Organizational factors play an important role in the adoption of digital technologies in SMEs. The existing studies such as: (Mittal et al., 2018) also suggested that management support is important to adopt digital technologies on the shop floor which helps in shop floor digitalization. (Yadav et al., 2020a, 2020b) suggested that digitalization in manufacturing requires smart budget allocation which guides manufacturing firms to prioritize their investment areas related to technological upgradation.

Adopting smart budget allocation strategies in the SMEs helps to improve the circular economy practices through more sustainable closed loop business models (Jabbour et al., 2019). Investments on developing recycling infrastructure will help manufacturing firms to reduce their waste and promote resource efficiency (Thorley et al., 2021). A good top level management support will be helpful to create a supportive environment for new innovation which will further help organization to achieve their sustainability goals (Sehnem et al., 2019). Organizations can focus on their employee engagement in circularity practices which can be done through the support of top level management (Moktadir et al., 2020).

SMEs can also focus on the reverse logistics practices and digital technologies adoption to enable real-time tracking and data-driven decision-making (Chauhan et al., 2022). Formulating dedicated teams for circular economy practices will help the manufacturing organizations to improve their resource efficiency and resource management (Torres–Guevara et al., 2021).

Big data analytics has a weight of (0.0427). Adopting big data analytics–based approaches in manufacturing sector will be helpful to improve data-driven decision-making with more transparency and visibility (Awan et al., 2021). Blockchain technology has a weight of (0.0438). Adopting blockchain technology increases accountability and trust among the supply chain partners by better data management which helps develop more sustainable business models through sustainable value creation (Kouhizadeh et al., 2020; Shojaei et al., 2021).

Cloud Computing has a weight of 0.0400. Adopting cloud computing provides a highly scalable platform for better data management (Tseng et al., 2018). AI and Machine learning–based approaches have a weight of 0.0526. Machine learning and AI–based approaches help in predictive analytics, which allows manufacturing firms to predict their demands and improve resource utilization (Agrawal et al., 2021). IoT has a weight of 0.0645. Adopting IoT–based platforms will help industries monitor their waste in real–time and make data–driven decisions (Pagoropoulos et al., 2017).

Distributed manufacturing systems have a weight of (0.0474). Distributed manufacturing helps reduce the need for centralized production and enhances production through decentralized production (Moreno et al., 2017). Additive manufacturing has a weight of (0.0427). Additive manufacturing technologies help reduce waste associated with traditional manufacturing approaches (Ponis et al., 2021). Flexible manufacturing systems have a weight of (0.0415). Adopting a flexible manufacturing system improves resource utilization by minimizing overproduction and underutilization of resources (Reddy & Kumar, 2021).

Man–machine interaction has a weight of 0.0383. Improvement in man–machine interaction helps the operators to work more closely with the manufacturing system on the shop floor (Shayganmehr et al., 2021). Adopting safety modules helps improve circular business models by reducing accidents in the workplace and exposing workers to hazardous areas (Fontana et al., 2021). Quality Management has a weight of 0.0395. Digital technologies can play an important role in building circular business models through quality management (Barbaritano et al., 2019). Sustainability rewards have a weight of 0.0348. Sustainability reward system is helpful for organizations build circular business models by motivating them to reduce waste (Marrucci et al., 2021). Ecosystem collaboration has a weight of 0.0520. Ecosystem collaboration or cooperation between various stakeholders or supply chain partners helps to improve the circular economy practices (Suchek et al., 2021).

Recycling and resource recovery practices have a weight of (0.0261). In manufacturing firms both recycling and recovery strategies are important to reduce waste, promote innovation and improve resource efficiency. These practices help organizations to develop an equitable as well as sustainable economy (Nelles et al., 2016). Remanufacturing initiatives have a weight of (0.0527). Adopting remanufacturing strategies are helpful to create new market jobs in the manufacturing sector (Hazen et al., 2017). Further, we have developed a pairwise superiority network based on the credal ranking which is shown in Fig. 5.

