Abstract

An efficient and convenient procedure has been described for one-pot multi-component synthesis of tetrahydrobenzo[b]pyrans known as 4H-chromenes and 1,4-dihydropyrano[2,3-c]pyrazole derivatives in the presence of nano-titania-supported Preyssler-type heteropolyacid, n-TiO2/H14[NaP5W30O110], as a heterogeneous catalyst. The reactions proceeded smoothly under ultrasound irradiation condition to afford the corresponding products in quantitative yields. The catalyst can be easily recovered and reused for several successive fresh runs with no significant loss of catalytic activity.

An efficient and convenient procedure has been described for one-pot multicomponent synthesis of 4H-chromenes and 1,4-dihydropyrano[2,3-c]pyrazoles using nano-titania-supported Preyssler-type heteropolyacid as a heterogeneous and reusable catalyst. The reactions proceed smoothly under ultrasoundaccelerated condition to afford the corresponding products in quantitative yields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Multi-component coupling reactions (MCRs) are known as efficient procedures for generating various products in organic and medical chemistry, and have attracted much industrial and academic interests.[1, 2] Moreover, these reactions appear as useful sources for approaching small drug-like molecules with several levels of structural diversity.[3] In such processes, three or more compounds undergo consecutive reactions in a single event to form new products, which contain the essential parts of all the starting materials.

Pyrans belong to an important class of heterocyclic compounds which exhibit wide range of biological activities,[4] and are widely employed as cosmetics, pigments and potentially biodegradable agrochemicals.[5] In recent years, various methods have emerged from the literature for the synthesis of these compounds. Most of these methods employ various catalysts such as ionic liquids,[6] hexadecyltrimethyl ammonium bromide,[7] Mg/La mixed metal oxides,[8] and nano-silica[9] under different conditions including the use of reactants in solid or molten state,[10] and electrolysis condition.[11]

In addition, pyrano[2,3-c]pyrazoles constitute important precursors to promising drugs in the field of medicinal chemistry and exhibit wide range of biological activities.[12–14] Hence, development of new synthetic strategies in this field using easily accessible and benign catalysts appears to be an interesting challenge. The most used methods for the synthesis of pyrano[2,3-c]pyrazoles involve three-component cyclocondensation of 3-methyl-1-phenylpyrazolin-5-one with aldehydes and malononitrile, that benefits the use of ionic liquids,[15] refluxing in water,[16, 17] or using piperidine,[18] cupreine,[19] and MgO[20] as catalysts. However, many of these methods suffer from certain drawbacks such as low yield, harsh reaction conditions, prolonged reaction time, and application of hazardous and/or costly catalysts and solvents. Therefore, development of greener, clean, and environmentally friendly approaches is still in demand. Moreover, application of ultrasound irradiation in so-called ‘sonochemistry’ has received enormous attention since it offers a versatile and challenging technique in organic synthesis. Ultrasonic irradiation technique has been employed not only to decrease reaction times but also to improve yields in a large variety of organic syntheses.[21–23]

Currently, metal-oxide nano-particles as versatile heterogeneous catalysts have offered a new and environmentally benign approach towards modern synthetic organic chemistry.[24–27] Recently, we have reported the use of nano-magnetic complex lanthanum strontium magnesium oxide as an efficient catalyst in ultrasound-accelerated synthesis of the titled compounds.[28]

It has been known that the supported or bulk-type Preyssler-type heteropolyacid can exhibit high catalytic activity in various organic reactions.[29, 30] In this regard, nano-titania-supported Preyssler-type heteropolyacid has been explored as highly efficient solid acid catalyst which effects various chemoselective reactions in liquid media.[31, 32]

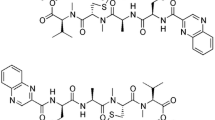

With regard to the importance of tetrahydrobenzo[b]pyrans (4H-chromenes) and pyrano[2,3-c]pyrazoles in synthetic organic chemistry, herein, we wish to report the one-pot three-component synthesis of highly functionalized 4H-chromenes 2a–k and 4H-pyrano[2,3-c]pyrazoles 3a–l from the ultrasound-promoted reactions between aldehydes 1, malononitrile and 5,5-dimethylcyclohexan-1,3-dione (dimedone) or 3-methyl-1-phenyl-2-pyrazolin-5-one, respectively, in the presence of nano-titania-supported Preyssler-type heteropolyacid as an efficient and reusable heterogeneous catalyst in EtOH at 40°C (scheme 1).

