Abstract

The transition metal (Zn2+)-doped Co3O4 nanoparticle was tailored through thermal decomposition of precursor synthesized by simple co-precipitation which is an experimentally and economically comfortable method. The precursor was characterized using EDS, FTIR and thermogravimetric analysis. Also, the nano-sized metal oxide synthesized from its precursor was investigated by powder X-ray diffraction, X-ray photoelectron spectroscopy, high-resolution transmission electron microscopy, scanning electron microscopy. The specific surface area was scrutinized through Bruner–Emmet–Teller (BET) adsorption. The ferromagnetic property of the nanoparticle was detected using vibrating sample magnetometer. The photocatalytic degradation performance of nano ZnCo2O4 was evaluated using methyl orange (MO), rhodamine B (RhB) and Congo red (CR) dyes under sunlight. The nanoparticle demonstrated good photocatalytic activity towards azo dyes (MO and CR) rather than rhodamine (RhB)-based dye. The degradation of organic dyes was found to follow first-order kinetics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

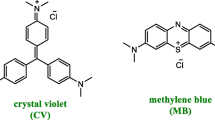

Today, environmental pollution and water scarcity have become a major threat to social and economic growth in developing countries. Modernization and industrialization have also led to the discharge of different types of toxic dye wastes, which cannot be removed by traditional sewage treatment [1,2,3,4,5]. Methyl orange (MO), Congo red (CR) and rhodamine B (RhB) dyes are commonly used in textile, food, paint, leather and cosmetic industries. These hazardous dye wastes from the industries can produce toxic by-products which cause severe health risks for humankind, animals and aquatic life [6,7].

There are numerous types of physical and chemical methods available for treating coloured wastewater. However, it is difficult to degrade toxic dyes by choosing feasible techniques [8,9]. Currently, the role of semiconductor photocatalysts in the degradation of organic dyes has attracted more attention due to their simple preparation, non-toxicity and photostability [10,11,12]. The heterogeneous transition metal oxides with general spinel structure AB2O4 (where A and B can be bivalent and trivalent, respectively) were reported that they were able to manage the effluent waste effectively due to their unique physical, chemical and optical properties. The transition metal dopants can create oxygen vacancies which are also delaying the e–/h+ pair recombination process [13,14,15]. Different transition metals, such as Co, Zn, Fe, Cu, Ni and Ag-doped semiconductor photocatalysts were reported for their enhanced photocatalytic efficiencies for the degradation of organic and inorganic pollutants [16,17,18,19,20,21]. However, the comparative analysis on the degradation of different dyes in the presence of ZnCo2O4 catalyst synthesized by simple co-precipitation has not been reported.

We report the structural, textural, magnetic, optical properties and photocatalytic efficiency of the nano ZnCo2O4 catalyst. In the present study, nano ZnCo2O4 was synthesized by a simple coprecipitation–calcination route by employing [Zn0.75Co2.25(PhOAc)2(N2H4)2] as a cobalt precursor. The decomposition of hydrazine content present in the precursor liberates energy in the form of heat which produces voluminous ultrafine metal oxides at relatively lower temperatures [22,23,24,25]. We observed the simple formation of nano ZnCo2O4 from the cobaltous phenoxyacetate hydrazinate precursor, but the formation of oxides synthesized from unhydrazinated precursor, needs rigorous temperature [26,27]. It has been reported that the hydrazinated metal carboxylates and mixed metal carboxylates yield spinels with a high surface area which must be attributed to the smaller size effect of the nanoparticles. Hence, these precursors are important in the preparation of nanosized materials which can have remarkable magnetic, biological and catalytic applications [28,29,30,31].

2 Experimental

2.1 Materials and reagents

The reagents used in this study have been purchased from a local vendor and used without further purification. Phenoxyacetic acid (PhOAc), cobalt nitrate hexahydrate, zinc nitrate hexahydrate, hydrazine hydrate (99%), ethanol, diethyl ether, carbon tetrachloride concentrated hydrochloric acid, CR, RhB and MO dyes were purchased from Sigma Aldrich and Himedia.

