Abstract

The chemistry, structure, and properties of spinel ferrites are largely governed by the method of preparation. The metal carboxylato-hydrazinate precursors are known to yield nanosized oxides at a comparatively lower temperature. In this study, we are reporting the synthesis of one such precursor, cobalt nickel ferrous fumarato-hydrazinate which decomposes autocatalytically to give cobalt nickel ferrite nanoparticles. The XRD study of this decomposed product confirms the formation of single-phase spinel, i.e., Co0.5Ni0.5Fe2O4. The thermal decomposition of the precursor has been studied by isothermal, thermogravimetric (TG), and differential scanning calorimetric (DSC) analysis. The precursor has also been characterized by FTIR, EDX, and chemical analysis, and its chemical composition has been determined as Co0.5Ni0.5Fe2(C4H2O4)3·6N2H4.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There has been a surge of research reports focusing on nanosized magnetic materials, having significant potential for many applications [1–6]. Research in this area for better and improved materials still continues. In recent times, many innovative synthetic strategies [7–12] have been devised which have led to engineering new and efficient materials exhibiting fascinating properties.

Over the years, our research group has been involved in synthesizing nanomaterials from novel precursors which are hydrazine derivatives of metal carboxylates [13–22]. The chemistry of hydrazine is of particular interest since it forms a number of complexes with transition metals, and being a fuel, it not only supports combustion but also lowers the decomposition temperature of the metal complexes [18, 19]. Thermal analysis, X-ray, and spectral studies are very important techniques for material characterization. Therefore, many authors have used these techniques for various materials characterization [23–55]. Here, we are reporting the synthesis, X-ray and spectral characterization, and thermal decomposition of a new precursor, cobalt nickel ferrous fumarato-hydrazinate, which decomposes autocatalytically to give nanosized Co0.5Ni0.5Fe2O4.

Experimental

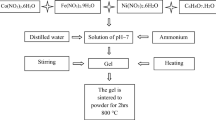

Preparation of cobalt nickel ferrous fumarato-hydrazinate

The cobalt nickel ferrous fumarato-hydrazinate precursor was synthesized by employing the method first devised by our group [20]. A requisite quantity of sodium fumarate in aqueous medium was stirred with hydrazine hydrate N2H4·H2O (99–100%) in an inert atmosphere for 2 h. To this, a mixed metal ion solution containing cobalt, zinc, and iron in stoichiometric amount was added dropwise with constant stirring. The precipitate thus obtained was filtered off, washed with ethanol, dried with diethyl ether, and stored in vacuum desiccators.

Methods of characterization

The precursor was chemically analyzed by titration to determine its hydrazine content using KIO3 as the titrant [56]. The percentage of cobalt, nickel, and iron in the precursor was estimated by the standard methods given in the Vogel’s textbook [56]. The metal content in the sintered oxide sample was also determined by EDX. Infrared analysis of the precursor and its thermal products, i.e., Co05Ni05Fe2O4 was carried out on a Shimadzu FTIR IR Prestige-21 spectrophotometer.

The thermal decomposition pattern of the precursor was studied by simultaneous differential scanning calorimetry (DSC) and thermogravimetric (TG) analysis on a NETZSCH, STA 409 PC (Luxx) analyzer, from RT to 900 °C in dry air. The heating rate was maintained at 10 °C min−1. The isothermal and total mass loss studies of the sample were also carried out at different predetermined temperatures.

Autocatalytic decomposition of the precursor

The dried precursor was spread on a Petri dish and ignited with a burning splinter. A small portion of it caught fire which spread immediately to the entire bulk. The precursor decomposes autocatalytically in this manner in an ordinary atmosphere to yield nanosized particles of the ferrite.

