Abstract

The influence of Toruzyme® cyclomaltodextrin glucanotransferase concentration and the presence of ethanol have been studied for the production of α-, β-, and γ-cyclodextrins (CDs) from 15% (w/v) cornstarch, at 65 °C and pH 6, with the aim of increasing CD yield. The selected concentrations for a single batch reactor were 10% (v/v) ethanol and 0.1% (v/v) enzyme, yielding after 12 h, 37% total CDs, of which 52.2% was α-CD, 38.8% β-CD, and 9.0% γ-CD. The enzyme specific activities per unit mass of protein for producing α-, β-, and γ-CD were 37.25, 19.61, and 8.63 U mg−1, respectively. Total CD yield per milliliter of enzyme was 55 g. To increase CD yield per enzyme charge and thus reduce costs, the production of CDs was tested with two sequential batches in which a single enzyme charge was used. At the end of the first batch, the enzyme was adsorbed either on 65 °C pretreated starch granules or on raw starch, and a second batch was run with this material. The best result, in this case, was obtained for pretreated starch, increasing total CD produced by 57.4%, with 53.2% α-CD, 36.1% β-CD, and 10.7% γ-CD. CD yield per milliliter of enzyme was then 87 g.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cyclodextrins (CDs) are produced from starch or starch derivatives by the action of the CGTase enzyme (cyclomaltodextrin glucanotransferase, EC 2.4.1.19, International Union of Biochemistry and Molecular Biology enzyme nomenclature). The enzymatic product is usually a mixture of cyclodextrins, including mainly α-, β-, and γ-CD consisting of six, seven, or eight α-1,4-d-glucopyranosyl residues, respectively (Fig. 1). Their structure has a hydrophilic outer surface and a hydrophobic cavity [1–4]. Because of their ability to form inclusion complexes with many organic molecules, CDs and their derivatives have become increasingly useful in food, pharmaceuticals and cosmetics industries, analytical chemistry, agriculture, and biotechnology. The physical properties of the CD-complexed compound can be altered to improve stability, volatility, solubility, or bioavailability [5]. In the last decade, a few interesting large-ring CDs showing novel structural features were isolated and characterized, but α-, β-, and γ-CDs are the most extensively studied and used products [6]. Due to their different sizes and structural features, large-ring CDs could find applications as novel host compounds in molecular recognition processes in nanobiotechnology [7]. A CD with five residues (cyclomaltopentaose) was chemically synthesized by Nakagawa et al. [8], but its physicochemical properties and inclusion complex formation ability have not been reported yet [9].

Chemical structure of α-, β-, and γ-cyclodextrin (CD), consisting of six, seven, or eight α-1,4-d-glucopyranosyl residues, respectively [1]

The size of CDs obtained in synthesis reactions with CGTases is largely dependent on the type of CGTase, the reaction conditions, and the chosen production process. Modifying the production process, for example by the addition of complexing agents or organic solvents like ethanol, toluene, or 1-butanol to the reaction medium, the total CD yield and selectivity can be controlled [7].

Ethanol can be an important tool in the production of CDs because it is a virtually harmless additive that can easily be evaporated and reused. Moreover, its presence prevents microbial contamination during the process. Ethanol excludes water molecules from the active center of the enzyme, preventing hydrolytic reactions, in addition to reverse reactions, and thus slows down the decomposition of CD formed. This increases CD yield. For ethanol concentrations above 20%, however, an abrupt decrease in the yield of CDs was also found, possibly due to denaturation of the enzyme. The favorable effects of ethanol are more pronounced for higher starch concentrations [10]. Where the substrate starch is available at low cost, there is great motivation for the study of methods for increasing yields of CDs because they are products of high added value [11].

Reuse of enzymes for many reaction cycles, lowering the total production cost, has been studied, but the methods for the immobilization of enzymes found in literature involve (often expensive) supports, cross-linking reagents, and immobilized enzyme stability studies. The general idea of this work was to develop a technology that may allow cost reduction in the production of CDs, enabling many of their potential applications, still restricted due to high costs. Specific objectives were: (a) To study the production of CDs from cornstarch using CGTase enzyme in the presence of ethanol, and (b) To produce CDs in a sequential batch mode, maintaining the presence of ethanol. This process was conceived with the aim of partially recovering the CGTase enzyme by adsorption on the substrate in each batch cycle, potentially leading to a higher yield of CDs using the same amount of CGTase. In addition, the use of a moderate temperature allows the reuse of the unreacted starch.