2.2 Preparation of precursor [Zn0.75Co2.25(PhOAc)2(N2H4)2]

The precursor [Zn0.75Co2.25(PhOAc)2(N2H4)2] was synthesized by a simple co-precipitation method. In a typical synthesis route, the precursor solution was prepared by dissolving cobalt nitrate hexahydrate (2.25 g, 0.0077 mol) in 50 ml of distilled water. To accomplish transition metal doping, an appropriate amount of zinc nitrate hexahydrate (0.75 g, 0.0025 mol), was added to the precursor solution with constant stirring. The aqueous solution (50 ml) of hydrazine hydrate (2.0 ml, 0.0399 mol) and phenoxyacetic acid (2 g, 0.0131 mol) was added to the aqueous mixture with constant stirring. The obtained mixture was kept aside for 3 h to achieve complete precipitation. The pink precipitate is filtered and washed many times with water, alcohol followed by diethyl ether to remove adsorbed impurities and then, the pink cake is dried at room temperature. The precursor was analysed by EDS, FTIR and TG/DTA analysis.

2.3 Preparation of nano ZnCo2O4

Nano ZnCo2O4, obtained from thermal decomposition of its precursor [ZnCo(PhOAc)2(N2H4)2] was done by transferring the desiccated precursor to the silica crucible and calcined in a muffle furnace at 400°C for 3 h. The fine black cobaltite crystals were allowed to cool to room temperature and stored in airtight containers.

This final product was characterized by EDS, FTIR, XRD, SEM, UV-DRS, XPS, PL, BET, TEM and VSM techniques. Synthesis of nano ZnCo2O4 is illustrated in figure 1.

2.4 Characterization

Elemental analysis was done on the Bruker nano GmbH EDS analyzer. The FTIR spectrum of the powdered sample has been recorded from 4000 to 400 cm–1 by Shimadzu with pressed KBR pellets.TG/DTA trace was performed on Perkin Elmer STA 6000 thermal analyzer with a heat rating of 20°C min–1 at temperature range of room temperature (RT)–700°C. Bruker AXS D8 advance analyzer has been utilized to derive a powder XRD (PXRD) pattern with an angle range of 10–90°. UV–VIS–NIR (Varion Cary 5000) has been carried out to record absorption data. PL spectrum in the range of 200–800 nm at an excitation wavelength of 380 nm was done by Floromax-4 spectrometer. The surface chemical state of the sample was studied by the PHI VersaProbe II XPS analyzer. TEM micrograph and SAED pattern were found by JEOL/JEM 2100 HRTEM analyzer. The morphological and compositional observations were recorded by JOEL JSM-6390LV and OXFORD XMX N. Quantachrome gas sorption system was exploited to find BET surface area. The magnetic measurements of metal oxide were performed by a vibrating sample magnetometer (Lakeshore VSM 7410) at RT. The photodegradation study was carried out using Shimadzu UV-2550 UV–Vis spectrophotometer.

2.5 Dye degradation study

The catalytic performance of the sample was detected by catalytic degradation of MO, CR and RhB dyes. Stock solution (500 mg l–1) was prepared by dissolving 0.5 g dye in 1000 ml deionized water. Before the irradiation process, the dye solutions were constantly stirred for about 30 min to attain adsorption equilibrium between the dye molecules and catalyst surface. Then, the suspension is irradiated in the presence of sunlight at regular time intervals and the degradation process was recorded by UV–Vis spectrophotometer at 464, 497 and 550 nm for MO, CR and RhB, respectively.

3 Results and discussion

3.1 Characterization of precursor

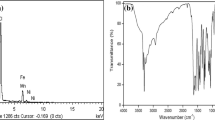

The hydrazine content in the precursor was determined by using standard 0.025 M KIO3 as titrant under Andrew’s conditions [32]. Molar ratio of 2:2 was maintained for the aqueous mixture of phenoxy acetate and hydrazine hydrate in the preparation of the precursor. The analytical data of the precursor was found to be in good agreement with the composition of [Zn0.75Co2.25(PhOAc)2(N2H4)2]. The presence of elements was identified from EDS analysis as shown in figure 2.

Figure 3 shows the FTIR spectrum of the precursor [Zn0.75Co2.25(PhOAc)2(N2H4)2]. The bands in the region of 3204–3328 cm–1, are due to the N–H stretching frequency of hydrazine moiety. The N–N stretching frequency observed at 952 cm–1, proved the bidentate bridging nature of hydrazine. The frequency separation of 262 cm–1 shows the difference between asymmetric and symmetric carbonyl stretchings (∆υ = υasym – υsym) which confirms the monodentate coordination of the carboxylate group in the phenoxyacetic acid to the central metal atom [33].