The study results reveal that SMEs are focused on the digital technology adoption for circular economy business models. But besides, it is important to understand that technological landscape are constantly changing. So, SMEs need to think beyond the initial adoption of digital technologies. They need to embrace the strategy of continuous adaptation to evolving technologies and regularly upgrade these to maximize the benefits of circular business models. The previous cases in the automobile sectors such as by: Momaya, (2017) also shared the experiences of automobile firm and suggested that once technologies are adopted, organizations can start initiatives on the capabilities for technology transfer and absorption. In this context, the adaptability of technologies will be helpful for the seamless integration of digital technologies into the existing processes and alignment with circular model. Also, SMEs need to be put more efforts on their technological upgradation and remains informed about latest innovations to enhance their digital infrastructure. This will help them not only to improve their resource tracking capabilities but also optimize their supply chain, improve competitiveness, commitment towards responsible production and consumption.

Implications

Theoretical Implications

The present study contributes to advance the knowledge in the area of digital technologies and circular economy by developing theoretical concepts related to these two topics. Firstly, this study identifies the critical enablers for adopting circular economy through digital technologies enablers by understanding the literature. This study also provides insights about the prioritization of enablers in SMEs. In addition, this study contributes to the theory of technology adoption by including the circular economy perspective in the framework of environmental, technological and environmental factors in the SMEs.

Practical Implications

The present study has practical implications for both policymakers and practitioners. R&D efforts in SMEs can help drive innovations and develop sustainable solutions for Industry 4.0 practices, which can improve maturity and readiness levels. By understanding the significance of digital technologies for circularity and sustainability, SMEs can develop an adoption roadmap through prioritization for circular business models. The major implications of the study are as follows:

-

1.

Improved resource efficiency: The findings indicate that digital transformation in SMEs helps to optimize the resource utilization through advanced technologies such as: IoT and data analytics. These technologies can be used by SMEs to address the energy consumption, emissions, waste generation issues.

-

2.

Supply chain visibility: Adoption of digital technologies enhances supply chain visibility and transparency in SMEs. It also allows SMEs to track their waste generation, demand trends in the supply chain so that they can manage their inventory in the better way.

-

3.

Circular business models: SMEs can adopt digital technologies for remanufacturing strategies which support circular economy business models. These initiatives will help SMEs to explore new opportunities for recyclability and repairability.

-

4.

Sustainability practices: SMEs can invest on digital technologies such as: machine learning and IoT platforms to promote sustainability through real time monitoring of energy consumption trends and resources. Also, they can align their consumer preferences and regulations to promote market competitiveness and improve corporate social responsibility.

These are the major implications of the study for practitioners and policymakers. In this sense, digital technologies can support the digital transformation in the manufacturing sector and provide new opportunities for Indian SMEs to develop sustainable business models and make India as a world–class manufacturing hub.

Conclusions

In the context of urbanization and global market competition, adopting digital technologies for circular economy is important for manufacturing SMEs. The adoption of digital technologies in SMEs of emerging economies is still lower due to a lack of understanding about their sustainability and circular economy benefits. To address this issue, we followed a systematic literature review approach and find out 22 key enablers which can support the circular economy business modes. Further, these enablers were validated through a survey conducted in the Indian manufacturing sector in which 183 responses were utilized for the data analysis. The findings indicate that organizational factors plays a vital role in circular economy adoption and emphasize the need for dedicated teams and budget allocation. SMEs can invest in upgrading digital skills for labour, which will help facilitate digitalization projects and foster a sustainable culture. Also, SMEs can focus on strategies like resource conservation, sustainable product design and remanufacturing to promote circular economy. This study's findings can serve as a basis for developing a conceptual framework for future studies, which can be validated using structural equation modelling. However, the study’s limitations is the inclusion of limited number of responses and industry–specific focus, which can addressed in future. Further research will be carried out by exploring alternative decision–making approaches and including other industry sectors.

Key Questions Reflecting Applicability in Real Life

Based on the study, following are key questions reflecting the applicability of study in real life:

-

1.

How manufacturing firms can efficiently implement and integrate digital technologies for circular economy?

-

2.

What different strategies can be implemented to enhance the awareness and understanding regarding the benefits of digital technologies for circular economy and sustainability in SMEs?

