Abstract

The research on cyclodextrin started at the beginning of the 1970s at Cyclodextrin Research Laboratory of Chinoin Pharmaceutical and Chemical Works Co. Ltd. in Hungary. Professor József Szejtli, the leading scientist of the field, soon recognized the importance of production. According to his estimations, market demands were likely to reach 1000–2000 tons per year. In early times, cyclodextrins were available on the market only as fine chemicals in few gram quantities. Cyclodextrins were produced by enzymatic degradation and subsequent cyclization of starch, forming a mixture of acyclic and cyclic dextrins. The converting enzyme, cyclodextrin glucosyltransferase, could be found in some strains of soil microorganisms. The industrial scale production of enzyme possessing high cyclizing activity was an essential demand for the high capacity cyclodextrin production. It was also aimed to develop an appropriate starch conversion technology capable to produce alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin at high yields by the means of processed enzyme.

Development of both enzyme fermentation and starch conversion technology was started simultaneously around the mid of the 1970s, in the microbial and processing laboratories of Chinoin, respectively. The researcher had to tackle (i) selecting the microorganism producing cyclodextrin glucosyltransferase enzyme; (ii) building up analytical methods for cyclodextrin glucosyltransferase enzyme activity; (iii) optimizing the conditions for cultivation; (iv) separating the enzyme from culture medium; (v) purification and characterization of the enzyme; (vi) selection of starch and optimization of hydrolysis by alpha-amylase; (vii) optimizing the enzymatic conversion of starch to the mixture of cyclic and acyclic maltodextrins; (viii) optimizing the conditions for the desired ratio of alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin in the conversion mixture; (ix) developing an alpha-cyclodextrin-specific conversion pathway; (x) developing a gamma-cyclodextrin-specific conversion pathway; (xi) developing analytical techniques for characterization of the composition of the conversion mixture; (xii) separating cyclodextrin(s), purification, and crystallization; (xiii) scaling up the production; and (xiv) developing an immobilized enzyme.

As a result of substantial development, the first 100 kg beta-cyclodextrin was produced in 1978. Parallel to the development of the cyclodextrin production, the technologies for the preparation of some cyclodextrin derivatives were also scaled up: hydroxypropyl-beta-cyclodextrin as a parenteral drug carrier and cyclodextrin bead polymer for wound healing were selected for industrial production.

This chapter gives the details on how the development of the production technologies proceeded and how the difficulties were overcome until the final technologies were documented and the industrial production realized.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- History

- Production

- Enzyme production

- Native cyclodextrins

- Cyclodextrin derivatives

- Cyclodextrin polymer

- Industry

4.1 Introduction

Cyclodextrin research in Chinoin Pharmaceutical and Chemical Works Co. Ltd., one of the biggest pharmaceutical companies in Hungary and Central Europe, started after Professor József Szejtli established the Biochemical Research Laboratory in 1972. The radical development of cyclodextrin processing began after 1975 and continued in close collaboration with the Biotechnology Development Department of the factory. The first cyclodextrin-related research paper on achievements of laboratory was published in 1975. Also in this and subsequent years, the authors of this chapter were involved in the cyclodextrin research to witness or participate in research and development of cyclodextrin production.

In the mid of the 1970s, it was generally accepted that (i) cyclodextrins were interesting compounds able to molecularly encapsulate various organic materials; (ii) cyclodextrins were toxic, hindering practical utilization; and (iii) cyclodextrin production was complicated and expensive; therefore large-scale applications were not conceivable. There were only a few, including Professor Szejtli, who did not believe in these statements. He was sure in that times that oligosaccharides, like cyclodextrins, cannot be toxic and their production should be economical in large scale. It was clarified later that the toxicity was concluded based on erroneous experiments using unpurified cyclodextrins.

In the time 1975–1976, cyclodextrins were available in small quantities, mainly as fine chemicals produced on laboratory scale. According to common procedure, a cyclodextrin glucosyltransferase enzyme was added to a dilute solution of gelatinized starch, and the enzymatic degradation was allowed to proceed for a sufficient time. The main drawback of this procedure was that acceptable conversion was achieved only at low substrate concentration owing to high viscosity of >5% potato starch solution which limits the enzyme reaction. The viscosity was reduced by means of hydrolyzing starch to small fragments resulting an average dextrose equivalent (the amount of reducing sugars present in a sugar product, expressed as a percentage on a dry basis relative to dextrose) of <20. This preliminary procedure allowed to use 30% substrate concentration resulting in cyclodextrin yields high enough for scaling up the process to industrial level (Armbruster and Kool 1969). The pre-hydrolysis performed either by acidic hydrolysis (Armbruster and Mukhtar 1968) or by α-amylase resulted in water-soluble starch fractions with reduced tendency for retrogradation. After the partial hydrolysis, the starch was converted to cyclodextrins by cyclodextrin glucosyltransferase. Utilizing the outstanding inclusion complex-forming ability of cyclodextrins and the low solubility of resulting complexes, various apolar precipitating agents, such as toluene, trichloroethylene, and bromobenzene, were recommended for selective beta-cyclodextrin formation (Armbruster and Kool 1969; Armbruster 1970).

It was already known that the cyclodextrin yield could be highly enhanced by applying these complexing agents in the cyclodextrin glucosyltransferase-catalyzed starch conversions. Cyclodextrin reaction products could be collected from the enzyme-catalyzed reaction mixture by precipitation, inclusion complex formation, and crystallization (Table 4.1) (Armbruster and Kool 1969). Figure 4.1 refers to the general principle of cyclodextrin production. It was also recognized that using an appropriate complexing agent, the conversion equilibria could be shifted toward the production of desired cyclodextrin. For instance, long alkyl chain alcohols were found useful for production of alpha-cyclodextrin as dominant cyclodextrin component (Armbruster and Jacaway 1969) (Table 4.1).

Optimizing the reaction conditions, 100% pure alpha-cyclodextrin or beta-cyclodextrin was obtained by applying a selective precipitant, 1-decanol or toluene, respectively (Armbruster and Jacaway 1969). Figure 4.2 shows the Schardinger β-dextrin (beta-cyclodextrin) marketed as cyclohexane complex and purchased from Sigma, at the end of the 1970s.

Because of the growing interest for cyclodextrin production, the focus was directed to isolation and purification of cyclodextrin-producing enzymes. Before the 1970s, only few bacteria, i.e., Bacillus macerans, Bacillus circulans, and Bacillus polymyxa, were described as appropriate cyclodextrin glucosyltransferase enzyme sources. According to the patent of Armbruster and Kool (1969), maximum yields of cyclodextrin were obtained within 2–7 days at 50 °C and a pH of about 7 when the enzyme dosage ranged between 100 and 1000 Tilden-Hudson units per 100 grams of starch.

A few other cyclodextrin-producing bacterium strains were reported later, e.g., B. megaterium and B. stearothermophilus were recognized as good enzyme producers (Shiosaka 1973; Okada and Kitahata 1975). For purification of enzyme, various multistep processes including precipitation, adsorption on starch, and gel filtration were developed (Okada and Kitahata 1975). Later, an alkalophilic and thermostable cyclodextrin glucosyltransferase derived from Klebsiella pneumoniae with a considerably high initial cyclization rate especially on long-chain maltodextrin was reported (Bender 1977).