The thermal decomposition of the hydrazine precursor can be determined by TG/DTA trace. As shown in figure 4, four endothermic processes were observed. Weak endothermic peaks observed from 120 to 175°C are attributed to the removal of hydrazine molecules in the precursor [34,35]. The strong endothermic peaks observed at 286.36 and 373.79°C were accompanied by the elimination of two carboxylate groups. No other endothermic peaks were detected, indicating that the organic matter of the precursor has been completely degraded. The thermal analysis result shows the decomposition temperature of ZnCo2O4 nanoparticles formed at 400°C.

3.2 Characterization of nano ZnCo2O4

3.2a Structural studies:

The crystalline nature of the as-prepared sample was precisely resolved by XRD analysis, is shown in figure 5. The diffraction peaks at (220), (311), (222), (400), (331), (422), (511), (440) and (531) are in good agreement with spinel cubic ZnCo2O4 structure (JCPDS #23-1390) [36], suggesting no secondary phases. The well-ordered peaks of nanoparticles proposed the good crystallinity of the sample [37]. The average particle size was determined by using the Scherrer formula, \(d=0.9\lambda /\beta \mathrm{ cos} \theta ,\) where d, λ, β and θ denote particle size, wavelength of X-ray (1.504 Å), the half-width of highest intensity reflection in radian and angle of reflection. The average crystallite size was found to be 17 nm. The calculated value of the lattice parameter, a = 8.096 Å of nano ZnCo2O4 is close to the reported value. The FTIR spectra of as-prepared nanoparticle show two absorption bands at 671 and 565 cm−1, indicating stretching vibration of M–O bond in spinel Co3O4 metal oxide. The band found at 565 cm−1 is ascribed to the vibrations of bond evolved by Co3+ ion present in the octahedral holes of the crystal lattice. Another band found at 671 cm−1 is attributed to Co2+ ion which is present in tetrahedral holes of the lattice [38,39]. Figure 6 shows the FTIR transmission spectrum of nano ZnCo2O4 nanoparticle and the spectral details are in good agreement with the PXRD results. The SEM micrographs have demonstrated the agglomerated microcrystalline grains with few overgrown particles. To confirm the presence of elements, the EDS analysis was performed and is shown in figure 7.

Figure 8a–d shows the HRTEM images of nano ZnCo2O4 synthesized by thermal decomposition of [ZnCo(PhoAc)2(N2H4)2] precursor at 400°C. Corresponding SAED pattern substantiated the polycrystalline nature of the sample. Figure 8b shows SAED rings which are well-matched with spinel ZnCo2O4 lattice. HRTEM image of nano ZnCo2O4 shows lattice spacing of 0.4 and 0.24 nm agreed with (111) and (311) planes (figure 8c). The particle size distribution of nanoparticles is shown in figure 8d and it acquires a narrow size distribution of 14–22 nm. The average particle size derived from the TEM image using Image J software is very close to the average particle size determined from the Scherrer formula.

Figure 9 shows N2 adsorption–desorption isotherm of the prepared sample. According to the IUPAC classification, the shape of nano ZnCo2O4 isotherm corresponding to type IV and H3 hysteresis loop with specific surface area calculated at about 29 m2 g–1. The relative pressure ranges from 0.3 to 1, suggesting that the fabricated material is mesoporous [40]. Pore size distribution, demonstrated by the BJH method, is displayed in the inset (figure 9). Fine-sized pores of a radius of about 10.5 nm with a pore volume of 0.078 cm3 g–1 is observed clearly from figure 9.

The surface chemical state of the as-obtained material was studied by XPS analysis. The survey spectrum of nano ZnCo2O4 confirms the presence of Zn 2p, Co 2p and O 1s atoms only (figure 10a). Figure 10b shows the XPS spectrum of Zn 2p of Zn3/2 and Zn1/2 peaks, located at 1021.1 and 1044.4 eV, confirms the presence of Zn (II) oxidation state [41]. The doublet positioned at 779.20 and 780.23 eV are ascribed to Co 2p3/2, whilst the doublet peaked at 796.03 and 794.75 eV are associated with Co 2p1/2 (figure 10c). Peaks at 780.23 and 796.03 eV are characteristic of Co2+, while peaks at 779.20 and 794.75 eV are indexed to Co3+ ions. Also, the satellite peaks pointed at 803.31 and 786.37 eV, confirms the formation of cobalt (Co2+ and Co3+) species [42,43]. Figure 10d shows the O 1s spectrum of ZnCo2O4 and the contribution at 529.56 eV is related to M–O bonding and the peak at 531.08 eV is attributed to defects in subsurface [44].