Materials and Methods

A liquid enzyme preparation containing a heat-stable Thermoanaerobacter sp. CGTase (Toruzyme® 3.0L) was kindly provided by Novozymes A/S. Commercial cornstarch Maizena® was used as substrate. The standards for chromatographic analysis were purchased from Fluka Chemie AG (α-CD), Sigma Chemical Co. (β-CD), and Wacker Consortium (γ-CD). The protein concentration of the enzyme solution was measured by the Bradford method [12], using Coomassie Blue G and bovine serum albumin as the standard protein, both reagents purchased from Sigma Chemical Co. All other reagents were of analytical grade. To perform the analyses, the following equipment were used: high-performance liquid chromatograph (Gilson) with IR Iota two detector and spectrophotometer UV-1601-PC (Shimadzu).

The CD production experiments were carried out in a 100-mL batch reactor, under magnetic stirring with 15% (w/v) raw cornstarch suspension buffered with 10% (v/v) 10 mmol L−1 sodium citrate. Ethanol (0–15% (v/v)) and enzyme (0.05–0.2% (v/v)) were added at the beginning of the reaction. Based on literature [6, 13], the reaction conditions were pH 6 and temperature of 65 °C. For all experiments described in this work, samples of 1 mL were collected, added to 1 mL of 0.02 mol L−1 hydrochloric acid and taken to a boiling bath for 5 min to inactivate the enzyme. The samples were then centrifuged at 40 °C and 5,000×g for 10 min, and the supernatants were diluted for the analysis of CDs by the dye-extinction colorimetric method using phenolphthalein (PHCM) at 550 nm, which is selective for β-CD [3], or by high-performance liquid chromatography (HPLC), which determines α-, β-, and γ-CDs. For these analyses, the column used was Microsorb-MV, 100-5, Amino 250 × 4 (Varian), and the mobile phase was acetonitrile/water mixture (65:35 (v/v)) at a flow rate of 2 mL min−1 at room temperature. All samples were filtered in 0.45-μm membranes (Millipore) prior to doing the assays.

Enzyme and Ethanol Concentration in the Reaction Medium

Aiming at optimizing the concentration of ethanol and enzyme, β-CD production was initially evaluated with a fixed ethanol concentration of 15% (v/v) and variable CGTase concentration (0.05%, 0.1%, and 0.2% (v/v)), using PHCM to analyze the samples. Once the volume of enzyme was defined, the concentration of ethanol in the substrate was varied as 0%, 5%, 10%, and 15% (v/v). To minimize the loss of ethanol, samples were taken only at 12-h intervals. With this new procedure, there was no interference with the yields obtained from different fixed ethanol concentrations. A second objective of this experiment was to determine whether, without the loss of ethanol, there would be a significant increase in the production of CDs when reaction time was extended from 12 to 24 h. This is important for the industrial process because if no significant increase in production with 24 h of reaction occurred, then the choice of 12 h would lead to greater productivity of the batch reactor. In this experiment, the samples were analyzed by HPLC to determine the effect of ethanol concentration on the production of the three CDs, α, β, and γ. Then, using the best concentration of ethanol for higher CD yield, the experiment for determining the best concentration of enzyme was repeated, with sampling only after 12 and 24 h. β-CD production was analyzed by PHCM. Gas chromatography analyses after 24 h of reaction showed no loss of ethanol in the experiments where only two samples were collected.

Determination of the Enzyme Specific Activity

CGTase enzyme activity was determined by the initial velocities method [14], and 0.1 mL of it was added to 100 mL of 15% (w/v) starch granules suspension, containing 10 mL of ethanol and 10 mL of sodium citrate buffer, pH 6. After the addition of enzyme, the procedures already described for the production of CD were followed for 90 min, with samples collected at 10, 20, 30, 40, 50, 60, and 90 min. These samples were analyzed by HPLC. From the resulting data, curves of CD concentration as a function of reaction time were plotted. The slope of the linear portion of each curve was then used to calculate the enzymatic activity of CGTase by Eq. 1, where A E is the enzyme specific activity (units per milligram), ΔC/Δt is the slope of the linear region of the curve (millimoles per liter per minute), V R is the reaction volume (milliliters), V E is the volume of enzyme (milliliters), and C P is the protein concentration of the commercial liquid preparation of CGTase (milligrams per milliliter). Thus, the production of one micromole of CD per minute under the conditions described is equivalent to one International Unit of Enzyme Activity (U) [14–16] for the enzyme CGTase, and Eq. 1 gives the specific activity, which is the number of Activity Units per milligram of protein.