Results and discussion

Chemical formula determination of cobalt nickel ferrous fumarato-hydrazinate

The infrared spectra of the complex (Fig. 1) show three absorption bands in the region 3,150–3,300 cm−1 due to the N–H stretching frequencies. The N–N stretching frequencies at 975 cm−1 prove the bidentate bridging nature of the hydrazine ligand unequivocally. The asymmetric and symmetric stretching frequencies of the carboxylate ions are seen at 1,590 and 1,370 cm−1, respectively, with the Δν (νasy − νsym) separation of 220 cm−1, which indicate the monodentate linkage of both carboxylate groups in the dianion. The IR data confirm the formation of cobalt nickel ferrous fumarato-hydrazinate complex.

The chemical formula Co0.5Ni0.5Fe2(C4H2O4)3·6N2H4 has been assigned to the complex cobalt nickel ferrous fumarato-hydrazinate based on the observed percentage of hydrazine (26.84), cobalt (12.53), nickel (12.49), and iron (47.52) which match closely with the calculated values of 27.25, 12.56, 12.51, and 47.63% for hydrazine, cobalt, nickel, and iron, respectively (Table 1). Similarly, the observed mass loss of 65.92% in total mass loss studies (~800 °C) matches with the calculated value 66.71% based on the above-mentioned formula.

Thermal analysis of the precursor

The TG-DSC curves of thermal decomposition of Co0.5Ni0.5Fe2(C4H2O4)3·6N2H4 are shown in Fig. 2. The TG curve from room temperature to 900 °C shows four mass loss regions with two major ones (Table 2). The mass losses of 18.12 and 9.08% from room temperature (RT) to 135 °C and from 135 to 170 °C were due to the loss of four N2H4 and two N2H4 molecules, respectively. The DSC curve shows a corresponding sharp exotherm with a peak at 133.5 °C followed by another small exotherm with a peak at 165.6 °C due to dehydrazination as explained above. The major mass loss of 31.22% followed by minor mass loss of 7.05% from 170 to 300 °C and from 300 to 375 °C, respectively, on the TG curve was due to two-step decarboxylation of dehydrazinated fumarate precursor. DSC curve shows one sharp exothermic peak followed by an exothermic hump in this region with the peak temperature at 291.7 and 328.6 °C, respectively, due to this two-step oxidative decarboxylation. A marginal mass loss of 5.2% was observed from 375 to 900 °C on the TG curve due to the oxidation of unburned carbon.

The mass loss studies of the precursor carried out separately at 400 °C show total mass loss of 65.92%. It has been reported that the hydrazinated precursors lose the hydrazine molecules in presence of air between 100 and 300 °C [18]. It reacts explosively with atmospheric oxygen liberating enormous amount of energy which is sufficient to oxidatively decompose the hydrazinated complex into its respective metal oxide. The formation of monophasic Co0.5Ni0.5Fe2O4 nanoparticles soon after the autocatalytic thermal decomposition of the precursor has been confirmed by XRD. The bands in the IR spectra of Co0.5Ni0.5Fe2O4 are in agreement with the reported ones [8].

Conclusions

The mixed metal fumarato-hydrazinate precursor offers a convenient synthetic route to prepare nanosized mixed metal oxides. The hydrazine precursor exhibits autocatalytic decomposition behavior after ignition in air, forming nanosize Co0.5Ni0.5Fe2O4 in this study too. The chemical analysis, total mass loss, and infrared spectral analysis of the complex confirms the formation of the complex with the formula Co0.5Ni0.5Fe2(C4H2O4)3·6N2H4. The TG-DSC studies of the complex show two-step dehydrazination followed by two-step decarboxylation to form single-phase Co0.5Ni0.5Fe2O4 nanoparticles. The formation of Co0.5Ni0.5Fe2O4 nanoparticles was confirmed by XRD and IR.

References

Patil KC, Hegde MS, Rattan T, Aruna ST. Chemistry of nanocrystalline oxide materials: combustion synthesis, properties and applications. Singapore: World Scientific; 2008.

Maensiri S, Masingboon C, Boonchom B, Seraphin S. Scr Mater. 2007;56(9):797.

