Abstract

Carbonyl compounds were prepared by selective oxidation of alcohols in the presence of recoverable \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}@\hbox {Pd}\) magnetic nanocatalyst in aqueous media as a green solvent. Molecular oxygen served as an oxidant. The catalyst was removed from the reaction media by external magnetic field, washed with methanol, and reused for six more times without any considerable reduction in its reactivity. The chemoselectivity and regioselectivity of the catalyst can serve for selective oxidation of primary alcohols in the presence of secondary ones, and for oxidation of unhindered alcohols in the presence of hindered ones.

Graphical Abstract

Selective and facile oxidation of alcohols to their corresponding carbonyl compounds in the presence of immobilized, recoverable, and magnetic nano Pd-particles in water by molecular oxygen.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Carbonyl compounds are excellent precursors for the synthesis of molecules with versatile applications in industry, pharmacology and other research work.[1] So, their synthesis from the corresponding alcohols is of paramount importance.[2] Many different ways and reagents such as oxalyl chloride-dimethyl sulfoxide (Swern oxidation),[3] hypervalent iodine[4] and stoichiometric amounts of Cr(VI) salts[5] have been previously reported, but they suffer from many drawbacks such as toxic and hazardous reagents, nonselective alcohol oxidation, noncompliance of atom economy, low yield and high price, as well as serious environmental damages. They also produce a lot of waste, which is not acceptable from the green chemistry point of view. Consequently, the selective oxidation of alcohols to their corresponding carbonyl compounds with molecular oxygen, instead of stoichiometric toxic oxidants in the green medium, has attracted attention of researchers.[6] Catalysts speed up the reactions by reducing the activation energy without being consumed. They are divided into two general groups, heterogeneous and homogenous.[7] Among them, homogenous ones are generally more effective, but the time-consuming separation and expensive recyclability limit their application, especially in industry. Moreover, the final products can be polluted by the homogeneous catalysts. On the contrary, heterogeneous catalysts are non-soluble in reaction media and can be easily removed from the reaction and reused for several times. The heterogeneous catalysts suffer from low yield, which can be attributed to their poorly defined active sites. Therefore, the quality of the surface area of a heterogeneous catalyst determines the availability of catalytic active sites for reactants. To increase the effectiveness of a heterogeneous catalyst, its surface area should be increased, which is possible by using it in nanoscale.[8] Although the collision number increases by using nanoparticles, they have generally high surface energy and are thermodynamically unstable and susceptible to form agglomeration. By using magnetic nanoparticles and coating them with an organic linker, not only this deficiency is obviated, but also the long, tedious filtration or centrifugation removal of nanocatalyst becomes easier by just applying an external magnetic field.[9]

Not all metals are magnetic, but it is possible to couple them with those with magnetic properties directly or through a ligand. Metal leaching is the problem of directly attached metals to magnetic nanoparticles, which is solved by coating the core by organic linkers and anchoring active metals to them.[10] Moreover, it has been shown that the reactivity of a nanomagnetic catalyst can be even better than a corresponding homogeneous catalyst.[11]

For oxidation reactions, different metals like \(\hbox {Fe}\),[12] \(\hbox {Cu}\),[13] \(\hbox {Co}\),[14] \(\hbox {Bi}\),[15] and \(\hbox {Au}\)[16] have been used as a catalyst, but among them, palladium-based catalysts (both homogeneous and heterogeneous) have shown better activity.[17] For green and selective alcohol oxidation, different metals, oxidants, heterogeneous and homogeneous catalysts have been reported in literature up to now. Among them, the heterogeneous ones have exceeded the homogeneous ones.[18]

In this work, we combined the advantages of eco-friendly molecular oxygen as a green oxidation source, Pd nanomagnetic particles as an efficient catalyst, and water as a green solvent for the selective oxidation of alcohols in mild reaction conditions without any environmentally unfriendly mediator, like 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO).[19]