-

3.

What are the key challenges and success factors influencing the adaptation of circular economy–based business models in SMEs and how do these factors contribute to or hinder the competitiveness of SMEs?

-

4.

How organizational related factors such as dedicated teams and smart budget allocation can help to promote circular economy in SMEs?

-

5.

What specific strategies for resource conservation, remanufacturing and sustainable product design can be employed to promote circular economy?

-

6.

How digital skills can be enhanced for workforce in SMEs?

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Agrawal, R., Wankhede, V. A., Kumar, A., Luthra, S., Majumdar, A., & Kazancoglu, Y. (2021). An exploratory state–of–the–art review of artificial intelligence applications in circular economy using structural topic modeling. Operations Management Research. https://doi.org/10.1007/s12063-021-00212-0

Awan, U., Shamim, S., Khan, Z., Zia, N. U., Shariq, S. M., & Khan, M. N. (2021). Big data analytics capability and decision–making: The role of data–driven insight on circular economy performance. Technological Forecasting and Social Change, 168, 120766. https://doi.org/10.1016/j.techfore.2021.120766

Bag, S., Sahu, A. K., Kilbourn, P., Pisa, N., Dhamija, P., & Sahu, A. K. (2022). Modeling barriers of digital manufacturing in a circular economy for enhancing sustainability. International Journal of Productivity and Performance Management, 71(3), 833–869.

Barbaritano, M., Bravi, L., & Savelli, E. (2019). Sustainability and quality management in the Italian luxury furniture sector: A circular economy perspective. Sustainability, 11(11), 3089. https://doi.org/10.3390/su11113089

Berndtsson, M. (2015). Circular Economy and Sustainable Development. Master’s Thesis, Uppsala University, Upsala, Sweden. http://urn.kb.se/resolve?urn=urn:nbn:se:uu:diva-259772. Accessed 30 Mar 2023.

Bhandari, N., Garza–Reyes, J. A., Rocha–Lona, L., Kumar, A., Naz, F., & Joshi, R. (2022). Barriers to sustainable sourcing in the apparel and fashion luxury industry. Sustainable Production and Consumption, 31, 220–235. https://doi.org/10.1016/j.spc.2022.02.007

Chauhan, C., Parida, V., & Dhir, A. (2022). Linking circular economy and digitalisation technologies: A systematic literature review of past achievements and future promises. Technological Forecasting and Social Change, 177, 121508. https://doi.org/10.1016/j.techfore.2022.121508

Çınar, Z. M., Abdussalam Nuhu, A., Zeeshan, Q., Korhan, O., Asmael, M., & Safaei, B. (2020). Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability, 12(19), 8211. https://doi.org/10.3390/su12198211

de Sousa Jabbour, A. B. L., Jabbour, C. J. C., Foropon, C., & Filho, M. G. (2018). When titans meet—Can industry 4.0 revolutionise the environmentally–sustainable manufacturing wave? The role of critical success factors. Technological Forecasting and Social Change, 132, 18–25. https://doi.org/10.1016/j.techfore.2018.01.017

Del Giudice, M., Chierici, R., Mazzucchelli, A., & Fiano, F. (2021). Supply chain management in the era of circular economy: The moderating effect of big data. The International Journal of Logistics Management, 32(2), 337–356.

Dwivedi, A., Moktadir, M. A., Jabbour, C. J. C., & de Carvalho, D. E. (2021). Integrating the circular economy and industry 40 for sustainable development: Implications for responsible footwear production in a big data–driven world. Technological Forecasting and Social Change. https://doi.org/10.1016/j.techfore.2021.121335

Field, A. (2013). Discovering statistics using IBM SPSS statistics. Sage.

Fontana, A., Barni, A., Leone, D., Spirito, M., Tringale, A., Ferraris, M., Reis, J., & Goncalves, G. (2021). Circular economy strategies for equipment lifetime extension: A systematic review. Sustainability, 13(3), 1117. https://doi.org/10.3390/su13031117

Ghadge, A., & Mogale, D. G. (2023). Big data analytics and its applications in supply chain management: a literature review using SCOR model. In M. K. Tiwari, M. R. Kumar, & R. Mitra (Eds.), Applications of emerging technologies and AI/ML algorithms (pp. 57–67). Singapore: Springer Nature.