2 Experimental

2.1 Materials and instruments

All the chemicals used in this research including the commercially available micro-titania were purchased from Merck Chemical Company and used without purification. Titanium tetra n-butoxide (TTB) obtained from Fluka Company was converted to nano-sized titania with different particle sizes according to the reported procedure.[31, 33] Preyssler acid was prepared as reported in the literature.[34] IR spectra were recorded on a Brucker 500 Scientific Spectrophotometer from KBr pellets. 1H and 13C NMR spectra were obtained on a Bruker 300 MHz Avance spectrometer using d 6-DMSO as solvent. Ultrasonication was performed in a TRANSSONI 660/H ultrasound cleaner with a frequency of 35 KHz and an output power of 70 W.

2.2 Preparation of the nano-titania supported Preyssler-type heteropolyacid nano-TiO2/H14[NaP5W30O110]

Nano-titania particles of 15 nm size (1.0 g) were added to a solution of Preyssler acid (4.5 g) in water (30 mL) and the mixture was stirred at 20°C for 24 h. Then, the resulting mixture was centrifuged to separate the resulting solid material which was stirred in fresh water (30 mL) for 1 h. Finally, the mixture was centrifuged, washed with ethanol and dried in an oven at 100°C. The Preyssler heteropolyacid content of the resulting catalyst was determined by titration of the combined water filtrate against 0.01 N aqueous NaOH solution that was found to be 0.0056 mmol Preyssler acid per 1 g 15 nm titania.[32]

2.3 General procedure for one-pot synthesis of tetrahydrobenzo[b]pyrans and 1,4-dihydropyrano[2,3-c]pyrazoles

To a mixture of aldehyde (1 mmol), malononitrile (1 mmol), dimedone (1 mmol) or 3-methyl-1-phenylpyrazolin-5-one, in absolute ethanol (5 mL), was added nano-titania supported Preyssler-type heteropolyacid catalyst (25 mg) with 0.0056 mmol/g ratio. The reaction mixture was sonicated at 40°C for an appropriate time (see tables 3 and 4). After completion of the reaction as monitored by TLC, the resulting mixture was diluted with methanol (5 mL) and centrifuged to separate the solid catalyst. The filtrate was evaporated under reduced pressure to leave the solid product which was purified by crystallization from ethanol. Structures of the resulting products were established on the basis of their IR, 1H- and 13C-NMR spectra and physical properties that were consistent with those reported.[5, 9, 11, 17–20, 28, 35–41]

2.4 Recycling potential of the catalyst

In order to study the stability and potential reusability of the catalyst, the reaction mixture was centrifuged after the completion. The separated solid was washed with ethyl acetate (2 × 5 mL) and dried under reduced pressure (20°C). The recovered catalyst was reused for three consecutive fresh runs without any significant loss of activity (see tables 3 and 4, entry 1).

3 Results and discussion

3.1 Effect of the titania particle size

In the present study, various particle sizes of titania were prepared via sol–gel method according to the reported procedure.[31, 33] The resulted particle size distribution was estimated to be 15, 30 and 50 nm as determined by transmission electron microscopy (TEM) images. To investigate the effect of minimizing the particle size of the titania on the rate and yield of the titled reactions, initially we studied the reaction between benzaldehyde (1 mmol), malononitrile (1 mmol) and 5,5-dimethylcyclohexan-1,3-dione (1 mmol) in EtOH (5 mL) as the model reaction under reflux condition using various sizes of titania (25 mg) as the catalyst, and the results are schematically presented in figure 1.