Sequential Batches

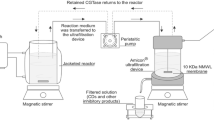

The production of CDs was also studied in a sequential batch mode, using the same reaction conditions of the previous tests and the previously selected amounts of ethanol and enzyme. The first batch was carried out for 12 h, followed by centrifugation (40 °C, 20 min, 12,000×g) to separate the unreacted starch. CGTase enzyme was then recovered from the supernatant solution by adsorption on new starch granules (15% (w/v)) that had been hydrothermally pretreated (1 h at 65 °C under magnetic stirring, followed by centrifugation in the conditions described above) or on new raw starch. To adsorb the enzyme, this suspension was left under magnetic stirring for 1 h at 25 °C, centrifuged, and then water containing 10% (v/v) ethanol and 10% (v/v) sodium citrate buffer pH 6 was added to the precipitate to complete 100 mL. With this suspension, the second batch was run for 24 h. Longer reaction time was employed in the second batch because there was a smaller amount of enzyme in the reaction medium (only the enzyme that was adsorbed in the new starch granules). Afterwards, the suspension was centrifuged.

For the recovery of CDs retained in the precipitates after centrifugation, each precipitate was diluted with distilled water to a total volume of 100 mL and kept under magnetic stirring at 25 °C for 30 min. The CDs were then determined in the supernatant after centrifugation (40 °C, 20 min, 12,000×g).

To calculate the yield from the process with two sequential batches, the CDs produced in three streams of this process were taken into account:

-

(a)

First, the CDs from the supernatant of the first batch after the enzyme was adsorbed on pretreated or raw starch granules,

-

(b)

Second, the CDs that were present in the final supernatant after the second batch, and

-

(c)

Third, the CDs recovered from the unreacted starch precipitates.

For the single batch process, the CDs added up for yield calculation were those from the supernatant and those recovered from the unreacted starch precipitate after centrifugation.

Results and Discussion

Enzyme and Ethanol Concentration in the Reaction Medium

The results of the preliminary tests to determine the optimal enzyme concentration, presented in Fig. 2, show that β-CD concentration gradually increased with the reaction time, as expected, and it can be observed that the concentration of 0.1% (v/v) of enzyme was the most advantageous because there was little increase in the production of β-CD when twice as much enzyme was used (0.2%). However, for the concentration of 0.05% (v/v) enzyme, low CD yield was obtained and stirring was difficult due to the higher viscosity of the substrate suspension, caused by a slower reaction. After 24 h of reaction, and due to frequent sampling, the loss of ethanol from the reaction medium had reached 50%, and then, these experiments were repeated with more spaced sampling.

The results obtained with variation of ethanol concentration, using 0.1% (v/v) of enzyme and sampling at 12-h intervals, are shown in Fig. 3. Higher production of α-CD and β-CD was obtained with ethanol addition. With 10% ethanol, there was a moderate increase in β-CD production (around 18%) and a significant increase in α-CD production, which has nearly tripled. Regarding γ-CD, the production was very low, regardless of ethanol concentration (less than 4.0 mmol L−1).

Based on these results, the concentration of 10% ethanol was selected since a small reduction in β-CD production (from 21.96 to 20.43 mmol L−1 after 12 h) and a less significant increase in α-CD were observed with 15% ethanol compared with 10% ethanol. The increased production of CDs in the presence of ethanol, which was far more significant for α-CD, is in agreement with the results obtained by Blackwood and Bucke [17]. These authors used partially hydrolysed potato starch as substrate. Mattsson et al. [10] observed an increase in the production of β-CD and γ-CD, with a reduction in α-CD, as the concentration of ethanol in the reaction medium was increased. Moreover, the effect of ethanol on starchy materials from various sources was similar. Mori et al. [18], using soluble starch, obtained higher yields of γ-CD in the presence of ethanol. The last two groups of authors worked with CGTase enzymes other than Toruzyme®, indicating that the influence of ethanol on the formation of CDs is dependent on the enzyme source.