Thakur S, Katyal SC, Singh M. J Magn Magn Mat. 2009;321:1.

Chen Z, Gao L. Mater Sci Eng B. 2007;141:82.

Vital A, Angermann A, Dittmann R, Graule T, Topfer J. Acta Mater. 2007;55:1955.

Hua ZH, Chen RS, Li CL, Yang SG, Lu M, Gu XB, et al. J Alloys Compd. 2007;427:199.

Singhal S, Singh J, Barthwal SK, Chandra K. J Solid State Chem. 2005;178:3183.

Baykal A, Kasapoglu N, Koseoglu Y, Basaran AC, Kavas H, Toprak MS. Cent Eur J Chem. 2008;6(1):125.

Kasapoglu N, Birsoz B, Baykal A, Koseoglu Y, Toprak MS. Cent Eur J Chem. 2007;5(2):570.

Shobana MK, Rajendran V, Jeyasubramanian K, Suresh Kumar N. Mater Lett. 2007;61:2616.

Ryu BH, Chang HJ, Choi YM, Kong KJ, Lee JO, Kim CG, et al. Phys Status Solidi a. 2004;201(8):1855.

Jiang J. Mater Lett. 2007;61:3239.

Verenkar VMS, Rane KS. In: Dharwadkar SR, Bharadwaj SR, Mukherjee SK, Sood DD, editors. Proc. 10th Nat. Symp. on Thermal Analysis, DMSRDE; Kanpur. Mumbai: Indian Thermal Analysis Society; 1995. p. 175.

Verenkar VMS, Rane KS. In: Ravindran PV, Sudersanan M, Misra NL, Venugopal V, editors. Proc. 12th Nat. Symp. on Thermal Analysis, Gorakhpur, India. Mumbai: Indian Thermal Analysis Society; 2000. p. 194.

Sawant SY, Verenkar VMS, Mojumdar SC. J Therm Anal Calorim. 2007;90:669.

More A, Verenkar VMS, Mojumdar SC. J Therm Anal Calorim. 2008;94(1):63.

Gonsalves LR, Verenkar VMS, Mojumdar SC. J Therm Anal Calorim. 2009;96(1):53.

Porob RA, Khan SZ, Mojumdar SC, Verenkar VMS. J Therm Anal Calorim. 2006;86:605.

More A, Mojumdar SC, Parab S, Verenkar VMS. 15th CTAS Annual Workshop and Exhibition, 17–18 May 2005. National Research Council Canada, Bouchervile, Quebec, J4B 6Y4, Canada. p. 22.

Sawant SY, Kannan KR, Verenkar VMS. In: Pillai CGS, Ramakumar KL, Ravindran PV, Venugopal V, editors. Proc. 13th Nat. Symp. on Thermal Analysis, B.A.R.C., Mumbai. Mumbai: Indian Thermal Analysis Society; 2002. p. 154.

Verenkar VMS, Rane KS. In: Dharwadkar SR, Bharadwaj SR, Mukherjee SK, Sood DD, editors. Proc. 10th Nat. Symp. on Thermal Analysis, DMSRDE; Kanpur. Mumbai: Indian Thermal Analysis Society; 1995. p. 171.

Rane KS, Verenkar VMS, Sawant PY. J Mater Sci Mater Electron. 1999;10:133.

Xie W, Gao Z, Liu K, Pan WP, Vaia R, Hunter D, et al. Thermochim Acta. 2001;367:339.

Mojumdar SC. Res J Chem Environ. 2005;9:23.

Davis RD, Gilman JW, Sutto T, Callahan JH, Trulove PC, De Long H. Clays Clay Miner. 2004;52:171.

Ovadyahu D, Lapides I, Yariv S. J Therm Anal Calorim. 2007;87:125.

Mojumdar SC. J Therm Anal Calorim. 2001;64:629.