2 Experimental

2.1 General procedure for catalyst preparation

2.1.1 General procedure for preparation of \({Fe}_{3}{O}_{4}@{SiO}_{2}\)

\(\hbox {FeCl}_{3}\) (66.58 mmol) and \(\hbox {FeCl}_{2}\) (31.56 mmol) were dissolved in 40 mL deionized water in an inert atmosphere of argon. Ammonium hydroxide 28% (v/v) was added to the solution to adjust pH=10. The solution was mechanically stirred at room temperature for 20 min until a black suspension was formed. The prepared \(\hbox {Fe}_{3}\hbox {O}_{4}\) magnetic nanoparticles were filtered, washed, and dried. The powder was then dispersed ultrasonically in ethanol for 20 min. 3 mL of tetraethylorthosilicate (TEOS) was slowly added to the solution. Ammonium hydroxide (3 mL) was added to the solution within 15 min and stirred for 12 h at 40 \(^{\circ }\hbox {C}\). The silica coated \(\hbox {Fe}_{3}\hbox {O}_{4}\) magnetic nanoparticles (\(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2})\) were collected by external magnetic field, washed with methanol and dried under vacuum in a rotary evaporator.[20]

2.1.2 Preparation of \(Fe_{3}O_{4}@SiO_{2}@3\hbox {-}glycidoxy\hbox {-}propyltrimethoxysilane\)

2 g of silica-coated \(\hbox {Fe}_{3}\hbox {O}_{4}\) was sonicated in toluene for 30 min, and then 11.32 mmol 3-glycidoxypropyltrimethoxy-silane was added and refluxed for 48 h. The prepared catalyst was washed with methanol and dried under vacuum.[20]

2.1.3 Preparation of \(Fe_{3}O_{4}@SiO_{2}@triazole@Cu\)

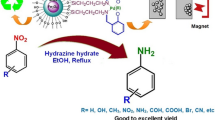

\(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@3-glycidoxypropyltrimethoxysilane}\) (1 g) and 18.2 mmol phenylacetylene were added to the solution of sodium azide (22.7 mmol), copper(II) chloride (0.74 mmol) and sodium ascorbate (0.76 mmol) in THF/water (80/20) for 10 h at 60 \({^{\circ }}\hbox {C}\). The catalyst was removed, washed and dried.[21]

2.1.4 Preparation of \(Fe_{3}O_{4}@SiO_{2}@triazole\)

To remove Cu from catalyst structure, 1.5 g potassium cyanide was dissolved in \(\hbox {H}_{2}\hbox {O/methanol}\) (1/1, 10 mL) and the solution was added to \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@triazole@Cu}\) which was synthesized in the previous step and stirred for 5 h at room temperature. The catalyst was then removed by an external magnetic field, washed, and dried in air at room temperature.[21]

2.1.5 Preparation of \(Fe_{3}O_{4}@SiO_{2}@triazole@Pd\)

Potassium chloride (0.3 g) was dissolved in methanol/water (50/50, 10 mL), and 0.1 g palladium chloride was added to the solution and stirred for 4 h at room temperature. The transparent and clear reddish solution was [\(\hbox {K}_{2}\hbox {PdCl}_{4}\)]. The prepared \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@triazole}\) was dispersed and sonicated for 15 min in 10 mL methanol. The [\(\hbox {K}_{2}\hbox {PdCl}_{4}\)] solution was added to that and stirred for 24 h at room temperature. Then, the catalyst was removed by an external magnetic field, washed 2 times with methanol and dried in air at room temperature.[22]

2.2 General procedure for alcohol oxidation

A mixture of alcohol (1 mmol), \(\hbox {K}_{2}\hbox {CO}_{3}\) (1 mmol), and catalyst (1 mmol%) in \(\hbox {H}_{2}\hbox {O}\) (5 mL) was prepared in a flask equipped with a condenser. The flask was then filled with pure oxygen and equipped with an oxygen balloon. The mixture was stirred at \(80\;{^{\circ }}\hbox {C}\). The progress of the reaction was monitored by thin layer chromatography (TLC) and gas chromatography (GC). After completion of the reaction, the catalyst was separated by an external magnetic field from the reaction media and corresponding carbonyl compounds were extracted with ethyl acetate. To have a complete extraction of products, sodium chloride was added to the mixture and after separation of the aqueous layer, the organic solvent was evaporated by rotary evaporator under reduced pressure. The products were purified by column chromatography or re-crystallization method. The separated catalyst was washed two times with methanol, and dried overnight at room temperature and then used directly for subsequent reaction runs.

