Abstract

Tris(pentafluorophenyl)borane catalyzed, one-pot, simple, efficient and environmentally benign protocol for the synthesis of dihydropyrimidinones/thiones via Biginelli reaction has been described. The main highlights of the present protocol is low catalyst loading, low toxicity, compatibility with acid-labile-protecting groups, short reaction time, consistently excellent yields and simple reaction/workup procedure. Moreover, the applicability of the present methodology for large-scale synthesis of monastrol highlights its potential for bulk synthesis.

Tris(pentafluorophenyl)borane catalyzed, one-pot, simple, efficient and environmentally benign protocol for the synthesis of dihydropyrimidinones/thiones via Biginelli reaction has been described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Biginelli reaction is inarguably one of the most useful multi-component reactions that involves the condensation between aldehydes and β-dicarbonyl compounds with urea or thiourea to give 3,4-dihydropyrimidin-2-(1H)-ones (DHPMs) and their thione analogues.[1] The original reaction was first reported by the Italian chemist Pietro Biginelli in 1893 and was catalyzed by mineral acids.[2]

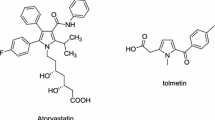

In recent decades, dihydropyrimidinones and its derivatives gained prominence in organic and medicinal chemistry because of their versatile pharmacophoric features, as compounds with this scaffold exhibit a broad range of biological activities such as calcium channel modulator, anti-hypertensive, anti-viral, anti-oxidant, anti-bacterial, anti-inflammatory agents, neuropeptide Y (NPY) antagonist, and α 1a-adrenergic antagonist.[3] Monastrol is the only cell-permeable molecule currently known as a specific inhibitor of mitotic kinesin Eg5 and is considered as lead molecule for the development of new anti-cancer agents.[4]a,b Also, SQ 32926 and SQ 32547 have been identified as a potent orally active antihypertensive agents.[4]c,d Moreover, several natural alkaloids, such as batzelladine[4]e and crambine[4]f containing the dihydropyrimidine core unit, isolated from marine sources were found to be potent HIV gp-120-CD4 inhibitors.

The outstanding outcome of dihydropyrimidinones/ thiones motifs as pharmacologically active compounds has contributed towards Biginelli cyclocondensation applications in drug industries.[4]g,h The expansion of natural products chemistry with structural diversification of dihydropyrimidinone motif also found synthetic attention from Biginelli reaction. Therefore, there has been continuous interest from organic and medicinal chemists towards the development of milder and more efficient methodologies for the synthesis of this class of compounds. A variety of methods for promoting the Biginelli reaction employing reagents and catalysts such as NaHSO4/SiO2,[5]a NH2SO3H,[5]b 12-molybdophosphoric acid,[5]c KHSO4[5]d trifluoromethanesulfonate,[5]e Fe(HSO4)3,[5]f Yb(OTf)3,[5]g Mn(OAc)3,[5]h BF3⋅Et2O,[5]i Yb(III)-resin,[5]j sulfated zirconia,[5]k Al2 O3,[5]l Bi(OTf)3,[6]a TaBr5,[6]b Cu(OTf)2,[6]c Ce(NO3)3⋅ 6H2O,[6]d SmI2,[6]e ZrOCl2⋅8H2O,[6]f ZrCl4,[6]g Sr(OTf)2,[6]h InCl3,[6]i H4PMo11 VO 40,[7]a H3PW12O40/SiO2,[7]b Dowex- 50W,[7]c CaF2,[7]d Fe3O4 nanoparticles,[7]e sulfonated β-cyclodextrine,[7]f hexaaquaaluminium(III) tetrafluoroborate,[7]g zeolite[7]h and polyoxometalate[7]i have been developed. Many other synthetic approaches including combinatorial approach,[8]a microwave,[8]b sonication,[8]c ionic liquids[8]d and organocatalysts[8]e have been actively pursued for the preparation of Biginelli products. Very recently, Fe(OTs)3⋅6H2O,[9]a piperazine/TMSCl,[9]b I2,[9]c nanomagnetic-supported sulfonic acid,[9]d and Q-tube[9]e have also been utilized for the synthesis of 3,4-dihydropyrimidinones/thiones. However, some of the reported protocols suffer from various disadvantages such as high catalyst loading, strong acidic conditions, incompatibility with acid-sensitive protecting groups, low yield, high temperature, prolonged reaction times, cumbersome methodology, eco-hazards and complexity in product isolation.