The first Japanese patents described processes using trichloroethylene, chloroform, and bromobenzene as appropriate beta-cyclodextrin precipitation agents in potato starch conversion (Okada and Tsujama 1974; Horikoshi 1975; Horikoshi and Nakamura 1979). The other Japanese technologies applied strict control on maltose and glucose concentration (Suzuki et al. 1975) and used ion-exchange resin for separation of cyclodextrins from glucose and other linear dextrins with reducing end groups in conversion mixture (Suzuki et al. 1975; Yoritomi and Yoshida 1976). At the beginning of the 1980s, the latter technologies led to the early approval of cyclodextrins as enzymatically modified starch for food and pharmaceutical use by the Japanese Food and Drug Administration Agency (Nagai 1982). Szejtli (1988, 1990) reviewed the various cyclodextrin-producing technologies.

4.2 History of Hungarian Cyclodextrin Production

The cyclodextrin research at Chinoin Pharmaceutical and Chemical Works Co. Ltd. started in 1975. As a world-known outstanding expert of carbohydrate chemistry, Professor Szejtli received the background including a new laboratory and annual budget for this research. The management of the factory supported his initiative for the cyclodextrin production. According to Chinoin marketing experts, it seemed to be a massive beta-cyclodextrin demand in world market, in not too distant future. Cooperation agreement between the Biochemical Research Laboratory (this was the name of the cyclodextrin research laboratory headed by Professor Szejtli) and the Fermentation Factory Group of Chinoin including Biotechnology Development Department was signed in 1976. Further, both cyclodextrin glucosyltransferase preparation and cyclodextrin production proceeded in close cooperation of research and development members. Milestones of the technology development are summarized in chronological order in Fig. 4.3.

4.2.1 Development of Enzyme Production

4.2.1.1 Selection of a Cyclodextrin Glucosyltransferase Enzyme-Producing Microorganism and Optimizing the Cultivation Conditions

Cyclodextrin glucosyltransferase is a unique enzyme, which reacts with starchy substrates with three action mechanisms: cyclizing, transglucosylation (coupling and disproportionation), and hydrolyzing. It should be noted that cyclodextrin glucosyltransferases always produce alpha-cyclodextrin as primary cyclization product, which is transformed into beta-cyclodextrin and gamma-cyclodextrin in parallel due to coupling and cyclization reactions proceeding mainly in late stage of starch conversion.

The research started with selecting the proper bacteria expressing the desired enzyme able to produce cyclodextrins with highest activity and productivity. Various B. macerans, B. circulans, B. stearothermophilus, and B. polymyxa strains were screened for the best cyclodextrin glucosyltransferase, which converts starch into the preferable beta-cyclodextrin in the maximal ratio. The following parameters had to be optimized: (i) cultivating circumstances of an industrial strain; (ii) ingredients of culture medium; (iii) screening of various amino acid nitrogen sources; and (iv) fermentation parameters such as determination of optimal pH, cultivation temperature, and oxygen uptake.

Hundreds of experiments were carried out to find optimal conditions for cultivation of these bacteria. Mutagenic stimulation by either UV or X-ray irradiation was also intensively applied. It was crucial also to select an optimal cultivation medium. Finally, selection among various carbon sources led to a recognition that oat bran was the best nutrient for culturing. The main steps in laboratory development of cyclodextrin glucosyltransferase enzyme (1976–1982) are summarized in Fig. 4.4.

Development steps for enzyme production by fermentation (screening methods, Tilden-Hudson (TH) method and Fuwa method for enzyme activity measurements; see section “Measuring of Enzyme Activity”)

4.2.1.2 Measuring of Enzyme Activity

In very early times, in correspondence with the actual literature sources, cyclodextrin glucosyltransferase activity was measured by the earliest Tilden-Hudson method (Tilden and Hudson 1942). This simple procedure was based on visual observation of primary enzyme attack, i.e., alpha-cyclodextrin production from soluble starch substrate. The enzyme-catalyzed metamorphosis of starch-iodine-enzyme mixture can be visualized under microscopic investigation. The reaction endpoint relates to the time required for disappearance of the blue color of initial starch-iodine complex and the appearance of characteristic dichroic needle-like alpha-cyclodextrin crystals. One Tilden-Hudson (TH) unit is the amount of enzyme required to convert 30 mg of starch in 30 min at 40 °C to the brown-violet stage. The disadvantages of Tilden-Hudson method are the individual uncertainty in microscopic observation and that it only detects an unwanted property: initial alpha-cyclodextrin cyclisation rates can be seen only and gives no direct information on beta-cyclodextrin producing ability of the enzyme. Additionally, other carbohydrase enzymes can disturb the measurement.

In the later conversion stage, cyclodextrin glucosyltransferase promotes decylization and transferring glucosyl moieties to the initially produced alpha-cyclodextrin, resulting in the formation of higher degree of polymerization beta- and gamma-cyclodextrins in the conversion mixture. The methods of Fuwa (1954) and Kitahata et al. (1974) for determination and screening of cyclodextrin glucosyltransferase activities characterized this second step. The reaction mixture containing soluble starch and the enzyme in a pH 5.5 buffer was incubated at 40 °C for 10 min. Thereafter, aliquot of this mixture was added to iodine in potassium iodide solution and diluted with distilled water. As zero control, aliquot of this reaction mixture was also added to the iodine solution before the incubation. Absorbance was measured at 660 nm. According to Fuwa (1954), the enzyme activity is defined as the amount of enzyme that produced a difference in absorbance of 1.0 unit per min under the described conditions. According to the later published and generally accepted Kitahata method, one Kitahata unit corresponds to 1% decrease in light absorption in 1 min (Kitahata et al. 1974). Because this assay refers to time-lapsed secondary stage of enzyme starch conversion, it fulfills the development requirements for not only beta-cyclodextrin but gamma-cyclodextrin formation, too. To match the early-published data, it was postulated that one Tilden-Hudson unit activity corresponds to approximately 3 Kitahata units.

To detect parallel both recycling and glucosyl coupling enzyme activity, a method utilized in presence of alpha-methyl glucoside acceptor was also developed. The reaction product of hydrolysis by hog pancreatic alpha-amylase (maltose) can easily be measured by any conventional reducing sugar determination method. The main advantage of this method is that the cyclodextrin glucosyltransferase enzyme action is not disturbed by the presence of common hydrolytic enzymes, because these enzymes are unable to split alpha-cyclodextrin substrate (Thoma and Stewart 1965).

A similar rapid method for determination of cyclodextrin glucosyltransferase activity was elaborated in the Chinoin Biotechnology Development Laboratory by further development of Thoma’s activity assay (Péterfi and Seres 1982). This method was based also on general glucosyltransferase mechanism: the forming enzyme splits alpha-cyclodextrin substrate, and –in the presence of hog pancreatic amylase – the resulting linear fragment is coupled to the C-1 terminal of p-nitrophenyl-beta-D-glucoside acceptor. The resulting mixture of saccharides can easily be detected as reducing sugars by any conventional method measuring reducing ability, by dinitrosalicylic acid assay in this case.