As shown in figure 1, comparison of the reaction rates and yields resulted in the presence of various particle sizes of titania indicates that these two factors of the reaction are both improved with decreasing the size of titania nanoparticles. Moreover, no completion of conversion occurs when the reaction is carried out using micro-titania or in the absence of the catalyst.

These results are consistent with the BET-specific surface areas of titania of different particle sizes, and indicate that increasing the surface area of titania as catalyst can cause the improvement of reaction rate and yield as well. The BET results obtained from different particle sizes of nano-titania are shown in table 1.

3.2 Effect of supporting Preyssler acid on nano-titania

As previously reported,[31, 32] supporting the homogeneous Preyssler acid on the titania can alter the efficiency of the catalyst to improve the reaction yield. Here, we studied the effect of supporting Preyssler acid on nano-titania of 15 nm particle size as the favourite particle size. To find the most effective molar ratio of the Preyssler acid/nano-titania, we performed thermodynamic study of the adsorption of Preyssler acid on 15 nm titania. The amount of the adsorbed Preyssler acid per unit mass of the adsorbent (mg/g) as defined by (q e ) was calculated using the equation (1), where C o and C e are initial and final concentrations of Preyssler acid, respectively (mg/L=ppm), V is the volume of water as solvent (Lit) and m is the weight of nano-titania as adsorbent (g).[32]

3.3 Optimizing the reaction conditions

To establish the reaction conditions, the effect of molar ratio of the Preyssler acid/nano-titania on the aforementioned model reaction was studied under various conditions using the neat nano-titania as well as nano-titania-supported Preyssler-type heteropolyacid with different molar ratios (table 2).

The results summarized in table 2 clearly indicate the compelling effect of the Preyssler acid on the yield of the reaction (95%, entry 8) when supported on nano-titania in comparison with the yield (72%) obtained from the neat nano-titania as the catalyst (entry 3). In addition, the important role of nano-titania as the catalyst was approved by conducting the reaction under the catalyst-free condition and also in the presence of neat Preyssler acid that resulted in low (10%, entry 1) and medium (81%, entry 2) yields, respectively (entries 1 and 2). Among the green solvents EtOAc, t-BuOH, EtOH, H2O, and the mixed solvent EtOH/H2O examined in this reaction, EtOH was found as the solvent of choice which provided the highest rate and yield. Furthermore, the important role of ultrasound irradiation in the acceleration of these reactions is clearly understood by comparing the reaction times and yields carried out under ultrasound conditions (entry 16) with those obtained under conventional heating under reflux (entry 9).

The best result in terms of the reaction time (20 min) and yield (98%) was obtained when the reaction was conducted under ultrasound irradiation condition at 40°C using the Preyssler acid/nano-TiO2 catalyst in 0.0056 mmol/g ratio (entry 16). As seen in table 2 (entries 17 and 18), the reaction yield gradually diminishes with increasing the sonication temperature from 40°C to 50°C and 60°C. Seemingly, higher temperatures may cause the increase of side product formation in the presence of acidic catalyst. In fact, ultrasound irradiation at lower temperatures not only reduces the reaction times, but can also prevent the possible occurrence of side reactions such as polymerization, hydrolysis or functional group conversions that may occur at higher temperatures.

In order to develop the scope of these reactions, we conducted the reaction with a series of aromatic aldehydes 1a–n bearing different substituent groups under the determined optimized conditions as indicated in table 2 (entry 16). All the reactions proceeded smoothly to afford the respective products 2a–n in quantitative yields as summarized in table 3.

