Abstract

2,4,5-Trisubstituted pyrrole derivatives were efficiently synthesized by one-pot condensation of 1,3-diones, α-bromoacetophenones, and ammonium acetate in ionic liquid [bmim]BF4. The new synthetic method offers multisubstituted pyrroles with the advantages of mild reaction conditions, operational simplicity, higher yield, and environmental friendliness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

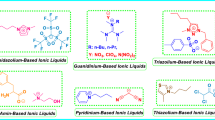

Pyrroles represent an important class of heterocycles in organic chemistry. They are structural units in many natural products and pharmaceuticals and key intermediates for synthesis of a variety of biologically active molecules and functional materials [1, 2]. They are also the key structural fragment of heme and chlorophyll, two pigments essential for life [3, 4]. Examples of pyrrole-derived drugs include the nonsteroidal antiinflammatory compound tolmetin, the anticancer drug candidate tallimustine, and the cholesterol-lowering agent atorvastatin calcium (Lipitor), one of the top-selling drugs worldwide (Fig. 1) [5–7].

While many classical methods including Knorr [8], Paal–Knorr [9], and Hantzsch syntheses [10] are known for synthesis of pyrrole derivatives, some of them involve tedious multistep synthetic operations and explosive starting materials. On the other hand, several catalytic methodologies have been established for synthesis of trisubstituted pyrroles, including N-substituted pyrroles. Among the transition metals used in synthesis of trisubstituted pyrroles, copper [11–17] and palladium [18, 19] metals have been extensively investigated, as well as other metals including Ag [20–22], Au [23], Rh [24], Ir [25], Zr [26], Bi [27], In [28], Co [29], Zn [30], and Yb [31]. Though some metal catalysts have proven to be efficient and inexpensive, others have limitations regarding cost, involving multiple steps, and moderate yield. In spite of these outstanding efforts, it is still challenging to prepare polysubstituted pyrroles possessing diverse substituents directly from commercially available starting materials in a one-pot simple synthetic operation. Multicomponent reactions (MCRs), in which a number of multiple reactions are combined into a one-pot synthetic operation, have been widely used to prepare bioactive heterocyclic compounds [16, 32–34]. Recently, ionic liquids have attracted extensive interest as benign reaction media for use in organic synthesis because of their unique properties of nonvolatility, nonflammability, recyclability, and ability to dissolve a wide range of materials [35]. Ionic liquid-promoted synthesis of pyrroles was recently accomplished by Siddiqui et al. [36]. Therefore, development of an environmentally benign, simple, and efficient protocol for synthesis of substituted pyrrole derivatives is in great demand.

Inspired by previous literature on development of environmentally benign methodologies for synthesis of heterocyclic compounds [37–39], we turned our attention to three-component condensation of 1,3-diketones, α-bromoacetophenones, and ammonium acetate in ionic liquid [bmim]BF4. Herein, we report a novel, efficient, and green procedure for synthesis of 2,4,5-trisubstituted pyrroles via three-component condensation. To the best of our knowledge, this methodology has not been reported in literature.

The three-component condensation reaction was initiated with acetylacetone, α-bromoacetophenone, and ammonium acetate (1 equiv) in presence of ionic liquid [bmim]BF4 at 70 °C to target synthesis of substituted pyrrole. To our surprise, in this three-component condensation, the cyclization product 3a was obtained in moderate yield. Screening of solvents using different temperatures and times was carried out to achieve high yield of desired pyrrole (Table 1).

First, we investigated the effect of temperature on reaction rate and product yield. This showed that desired product was not formed at room temperature even after 12 h (Table 1, entry a). The yield of product 3a was improved and the reaction time was shortened as the temperature was increased from 35 to 70 °C (Table 1, entry c), so the most appropriate reaction temperature was 70 °C. When we employed the same reaction condition using other solvents (DMF, DMSO, toluene, CH3CN, and DCE) and ecofriendly solvent (PEG), product 3a was formed in low yields after a long time (Table 1, entries d–i). These results show that 2 equiv NH4OAc was essential to the reaction, and the best result was obtained when the reaction was carried out with 2 equiv NH4OAc in ionic liquid [bmim]BF4 at 70 °C.

The base NH4OAc acts as proton transporter as well as reactant. Furthermore, we found that the yields were clearly affected by the quantity of NH4OAc used in the reaction. The greater the quantity of NH4OAc used from 1 to 2 equiv, the higher the obtained product yield (up to 85 %) (Table 1, entry c).