3.2b Magnetic studies:

Figure 11 shows the room-temperature ferromagnetic (RTFM) nature of the prepared material with saturation magnetization (Ms) of 49.928 × 10–3 emu g–1, remanent magnetization (Mr) of 0.0121 emu g–1 and coercivity (Hc) of 400 Oe. The magnetic properties of the nanoparticle were supposed to derive from shape, crystallinity, direction of magnetization and so on. The inset (figure 11) shows that the ferromagnetic nano ZnCo2O4 can be recovered and recycled for application studies.

3.2c Optical studies:

The optical absorption spectrum of nano ZnCo2O4 is shown in figure 12a (inset). The diffuse reflectance UV–visible spectrum of ZnCo2O4 shows two absorption bands owing to the ligand to metal charge transfer referred as (O−2 → Co2+) and (O−2 → Co3+). The band gap energy of the prepared nanoparticle was determined from the Kubelka–Munk function. According to the transformed Kubelka–Munk relation [45]:

\(F(R)\), Kubelka–Munk function, which is directly proportional to the absorption coefficient K, whereas \(K={\left(1-R\right)}^{2}\) and inversely proportional to the scattering factor S, S = 2R where R is the diffused reflectance of the material \(R=\frac{R\%}{100}\). (F(R)hν)2 vs. hν plot gives optical band gap energy of bimetal oxides. The obtained multiple band gaps of nano ZnCo2O4 are due to the degeneracy of valence band [46] (figure 12a). The photoluminescence spectrum provides information on the band gap and recombination effects. The band observed near 408 nm is due to near band edge emission and the band near blue emission is ascribed to oxygen vacancy (figure 12b).

4 Photocatalytic performance and photodegradation kinetics of nano ZnCo2O4

4.1 Catalyst loading

The as-prepared catalyst is used to degrade MO, CR and RhB dyes under similar experimental conditions in the presence of sunlight. Working solutions of the desired concentration were prepared by successive dilution of the stock solution. To find the optimal catalyst loading, different amounts of the catalyst (20, 40, 60 and 80 mg) were taken for the photocatalytic experiment. The increase in catalyst dosage up to 80 mg, increased the degradation efficiency. Hence, 80 mg of catalyst is found to be optimal for degrading the dye solution.

4.2 Effect of catalyst

To explore the catalytic performance, the comparative experiments with different dyes and degradation kinetics were inspected. The degradation efficiency was determined by the following equation:

The catalyst shows different efficiencies for different dyes. The results suggest that the nano catalyst shows better catalytic efficiency for azo dyes than RhB dye. The degradation percentage of azo dyes, such as MO (85%) and CR (61%) were higher than RhB (38%) dye (figure 13a). During dye degradation process, azo dyes formed inorganic anion SO42− with hydroxyl radical (OH*). An additional fact is that this process takes place faster and increases the rate of cleavage of the chromophore in azo dyes. Compared to RhB, azo dyes experienced higher degradation which specifies the absence of anchoring group SO42− in rhodamine B-based dyes to enhance the photocatalytic degradation [47,48,49,50]. In the case of azo dyes, MO (mono azo) encountered faster degradation than CR (diazo) dye. Degradation of these dyes were instigated by the electrophilic cleavage of chromophoric azo (−N=N−) bond in the naphthalene ring. Thus, the dye that contains more azo bonds in its structure, will take a longer time to get degraded [51,52]. These observations validate the proposed direct relationship between degradation efficiency and the number of chromophoric azo bonds (−N=N−) attached.

Figure 13b depicts the C/C0 relation which describes the catalytic efficiency of the sample, where C0 is the initial concentration of dye and C is the concentration of a pollutant at time t. The kinetics of photocatalytic reactions can be expressed in terms of the Langmuir–Hinshelwood (L–H) model [53].

where kapp is the apparent pseudo-first-order reaction rate constant and t the reaction time. The pseudo-first-order rate constant is derived from the slope of the plot between ln(C/C0) and irradiation time is shown in figure 13c. Nano ZnCo2O4 catalyst degrades azo dyes MO (1.67 × 10−2) and CR (8.1 × 10−3) and RhB (3.2 × 10−3) at different rates. The catalyst has the highest rate constant of 0.0167 min−1, which proves as a model catalyst in this study.