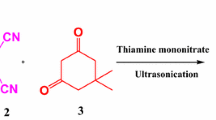

In continuation with our interest in developing novel synthetic methodologies, we report an efficient and environmentally benign protocol for the synthesis of 3,4-dihydropyrimidin-2(1H)-ones/thiones using catalytic amount of tris(pentafluorophenyl)borane as a convenient and non-conventional Lewis acid. Tris(pentafluorophenyl)borane is gaining importance due to its availability, less toxicity, thermal stability and water-tolerant nature.[10]a In recent years, the potential utility of B(C6F5)3 was explored by several researchers in various organic transformations such as Friedel-Crafts alkylation of activated arenes,[10]b regio- and stereo-selective cyclizations of unsaturated alkoxysilanes,[10]c polymethylhydrosiloxane (PMHS) activation for reduction of different functional groups.[10]d,e B(C6F5)3 was also employed in the reduction of imines,[11]a Ferrier azaglycosylation,[11]b epoxide ring opening[11]c and reduction of alcohols with silane.[11]dB(C6F5)3 was also used for the multi-component synthesis of 1,8-dioxodecahydroacridines and α-amino nitriles.[12] Very recently, we also reported an efficient protocol for the synthesis of 5-substituted 1H-tetrazoles via [3 + 2] cyclo-addition, acylation reactions and one-pot oxidative esterification of aldehydes to carboxylic esters using B(C6F5)3.[13]To the best of our knowledge, this is the first demonstration of B(C6F5)3 promoted one-pot Biginelli cyclocondensation reaction.

2 Experimental

2.1 General experimental procedure for the synthesis of dihydropyrimidinones

A mixture of benzaldehyde 1a (106 mg, 1 mmol), ethyl acetoacetate 2a (130 mg, 1 mmol) and urea 3a (90 mg, 1.5 mmol) in EtOH (10 mL) was refluxed in the presence of B(C6F5)3 (18.1 mg, 1 mol%). After completion of reaction, as indicated by TLC analysis, the solvent was evaporated. The resulting mass was treated with ice-cold water and the solid obtained was filtered, washed with cold water, dried and re-crystallized from ethanol to give pure product (4a).

3 Results and Discussion

To evaluate the feasibility of using tris(pentafluorophenyl)borane [B(C6F5)3] as a catalyst in the Biginelli reaction, a model reaction (scheme 1) utilizing building blocks such as benzaldehyde (1a) ethyl acetoacetate (2a) and urea (3a) to get 5-ethoxycarbonyl-4-phenyl-6-methyl-3,4-dihydropyrimidin-2(1H)-one (4a), the reactions were performed under various reaction conditions and the results are summarized in table 1. The reaction of 1a, 2a and 3a in EtOH was first tested in the presence of 0.5 mol% of B(C6F5)3, the desired product 4a was obtained in 76% yield after 4 h (table 1, entry 1). Next, optimization of reaction conditions was undertaken to increase the yield of the product using different amounts of B(C6F5)3. Interestingly, the yield of 4a was significantly increased to 95% by employing 1 mol% of the catalyst (table 1, entry 2). Further improvement was not observed in terms of either reaction time or yield on increasing the amount of catalyst (table 1, entry 3). On the basis of these results, 1 mol% of B(C6F5)3 was considered to be the optimum concentration of catalyst for this reaction. In the absence of a catalyst, only 15% yield of the desired product was acquired even after longer reaction time (table 1, entry 4). The reaction was also executed under solvent-free conditions and afforded desired product in 70% yield after 5 h (table 1, entry 5). Furthermore, the catalytic efficiency of B(C6F5)3 was examined using different solvents, which showed prominent influence on reaction time and yields to obtain desired products (table 1, entries 6–9). Water, THF and toluene were not found to be suitable solvents for the reaction; however excellent yield of the desired product was obtained using CH3CN, although longer reaction time was required for the completion of reaction (table 1, entry 9). Among the solvents tested, EtOH was chosen as the best solvent with consideration to the reaction time, yields and environmental impact. Consequently, 1 mol% of B(C6F5)3 and EtOH as solvent were selected as the optimized reaction parameters for the synthesis of respective dihydropyrimidinones/thiones (table 1, entry 2).

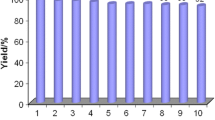

To establish the generality and scope of present methodology, various aromatic and heteroaromatic aldehydes (1a-o) were treated with urea or thiourea (3a/3b) and 1,3-dicarbonyl compounds (2a-c) under optimized reaction conditions to afford corresponding dihydropyrimidinones/thiones and the results are summarized in table 2.