With the set of optimized reaction conditions, we extended this method to other α-bromoacetophenones such as 4-methyl-, 3-methyl-, and 3,4,5-trimethoxy-substituted α-bromoacetophenones. In all cases, corresponding pyrrole derivatives were obtained in good yields (Table 2, entries a, b, e, h, and i). Furthermore, we examined the reactivity of different 1,3-diones. Interestingly, other 1,3-diones such as ethyl acetoacetate, methyl acetoacetate, and heptane-3,5-dione afforded corresponding pyrroles in good yields as well (Table 2, entries c, d, f, and g). In addition, this method works not only with linear 1,3-diones but also with cyclic 1,3-diones such as dimedone and cyclohexane-1,3-dione. In the case of cyclic diketones, corresponding pyrroles were obtained in lower yields (Table 2, entries j and k) than acyclic counterpart. In all cases, the reactions proceeded efficiently in ionic liquid [bmim]BF4 at 70 °C and products were obtained in good yields.

Recovery and reusability of [bmim]BF4

After the reaction, the reaction mass was cooled to room temperature (RT) and the crude product extracted with ether (2–3 times). The combined ether layers were subjected to flash chromatography to obtain pure product, and trace amount of ether was removed from the ionic liquid using vacuum pump at 90 °C for about 13 h, followed by use in subsequent runs without further purification.

The recovered ionic liquid was further used as solvent in the second cycle of the condensation reaction. As shown in Fig. 2, though the activity of the ionic liquid diminished in terms of product yield from 85 to 55 % in the fifth cycle, the yields of substituted pyrroles were almost the same during two recycles.

Based on the experimental results, a plausible mechanism for the ammonium acetate-catalyzed condensation for formation of derivatives 3 is proposed in Scheme 1. Initially, ammonium acetate condensation between 1,3-dione 1 and α-bromoacetophenones 2 would give intermediate 4. Later, displacement of bromine would furnish intermediate 5, which underwent aromatization to give product 3.

In conclusion, an efficient, environmentally friendly, and simple procedure for condensation of 1,3-diketones, α-bromoacetophenones, and ammonium acetate to synthesize trisubstituted pyrroles in ionic liquid is reported. Mild reaction conditions, operational simplicity, higher yields (55–85 %), short reaction time, cheap starting materials, and environmental friendliness are notable features of this procedure. Meanwhile, ionic liquid [bmim]BF4 could be reused in up to five cycles without much loss of activity. The methodology opens a new green route to synthesis of trisubstituted pyrrole derivatives with simple workup.

Supplementary data

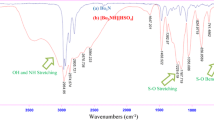

Experimental details, characterization data, and 1H and 13C NMR spectra of products can be found in the online version at http://dx.doi.org/10.1007/s11164-016-2501-3.

References

P. Novak, K. Muller, S.V. Santhanam, O. Hass, Chem. Rev. 97, 207 (1997)

S. Gabriel, M. Cecius, K. Fleury-Frenette, D. Cossement, M. Hecq, N. Ruth, R. Jerome, C. Jerome, Chem. Mater. 19, 2364 (2007)

R.J Sundburg, in Comprehensive Heterocyclic Chemistry II, ed by A.R. Katritzky, C.W. Rees, E.F.V. Scriven (Pergamon, Oxford, 1996), vol 2, p. 119

H. Fan, J. Peng, M.T. Hamann, J.F. Hu, Chem. Rev. 108, 264 (2008)

L. Zeng, E.W. Miller, A. Pralle, E.Y. Isacoff, C.J. Chang, J. Am. Chem. Soc. 128, 10 (2006)

G. La Regina, R. Silvestri, M. Artico, A. Lavecchia, E. Novellino, O. Befani, P. Turini, E. Agostinelli, J. Med. Chem. 50, 922 (2007)

B.R. Clark, R.J. Capon, E. Lacey, S. Tennant, J.H. Gill, Org. Lett. 8, 701 (2006)

L. Knorr, Dtsch. B. Chem. Ges. 17, 1635 (1884)

C. Paal, Dtsch. B. Chem. Ges. 18, 367 (1885)

A. Hantzsch, Dtsch. B. Chem. Ges. 23, 1474 (1890)

H. Rao, S.P. Rao, A.V. Bhadra, S. Sivakumar, Synth. Commun. 45, 2712 (2015)

K.P. Hanuman, V.S. Kamlesh, M. Kaliyappan, C.C. Atul, New J. Chem. 39, 4631 (2015)