A reliable cyclodextrin glucosyltransferase activity measuring method, which is based on direct determination of nascent cyclodextrins by means of high-performance liquid chromatography, applies a polymer-based reverse phase column equipped with a refractive index detector. The advantage of this assay is that enzyme activity is expressed in SI system in units of micromoles cyclodextrin/g substrate, in accordance with later regulations of Enzyme Commission (Sato 1985).

Because of the simplicity of Kitahata method, and due to its wide representation in overall process technology documentation, the proposed more specific and accurate glucosyl transfer methods were not introduced into Chinoin practice, and in the lack of any equipment, high-performance liquid chromatography-based activity method was not applied either. A basic language computer program was compiled later for quick calculation of Kitahata unit values and immersing results directly into the newly established technology database of Chinoin (Seres 1986). Figure 4.5 shows the computer used for these calculations.

4.2.1.3 Separation of Enzyme from Culture Medium and Purification

Summarizing the forthcoming data of enzyme purification technologies described in the literature, it was concluded that the technology based on multistep precipitation, sorption on starch, and chromatography was expensive, complicated, and time-consuming (Kobayashi et al. 1978).

Initially, researchers had to develop an independent and patentable cyclodextrin glucosyltransferase-producing bacterial strain. After numerous isolation and screening efforts, an appropriate soil microorganism Bacillus macerans strain – isolated from putrid potato – proved the best enzyme-producing source. Unfortunately, this strain was covered by an American patent (Armbruster and Mukhtar 1968). So, profound X-ray and UV light mutagenic treatments were needed to isolate a taxonomically different new bacterial strain. The resulting new mutant was characterized and patented thereafter.

The first documentation filed in 1976 referred to the preparation of a crude enzyme powder of independent B. macerans mutant industrial strain and involved the instructions for laboratory-scale preparation. It was not easy to work out a process, because of permanent industrial aim to develop a simple, economical, and relatively not time-consuming procedure, robust and reproducible enough and suitable for continuous manufacturing. The problem was that fermentation liquor always contained other hydrolytic amylases synthetized in final stage of cultivation. These hydrolytic enzymes interfered with cyclodextrin glucosyltransferase and reduced randomly the yield of cyclodextrins. Therefore, continuous efforts were made, and an outstanding attention focused to the development of a hydrolytic factor proof enzyme isolation and purification technology. The objective was inserting a fractional salting out step into the downstream enzyme processing. This fractional precipitation was carried out using ammonium sulfate. In this way, the alpha-amylase contamination of final product could be reduced. A combined purification procedure involving gel filtration and isoelectric focusing was applied to get a fine enzyme preparation and for physicochemical characterization of our new B. macerans mutant enzyme (Seres 1984). As a result of these investigations, the molecular weight was found 79 kDa, and two isomeric forms were proved (Seres 1986 and Table 4.2).

In the early 1980s, a new and innovative enzyme purification method was worked out in cooperation of the Chinoin researchers (Seres’s team) with research members (Professors E. László, Á. Hoschke, and B. Bánky) of Agrochemical Department of Budapest University of Technology. This ingenious chromatography procedure was based on the specific key-lock enzyme substrate affinity property. Alpha-cyclodextrin was immobilized on an agarose gel matrix at first, to get an immobilized affinity chromatography stationary phase. When passing the crude cyclodextrin glucosyltransferase concentrate through this alpha-cyclodextrin-agarose gel column, cyclodextrin glucosyltransferase enzyme was selectively affixed to its covalently bound substrate. After completely washing off the unbound constituents, the enzyme could be eluted by concentrated solution of alpha-cyclodextrin substrate (Fig. 4.6). The technology was scaled up to 250-cm3 volume affinity column, which allowed to load 1.5–2.0 mega-Kitahata unit crude enzyme concentrate in a single cycle, resulting in a highly purified enzyme product, with 78–94% overall yield. The chromatography was carried out at 5–7 °C to avoid enzyme decomposition. The time requirement of one affinity adsorption-desorption cycle was typically 26–30 h (Seres et al. 1980).

Four steps for purification of cyclodextrin glucosyltransferase (CGTase) enzyme by affinity chromatography: 1. sample introduction; 2. adsorption of cyclodextrin glucosyltransferase on alpha-cyclodextrin substrate bound to column packing; 3. removal of impurities such as other proteins, low molecular weight compounds, and inorganic salts; 4. retrieval of cyclodextrin glucosyltransferase by selective elution with alpha-cyclodextrin-containing buffer

The affinity-chromatography-based enzyme processing can be summarized in three main steps:

-

Step 1: Preparation of affinity chromatographic sorbent (occasional) – sepharose-6B agarose gel was reacted with 1,4-butanediol diglycidyl ether, and alpha-cyclodextrin was added to be bonded; approximately 10 μmol alpha-cyclodextrin/g wet gel was immobilized by this method; the resulting affinity sorbent was quite stable and reusable many times and possessed high binding affinity toward cyclodextrin glucosyltransferase.

-

Step 2: Laboratory-scale concentration of enzyme via affinity chromatography – initially, the crude fermentation liquor filtrate was concentrated to 1/10 in volume, and its pH maintained to slightly acidic (pH 6); this filtered concentrate was passed through the cooled chromatographic column filled with the special affinity chromatographic absorbent; loading about 2000 mL of filtrate corresponding to 200,000 Kitahata units with 100 mL/(cm2*h) linear flow velocity, the whole cyclodextrin glucosyltransferase content was bound to the affinity stationary phase; the unreacted proteins, pigments, and further organic and inorganic ingredients could be removed by washing the column with water and diluted sodium chloride solution thereafter; the column effluent contained unreacted hydrolytic enzyme constituents, except for cyclodextrin glucosyltransferase active ingredient.

-

Step 3: Elution and freeze-drying of purified product – the cyclodextrin glucosyltransferase enzyme bound to the column was eluted by 1% alpha-cyclodextrin-containing buffer; the resulting column effluent was a concentrated solution having high (2 Kitahata units/100 mg protein) cyclodextrin glucosyltransferase activity. This alpha-cyclodextrin-containing enzyme solution was diluted with buffer to 104 Kitahata units/mL, filtered through a 0.2 μm pore size membrane filter, and dispensed into sterile glass lyophilization vials to obtain a uniform filling quantity of 104 Kitahata units/vial via freeze-drying; finally, the vials were closed under vacuum and labeled.

At the time of these technology developments, Hungary belonged to the Soviet block, and any sophisticated equipment, for example, automatic chromatography instrument (Pharmacia) or any HPLC analytical system, was embargoed. The spare parts of the chromatographs needed for automation of affinity chromatography and protein purification were purchased in the Western countries by the researchers as tourists and personally imported, violating the embargo. Finally, a chromatograph was constructed by Chinoin’s researchers, who developed also an elution control program to obtain the equipment useful for attention-free, semi-automatic enzyme production.