3 Results and Discussion

3.1 Catalyst synthesis and characterization

The catalyst \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@triazole@Pd}\) was synthesized according to the previously described procedure by the authors (Scheme 1),[19] and its structure was re-characterized by field emission scanning electron microscope (FESEM) (Figure 1), thermal gravimetric analysis (TGA) (Figure 2), Fourier transform infrared spectroscopy (FTIR) (Figure 3), CHN analysis, vibrating sample magnetometery (VSM) (Figure 4) and inductively coupled plasma optical electron spectrometry (ICP-OES).

The catalyst shape and size was confirmed by FESEM. The diameter of the nanoparticles is about 50 nm, and they are approximately spherical (Figure 1).

According to the TGA analysis in Figure 2, adsorbed water in catalyst structure is removed before \(200\;{^{\circ }}\hbox {C}\). The catalyst decomposition occurs between about \(190\;{^{\circ }}\hbox {C}\) and \(540\;{^{\circ }}\hbox {C}\), which is equal to ca. 21% of the weight of the catalyst and certified the immobilization of organic groups onto the magnetic core. As the catalyst is stable up to ca. \(200\;{^{\circ }}\hbox {C}\), it can be also used for high-temperature organic reactions.

The FT-IR spectra of the catalyst shows strong absorption bands at 1150 \(\hbox {cm}^{-1}\) and 600 \(\hbox {cm}^{-1}\), which refer to the Si-O and Fe-O vibrations, respectively (Figure 3). The peaks at 2930 and 2910 \(\hbox {cm}^{-1}\) are attributed to C-H stretching vibrations, which confirm the presence of the alkylsilane groups on \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\).

The palladium loading on the catalyst surface was determined by ICP-OES as 1.24 mmol.\(\hbox {g}^{-1}\), while the nitrogen content was determined by CHN analysis as 3.00 wt%. This amount of nitrogen corresponds to ca. 0.71 \(\hbox {mmol.g}^{-1 }\hbox {N}_{3 }\) moiety. This means that not all the Pd atoms are exclusively coordinated by the nitrogen atoms in the \(\hbox {N}_{3}\) group, as shown in Scheme 1. There are also some other possibilities as shown in Scheme 2. As shown, Pd atoms can also be chelated by oxygen atoms present in the structure. It is also possible that a Pd atom has been coordinated by a nitrogen atom of a particle chain along with a nitrogen or an oxygen atom of another chain.

Anyway, owing to the strong coordination of nitrogen and oxygen groups to palladium, metal loading was relatively high, and leaching during reactions was negligible. Furthermore, palladium black formation, which is generally resulted from palladium nanoparticles agglomeration, was not formed here; so the activity of palladium did not diminish. The magnetic property of the catalyst was measured by a vibrating sample magnetometer (VSM) at room temperature. According to Figure 4, the saturation magnetization of the catalyst is about 38 emu/g with a magnetic field within the range of −9000 to 9000 Oe. This magnetization value is enough for separating the magnetic catalyst from reaction media by an external magnetic field.

3.2 Catalytic experiments

To find the optimized reaction conditions, oxidation of 1.0 mmol benzyl alcohol was chosen as the model reaction. An oxygen balloon was chosen as an oxidant source. The effect of the catalyst, base and solvent has been investigated (Table 1). As it is shown in Table 1 (Entries 1–3), in the absence of the catalyst, no product was formed after 4 h in 3 different solvents. The addition of the catalyst (0.5 mmol%) changed the yield of the reaction in aqueous media considerably, whereas the reactions in toluene and \(\hbox {H}_{2}\hbox {O}/^{\mathrm{t}}\hbox {BuOH}\) were not successful (Entries 4–6). By increasing the amount of the catalyst from 0.5 mmol% to 1 mmol%, the reaction yield was increased from 45 to 96% in water (Entries 6 and 9). The same reaction, as in Entry 9, was repeated but in the absence of any base. As shown in Entry 11, it was realized that the presence of a base is necessary. Obviously, it seems that \(\hbox {K}_{2}\hbox {CO}_{3 }\) is the most suitable base among the others (compare Entry 9 with 12 and 13).