Ghadge, A., Mogale, D. G., Bourlakis, M., Maiyar, L. M., & Moradlou, H. (2022). Link between Industry 4.0 and green supply chain management: Evidence from the automotive industry. Computers & Industrial Engineering, 169, 108303. https://doi.org/10.1016/j.cie.2022.108303

Haapala, K. R., Zhao, F., Camelio, J., Sutherland, J. W., Skerlos, S. J., Dornfeld, D. A., Jawahir, I. S., Clarens, A. F., & Rickli, J. L. (2013). A review of engineering research in sustainable manufacturing. Journal of Manufacturing Science and Engineering, Transactions of the ASME. https://doi.org/10.1115/1.4024040

Hair, J. F., Black, W. C., Babin, B. J., & Anderson, R. E. (2009). Multivariate data analysis (7th ed.). Prentice-Hall.

Hazen, B. T., Mollenkopf, D. A., & Wang, Y. (2017). Remanufacturing for the circular economy: An examination of consumer switching behavior. Business Strategy and the Environment, 26(4), 451–464. https://doi.org/10.1002/bse.1929

Jabbour, C. J. C., Sarkis, J., de Sousa Jabbour, A. B. L., Renwick, D. W. S., Singh, S. K., Grebinevych, O., Kruglianskas, I., & Godinho Filho, M. (2019). Who is in charge? A review and a research agenda on the ‘human side’of the circular economy. Journal of Cleaner Production, 222, 793–801. https://doi.org/10.1016/j.jclepro.2019.03.038

Jamwal, A., Agrawal, R., & Sharma, M. (2023). Challenges and opportunities for manufacturing SMEs in adopting industry 4.0 technologies for achieving sustainability: Empirical evidence from an emerging economy. Operations Management Research. https://doi.org/10.1007/s12063-023-00428-2

Jamwal, A., Agrawal, R., Sharma, M., & Giallanza, A. (2021). Industry 4.0 technologies for manufacturing sustainability: A systematic review and future research directions. Applied Sciences, 11(12), 5725. https://doi.org/10.3390/app11125725

Kagermann, H., Lukas, W. D., & Wahlster, W. (2011). Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen revolution. VDI Nachrichten, 13(1), 2–3.

Khan, S. A. R., Piprani, A. Z., & Yu, Z. (2022). Digital technology and circular economy practices: Future of supply chains. Operations Management Research, 15(3–4), 676–688.

Kim, J. H. (2017). A review of cyber–physical system research relevant to the emerging IT trends: Industry 4.0, IoT, big data, and cloud computing. Journal of Industrial Integration and Management, 2(03), 1750011. https://doi.org/10.1142/S2424862217500117

Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling, 127, 221–232. https://doi.org/10.1016/j.resconrec.2017.09.005

Kouhizadeh, M., Zhu, Q., & Sarkis, J. (2020). Blockchain and the circular economy: Potential tensions and critical reflections from practice. Production Planning & Control, 31(11–12), 950–966. https://doi.org/10.1080/09537287.2019.1695925

Kumar, P., Singh, R. K., & Kumar, V. (2021). Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resources, Conservation and Recycling, 164, 105215. https://doi.org/10.1016/j.resconrec.2020.105215

Kumar, A., Sah, B., Singh, A. R., Deng, Y., He, X., Kumar, P., & Bansal, R. C. (2017). A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renewable and Sustainable Energy Reviews, 69, 596–609. https://doi.org/10.1016/j.rser.2016.11.191

Luthra, S., & Mangla, S. K. (2018). Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Safety and Environmental Protection, 117, 168–179. https://doi.org/10.1016/j.psep.2018.04.018

Machado, C. G., Winroth, M. P., & Ribeiro da Silva, E. H. D. (2020). Sustainable manufacturing in Industry 4.0: An emerging research agenda. International Journal of Production Research, 58(5), 1462–1484. https://doi.org/10.1080/00207543.2019.1652777