4.3 Stability and recycle of nano ZnCo 2 O 4

To understand the chemical stability of nano ZnCo2O4, the recycling process of the catalyst for MO dye was carried out by repeating four consecutive experiments for a total duration of 8 h. The magnetization curve exhibits that the nano ZnCo2O4 is ferromagnetic and it can be recovered by the external magnet (figure 11). After the recovery, the sample was filtered and dried for degradation of MO dye recycling process. Based on the results (figure 13d), the nano ZnCo2O4 photocatalyst exhibits high chemical stability and recycling ability.

5 Conclusion

In summary, nano ZnCo2O4 has been synthesized by co-precipitation and followed by thermal decomposition of the precursor at 400°C to explore the structural, textural, optical, magnetic and chemical state properties. XRD pattern of prepared metal oxide was indexed to cubic spinel structure and predominantly oriented in (311) plane with a crystalline size of 17 nm and the findings were further acknowledged by SEM, HRTEM and SAED pattern. Nano ZnCo2O4 with smaller size and high specific surface area degrades MO, CR and RhB dyes to 85, 61 and 38%, respectively. Based on the findings, it has been concluded that the synthesized catalyst was found to degrade azo dye faster than RhB under similar reaction conditions due to the anchoring sulphonic group on the catalyst surface. Degradation of mono azo dye faster than diazo dye indicates the number of chromophoric azo bonds present in the azo dye which determined the degradation rate.

References

Torretta V, Katsoyiannis I, Collivignarelli M C, Bertanza G and Xanthopoulou M 2020 MATEC Web Conf. 305 00090

Hu X, Lei L, Chen G and Yue P L 2001 Water Res. 35 2078

Li X, Yu J, Li G, Liu H, Wang A, Yang L et al 2018 J. Colloid Interface Sci. 526 158

Shehzadi M, Afzal M, Khan M U, Islam E, Mobin A, Anwar S et al 2014 Water Res. 58 152

Shahmoradia B, Pordela M A, Pirsaheb M, Malekia A, Kohzadia S, Gongd Y et al 2017 J. Desalin. Water Treat. 88 200

Gnanaprakasam A, Sivakumar V and Thirumarimurugan M 2016 Water Sci. Technol. 74 1426

Bhattacharyya K G and Sarma A 2003 Dyes Pigm. 57 211

Asghar A, Raman A A A and Daud W M A W 2015 J. Clean. Prod. 87 826

Mondal S, Purkait M K and De S 2018 Advances in dye removal technologies. Springer, Singapore

Chaudhary A, Mohammad A and Mobin S M 2018 Mater. Sci. Eng.: B 227 136

Zhang T, Zhu H and Croue J P 2013 Environ. Sci. Technol. 47 2784

Mendret J, Hatat-Fraile M, Rivallin M and Brosillon S 2013 J. Sep. Purif. Technol. 111 9

Belver C, Bedia J, Gomez-Aviles A, Penas-Garzon M and Rodriguez J J 2019 Nanoscale Mater. Water Purif. 581, doi: https://doi.org/10.1016/B978-0-12-813926-4.00028-8

Yang X, Chen W, Huang J, Zhou Y, Zhu Y and Li C 2015 Sci. Rep. 5 10632

Letsholathebe D, Thema F T, Mphale K, Mohamed H E A, Holonga K J, Ketlhwaafetse R et al 2020 Mater. Today: Proc. 36 499

Gonçalves P F, Paganini M, Armillotta P, Cerrato E and Calza P 2019 J. Environ. Chem. Eng. 7 103475

Sun Yoo P, Amaranatha Reddy D, Jia Y, Eun Bae S, Huh S and Liu C 2017 J. Colloid Interface Sci. 486 136

Radha B, Rathi R, Lalithambika K C, Thayumanavan A, Ravichandran K and Sriram S 2018 J. Mater. Sci.: Mater. Electron. 16 13474