The reaction with optimum amounts of the ingredients was tested in the air, instead of the oxygen atmosphere. The yield was not desirable, and after 24 h, only 60% benzaldehyde was gained (Table 1, Entry 14). The reaction was also investigated in the nitrogen atmosphere (in the absence of any oxygen source). No product was obtained, which shows that palladium cannot act as the oxidant, solely (Table 1, Entry 15).

According to these data, the best result was obtained when 1 mmol% of \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@triazole@Pd}\) catalyst along with 1 mmol of \(\hbox {K}_{2}\hbox {CO}_{3 }\) in water media and oxygen were used (Entry 9).

Encouraged by these results, the scope of the reaction was expanded for oxidation of various alcohols. The results have been summarized in Table 2. Different kinds of primary and secondary benzylic alcohols with both electron-withdrawing and electron-donating groups were selectively oxidized to their corresponding carbonyl compounds with excellent yields. The catalyst was also able to oxidize primary and secondary aliphatic alcohols 1-octanol and 2-heptanol to octanal and heptanone, respectively, with good to excellent yield (Table 2, Entries 1 and 2). It is noteworthy to mention that no over-oxidation of primary alcohols to carboxylic acids was observed.

In comparison to benzyl alcohol (as a primary alcohol), 1-phenyl ethanol (as a secondary one) needed more time and gave less yield, obviously due to the steric effects and less activity (Table 2, Entries 3 and 14).

The reaction is substantially dependent on the electron nature of the substituents and their positions. Benzylic alcohols with electron donating groups at 4-position such as 4-methyl and 4-methoxy were oxidized with more yield in shorter reaction times (Table 2, Entries 6 and 8), while benzylic alcohols with electron-withdrawing groups such as 4-nitro need considerably more times (24 h) and afford less yield (77%) (Table 2, Entry 10).

The benzyl alcohols with a substituent at 2-position were substantially less active, because of steric hindrance. 2-Methyl- and 2-methoxybenzyl alcohols were converted to their corresponding aldehydes with only 41 and 39% yield after 10 h (Table 2, Entries 7 and 9). The less reactive 2-chloro and 2-nitrobenzyl alcohols were not oxidized to their corresponding aldehydes.

To show the merit of this restriction, we have investigated the oxidation of 1 mmol of 4-methoxybenzyl alcohol in the presence of 1 mmol of 2-methoxybenzyl alcohol and monitored the progress of the reaction after 2 and 4 h. The only product was 4-methoxybenzaldehyde with 52% and 97% yield, respectively, which shows the selectivity of the catalyst for oxidation of unhindered alcohols versus hindered ones (Scheme 3). It is postulated that in the oxidation of alcohols by Pd-species, the reaction proceeds via the formation of a Pd(II)-alcoholate.\(^{17f}\) As in the \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\)\(\hbox {@triazole@Pd}\) catalyst, Pd (II) sites are chelated by several nitrogen/or oxygen atoms, it is understandable that less hindered alcohols react faster than the hindered ones.

In order to examine the chemoselectivity of the catalyst, a mixture of benzhydrol as a secondary alcohol and benzyl alcohol as a primary alcohol was examined according to optimized reaction conditions. No benzophenone was produced, while benzyl alcohol was quantitatively reacted to benzaldehyde. This approves the advantages of this catalyst for selective oxidation of unhindered primary alcohols in the presence of hindered secondary ones (Scheme 4).

3.3 Leaching test

In the middle of the model reaction, the catalyst was removed from reaction media by a magnet, and the yield of the product was determined by GC as 54%. The reaction was continued for the rest of the time. No change in the yield was observed, which is a confirmation to declare that during the reaction, the palladium species did not leach into the aqueous phase and hence, the catalyst acts as a really heterogeneous catalyst.

3.4 Recovery test

The separation of the catalyst from the reaction media was very easy. At the end of each reaction, the catalyst was easily removed just by applying an external magnetic field (Figure 5).

The catalyst was washed two times with methanol, dried at room temperature and reused for at least six more times, without any negligible reduction in reactivity (Figure 6).

The Pd content after the \(7^{\mathrm{th}}\) run was measured by AAS which showed no significant loss of Pd (1.16 \(\hbox {mmol.g}^{-1}\) vs. 1.24 \(\hbox {mmol.g}^{-1}\) at the beginning).