It was observed that the compounds containing both electron-withdrawing and electron-donating substituents on aromatic ring reacted efficiently under the present reaction conditions to obtain corresponding 3,4-dihydropyrimidin-2(1H)-ones/thiones (4a-h,4q,4r) in excellent yields and high purity; however, ortho-substituted aromatic aldehydes (1c,1g) required longer reaction time to achieve desired products in high yields. To check the compatibility and mildness of the present reaction conditions, the reactions were carried out using aromatic aldehydes tethered with acid-sensitive protecting groups (1i,1j) under similar reaction conditions. It is noteworthy that acid-sensitive protecting groups such as TBDMS and TBDPS were unaffected and high yields of products (4i,4j) were obtained. The novel aspect of the present methodology was successfully extended to various heterocycles, which proceeded smoothly to afford the corresponding dihydropyrimidinones (4k-o) in good to excellent yields. However, heterocyclic aldehydes reacted relatively, in a sluggish manner, as compared to aromatic aldehydes. The yield of the desired products dropped significantly in case of 3,5-dimethyl-1-phenyl-1H-pyrazole-4-carbaldehyde (1n) and 7-hydroxy-4-methyl-2-oxo-2H-chromene-6 carbaldehyde (1o). To generalize the catalytic efficiency of B(C6F5)3 for the Biginelli reaction, we employed thiourea (3b) instead of urea (3a) under similar reaction conditions and obtained corresponding 3,4-dihydropyrimidin-(2H)-thiones (4p-s) in high yields, which are also of much interest with regard to biological activity. Comparatively, thiourea (3b) was found to be more reactive than urea (3a) (table 2, entry 1 vs. 16, entry 2 vs. 17 and entry 8 vs. 18). We further investigated the scope of the present protocol by replacing β-keto ester (2a) with β-diketone (2c). Notably, β-keto ester 2a exhibited better reactivity over the β- diketone 2c (entry 1 vs. 20, entry 2 vs. 22 and entry 11 vs. 21). The results mentioned earlier clearly indicate the generality and scope of the present methodology for the synthesis of 3,4-dihydropyrimidin-2(1H)-ones/ thiones expeditiously using a wide range of substrates. The notable features of this methodology are; mild reaction conditions, cleaner reaction, low catalyst loading, simple experimental and isolation procedures as well as tolerance of varied functional groups such as TBDMS, TBDPS, alkoxy, hydroxyl, nitro, chloro, bromo and nitrile under the present reaction conditions, which makes it a useful and attractive process for the synthesis of 3,4-dihydropyrimidin-2(1H)-ones/thiones.

Encouraged by the results mentioned above, we next examined the feasibility of the present protocol to synthesize biologically important molecule such as monastrol (mitotic kinesin Eg5 inhibitors) in large scale. On large-scale operation, the reaction of 3-hydroxy benzaldehyde (1w) (5 g, 1 equiv.) with equimolar amounts of ethyl acetoacetate (2a) (5.3 g, 1 equiv.) and thiourea (3b) (4.6 g, 1.5 equiv.) by employing (0.74 g, 1 mol%) of B(C6F5)3 in EtOH (40 mL) was refluxed for 3 h to achieve monastrol in 88% yield with 96.7% purity (scheme 2).

Presumably, the reaction may proceed via formation of acyl imine intermediate (6) formed by the reaction of aldehyde and urea, which is activated by co-ordination of B(C6F5)3 (key and rate-limiting step) and undergoes subsequent nucleophilic attack by the active methylene carbon of the β-dicarbonyl compounds through its enol form to produce open chain ureide (8), followed by intramolecular cyclo-addition and concomitant loss of water to afford dihydropyrimidinone (4a) (scheme 3).

4 Conclusions

We have demonstrated an extremely facile and efficient protocol for the synthesis of 3,4-dihydropyrimidin-2-(1H) ones and their thione analogues via one-pot cyclocondensation of aldehydes, urea/thiourea and β-ketoester/ β-diketone using catalytic amount of B(C6F5)3. The resulting protocol was proved to be suitable for a wide range of substrates. Furthermore, the present methodology was effectively extended to the large-scale synthesis of monastrol, which signifies its suitability for industrial application. Moreover, this method offers several advantages including mild reaction conditions, eco-friendliness, low catalyst loading, low toxicity, short reaction time, high yields and purity. Another important aspect of this procedure is tolerance of acid-sensitive protecting groups such as TBDMS and TBDPS and compatibility with a variety of functional groups under the present reaction conditions.