For pilot plant scale-up, affinity chromatography parameters were optimized: elution rate, temperature of binding, selection of buffer (acetate or phosphate), pH, volume of buffer, volume of column packing, and enzyme load. Based on these experiments, the optimized operation parameters were established, and the documentation of instructions for laboratory-scale production submitted in 1985. The column packing had the capacity to bind as much as 500 mg enzyme related to 1 mL gel bed volume from 100 to 1000 mL culture broth in one cycle (Szejtli et al. 1980a).

The industrial cyclodextrin glucosyltransferase manufacturing started at Chinoin Fermentation Plant in 1981, with the selected best mutant strain of B. macerans. Both inoculation and fermentation culture media consisted of oat flake and corn steep liquor as appropriate carbon sources. The essential nitrogen was applied in ammonium sulfate form. To ensure an optimal enzyme-stabilizing environment, pH of the oat-flake-containing fermentation broth was maintained to near neutral, with addition of potassium bisphosphate and calcium carbonate. The main fermentation was carried out at 37 °C, for 2 days. The fermentation liquor was filtered on a rotary vacuum drum filter and concentrated to its 1/10 volume in vacuum evaporators. The macromolecular enzyme fraction of resulting concentrate was salted out with ammonium sulfate, filtered, and dried. The industrial process technology, suitable for enzyme production in 10–100 mega Kitahata unit range in 3 m3 batch volumes, was realized in 1982. An amount of 150 mega Kitahata unit crude enzyme powder was processed this year, barely enough for producing about a 100 tons beta-cyclodextrin quantity.

The Chinoin’s cyclodextrin glucosyltransferase product was a highly purified preparation isolated from B. macerans fermentation liquor and concentrated by about 200-fold related to its original specific activity by affinity chromatography (Seres and László 1982). The enzyme was available as a white odorless freeze-dried powder shipped in 5 mL vials under reduced pressure.

In 1984 and 1985, 500 and 600 vials were sold as fine chemical via Lucerna-Chem AG. At that time only Chinoin and Amano Pharmaceutical Co. (Japan) produced this enzyme in purified form. Specification of the purified enzyme manufactured by Chinoin Pharmaceutical and Chemical Works Co. Ltd. was set up (Table 4.2).

At this time, the management of Chinoin was considering purified enzyme production for sale. As part of new economical era, a special new firm formation, so-called part-time work cooperative, the Cyclodextrin VGM was established in the factory in the late 1980s. This VGM was responsible for the affinity chromatographic manufacturing and qualification of the product, with a cooperation with Central Analytical Department of Chinoin. Due to lack of any export license, both sales and distribution of product were managed by an international cooperation between Reanal Fine Chemicals Co. (Budapest, Hungary) and LucernaChem AG (Luzern, Switzerland) (Fig. 4.7).

In the late 1980s, additional attempts were made to purify further this lyophilized cyclodextrin glucosyltransferase enzyme product by gel filtration in pilot plant scale. After separation by gel chromatography on Sephacryl-S-200, the resulting fractions were lyophilized on a Leybold-Heraeus industrial equipment (Seres and László 1988). Because no significant enhancement in specific activity and catalytic properties was observed after purification, the extra pure enzyme was not produced for commerce.

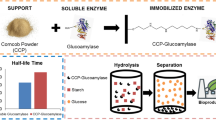

4.2.1.4 Immobilization of the Enzyme

As a final step of developments, the cyclodextrin glucosyltransferase enzyme was immobilized on an appropriate carrier to reduce the enzyme consumption and simplify the downstream procedure. Using immobilized enzyme, the same enzyme could be utilized in several conversion cycles either in batch-wise or continuously operating technologies. To implement above development concept, experiments started in 1980 using a commercially available carrier, Eupergit-C. Common coupling studies were performed at Reanal Fine Chemicals Co. (Budapest, Hungary) by researchers with high experience in enzyme immobilization. The cyclodextrin glucosyltransferase enzyme was reacted with carbodiimide-activated polysaccharide-based carrier. Another immobilizing procedure was invented using carboxyl functional group-containing acrylic polymer backbone (Boross et al. 1986; patent application was submitted in 1982).

In contrast to activity of enzyme immobilized on cellulose, which was only 26.5 Kitahata units/g dry weight, the enzyme immobilized on polyacrylamide reached the 230–450 Kitahata units/g. Immobilization shifted the pH optimum from 5.9 to 5.5. The temperature optimum range was rather broad, between 40 and 60 °C, whereas the soluble enzyme had a relatively sharp activity peak around 60 °C. Half-life was improved considerably at all pH values and temperatures. For example, the half-life of the soluble enzyme at 70 °C (optimum pH 5.9) is only 1.0 min, while that of the immobilized enzyme was 24.3 min (optimum pH 5.5) (Ivony et al. 1983a, b). Degree of immobilization was strongly dependent on the structure of disubstituted carbodiimides (Szajáni et al. 1991).

The continuous mass transfer kinetic of semi-permeable membranes made from immobilized cyclodextrin glucosyltransferase enzyme-containing acrylic polymers was thoroughly studied by Professors E. Nagy and Cs. Sisak, researchers at Technical Chemistry Research Institute, Veszprém (MÜKKI, Hungary). Compared to dissolved enzyme, enhanced stability and reusability were an important advantage, permitting a possibility for development of continuous cyclodextrin manufacturing procedure, instead of batch-wise processes (Sisak et al. 1996). A stirred tank reactor system, operated with immobilized cyclodextrin glucosyltransferase enzyme beads, was developed. This reaction vessel was coupled to a hollow fiber ultrafiltration membrane to separate cyclodextrin from the low molecular reaction products. This laboratory system worked in recycling mode developed for months. By means of such arrangement, starch substrate inhibition and the competitive blocking effect of glucose and short-chain oligosaccharides on the cyclization reaction diminished. Moreover, the time-dependent decomposition of parent cyclodextrins could be decreased in this system. Starch degradation and formation of glycosylic cyclodextrin coproducts were also repressed. Due to the change of regime in 1989 – unfortunately – the continuous production of cyclodextrins by using immobilized enzyme has not been scaled up on process scale.

4.2.2 Production of Beta-Cyclodextrin at Chinoin

Laboratory processing: The laboratory-scale experiments for development of beta-cyclodextrin production technology started in about 1977. The fundamentals of the technology have not changed since Schardinger (1903): A cyclodextrin glucosyltransferase enzyme of B. macerans origin was used. It was clear, at the first occasion, that foamy, stinking, and not easy-to-handle culture liquors of B. macerans were not suitable for an economical high-throughput industrial manufacturing. After optimizing the fermentation, crude enzyme filtering and fractionating parameters of the downstream processing were established, and a robust and reproducible enzyme technology was documented in 1982. Compared to achievable 8.7% and 10.2% cyclodextrin yields using crude enzyme powder supply, conversion rates of beta-cyclodextrin production increased to 12.6% and 17.5% after 3- and 5-day incubation, respectively, with a semi-purified and hydrolase-free enzyme preparation (Seres et al. 1980).

Beta-cyclodextrin manufacturing technology: In the early 1980s, only Japanese firms distributed limited quantities of purified beta-cyclodextrin in the world market: (i) Celdex-N from Nihon Shokuhin Kako (a company belonging to Mitsubishi, Japan); (ii) Ringdex from Ocean Sanraku (a company belonging to Sumitomo, Japan); and (iii) Dexypearl from Ensuiko Sugar Refining Co. Ltd. Japan.