The morphology of the recovered catalyst was analysed by FESEM (Figure 7). By comparing Figure 7 with Figure 1, it is clear that the size and the morphology of the particles remained unchanged.

Figure 8 is the powder X-ray diffraction pattern of the recovered catalyst, in the range of \(2\theta \) from 5 to 80 degrees. The diffraction pattern corresponds quite well to the \(\hbox {Fe}_{3}\hbox {O}_{4}/\hbox {SiO}_{2 }\) sample previously reported, which means that the structure of the catalyst is unchanged.[30]

3.5 Comparison of the effectiveness of the catalyst

A comparison between the present catalyst and other catalysts for alcohols oxidation has been done and the results are shown in Table 3. It is obvious that our catalyst is comparatively good for selective oxidation of alcohols to their corresponding carbonyl compounds, in the presence of molecular oxygen as an oxidant, water as a green media, and in shorter reaction time.

The turnover frequency (TOF) and turnover number (TON) of the catalyst have been compared to some of the similar catalysts in literature. The data have been summarized in Table 4, which show an acceptable TON and TOF for benzyl alcohol oxidation by the \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}@\hbox {Triazole@Pd}\) versus other mentioned catalysts.

4 Conclusions

In this work, we synthesized carbonyl compounds by selective oxidation of alcohols in the presence of recoverable \(\hbox {Fe}_{3}\hbox {O}_{4}@\hbox {SiO}_{2}\hbox {@Triazole@Pd}\) magnetic nanocatalyst in aqueous media as a green solvent. Molecular oxygen served as an oxidant. The absence of mediators like 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) and eco-unfriendly oxidizing agents and toxic and hazardous organic solvents make this method more precious. The catalyst was removed from the reaction media by a magnetic field, washed with methanol, and reused for at least six more times without any considerable reduction in its reactivity. The notable features and major advantages are ease of catalyst preparation, recyclability and reusability for several times, operational simplicity, and easy work-up procedure. The chemoselectivity and regioselectivity of the catalyst can serve for selective oxidation of primary alcohols in the presence of secondary ones, and for the oxidation of unhindered alcohols in the presence of hindered ones.

References

(a) Yus M, González-Gómez J C and Foubelo F 2013 Diastereoselective allylation of carbonyl compounds and imines: Application to the synthesis of natural products Chem. Rev. 113 5595; (b) Aggarwal V K and Winn C L 2004 Catalytic, asymmetric sulfur ylide-mediated epoxidation of carbonyl compounds: scope, selectivity, and applications in synthesis Acc. Chem. Res. 37 61; (c) R B Moffett and N Rabjohn (Eds.) 1963 In Organic Syntheses vol. 4 (USA: John Wiley & Sons) p. 605; (d) Dimmock J R, Vashishtha S C and Stables J P 2000 Anticonvulsant properties of various acetylhydrazones, oxamoylhydrazones and semicarbazones derived from aromatic and unsaturated carbonyl compounds Eur. J. Med. Chem. 35 241; (e) Silva C D, Silva D L, Modolo L V, Alves R B, Resende M D, Martins C V and Fatima A D 2011 Schiff bases: A short review of their antimicrobial activities J. Adv. Res. 2 1

Sheldon R A, Arends I W C E and Dijksman A 2000 New developments in catalytic alcohol oxidations for fine chemicals synthesis Catal. Today 57 157

Mancuso A J and Swern D 1981 Activated dimethyl sulfoxide: useful reagents for synthesis Synthesis 1981 165

Wang Y H, Cong H, Zhao F F, Xue S F, Tao Z, Zhu Q J and Wei G 2011 Selective catalysis for the oxidation of alcohols to aldehydes in the presence of cucurbit[8]uril Catal. Commun. 12 1127

Guochuan Y, Zuwei X, Guoying C, Shuhua F and Xiaodan H 1999 Selective oxidation of m-phenoxytoluene to m-phenoxy benzaldehyde with methanol as an additive in acetic acid Appl. Catal. A 185 277