Mohan R, Krishnamoorthy K and Kim S J 2012 Solid State Commun. 152 375

Raja K, Ramesh P S and Geetha D 2014 Spectrosc. 120 19

Boxi S S and Paria S 2014 RSC Adv. 4 37752

Verenkar V M S, Rane K S and Sawant P Y 1999 J. Mater. Sci. Mater. Electron. 10 133

Rane K S, Verenkar V M S, Pednekar R M and Sawant P Y 1999 J. Mater. Sci. Mater. Electron. 10 121

Porob R A, Khan S Z, Mojumdar S C and Verenkar M S 2006 J. Therm. Anal. Calorim. 86 605

More A and Verenkar V M S 2006 Inorganic materials: recent advances (New Delhi: Narosa Publishing House) p 230

Stella C, Soundararajan N and Ramachandran K 2015 AIP Adv. 5 087104

Anandha Babu G, Ravi G and Hayakawa Y 2014 Appl. Phys. A 119 219

Gawas U B, Verenkar V M S and Mojumdar S C 2011 J. Therm. Anal. Calorim. 104 879

Rane K S and Verenkar V M S 2001 Bull. Mater. Sci. 24 39

Borker V, Karmali R and Rane K 2014 Eur. Chem. Bull. 3 520

Vikram L and Sivasankar B N 2007 Thermochim. Acta 452 20

Vogel A I 1989 A textbook of quantitative chemical analysis, 5th edn (London: Longman) p 384

Braibanti A, Dallavalle F, Pellinghelli M A and Leporati E 1968 Inorg. Chem. 7 1430

Gonsalves L R, Mojumdar S C and Verenkar V M S 2010 J. Therm. Anal. Calorim. 100 789

Gawas U B and Verenkar V M S 2013 Thermochim. Acta 556 41

Zhu Y, Cao C, Zhang J and Xu X 2015 J. Mater. Chem. A3 9556

Qiu Y, Yang S, Deng H and Li W 2010 J. Mater. Chem. 20 4439

Wei X, Chen D and Tang W 2007 Mater. Chem. Phys. 103 54

Barakat N A M, Khil M S, Sheikh F A and Kim H Y 2008 J. Phys. Chem. C 112 12225

Matthias T, Katsumi K, Alexander V N, James P O, Francisco R, Jean R et al 2015 Pure Appl. Chem. 87 1051

Mariappan C R, Kumar R and Prakash G V 2015 RSC Adv. 5 26843

Pang M J, Jiang S, Long G H, Jia Y, Han W, Wang B B et al 2016 RSC Adv. 6 67839

Van H N, Charmaine L and Jae-Jin S 2016 Mater. Lett. 170 105

Varghese B, Hoong T C, Yanwu Z, Reddy M V, Chowdari B V R, Wee A T S et al 2007 Adv. Funct. Mater. 17 1932

Malkeshkumar P, Arvind C, Indrajit M, Joondong K and Abhijit R 2016 Nanoscale 8 2293

Pal J and Chauhan P 2010 Mater. Charact. 61 575

Abdullah M A, Muhammed S A A, Tariq A A T and Abdullah D A T 2011 J. Saudi Chem. Soc. 15 121

Sun M, Han X and Chen S 2019 Mater. Sci. Semicond. Process. 91 367

Liu Y, Chen X, Li J and Burda C 2005 Chemosphere 61 11

Hemamalini S and Manimekalai R 2020 J. Coord. Chem. 73 3431

Anku W W, Oppong S O, Shukla S K and Govender P P 2016 Acta Chim. Slov. 63 380

Rauf M A, Meetani M A and Hisaindee S 2011 Desalination 276 13

Galindo C, Jacques P and Kalt A 2001 Chemosphere 45 997

Acknowledgement

We are thankful to Kongunadu Arts and Science College for providing facilities. We also express our huge gratitude to CIT (Coimbatore), SAIF (Cochin), IIT (Madras), Karunya University (Coimbatore), Amrita Centre for Nanosciences and Molecular Medicine (AIMS, Cochin), CSIR – National Institute for Interdisciplinary Science and Technology (NIIST) Thiruvananthapuram, and BIT University (Bangalore) for providing instrument services.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

HEMAMALINI, S., MANIMEKALAI, R. Synthesis, physicochemical and photocatalytic activities of nano ZnCo2O4 catalyst for photodegradation of various dyes under sunlight irradiation. Bull Mater Sci 44, 154 (2021). https://doi.org/10.1007/s12034-021-02453-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-021-02453-y