The initial concept was based on the common accepted fact that continuous precipitation of water-insoluble toluene/beta-cyclodextrin complex shifted the conversion direction toward beta-cyclodextrin production. After preliminary laboratory procedures using potato starch, corn starch was selected as raw substrate because of the higher abundance in Hungary and its lower price. Due to its shorter chain and more branched structure of corn amylopectin, reduced viscosities could be achieved after gelation of the high-starch-containing gel. This gelatinization process makes possible to prepare a concentrated (20–45 w/w %) gelatinized starch solution with considerable viscosities without any observable retrogradation of starch and provides high cyclodextrin levels in the further cyclodextrin glucosyltransferase-catalyzed conversion (Vakaliu et al. 1979). An optimal starch concentration of around 30% was found to give the highest cyclodextrin yield. Additional step was inserted into the process to hydrolyze the resulted starch gel to 1–3 dextrose equivalents. For the sake of this mild hydrolysis, an alpha-amylase of Bacillus subtilis origin was applied. Existing calcium ions are essential to stimulate – as cofactor – both alpha-amylase and cyclodextrin glucosyltransferase activity. The optimal pH (7.2) and the essential cofactor input were maintained with sodium hydroxide and calcium carbonate. The cyclodextrin glucosyltransferase used in this process was the own product of Chinoin.

Laboratory-scale conversion technology using corn starch and toluene complexant was developed in the late 1970s. The optimized parameters include 30 w% pre-hydrolyzed corn starch, 5 v% toluene, 50 °C conversion temperature, pH 6.8, and 5 days conversion time.

The scale-up of cyclodextrin conversion technology started in 1978 in the pilot plant of Chinoin (plant IX). The cyclodextrin conversion (in presence of toluene complexant) was implemented at 3 m3 level. The preliminary pilot plant technology manual describes a cyclodextrin glucosyltransferase-catalyzed corn starch conversion leading to a high beta-cyclodextrin-containing starch degradation mixture. The downstream processing was based on a new development, namely, cyclodextrin content was separated via its soluble ethanol complex form. With 30 v/v % ethanol in the final conversion mixture, the beta-cyclodextrin and gamma-cyclodextrin are soluble; other insoluble cyclodextrins and degraded starch reaction products can be filtered off.

To realize this separation step, after filtration of final conversion mixture, the filter cake containing toluene-cyclodextrin complex was re-suspended in water; then the toluene content was eliminated by steam distillation. Beta-cyclodextrin was separated from linear starch degradants and maltodextrins in soluble ethanol complex form. For this reason, purification technology involved a step of adding twofold ethanol to the concentrate. The resulting ethanol complex solution was hot filtered, concentrated in vacuum, decolorized with charcoal, filtered, and crystallized. Using this technology 112 kg of pure beta-cyclodextrin was manufactured in 1978. The purity of resulting beta-cyclodextrin was >99.7%, and the overall yield was 33%, calculated on corn starch reference. This procedure was applied for patenting in 1977, and that patent was granted in 1980 (Vakaliu et al. 1979), based on a preliminary laboratory-scale production documentation compiled in 1977.

The high ethanol consumption, however, made the beta-cyclodextrin technology too expensive. To reduce the producing costs, a new process was elaborated at Chinoin Biotechnology Department. This concept was based on decaying the remaining unreacted dextrins derived from the high molecular weight fraction of conversion mixture. A thermostable alpha amylase of Bacillus amyloliquefaciens (BAN 240 L enzyme) was applied at the end of the cyclodextrin glucosyltransferase incubation period for this purpose. The resulting low viscosity conversion mixture could be filtered without difficulties. The cyclodextrin-toluene complex-containing filter cake was re-suspended in water, and toluene eliminated by steam distillation. Then the diluted material was decolorized with active carbon and hot filtered. The cyclodextrin-containing filtrate was concentrated in an evaporator thereafter. It was decolorized again with active carbon, and finally beta-cyclodextrin was crystallized. Based on initial laboratory-scale documentation, an industrial plant-scale technology was compiled by Biotechnology Department in 1979. Further experiments started in 1981 for industrial scale-up in plant Chinoin-IV in 1982.

For elimination of remaining toluene, sugar, and maltooligosaccharide traces, an additional purification procedure was inserted into the beta-cyclodextrin technology in 1981. It was realized by the application of mixed styrene divinylbenzene polymer-based Varion KS and Varion AD ion exchangers. To satisfy ongoing press for the substantial removal of toluene and also get rid of time-consuming intermittent drying technology, conventional drying ovens were substituted by a continuous fluid dryer. Based on these developments, the industrial beta-cyclodextrin manufacturing started in plant Chinoin-II, in 1985. Pure industrial beta-cyclodextrin was produced in a robust process with high throughput and appreciable yield (38% in average). The process and the parameters of the final technology can be seen in the flow chart in Fig. 4.8.

Between 1977 and 1981, 59 industrial batches of beta-cyclodextrin were characterized by the Quality Control Department of Chinoin. The pH of 26 lots did not conform the requirements (5 > pH > 8) with pH higher than the upper limit. The batches out of specification were qualified for using as additives in fire extinguishers, meanwhile the laboratory and the producing units tried to find explanation and solution for the phenomenon. That problem was resolved by flushing the converter’s connection lines with overheated steam before acid addition.

A wheat starch-based beta-cyclodextrin technology was also elaborated and documented by researchers of Chinoin Biotechnology Department in 1988. After mild alpha-amylolysis, toluene and methyl ethyl ketone as ternary cyclodextrin complexing agents were added simultaneously to partially degrade starch. Finishing the conversion, glucoamylase was used to disrupt high molecular weight dextrins. As final purification step, mixed strong anionic and cationic ion exchangers were inserted into the technology. Under these circumstances, also branched cyclodextrins of high aqueous solubility were produced from wheat starch substrate. In these branched cyclodextrins, glucosyl and maltosyl side chains were attached to glucopyranosyl units of the parent cyclodextrin via alpha-1,6 linkages. Compared with other starch sources, wheat starch produced the highest (35–40%) degree of conversion.

The conversion mixture obtained by processing pre-hydrolyzed starch using any cyclodextrin glucosyltransferase enzyme always contains negligible amounts of higher degree of oligomerization (9, 10, 11, and 12) cyclodextrins, so called large-ring cyclodextrins, moreover a series of branched cyclodextrins besides the three major (native) cyclodextrins. The solubilities of branched cyclodextrins in water, even in aqueous 80% ethanol or in aqueous 50% solutions of methanol, formaldehyde, and ethylene glycol, are extremely high in comparison with their parent cyclodextrins. Their ratio depends on the conversion time and the applied enzyme and can be strongly influenced by the reaction conditions, especially on the chemical nature of specific precipitating complexant. According to Chinoin developers, the ratio to beta-cyclodextrin can be enhanced if wheat starch and trichloroethylene or toluene is used as raw material and precipitating agent, respectively. From the crystallization mother liquors of wheat starch-based beta-cyclodextrin technology, the glucosyl beta-cyclodextrin content was recoverable at 50 °C, by the means of chromatography on Amberlite cation exchange resin (Seres et al. 1989). At that time, however, both branched cyclodextrins and large-ring cyclodextrins were considered scientific curiosities only.