(a) Chen Y, Wang H, Liu C J, Zeng Z, Zhang H, Zhou C, Jia X and Yang Y 2012 Formation of monometallic Au and Pd and bimetallic Au–Pd nanoparticles confined in mesopores via Ar glow-discharge plasma reduction and their catalytic applications in aerobic oxidation of benzyl alcohol J. Catal. 289 105; (b) Wang X, Wu G, Guan N and Li L 2012 Supported Pd catalysts for solvent-free benzyl alcohol selective oxidation: Effects of calcination pretreatments and reconstruction of Pd sites Appl. Catal. B: Environ. 115 7; (c) Su Y, Wang L C, Liu Y M, Cao Y, He H Y and Fan K N 2007 Microwave-accelerated solvent-free aerobic oxidation of benzyl alcohol over efficient and reusable manganese oxides Catal. Commun. 8 2181; (d) Yamada Y, Arakawa T, Hocke H and Uozumi Y 2007 A nanoplatinum catalyst for aerobic oxidation of alcohols in water Angew. Chem. Int. Ed. 119 718; (e) Zhou W, Chen D, Cui A, Qian J, He M and Chen Q 2017 Aerobic oxidation of alcohols to carbonyl compounds catalyzed by N-Hydroxyphthalimide (NHPI) combined with CoTPP-Zn\(_{2}\)Al-LDH J. Chem. Sci. 129 295

Chutia P, Kato S, Kojima T and Satokawa S 2009 Synthesis and characterization of Co (II) and Cu (II) supported complexes of 2-pyrazinecarboxylic acid for cyclohexene oxidation Polyhedron 28 370

(a) Schlogl R and Abd Hamid S B 2004 Nanocatalysis: mature science revisited or something really new? Angew. Chem. Int. Ed. 43 1628; (b) Otero Areán C, Mentruit M P, López A J L and Parra J B 2001 High surface area nickel aluminate spinels prepared by a sol–gel method Colloids Surf. A 180 253; (c) Somorjai G A 1979 Catalysis and surface science Surf. Sci. 89 496

(a) Melero J A, van Grieken R and Morales G 2006 Advances in the synthesis and catalytic applications of organosulfonic-functionalized mesostructured materials Chem. Rev. 106 3790; (b) Lu A H, Salabas E L and Schuth F 2007 Magnetische nanopartikel: synthese, stabilisierung, funktionalisierung und anwendung Angew. Chem. Int. Ed. 119 1242; (c) Lu A H, Salabas E L and Schuth F 2007 Magnetic nanoparticles: synthesis, protection, functionalization, and application Angew. Chem. Int. Ed. 46 1222; (d) Karaoğlu E, Baykal A, Erdemi H, Alpsoy L and Sözeri H 2011 Synthesis and characterization of DL-thioctic acid (DLTA)–\(\text{Fe}_{3}\text{ O }_{4}\) nanocomposite J. Alloys Compd. 509 9218; (e) Zhang M, Liu Y H, Shang Z R, Hu H C and Zhang Z H 2017 Supported molybdenum on graphene oxide/\(\text{ Fe }_{3}\text{ O }_{4}\): An efficient, magnetically separable catalyst for one-pot construction of spiro-oxindole dihydropyridines in deep eutectic solvent under microwave irradiation Catal. Commun. 88 39; (f) Gholinejad M, Ahmadi J and Nájera C 2016 Silica microparticles supported gold and copper ferrite nanoparticles: A magnetically recyclable bimetallic catalyst forsonogashira reaction ChemistrySelect 1 384; (g) Wang D and Astruc D 2014 Fast-growing field of magnetically recyclable nanocatalysts Chem. Rev. 114 6949; (h) Parella R and Babu S A 2012 Magnetic nano \(\text{ Fe }_{3}\text{ O }_{4}\) and Cu\(\text{ Fe }_{2}\text{ O }_{4}\) as heterogeneous catalysts: a green method for the stereo-and regioselective reactions of epoxides with indoles/pyrroles Catal. Commun. 29 118; (i) Kumar A, Parella R and Babu S A 2014 Magnetic Nano \(\text{ Fe }_{3}\text{ O }_{4}\) Catalyzed Solvent-Free Stereo-and Regioselective Aminolysis of Epoxides by Amines; a Green Method for the Synthesis of \(\beta \)-Amino Alcohols Synlett 25 835