According to the data in table 3, aromatic aldehydes bearing electron-withdrawing groups generally exhibit higher reactivity in this reaction compared to those bearing electron-releasing groups. In addition, the ortho-substituted aldehydes generally undergo this reaction less readily than the meta- and para-substituted aldehydes (see entries 5–6 and 8–10). Difference in reactivity stems from the highest steric hindrance in ortho-substituted aldehydes that makes the carbonyl site less accessible to nucleophilic additions. To the best of our knowledge, most of the reported methods for the synthesis of the titled products are mainly applicable to the aromatic aldehydes. In contrast, as seen in table 3, the present method is not only suitable for aromatic aldehydes but can also successfully be applied to aliphatic, heteroaromatic, and α,β-unsaturated aldehydes (entries 12–14).

In a putative mechanism suggested for the formation of 4H-chromenes as shown in scheme 2, the intermediate (I) is produced upon initial condensation of aldehyde with malononitrile under the catalytic activity of nano-titania-supported Preyssler-type heteropolyacid. Subsequent nucleophilic addition of dimedone to the intermediate (I) followed successively by intramolecular cyclization to the intermediate (II), and rearrangement to furnish the 2-amino-5-oxo-5,6,7,8-tetrahydro-4H-chromenes. A similar mechanism may occur for the formation of 4H-pyrano[2,3-c]pyrazole derivatives.

These interesting results have encouraged us to extend the scope and generality of the successful application of nano-titania-supported Preyssler-type heteropolyacid catalyst to the synthesis of dihydropyrano[2,3-c]pyrazoles 3a–m by one-pot reaction between 3-methyl-1-phenylpyrazolin-5-one, aromatic aldehydes and malononitrile under optimized condition (table 2, entry 16); the results are summarized in table 4. As shown in this table, these reactions take place smoothly to furnish the respective products in high to excellent yields. In a similar manner observed for the previous reactions, the rates of these reactions are also governed by steric hindrance around the carbonyl group in the reacting aldehyde.

4 Conclusion

In conclusion, we have developed a novel and highly efficient protocol for ultrasound-accelerated one-pot synthesis of tetrahydrobenzo[b]pyrans called chromenes, and 1,4-dihydropyrano[2,3-c]pyrazole derivatives in the presence of nano-titania-supported Preyssler-type heteropolyacid as a heterogeneous catalyst. The reactions proceed smoothly to afford the corresponding products in quantitative yields at short reaction times. The catalyst can be easily recovered and reused for several successive fresh runs with no significant loss of catalytic activity.

References

Zhu J and Bienayme’ H 2005 Multicomponent reactions, Weinheim: Wiley-VCH

Hall N 1994 Science 266 32

Domling A and Ugi I 2000 Angew. Chem. Int. Ed. 39 3169

Bonsignore L, Loy G, Secci D and Calignano A 1993 Eur. J. Med. Chem. 28 517

Khaksar S, Rouhollahpour A and Talesh S M 2012 J. Fluorine Chem. 141 11

Peng Y and Song G 2007 Catal. Commun. 8 111

Jin T-S, Liu L-B, Zhao Y and Li T-S 2005 Synth. Commun. 35 1859

Seshu B N, Pasha N, Venkateswara R K T, Sai P P S and Lingaiah N 2008 Tetrahedron Lett. 49 2730

Banerjee S, Horn A, Khatri H and Sereda G 2011 Tetrahedron Lett. 52 1878

Kaupp G, Naimi-Jamal M R and Schmeyers J 2003 Tetrahedron 59 3753

Fotouhi L, Heravi M M, Fatehi A and Bakhtiari K 2007 Tetrahedron Lett. 48 5379

Kuo S C, Huang L J and Nakamura H 1984 J. Med. Chem. 27 539

Wang J-L, Liu D, Zhang Z-J, Shan S, Han X, Srinivasula S M, Croce C M, Alnemri E S and Huang Z 2000 Proc. Natl. Acad. Sci. USA 97 7124