Application of an immobilized cyclodextrin glucosyltransferase made possible a continuous process in a stirred reactor connected with a laboratory-sized hollow fiber membrane-equipped diafiltration cassette. Low molecular weight components, cyclodextrins, and maltooligosaccharides squeezed through the membrane, whereas unreacted amylose and amylopectin degradation products were recirculated. With continuous input of corn starch hydrolysate, benzyl alcohol was added into the reaction vessel containing cyclodextrin glucosyltransferase beads. This system was operated in steady state, for months in laboratory size; it has not been scaled up due to the lack of a suitable industrial filtration device.

Because of limited scale-up capacity, Chinoin Pharmaceutical and Chemical Works Co. Ltd. initiated negotiations with Győri Szeszipari Vállalat (Győr Distillery, Hungary) in 1985, to adopt the beta-cyclodextrin technology and scale up it in the future to 100 tons/year capacity. The original toluene-based beta-cyclodextrin technology, used in Chinoin earlier, was transformed into a large-scale manufacturing pathway in the Győr Distillery. The industrial production in 20 m3 volume fermentors was continued over 2 years in 1987–1989 period, to produce approximately 20 tons of beta-cyclodextrin.

As a factory product subjected to Hungarian food manufacturing law, permanent problem was to reduce the toxic toluene residual solvent in the high capacity manufacturing. According to Hungarian dietary regulation, the allowable limit of toluene was 1 ppm at that time. Moreover, it was a purchaser demand to get a toluene-free product, which is utilizable safely in dietary or pharmaceutical products. To resolve this problem, a new toluene-free conversion technology was elaborated at Chinoin Biotechnology Department, applying nontoxic benzyl alcohol as appropriate beta-cyclodextrin precipitant. This new beta-cyclodextrin conversion process using benzyl alcohol as complexant was developed in 1986–1988 period. Briefly, partially hydrolyzed corn starch was converted to cyclodextrins with in-house-manufactured industrial cyclodextrin glucosyltransferase in presence of benzyl alcohol precipitant. The non-cyclic oligosaccharide content of final conversion mixture was degraded to dextrose with glucoamylase, and the resulting mixture filtered at room temperature. After suspending filtered material in water, the precipitant content was eliminated via atmospheric pressure steam distillation. Continued with carbon decolorization and subsequent evaporation, the pure beta-cyclodextrin product was crystallized from the resulting concentrate.

Benzyl alcohol is, however, not stable under conversion-reaction circumstances. In the late conversion, benzyl aldehyde and benzoic acid oxidation products were formed in the reaction mixture. Therefore, many efforts were made to optimize conversion and steam distillation parameters to eliminate the cyclodextrin-benzaldehyde complexes. Additional experiments were focused on replacement of the original corn starch to its fiber-free corn starch grease form. Later corn starch was replaced with cheap wheat corn grinder, but because of its relatively high protein content, it was not proved an appropriate substrate. Due to change of regime, these technology variations were not realized in the process-scale manufacturing.

4.2.3 Production of Alpha-Cyclodextrin and Gamma-Cyclodextrin

The other two cyclodextrins, i.e., alpha-cyclodextrin and gamma-cyclodextrin, can be isolated from the conversion mixture by subsequent and combined application of bromobenzene and trichloroethylene according to method of French et al. (1949). The resulting products are of low purity materials, often contaminated by a toxic residual solvent (Armbruster and Jacaway 1969). Starch conversion was conducted in the presence of any aliphatic compounds having >8 carbon chain length, e.g., n-decanal resulted in mainly alpha- and beta-cyclodextrin-containing potato starch conversion mixture. Bromobenzene was applied by Bender (1984) for the special purpose to obtain a gamma-cyclodextrin-enriched conversion mixture. After removing bromobenzene by distillation, the linear dextrin fraction was precipitated by methanol, beta-cyclodextrin was removed by crystallization, and the residual solution was treated again with bromobenzene to obtain a product with 90% gamma-cyclodextrin and 10% beta-cyclodextrin composition. The final purification step was a crystallization in pyridine-methanol solvent mixture to get a gamma-cyclodextrin product of 98–99% purity.

Another method for separation of alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin from the conversion mixture was based on chromatography using ion-exchange columns (Okada et al. 1980). The main advantage of this method was elimination of the total quantity of organic precipitant; therefore no toxicity issues arose. On the other hand, the low capacity and high energy consumption required for the concentration of diluted solutions of cyclodextrins are drawbacks hindering the industrialization of this technology.

In consequence of the expensive multistep precipitation processes and chromatography, moreover the lack of industrial processing, both alpha- and gamma-cyclodextrins were available only as fine chemicals in the 1970s–1980s. In the conversion step, various polycyclic compounds were applied as precipitating agent. For instance, in 1982 gamma-cyclodextrin was available as fine chemical only purchased with a price of 1800 $/kg from Nihon Shokuhin Kako and 2740 $/kg from Senn Chemicals (Fig. 4.9). The high price of the gamma-cyclodextrin was the consequence of the special producing technology using a galaxolide-containing expensive musk oil, which is a common component in luxury perfumes.

Before elaboration of selective conversion technologies, in the early times, researchers focused on isolation of alpha- and gamma-cyclodextrin by-products, which originated from beta-cyclodextrin conversion. Primary efforts were taken to achieve remaining cyclodextrin content of crystallization mother liquors of beta-cyclodextrin manufacturing. This concentrated solution typically contained 3–5% alpha-cyclodextrin, 2% beta-cyclodextrin, and 6–10% gamma-cyclodextrin. Adding xylene precipitant to mother liquor, the beta-cyclodextrin and gamma-cyclodextrin complex was filtered off. The remaining short-chain maltodextrin and oligosaccharide components of filtrate were hydrolyzed with amyloglucosidase. After concentration in vacuum, cyclohexene was added to precipitate alpha-cyclodextrin. After filtration, the resulting insoluble complex was re-suspended in water, and cyclohexane was removed in the final concentration step carried out in a vacuum evaporator. The final 40% dry matter-containing concentrate was crystallized in a refrigerator to get pure alpha-cyclodextrin with 24% yield. After clarification by using active carbon, the cyclohexane filtrate containing gamma-cyclodextrin was concentrated up to 50% and crystallized, resulting in gamma-cyclodextrin with 40% yield, calculated on the basis of total cyclodextrin content of the initial mother liquor (Seres 1980b). After satisfying an initial, approximately 10 kg beta-cyclodextrin demand of Chinoin research, a concentrated attention was focused on targeted manufacturing of other cyclodextrins.

To retrieve a remaining considerable amount of gamma-cyclodextrin from xylene complex, the filtered cake was re-suspended in water, and the xylene was eliminated from the destroyed complex by steam distillation. The yield for gamma-cyclodextrin was 2.5%, expressed on initial corn starch base. Based on 1977–1979 experiments, laboratory documentation was issued in 1980, from Chinoin Biotechnology Department (Seres 1980b).