(a) Kim M J, Choa Y H, Kim D H and Kim K H 2009 Magnetic behaviors of surface modified superparamagnetic magnetite nanoparticles IEEE Trans. Magn. 45 2446; (b) Wu T M and Chu M S 2005 Preparation and characterization of thermoplastic vulcanizate/silica nanocomposites J. Appl. Polym. Sci. 98 2058; (c) Baeza A, Guillena G and Ramón D J 2016 Magnetite and Metal Impregnated Magnetite Catalysts in Organic Synthesis: A Very Old Concept with New Promising Perspectives ChemCatChem 8 49

(a) Shi F, Tse M K, Pohl M M, Brückner A, Zhang S and Beller M 2007 Tuning Catalytic Activity between Homogeneous and Heterogeneous Catalysis: Improved Activity and Selectivity of Free Nano \(\text{ Fe }_{2}\text{ O }_{3}\) in Selective Oxidations Angew. Chem. Int. Ed. 46 8866; (b) Zhang D H, Li G D, Li J X and Chen J S 2008 One-pot synthesis of Ag–\(\text{ Fe }_{3}\text{ O }_{4}\) nanocomposite: a magnetically recyclable and efficient catalyst for epoxidation of styrene Chem. Commun. 3414; (c) Tong J, Liu F, Wang W, Bo L, Mahboob A and Fan H 2016 Highly efficient epoxidation of cyclopentene catalyzed by magnetically recoverable Mg–doped cobalt ferrites with greatly improved performances ChemistrySelect 1 6356

Wang N, Liu R, Chen J and Liang X 2005 \(\text{ NaNO }_{2}-\text{ activated }\), iron–TEMPO catalyst system for aerobic alcohol oxidation under mild conditions Chem. Commun. 5322

Hoover J M and Stahl S S 2011 Highly practical copper (I)/TEMPO catalyst system for chemoselective aerobic oxidation of primary alcohols J. Am. Chem. Soc. 133 16901

Sharma V B, Jain S L and Sain B 2004 Cobalt (II) Schiff base catalyzed aerobic oxidation of secondary alcohols to ketones J. Mol. Catal. A: Chem. 212 55

Baruah D, Hussain F L, Suri M, Saikia U P, Sengupta P, Dutta D K and Konwar D 2016 Bi (\(\text{ NO }_{3})_{3}\cdot 5\text{ H }_{2}\text{ O }\) and cellulose mediated Cu-NPs — A highly efficient and novel catalytic system for aerobic oxidation of alcohols to carbonyls and synthesis of DFF from HMF Catal. Commun. 77 9

Zheng N and Stucky G D 2007 Promoting gold nanocatalysts in solvent-free selective aerobic oxidation of alcohols Chem. Commun. 3862

(a) Steinhoff B A, King A E and Stahl S S 2006 Unexpected roles of molecular sieves in palladium-catalyzed aerobic alcohol oxidation J. Org. Chem. 71 1861; (b) Iwasawa T, Tokunaga M, Obora Y and Tsuji Y 2004 Homogeneous palladium catalyst suppressing Pd black formation in air oxidation of alcohols J. Am. Chem. Soc. 126 6554; (c) Du X, Zhao C, Li X, Huang H, He J, Wen Y and Zhang X 2017 Smart design of small Pd nanoparticles confined in hollow carbon nanospheres with large center radial mesopores Eur. J. Inorg. Chem. 2017 2517; (d) Abedi S and Morsali A 2017 Improved activity of palladium nanoparticles using a sulfur-containing metal–organic framework as an efficient catalyst for selective aerobic oxidation in water New J. Chem. 41 5846; (e) Zhang L, Li P, Yang J, Wang M and Wang L 2014 Palladium supported on magnetic core–shell nanoparticles: an efficient and reusable catalyst for the oxidation of alcohols into aldehydes and ketones by molecular oxygen ChemPlusChem 79 217; (f) Nishimura T, Onoue T, Ohe K and Uemura S 1999 Palladium(II)-catalyzed oxidation of alcohols to aldehydes and ketones by molecular oxygen J. Org. Chem. 64 6750