Zaki M E A, Soliman H A, Hiekal O A and Rashad A E 2006 Z. Naturforsch. C 61 1

Balaskar R S, Gavade S N, Mane M S, Shingate B B, Shingare M S and Mane D V 2010 Chinese Chem. Lett. 21 1175

Mecadon H, Rohman M R, Kharbangar I, Laloo B M, Kharkongor I, Rajbangshi M and Myrboh B 2011 Tetrahedron Lett. 52 3228

Heravi M M, Ghods A, Derikvand F, Bakhtiari K and Bamoharram F F 2010 J. Iran Chem. Soc. 7 615

Vasuki G and Kumaravel K 2008 Tetrahedron Lett. 49 5636

Gogoi S and Zhao C-G 2009 Tetrahedron Lett. 50 2252

Sheibani H and Babaie M 2010 Synth. Commun. 40 257

Azarifar D, Nejat-Yami R, Sameri F and Akrami Z 2012 Lett. Org. Chem. 9 435

Azarifar D and Sheikh D 2012 Helv. Chim. Acta 95 1217

Azarifar D and Sheikh D 2011 Chem. Het. Comp. 47 1128

Teimouri A and Chermahini A N 2011 J. Mol. Catal. A: Chem. 346 39

Itoh H, Utamapanya S, Stark J V, Klabunde K J and Schlup J R 1993 Chem. Mater. 5 71

Guzman J and Gates B C 2001 Nano Lett. 1 689

Choudary B M, Kantam M L, Ranganath K V S, Mahendar K and Sreedhar B 2004 J. Am. Chem. Soc. 126 3396

Azarifar A, Nejat-Yami R, Al-Kobaisi M and Azarifar D 2013 J. Iran Chem. Soc. 10 439

Bamoharram F F, Heravi M M and Omidinia R 2010 Asian J. Chem. 24 5582

Heravi M M, Bamoharram F F, Rajabzadeh G, Seifi N and Khatami M 2006 J. Mol. Catal. A: Chem. 259 213

Rahimizadeh M, Rajabzadeh G, Khatami S-M, Eshghi H and Shiri A 2010 J. Mol. Catal. A: Chem. 323 59

Azarifar D, Khatami S-M, Zolfigol M A and Sheikh D 2013 J. Iran Chem. Soc. 10 1039

Rajabzadeh G and Jalalian A 2007 Proceedings of the 14th International Sol-gel Conference, Montpellier, France

Alizadeh M H, Harmalker S P, Jeannin Y, Martin-Frere J and Pope M T 1985 J. Am. Chem. Soc. 107 2662

Peng Y, Song G and Dou R 2006 Green Chem. 8 573

Gao Y, Tu S, Li T, Zhang X, Zhu S, Fang F and Shi D 2004 Synth. Commun. 34 1295

Yu J and Wang H 2005 Synth. Commun. 35 3133

Gao S, Tsai C H, Tseng C and Yao C-F 2008 Tetrahedron 64 9143

Wang L-M, Shao J-H, Tian H, Wang Y-H and Liu B 2006 J. Fluorine Chem. 127 97

Jin T S, Zhao R Q and Li T S 2006 Arkivoc xiv 176

Mohammadi-Ziarani G, Abbasi A, Badiei A and Aslani Z 2011 E-J. Chem. 8 293

Vasyun’kina T N, Bykova L M, Plotkin V N and Ramsh S M 2005 Russ. J. Org. Chem. 41 742

Acknowledgements

The authors wish to thank the Research Council of Bu-Ali Sina University and also the Ministry of Science, Research and Technology of Islamic Republic of Iran for financial support to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

AZARIFAR, D., KHATAMI, SM. & NEJAT-YAMI, R. Nano-titania-supported Preyssler-type heteropolyacid: An efficient and reusable catalyst in ultrasound-promoted synthesis of 4H-chromenes and 4H-pyrano[2,3-c]pyrazoles. J Chem Sci 126, 95–101 (2014). https://doi.org/10.1007/s12039-013-0548-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-013-0548-x