Czakis-Sulikowska D, Czylkowska A, Malinowska A. J Therm Anal Calorim. 2002;67:667.

Mojumdar SC, Raki L. J Therm Anal Calorim. 2006;85:99.

Bylina I, Trevani L, Mojumdar SC, Tremaine P, Papangelakis VG. J Therm Anal Calorim. 2009;96:117.

Mojumdar SC, Varshney KG, Agrawal A. Res J Chem Environ. 2006;10:89.

Dováľ M, Palou M, Mojumdar SC. J Therm Anal Calorim. 2006;86:595.

Madhurambal G, Ramasamy P, Srinivasan PA, Mojumdar SC. J Therm Anal Calorim. 2007;90:673.

Varshney KG, Agrawal A, Mojumdar SC. J Therm Anal Calorim. 2007;90:731.

Mojumdar SC, Melník M, Jóna E. J Anal Appl Pyrolysis. 2000;53:149.

Borah B, Wood JL. Can J Chem. 1976;50:2470.

Mojumdar SC, Sain M, Prasad R, Sun L, Venart JES. J Therm Anal Calorim. 2007;90:653.

Ramadevi A, Srinivasan K. Res J Chem Environ. 2005;9:54.

Meenakshisundaram S, Parthiban S, Madhurambal G, Mojumdar SC. J Therm Anal Calorim. 2008;94:21.

Skoršepa JS, Györyová K, Melník M. J Therm Anal. 1995;44:169.

Ondrušová D, Jóna E, Šimon P. J Therm Anal Calorim. 2002;67:147.

Verma RK, Verma L, Ranjan M, Verma BP, Mojumdar SC. J Therm Anal Calorim. 2008;94:27.

Jona E, Rudinska E, Sapietova M, Pajtasova M, Ondrusova D. Res J Chem Environ. 2006;10:31.

Kubranová M, Jóna E, Rudinská E, Nemčeková K, Ondrušová D, Pajtášová M. J Therm Anal Calorim. 2003;74:251.

Jóna E, Hvastijová M, Kohout J. J Therm Anal. 1994;41:161.

Czakis-Sulikowska D, Czylkowska A. J Therm Anal Calorim. 2003;71:395.

Madhurambal G, Ramasamy P, Anbusrinivasan P, Vasudevan G, Kavitha S, Mojumdar SC. J Therm Anal Calorim. 2008;94:59.

Ukraintseva EA, Logvinenko VA, Soldatov DV, Chingina TA. J Therm Anal Calorim. 2004;75:337.

Mojumdar SC, Melník M, Jóna E. J Therm Anal Calorim. 1999;56:541.

Rathore HS, Varshney G, Mojumdar SC, Saleh MT. J Therm Anal Calorim. 2007;90:681.

Mojumdar SC, Madhurambal G, Saleh MT. J Therm Anal Calorim. 2005;81:205.

Varshney KG, Agrawal A, Mojumdar SC. J Therm Anal Calorim. 2005;81:183.

Mojumdar SC, Šimon P, Krutošíková A. J Therm Anal Calorim. 2009;96:103.

Jóna E, Rudinská E, Sapietová M, Pajtášová M, Ondrušová D, Jorík V, et al. Res J Chem Environ. 2005;9:41.

Mojumdar SC, Miklovic J, Krutošíková A, Valigura D, Stewart JM. J Therm Anal Calorim. 2005;81:211.

Vogel I. Vogel’s text book. In: Jeffery GH, Bassett J, Mendham J, Denney RC, editors. Quantitative inorganic analysis, 5th ed. London, UK: Longman Scientific and Technical; 1989, p.1–906.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gonsalves, L.R., Mojumdar, S.C. & Verenkar, V.M.S. Synthesis of cobalt nickel ferrite nanoparticles via autocatalytic decomposition of the precursor. J Therm Anal Calorim 100, 789–792 (2010). https://doi.org/10.1007/s10973-010-0719-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0719-7