H.M. Lokman, Y. Fei, Z. Yan, W. Jianbo, Tetrahedron 70, 6957 (2014)

L. Jihui, N. Luc, Org. Lett. 15, 6124 (2013)

L. Ende, X. Cheng, W. Chengyu, S. Xia, L. Yanzhong, RSC Adv. 3, 22872 (2013)

B.V.S. Reddy, M.R. Reddy, Y.G. Rao, J.S. Yadav, B. Sridhar, Org. Lett. 15, 464 (2013)

Z. Qingwei, H. Ruimao, Tetrahedron Lett. 51, 4512 (2010)

S.G. Chandru, W.-P. Hu, A.M. Garkhedkar, S.S.K. Boominathan, J.-J. Wang, Chem. Commun. 51, 13795 (2015)

X.-L. Lian, Z.-H. Ren, Y.-Y. Wang, Z.-H. Guan, Org. Lett. 16, 3360 (2014)

L. Jianquan, F. Zhongxue, Z. Qian, L. Qun, B. Xihe, Angew. Chem. Int. Ed. 52, 6953 (2013)

R.J. Billedeau, K.R. Klein, D. Kaplan, Y. Lou, Org. Lett. 15, 1421 (2013)

Y.-Q. Zhang, D.-Y. Zhu, B.-S. Li, Y.-Q. Tu, J.-X. Liu, Y. Lu, S.-H. Wang, J. Org. Chem. 77, 4167 (2012)

H.M. Peng, J. Zhao, X. Li, Adv. Synth. Catal. 351, 1371 (2009)

B. Chattopadhyay, V. Gevorgyan, Org. Lett. 13, 3746 (2011)

H.-Y. Wang, D.S. Mueller, R.M. Sachwani, R. Kapadia, H.N. Londino, L. Anderson, l. J. Org. Chem. 76, 3203 (2011)

A. Rahmatpour, Appl. Organomet. Chem. 25, 585 (2011)

D. Bandyopadhyay, A. Chavez, B. K. Banik, in Abstracts of Papers, 245th ACS National Meeting & Exposition, New Orleans, LA, United States, April 7–11, 2013

S.K. Mahato, J. Vinayagam, S. Dey, A.K. Timiri, S. Chatterjee, P. Jaisankar, Aust. J. Chem. 66, 241 (2013)

S.K. De, Heteroat. Chem. 19, 592 (2008)

M.L. Kantam, S. Priyadarshini, P.J. Amal Joseph, P. Srinivas, A. Vinu, K.J. Klabunde, Y. Nishina, Tetrahedron 68, 5730 (2012)

G.R. Reddy, T.R. Reddy, S.C. Joseph, K.S. Reddy, C.L.T. Meda, A. Kandale, D. Rambabu, G. Rama Krishna, C. Mallareddy, K.V.L. Parsa, K. Shiva Kumar, K. Pal, RSC Adv. 2, 9142 (2012)

M.A.P. Martins, C.P. Frizzo, D.N. Moreira, L. Buriol, P. Machado, Chem. Rev. 109, 4140 (2009)

H.M. Meshram, V.M. Bangade, B.C. Reddy, G.S. Kumar, P.B. Thakur, Int. J. Org. Chem. 2, 159 (2012)

S.N. Murthy, B. Madhav, A. Vijay Kumar, K.R. Rao, Y.V.D. Nageswar, Helv. Chim. Acta 92, 2118 (2009)

H. Livier-Bourbigou, L. Magna, D. Morvan, Appl. Catal. A Gen. 373, 1 (2010)

I.R. Siddiqui, K. Devesh, S. Shamim, J. Heterocycl. Chem. 50, E111 (2013)

Y.L. Li, D.G. Gu, X.P. Xu, S.J. Ji, Chin. J. Chem. 27, 1558 (2009)

Y.L. Li, H. Chen, C.L. Shi, D.Q. Shi, S.J. Ji, J. Comb. Chem. 12, 231 (2010)

Y.L. Li, B. Zhao, B.X. Du, Q.S. Jiang, X.S. Wang, C.S. Cao, Tetrahedron Lett. 54, 227 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, G.N., Likhar, P.R. Green multicomponent reaction for synthesis of trisubstituted pyrroles in ionic liquid [bmim]BF4 . Res Chem Intermed 42, 6873–6879 (2016). https://doi.org/10.1007/s11164-016-2501-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-016-2501-3