References

(a) Roy S R, Jadhavar P S, Seth K, Sharma K K and Chakraborti A K 2011 Synthesis 2261; (b) Simon C, Constantieux T and Rodriguez J 2004 Eur. J. Org. Chem. 4957

Biginelli P 1893 Gazz. Chim. Ital. 23 360

(a) Goldman S and Stoltefuses J 1991 Angew. Chem. Int. Ed. Engl. 30 1559; (b) Kappe C O 1993 Tetrahedron 49 6937; (c) Wan J P and Liu Y 2010 Synthesis 23 3943; (d) Kappe C O 2000 Acc. Chem. Res. 33 879

(a) Maliga Z, Kapoor T M and Mitchison T J 2002 Chem. Biol. 9 989; (b) Debonis S, Simorre J P, Crevel I, Lebeau L, Skoufias D A, Blangy A, Ebel C, Gans P, Cross R, Hackney D D, Wade R H and Kozielski F 2003 Biochemistry 42 338; (c) Atwal K S, Swanson B N, Unger S E, Floyd D M, Moreland S, Hedberg A and O’Reilly B C 1991 J. Med. Chem. 34 806; (d) Grover G J, Dzwonczyk S, McMullen D M, Normandin D E, Parham C S, Sleph P G and Moreland S 1995 Cardiovasc. Pharmacol. 26 289; (e) Patil A D, Kumar N V, Kokke W C, Bean M F, Freyer A J, Debrosse C, Mai S, Truneh A, Faulkner D J, Carte B, Breen A L, Hertzberg R P, Johnson R K, Westly J W and Ports B C M 1995 J. Org. Chem. 60 1182; (f) Snider B B and Shi Z 1993 J. Org. Chem. 58 3828; (g) S Panda S, Khanna P and Khanna L 2012 Curr. Org. Chem. 16 507; (h) Suresh and Sandhu J S 2012 Arkivok 1 66

(a) Chari M A and Syamasundar K 2004 J. Mol. Catal. A. Chem. 221 137; (b) Kotharkar S A, Jadhav M R, Nagawade R R, Bahekar S S and Shinde D B 2005 Lett. Org. Chem. 2 662; (c) Heravi M M, Bakhtiari K and Bamoharram F F 2006 Catal. Commun. 7 373; (d) Amini M M Shaabani A and Bazgir A 2006 Catal. Commun. 7 843; (e) Adibi H, Samimi H A and Beygzadeh M 2007 Catal. Commun. 8 2119; (f) Shirini F, Zolfigol M A and Abri A R 2008 J. Iran Chem. Soc. 5 96; (g) Ma Y, Qian C T, Wang L M and Yang M 2000 J. Org. Chem. 65 3864; (h) Kumar K A, Kasturaiah M, Reddy C S and Reddy C D 2001 Tetrahedron Lett. 42 7873; (i) Hu E H, Sidler D R and Dolling U H 1998 J. Org. Chem. 63 3454; (j) Dondoni A, and Massi A 2001 Tetrahedron Lett. 42 7975; (k) Beltran D A, Romero L L, Corona V H L, Zamora E G and Silva G N 2006 Molecules 11 731; (l) Sharghi H and Jokar M 2009 Synth. Commun. 39 958

(a) Varala R, Alam M M and Adapa S R 2003 Synlett 67; (b) Ahmed N and van Lier J E, 2007 Tetrahedron Lett. 48 5407; (c) Paraskar A S, Dewkar G K and Sudalai A 2003 Tetrahedron Lett. 44 3305; (d) Adib M, Ghanbary K, Mostofi M and Ganjali M R 2006 Molecules 11 649; (e) Han X, Xu F, Luo Y and Shen Q 2005 Eur. J. Org. Chem. 1500; (f) Shirini F, Zolfigol M A and Mollarazi E 2006 Synth. Commun. 36 2307; (g) Reddy C V, Mahesh M, Raju P V K, Babu T R and Reddy V N 2002 Tetrahedron Lett. 43 2657; (h) Su W K, Li J J, Zheng Z G and Shen Y C 2005 Tetrahedron Lett. 46 6037; (i) Ranu B C, Hajra A and Jana U 2000 J. Org. Chem. 65 6270