For the selected concentration of ethanol, 10% (v/v), the results for the variation in enzyme concentration and sampling at 12-h intervals confirmed what had already been observed in Fig. 2. The increase in β-CD production was 29% after 12 h of reaction and 18% after 24 h, using 0.1% (v/v) enzyme instead of 0.05% (v/v). As for the enzyme concentration of 0.2% (v/v), an increase of only 5% was observed in the production of β-CD after 12 h of reaction and approximately 9% after 24 h compared with the enzyme concentration of 0.1% (v/v). Thus, the concentration of 0.1% (v/v) was selected for the process since it allowed a rapid reduction in viscosity of the starch suspension, and the little increase of β-CD production for 0.2% (v/v) enzyme does not justify the utilization of much more enzyme, which is expensive (about 60 USD kg−1). According to Brewster and Loftsson [19], the price of the CDs will depend on their purity and technological grade, but the approximate bulk price given as the price of 1 kg in US dollars is 45 USD kg−1 for α-CD and 5 USD kg−1 for β-CD. So, the use of twice more enzyme is uneconomical: the ratio (milligrams of CD produced)/(US dollars invested) is lower. The results of CD production versus time using the selected concentrations of ethanol (10% (v/v)) and enzyme (0.1% (v/v)) indicated that there was no significant increase in the production of CDs between 12 and 24 h of reaction. The highest production was that of α-CD, 32.92 mmol L−1, whereas the production of β-CD was 21.96 mmol L−1 and that of γ-CD was 3.98 mmol L−1, after 12 h of reaction.

The analysis of Fig. 3 indicates that the kinetics of production of CDs changes from a faster production of α- and β-CD in the absence of ethanol to a much faster production of α-CD in the presence of ethanol, that is, the enzyme behavior changes from a αβ-CGTase to α-CGTase with the addition of 10% (v/v) ethanol to the reaction medium. Blackwood and Bucke [17] suggested that changes in both the hydration and infrastructure of the enzyme could explain these results (for example, displacement of water molecules by the solvent either on the surface of the protein or in the active site region). The polar groups contained in the solvent may make direct molecular effects on biocatalyst activity more likely. Mori et al. [18] supposed that ethanol might change the steric structures of the starch and (or) enzyme so as to repress the formation of β-CD.

Determination of the Enzyme Specific Activity

The slopes obtained from the straight lines (ΔC/Δt) were applied in Eq. 1, resulting in the specific activity of CGTase enzyme for α-CD, β-CD, and γ-CD. The results are presented in Table 1, along with the fitted straight lines. The protein content of Toruzyme®, determined by the Bradford method [12], was 5.65 mg mL−1.

Table 1 shows that the initial production of β-CD was nearly half the production of α-CD and slightly more than twice the production of γ-CD. The specific activities of Toruzyme® per unit mass of protein for producing α-, β-, and γ-CD, as determined under the reaction conditions, were 37.25, 19.61, and 8.63 U mg−1, respectively.

Sequential Batches

According to the results of HPLC analyses for the experiments that were carried out in the sequential batch mode, which are presented in Fig. 4, it was advantageous to employ two sequential batches because there was an increase in CD production compared with the single batch process. On average, CD production increased by 46.2% for the process without starch pretreatment for the second batch (2B) (α = 43.4%, β = 43.9%, and γ = 78.0%) and 57.4% for the process with starch pretreatment (2BP) (α = 60.8%, β = 46.7%, and γ = 84.0%). Comparing with the conventional single batch process without ethanol (1BwE), the increase in CD production was 184% using the process 2BP.

Although γ-CD is produced in smaller quantities than the other CDs, when the process was changed from one to two batches, the increase in its production was very significant, reaching 84.0% for the case with the use of pretreated starch at the second batch. This is an interesting result since γ-CD has a very high market value.

In Table 2, it can be observed that although more CD mass was obtained for the second process (8.7 versus 5.5 g), the yield of CDs produced relative to the amount of starch was 37% for the single batch process and 29% for the process with two sequential batches because the latter used twice as much starch as the first (30 versus 15 g). Nevertheless, as starch is a low-cost raw material (about US $0.5/kg) compared with the price of CDs (US $3–100/kg) [1] and Toruzyme® is a high-cost product (about 60 USD kg−1), the process with two sequential batches proved to be advantageous over the single batch process because it led to higher CD yield for the same quantity of enzyme used (87 versus 55 g of CD per milliliter of enzyme). In addition, unreacted starch can be reused in the process.