Marrucci, L., Daddi, T., & Iraldo, F. (2021). The contribution of green human resource management to the circular economy and performance of environmental certified organisations. Journal of Cleaner Production, 319, 128859. https://doi.org/10.1016/j.jclepro.2021.128859

Mhatre, P., Panchal, R., Singh, A., & Bibyan, S. (2021). A systematic literature review on the circular economy initiatives in the European Union. Sustainable Production and Consumption, 26, 187–202. https://doi.org/10.1016/j.spc.2020.09.008

Mittal, S., Khan, M. A., Romero, D., & Wuest, T. (2018). A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium–sized enterprises (SMEs). Journal of Manufacturing Systems, 49, 194–214. https://doi.org/10.1016/j.jmsy.2018.10.005

Moktadir, M. A., Kumar, A., Ali, S. M., Paul, S. K., Sultana, R., & Rezaei, J. (2020). Critical success factors for a circular economy: Implications for business strategy and the environment. Business Strategy and the Environment, 29(8), 3611–3635. https://doi.org/10.1002/bse.2600

Momaya, K. S. (2017). Management of technology and innovation (MOT) for competitiveness: diagnosing problems at vonda motors. Case Centre No. 318–0001–1. Retrieved 27 Dec 2023, from https://www.thecasecentre.org/products/view?id=149299

Moreno, M., Turner, C., Tiwari, A., Hutabarat, W., Charnley, F., Widjaja, D., & Mondini, L. (2017). Re–distributed manufacturing to achieve a circular economy: A case study utilizing IDEF0 modeling. Procedia CIRP, 63, 686–691. https://doi.org/10.1016/j.procir.2017.03.322

Nelles, M., Gruenes, J., & Morscheck, G. (2016). Waste management in Germany–development to a sustainable circular economy? Procedia Environmental Sciences, 35, 6–14. https://doi.org/10.1016/j.proenv.2016.07.001

Pagoropoulos, A., Pigosso, D. C., & McAloone, T. C. (2017). The emergent role of digital technologies in the circular economy: A review. Procedia Cirp, 64, 19–24. https://doi.org/10.1016/j.procir.2017.02.047

Ponis, S., Aretoulaki, E., Maroutas, T. N., Plakas, G., & Dimogiorgi, K. (2021). A systematic literature review on additive manufacturing in the context of circular economy. Sustainability, 13(11), 6007. https://doi.org/10.3390/su13116007

Raj, A., Dwivedi, G., Sharma, A., de Sousa Jabbour, A. B. L., & Rajak, S. (2020). Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter–country comparative perspective. International Journal of Production Economics, 224, 107546. https://doi.org/10.1016/j.ijpe.2019.107546

Rajput, S., & Singh, S. P. (2019). Connecting circular economy and industry 4.0. International Journal of Information Management, 49, 98–113. https://doi.org/10.1016/j.ijinfomgt.2019.03.002

Reddy, K. N., & Kumar, A. (2021). Capacity investment and inventory planning for a hybrid manufacturing–remanufacturing system in the circular economy. International Journal of Production Research, 59(8), 2450–2478. https://doi.org/10.1080/00207543.2020.1734681

Reio, T. G., Jr., & Shuck, B. (2015). Exploratory factor analysis: Implications for theory, research, and practice. Advances in Developing Human Resources, 17(1), 12–25. https://doi.org/10.1177/15234223145598

Schöggl, J. –P., Rusch, M., Stumpf, L., & Baumgartner, R. J. (2023). Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector. Sustainable Production and Consumption, 35, 401–420. https://doi.org/10.1016/j.spc.2022.11.012

Sehnem, S., Jabbour, C. J. C., Pereira, S. C. F., & de Sousa Jabbour, A. B. L. (2019). Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resources, Conservation and Recycling, 149, 236–248. https://doi.org/10.1016/j.resconrec.2019.05.021