Misono M 2013 In Heterogeneous Catalysis of Mixed Oxides (Oxford: Elsevier) p. 1

(a) Yan Y, Tong X, Wang K and Bai X 2014 Highly efficient and selective aerobic oxidation of alcohols in aqueous media by TEMPO-containing catalytic systems Catal. Commun. 43 112; (b) Berger O, Boucher R and Ruhnow M 2015 Part I. Mechanism of oxidation of \(\text{ Cr }_{2}\text{ AlC }\) films in temperature range \(700-1200^{\circ }\text{ C }\) Surf. Eng. 31 373

Pourjavadi A, Hosseini S H, Hosseini S T and Aghayeemeibody S A 2012 Magnetic nanoparticles coated by acidic functionalized poly (amidoamine) dendrimer: Effective acidic organocatalyst Catal. Commun. 28 86

Matloubi Moghaddam F and Ayati S E 2015 Copper immobilized onto a triazole functionalized magnetic nanoparticle: a robust magnetically recoverable catalyst for “click” reactions RSC Adv. 5 3894

Dadras A, Naimi Jamal M R, Matloubi Moghaddam F and Ayati S E 2018 Suzuki–Miyaura coupling reaction in water in the presence of robust palladium immobilized on modified magnetic \(\text{ Fe }_{3}\text{ O }_{4}\) nanoparticles as a recoverable catalyst Appl. Organomet. Chem. 32 doi: https://doi.org/10.1002/aoc.3993

Karimi B and Kabiri Esfahani F 2012 Gold nanoparticles supported on the periodic mesoporous organosilicas as efficient and reusable catalyst for room temperature aerobic oxidation of alcohols Adv. Synth. Catal. 354 1319

Zamani F and Hosseini S M 2014 Palladium nanoparticles supported on \(\text{ Fe }_{3}\text{ O }_{4}\)/amino acid nanocomposite: highly active magnetic catalyst for solvent-free aerobic oxidation of alcohols Catal. Commun. 43 164

Sadri F, Ramazani A, Massoudi A, Khoobi M, Tarasi R, Shafiee A, Azizkhani V, Dolatyari L and Joo S W 2014 Green oxidation of alcohols by using hydrogen peroxide in water in the presence of magnetic \(\text{ Fe }_{3}\text{ O }_{4}\) nanoparticles as recoverable catalyst Green Chem. Lett. Rev. 7 257

Karimi B, Abedi S, Clark J H and Budarin V 2006 Highly efficient aerobic oxidation of alcohols using a recoverable catalyst: the role of mesoporous channels of SBA-15 in stabilizing Palladium nanoparticles Angew. Chem. Int. Ed. 118 4894

Karimi B and Farhangi E 2011 A highly recyclable magnetic core shell nanoparticle supported TEMPO catalyst for efficient metal and halogen free aerobic oxidation of alcohols in water Chem. Eur. J. 17 6056

Polshettiwar V and Varma R S 2009 Nanoparticle-supported and magnetically recoverable palladium (Pd) catalyst: a selective and sustainable oxidation protocol with high turnover number Org. Biomol. Chem. 7 37

Dileep R and Bhat B R 2010 Palladium–Schiff base–triphenylphosphine catalyzed oxidation of alcohols Appl. Organomet. Chem. 24 663

Du Q, Zhang W, Ma H, Zheng J, Zhou B and Li Y 2012 Immobilized palladium on surface-modified \(\text{ Fe }_{3}\text{ O }_{4}\)/SiO\(_{2}\) nanoparticles: as a magnetically separable and stable recyclable high-performance catalyst for Suzuki and Heck cross-coupling reactions Tetrahedron 68 3577

Acknowledgements

We are grateful to the Research Council of Iran University of Science and Technology. We also thank the Faculty of Chemistry of Sharif University of Technology for partial supporting of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dadras, A., Naimi-Jamal, M.R., Moghaddam, F.M. et al. Green and selective oxidation of alcohols by immobilized Pd onto triazole functionalized \(\hbox {Fe}_{3}\hbox {O}_{4}\) magnetic nanoparticles. J Chem Sci 130, 162 (2018). https://doi.org/10.1007/s12039-018-1567-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-018-1567-4