Kim et al. [13] produced CDs using raw corn starch without pretreatment and a heat-stable CGTase from Thermoanaerobacter sp. (from Novo Nordisk Korea Ltd.), in the absence of ethanol. The conditions employed for CD production were: 65 °C; pH 6; substrate concentration, 7.5% (w/v); enzyme, 22 U/g−1 starch (=1,650 UL−1); reaction time, 24 h. The conversion of substrate to CDs was 27.9%, and the efficiency of CGTase was 12.68 mg CDs U−1. The higher efficiency obtained in the present work (148.7 to 235.1 mg CDs U−1), compared with that obtained by Kim et al. [13], may be explained by (1) the use of ethanol in the reaction that mainly favored the formation of α-CD, (2) the lower proportion of enzyme used in the reaction medium (370 UL−1), and (3) the use of the sequential batch process that allowed the reuse of the enzyme.

Conclusions

In conclusion, the production of cyclodextrins with the combined conditions of using starch granules as substrate, a thermostable enzyme, sequential batches, a single enzyme charge, enzyme reuse by adsorption, and 10% (v/v) ethanol is an economical process development that provides advantages such as higher cyclodextrin yield and relatively high temperature for an enzymatic process (65 °C), which is protective of microbial contamination and allows the practical separation of unreacted starch as an insoluble residue that can be easily centrifuged off.

References

Biwer, A., Antranikian, G., & Heinzle, E. (2002). Applied Microbiology and Biotechnology, 59, 609–617.

Martin Del Vale, E. M. (2004). Process Biochemistry, 39, 1033–1046.

Tardioli, P. W., Zanin, G. M., & Moraes, F. F. (2006). Enzyme and Microbial Technology, 39, 1270–1278.

Matioli, G., Zanin, G. M., & Moraes, F. F. (2002). Applied Biochemistry and Biotechnology, 98–100, 947–961.

Alves-Prado, H. F., Carneiro, A. A. J., Pavezzi, F. C., Gomes, E., Boscolo, M., & Franco, C. M. L. (2008). Applied Biochemistry and Biotechnology, 146, 3–13.

Li, Z., Wang, M., Wang, F., Gu, Z., Du, G., & Wu, J. (2007). Applied Microbiology and Biotechnology, 77, 245–255.

Qi, Q., Mokhtar, M. N., & Zimmermann, W. (2007). Journal of Inclusion Phenomena and Macrocyclic Chemistry, 57, 95–99.

Nakagawa, T., Ueno, K., Kashiwa, M., & Watanabe, J. (1994). Tetrahedron Letters, 35, 1921–1924.

Endo, T., & Ueda, H. (2004). FABAD Journal of Pharmaceutical Sciences, 29, 27–38.

Mattsson, P., Korpela, T., Paavilainen, S., & Mäkelä, M. (1991). Applied Biochemistry and Biotechnology, 30, 17–28.

Bertolini, A. C., Cereda, M. P., & Chuzel, G. (1998). Ciência e Tecnologia de Alimentos, 18(2), 224–229.

Bradford, M. M. (1976). Analytical Biochemistry, 72, 248–254.

Kim, T.-J., Kim, B.-C., & Lee, H.-S. (1997). Enzyme and Microbial Technology, 20, 506–509.

Dixon, M., & Webb, E. C. (1976). Enzymes (3rd ed.). London: Longman Group Ltd.

Bailey, J. E., & Ollis, D. F. (1986). Biochemical engineering fundamentals (2nd ed.). New York: McGraw-Hill.

Tipton, K. F. (2002). In R. Eisenthal & M. Danson (Eds.), Enzyme assays (2nd ed., pp. 1–47). New York: Oxford University Press.

Blackwood, A. D., & Bucke, C. (2000). Enzyme and Microbial Technology, 27, 704–708.

Mori, S., Goto, M., Mase, T., Matsuura, A., Oya, T., & Kitahata, S. (1995). Bioscience, Biotechnology, and Biochemistry, 59, 1012–1015.

Brewster, M. E., & Loftsson, T. (2007). Advanced Drug Delivery Reviews, 59, 645–666.

Acknowledgments

The authors thank the National Council for Scientific and Technological Development (CNPq), the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Fundação Araucária for financial support and Novozymes for the gift of Toruzyme®.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Calsavara, L.P.V., Dias da Cunha, A.R., Balbino, T.A. et al. Production of Cyclodextrins from Cornstarch Granules in a Sequential Batch Mode and in the Presence of Ethanol. Appl Biochem Biotechnol 165, 1485–1493 (2011). https://doi.org/10.1007/s12010-011-9369-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-011-9369-x