Because of continuous development of the beta-cyclodextrin processing technology, mother liquor reprocessing turned into uneconomically slow. The average yields both for alpha-cyclodextrin and gamma-cyclodextrin reduced below 1%. The faster the demand raised from world market for cyclodextrins, the greater effort was focused on developing special manufacturing technologies for target conversion, for not only beta-cyclodextrin but alpha-cyclodextrin and gamma-cyclodextrin, too.

Laboratory conversion experiments were initiated in the late 1970s to get alpha-cyclodextrin and gamma-cyclodextrin in intentional and selective conversion models. This work started with substantial screening experiments to find a specific cyclodextrin precipitant to achieve high alpha-cyclodextrin or gamma-cyclodextrin conversion rates (Seres 1980a, b). Moreover, researchers of Chinoin Biotechnology Department screened various starch substrates, too. Laboratory-scale micro-conversions were carried out in a thermostatted block reactor, equipped with 3 mL wells. The resulting conversion mixtures were concentrated by evaporation. Residual organic precipitant content was removed by combination of chromatography and activated carbon thereafter.

Micro-reaction mixtures were analyzed either by thin layer chromatography or overpressured layer chromatography. The latter method was a revolutionary new Hungarian investment that time (Tyihák et al. 1985). By means of this equipment, hundreds of chemicals were screened as potentially selective alpha-cyclodextrin or gamma-cyclodextrin complexants.

The pilot plant production of gamma-cyclodextrin was realized in Chinoin plant CH-VIII (Seres 1980c, 1985). A 70 kg quantity of corn starch was prehydrolized with B. subtilis alpha amylase. This partially degraded starch was converted to a mostly gamma-cyclodextrin-containing conversion mixture using Chinoin-manufactured B. macerans cyclodextrin glucosyltransferase, at 40 °C, and neutral pH, in presence of 1-naphtol and methyl ethyl ketone precipitants. After filtration of the conversion mixture, the cyclodextrin-enriched filter cake was suspended in methanol, refluxed, and separated. After centrifugation the resulting naftol-containing raffinate was removed, and the residue re-suspended in methanol-water mixture and refluxed again in presence of active carbon. After centrifugation the supernatant was passed through Varion KS and Varion AD ion-exchange columns. The column effluent was concentrated by evaporation, and the product crystallized from water. Processing of raw gamma-cyclodextrin, based on ternary complexation with 1-naphthol and methyl ethyl ketone, resulted in 11 kg of pure gamma-cyclodextrin in 1982.

The invention of Chinoin researchers was based on ternary complex formation and on the solubility-based separation of cyclodextrin complexes in different solvents, applied for patenting in 1983 and granted in 1988 (Seres et al. 1988). At first, the production of alpha-cyclodextrin was enhanced by using a proper complex-forming agent, for example, a strong ionic detergent, sodium dodecyl sulfate/methyl ethyl ketone, or a long-chain aliphatic alcohol and ketone. As the conversion was going on, the forming alpha-cyclodextrin was transformed into beta- and gamma-cyclodextrin especially in presence of ternary complex-forming agents such as toluene/methyl ethyl ketone or alpha-naphthol, respectively (Table 4.3). Both complexants were added together to the conversion mixture at the start. The synergy of the ternary system compared to the binary systems is illustrated in Fig. 4.10.

Comparison of binary and ternary complexing systems for gamma-cyclodextrin production after 140-h conversion. (Adapted from Seres and Barcza 1988)

An efficient specific and selective alpha-cyclodextrin conversion technology was developed in Biotechnology Department, which refers to a patented new ternary complex precipitation scheme, applying a long carbon chain surfactant in presence of an aliphatic ketone (Seres and Barcza 1988). In this case, sodium lauryl sulfate was applied together with methyl ethyl ketone as suitable ternary complexant. Using these ternary precipitants, cyclodextrin glucosyltransferase converted gelatinized corn starch hydrolysate (degree of polymerization 16–40) to alpha-cyclodextrin. The resulted conversion liquor was saccharified by fungal amylase (Fungamyl 800 L). After filtering, the filtrate containing soluble cyclodextrin complex was passed through a strong anion exchanger (Varion-AD, in OH form). After evaporation, cyclohexane was added into the resulting concentrate to precipitate the cyclodextrin. The solid complex was filtered off, and the filter cake washed with methanol to eliminate other dextrins. The centrifuged solid matter was dissolved in water and concentrated by steam distillation to remove the deliberated cyclohexane. After active carbon clarification, filtration, and evaporation, a high output of alpha-cyclodextrin (29 g) was crystallized at refrigeration temperature from 165 g initial optimized hydrolysate. The first industrial-scale production of alpha-cyclodextrin specially was realized at Chinoin plant CH-IV (Végh’s team). This procedure applied a long-chain alcohol (1-decanol) as complexant to shift the conversion to alpha-cyclodextrin. Because of violating Japanese patents, this manufacturing way was abandoned.

In the scaling up of the manufacturing technology, a lot of efforts were made to establish a unified process, which is good for production of all the three cyclodextrins in the same batch. The produced alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin were separated by consecutive precipitation with various solvents as shown in Fig. 4.11 (Seres et al. 1989). Adding chloroform to the concentrated conversion mixture, beta-cyclodextrin and gamma-cyclodextrin precipitated, while alpha-cyclodextrin and the other dextrins remained in solution. This solution was concentrated after filtration, and alpha-cyclodextrin was precipitated by adding n-decanol. The precipitate was suspended in water after filtration, and the residual solvent was removed by steam distillation. Pure alpha-cyclodextrin was obtained by crystallization upon cooling. The solid chloroform complexes of beta-cyclodextrin and gamma-cyclodextrin were suspended in water, and chloroform was removed by distillation. Cyclohexane was added in order to precipitate beta-cyclodextrin. The precipitate was re-suspended in water and cyclohexane removed by distillation. Then the pure beta-cyclodextrin was obtained by crystallization upon cooling. To obtain pure gamma-cyclodextrin, the filtrate was concentrated, and cyclohexane removed by distillation followed by crystallization. The resulting alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin products were of high purity (99.3%, 99.9%, and 99.8%, respectively). This new technology was brought into effect at the Chinoin plant CH-IV, in 1985. Overall 85.5 kg gamma-cyclodextrin was produced in four 1500 L volume conversion batches; neither alpha- nor beta-cyclodextrin was prepared by this way.

Separation of alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin by consecutive precipitation, filtration, and crystallization. (Adapted from Seres et al. 1989)

In the scaling up of alpha-cyclodextrin production based on developments of Chinoin Biotechnology Department (Seres’s team), decanol was used as precipitant to convert 25 v/v % corn starch into alpha-cyclodextrin as main component. The technology transfer and optimization were finished with success at the pilot plant at Győr Distillery in the first half of 1988. During this optimization series of experiments, the achieved typical alpha-cyclodextrin content was 7–13 v/v % of conversion mixture. The average yield was 9.6 kg alpha-cyclodextrin/100 kg corn starch. Because of political and economic changeover, industrial alpha-cyclodextrin processing efforts at Győr Distillery were interrupted.