Shayganmehr, M., Kumar, A., Garza–Reyes, J. A., & Moktadir, M. A. (2021). Industry 4.0 enablers for a cleaner production and circular economy within the context of business ethics: A study in a developing country. Journal of Cleaner Production, 281, 125280. https://doi.org/10.1016/j.jclepro.2020.125280

Shojaei, A., Ketabi, R., Razkenari, M., Hakim, H., & Wang, J. (2021). Enabling a circular economy in the built environment sector through blockchain technology. Journal of Cleaner Production, 294, 126352. https://doi.org/10.1016/j.jclepro.2021.126352

Singhal, D., Tripathy, S., & Jena, S. K. (2020). Remanufacturing for the circular economy: Study and evaluation of critical factors. Resources, Conservation and Recycling, 156, 104681. https://doi.org/10.1016/j.resconrec.2020.104681

Stahel, W. R. (2016). The circular economy. Nature, 531(7595), 435–438. https://doi.org/10.1038/531435a

Suchek, N., Fernandes, C. I., Kraus, S., Filser, M., & Sjögrén, H. (2021). Innovation and the circular economy: A systematic literature review. Business Strategy and the Environment, 30(8), 3686–3702. https://doi.org/10.1002/bse.2834

Sung, T. K. (2018). Industry 4.0: A Korea perspective. Technological Forecasting and Social Change, 132, 40–45. https://doi.org/10.1016/j.techfore.2017.11.005

Thorley, J., Garza–Reyes, J. A., & Anosike, A. (2021). Circular economy: A conceptual model to measure readiness for manufacturing SMEs. Benchmarking: an International Journal, 29(4), 1362–1390.

Torres–Guevara, L. E., Prieto–Sandoval, V., & Mejia–Villa, A. (2021). Success drivers for implementing circular economy: A case study from the building sector in Colombia. Sustainability, 13(3), 1350. https://doi.org/10.3390/su13031350

Trevisan, A. H., Lobo, A., Guzzo, D., de Vasconcelos Gomes, L. A., & Mascarenhas, J. (2023). Barriers to employing digital technologies for a circular economy: A multi–level perspective. Journal of Environmental Management, 332, 117437. https://doi.org/10.1016/j.jenvman.2023.117437

Tseng, M. –L., Tan, R. R., Chiu, A. S. F., Chien, C. –F., & Kuo, T. C. (2018). Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resources, Conservation and Recycling, 131, 146–147. https://doi.org/10.1016/j.resconrec.2017.12.028

Upadhyay, A., Mukhuty, S., Kumar, V., & Kazancoglu, Y. (2021). Blockchain technology and the circular economy: Implications for sustainability and social responsibility. Journal of Cleaner Production, 293, 126130. https://doi.org/10.1016/j.jclepro.2021.126130

Yadav, G., Kumar, A., Luthra, S., Garza–Reyes, J. A., Kumar, V., & Batista, L. (2020a). A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers. Computers in Industry. https://doi.org/10.1016/j.compind.2020.103280

Yadav, G., Luthra, S., Jakhar, S. K., Mangla, S. K., & Rai, D. P. (2020b). A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2020.120112

Acknowledgements

Authors are thankful to the Editor in Chief, Reviewers, Guest Editors and anonymous reviewers for their constructive feedback on the paper which helped to improve the quality of manuscript.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Conceptualization: RA, MS, SK, IG; Methodology: AJ, RA; Formal analysis and investigation: RA, SK, MS, IG; Writing—original draft preparation: AJ, IG; Writing—review and editing: AJ, RA, IG; Resources: RA, SK; Supervision: RA, SK, MS, IG.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Ethical Approval

Not applicable—Manuscript does not report on or involve the use of any animal or human data or tissue.

Consent for Publication

Not applicable—Manuscript does not contain data from any individual person.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jamwal, A., Kumari, S., Agrawal, R. et al. Unlocking Circular Economy Through Digital Transformation: the Role of Enabling Factors in SMEs. JGBC 19, 24–36 (2024). https://doi.org/10.1007/s42943-024-00090-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42943-024-00090-w

Keywords

- Circular economy

- Digital technologies

- Industry 4.0

- SMEs

- Exploratory factor analysis

- Bayesian best worst method

- Environmental management