(a) Maradur S P and Gokavi G S 2007 Catal. Commun. 8 279; (b) Rafiee E and Shahbazi F 2006 J. Mol. Catal. A: Chem. 250 57; (c) Singh K, Arora D and Singh S 2006 Tetrahedron Lett. 47 4205; (d) Pandiarajan C K 2009 Tetrahedron. Lett 50 2222; (e) Nasr-Esfahani M, Hoseini S J and Mohammadi F 2011 Chin. J. Catal. 32 1484; (f) Asghari S Tajbakhsh M, Kenari B J and Khaksar S 2011 Chin. Chem. Lett. 22 127; (g) Litvic M, Vecenaj I, Ladisic Z M, Lovric M, Vinkovic V and Litvic M F 2010 Tetrahedron 66 3463; (h) Kulkarni M G, Chavhan S W, Shinde M P, Gaikwad D D, Borhade A S, Dhondge A P, Shaikh Y B, Ningdale V B, Desai M P and Birhade D R 2009 Beilstein J. Org. Chem. 5 4; (i) Fazaeli R, Tangestaninejad S, Aliyan H and Moghadam M 2006 Appl. Catal., A 309 44

(a) Wipf P and Cunningham A 1995 Tetrahedron Lett. 36 7819; (b) Stefani H A and Gatti P M 2000 Synth. Commun. 30 2165; (c) Yadav J S, Reddy B V S, Reddy K B, Raj K S and Prasad A R 2001 J. Chem. Soc., Perkin Trans. 1 1 1939; (d) Ramos L M, Guido B C, Nobrega C C, Correa J R, Silva R G, de Oliveira H C B, Gomes A F, Gozzo F C and Neto B A D 2003 Chem. Eur. J. 19, 4156; (e) Suzuki I, Iwata Y and Takeda K 2008 Tetrahedron Lett. 49 3238

(a) Starcevich J T, Laughlin T J and Mohan R S 2013 Tetrahedron Lett. 54 983; (b) Wan J. –P, Lin Y, Hu K and Liu Y 2014 Beilstein J. Org. Chem. 10 287; (c) Qu H, Li X, Mo F and Lin X 2013 Beilstein J. Org. Chem. 9 2846; (d) Kolvari E, Nadiya K and Ozra A 2014 Tetrahedron 70 1383; (e) Oliverio M, Costanzo P, Nardi M, Rivalta I and Procopio A 2014 ACS Sustainable Chem. Eng. 2 1228

(a) Ishihara K and Yamamoto H 1999 Eur. J. Org. Chem. 527; (b) Thirupathi P, Neupane L N and Lee K H 2011 Tetrahedron 67 7301; (c) Shchepin R, Xu C and Dussault P 2010 Org. Lett. 12 4772; (d) Chandrasekhar S, Chandrashekar G, Vijeender K and Reddy M S 2006 Tetrahedron Lett. 47 3475; (e) Chandrasekhar S, Reddy C R and Babu B N 2002 J. Org. Chem. 67 9080

(a) Chen D and Klankermayer J 2008 Chem. Commun. 18 2130; (b) Chandrasekhar S, Reddy C R and Chandrashekar G 2004 Tetrahedron Lett. 45 6481; (c) Chandrasekhar S, Raji Reddy C, Babu B N and Chandrashekar G 2002 Tetrahedron Lett. 43 3801; (d) Blackwell J M, Sonmor E R, Scoccitti T and Piers W E 2000 Org. Lett. 2 3921

(a) Chandrasekhar S, Srinivasa Rao Y, Sreelakshmi L, Mahipal B and Raji Reddy C 2008 Synthesis 11 1737; (b) Yaragorla S, Sudhakar A and Kiranmai N 2014 Indian J. Chem. Sec B 53 1471

(a) Prajapti S K Nagarsenkar A and Babu B N 2014 Tetrahedron Lett. 55 3507; (b) Prajapti S K Nagarsenkar A and Babu B N 2014 Tetrahedron Lett. 55 1784; (c) Guggilapu S D, Prajapti S K and Babu B N 2015 Tetrahedron Lett. 56 889

Acknowledgements

The authors thank Department of Pharmaceuticals, Ministry of Chemicals and Fertilizers for providing funds and also acknowledge Indian Institute of Chemical Technology, Hyderabad, for the scientific and instrumental support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information

Spectral data for the synthesized compounds can be accessed at www.ias.ac.in/chemsci.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

PRAJAPTI, S.K., GUPTA, K.K. & BABU, B.N. B(C6F5)3 catalyzed one-pot three-component Biginelli reaction: An efficient and environmentally benign protocol for the synthesis of 3,4-dihydropyrimidin-2(1H)-ones/thiones. J Chem Sci 127, 1047–1052 (2015). https://doi.org/10.1007/s12039-015-0867-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-015-0867-1