4.2.4 Determination of the Individual Cyclodextrins in the Product

At the beginning, analyses of the cyclodextrins were only semi-quantitative. Thin-layer chromatography was a sufficient mode to separate individual cyclodextrins from process samples. A unique new reverse phase thin-layer chromatography method was developed for this purpose by researchers of Chinoin Biotechnology Development. The applied mobile phase on Kieselgel layer was a dioxane/ammonium hydroxide 10/7 v/v mixture. It was a preliminary implementation of the later discovered hydrophilic interaction chromatography mode in the early 1970s and has been shown to work in this case. Later overpressured layer chromatography was also used for analysis of high number of samples.

Based on Cramer’s early work on phenolphthalein cyclodextrin-induced decolorization, special quantitative analytical methods were developed by Cyclodextrin Research Laboratory team (Szejtli et al. 1978; Vikmon 1982) based on cyclodextrin complexation of various acid-base indicator dyes. The intensity of transmitted light due to the shift in absorption maxima in presence of cyclodextrin was measured spectrophotometrically. It was discussed later that appropriate dyes as methyl orange and Congo red also gave stable 1:1 complexes with cyclodextrin (Barcza and Buvari-Barcza 1989). These dyes having no any selectivity were able to detect only overall cyclodextrin quantities. The first quantitative gas chromatographic method applied for simultaneous analysis of various cyclodextrins was based on a derivatization of cyclodextrins to their corresponding dimethyl silyl derivatives, followed by separation on a porous layer open tubular column (Armbruster and Mukhtar 1968; Armbruster 1970).

In cooperation with a group at Eötvös Loránd University Faculty of Sciences (Budapest), a liquid chromatographic method was developed for the separation of the three natural cyclodextrins (Zsadon et al. 1978). This size exclusion chromatography method applied a mixture of strongly cross-linked dextran gels, Molselect G-15 and G-25, which were Hungarian-made column packings. Detection was carried out by continuous flow polarimetry. This detector had the unique property that only chiral compounds (like cyclodextrins) gave any response. The drawback of method was the elapsed analysis duration due to the achievable low flow rates on soft gel column packing. Figure 4.12 shows the separation of the native cyclodextrins in a conversion mixture sample obtained from industrial production.

Analysis of conversion mixture containing beta-cyclodextrin and gamma-cyclodextrin and soluble dextrins on a column of Molselect G-15 and G-25 gels (conditions, total bed volume 390 mL; flow rate 24 mL/h; eluent distilled water; Zsadon et al. 1978, CycloLab archive)

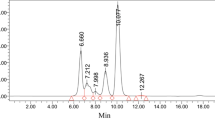

High-performance liquid chromatography was in the development phase in the second half of the 1970s. It proved to be more efficient than gel chromatography (Fig. 4.13). Although it was not postulated that time, the separation principle is a kind of hydrophilic interaction chromatography. A polar amino silica (μ-Bondapak NH2) stationary phase was applied; the mobile phase was an acetonitrile-water mixture. Due to lack of any chromophore in the cyclodextrin molecule, refractive index detection was applied. Practically, similar method was applied with Hungarian originated BST NH2 stationary phase (Seres and Greiner 1988).

Separation of alpha-cyclodextrin, beta-cyclodextrin, and gamma-cyclodextrin on μ-Bondapak carbohydrate column (30 m × 4 mm ID) with 2 mL/min flow rate at 25 °C using acetonitrile-water 3:1 mixture as eluent (Waters equipment with refractive index detector; Zsadon et al. 1979a; CycloLab archive)

To enhance sensitivity and support the common UV detection, a post-column complexation method used for sensitive detection with phenolphthalein was developed (Frijlink et al. 1987; Szathmary 1989). The principle of this method was the phenomenon that absorbance maximum of phenolphthalein dye applied to effluent mobile phase showed a hypsochromic shift due to cyclodextrin complexing (Vikmon 1982). With 550 nm detection wavelength setting, area of individual negative peaks existing in resulted chromatograms was directly proportional to the concentration of each cyclodextrin constituent of the sample.

4.2.5 Production of Cyclodextrin Derivatives

In the second half of the 1970s, it has been already recognized that beta-cyclodextrin having limited aqueous solubility cannot be used for parenteral applications because it forms insoluble complexes with lipids such as cholesterol resulting in renal toxicity. Therefore, a cyclodextrin derivative of high solubility was needed. 2-Hydroxypropyl-beta-cyclodextrin seemed to be the best candidate for this purpose. On the other hand, a cyclodextrin derivative not soluble at all was also required for certain applications. This was the cross-linked cyclodextrin polymer with extremely high molecular weight, swelling in a large extent in water and preserving the molecular inclusion capabilities. The experimental production of these two cyclodextrin derivatives was started in Chinoin.

4.2.5.1 2-Hydroxypropyl-Beta-Cyclodextrin

Between the 1970s and 1980s, cyclodextrin technologists were looking for the right type of cyclodextrin to fulfill the broken promise of parent beta-cyclodextrin due to its poor solubility in water, for utilizing it in pharmaceutical products. Chemical modifications were undertaken to improve aqueous solubility of parent beta-cyclodextrin, an improvement that was recognized to result in disruption of the hydrogen bond system between secondary O-2 and O-3 hydroxyls of the adjacent glucopyranose units.

Among the early derivatives, methylated cyclodextrins were considered as promising candidates. Szejtli’s team in Hungary was studying the properties of methylated beta-cyclodextrins aiming to find a pharmaceutical solubilizer complexing agent. Among methylated cyclodextrins, they found heptakis(2,6-di-O-methyl)-beta-cyclodextrin a particularly promising compound (Szejtli et al. 1980b; Szejtli 1983). They also filed a number of patents disclosing the synthesis and use of cyclodextrin-methyl-ethers, e.g., methylation (Szejtli et al. 1988a), complexes of dibenzopyran derivatives (Nógrádi et al. 1985), bile substitute (Szejtli et al. 1988b), and methyl carboxyacyl-cyclodextrins (Szabó et al. 1989). However, it was found that these beta-cyclodextrin-methyl ethers exhibited high cell membrane activity. This affinity to membrane lipids such as cholesterol resulted in cytotoxicity which prevented their utility as solubilizers in parenteral/liquid formulations.

Finally, the optimum cyclodextrin derivative was found in the early 1980s. This compound was a cyclodextrin-ether derivative, 2-hydroxypropyl-beta-cyclodextrin. In 1981, Josef Pitha, head of Macromolecular Chemistry Section at National Institute of Health Gerontology Research Center in Baltimore, prepared and studied a novel derivative with optimal properties: solubilizing power for lipophile, non-crystalline, non-crystalizing composite mixture, low parenteral toxicity, and slight membrane activity. The first synthetic route that Pitha applied to obtain this compound was a two-step method: (1) allylation of parent beta-cyclodextrin and (2) oxymercuration/demercuration of allyl beta-cyclodextrin resulting in 2-hydroxypropyl-beta-cyclodextrin (Pitha et al. 1986).

As this synthetic method was not easy to scale up, neither was it economic, Pitha decided to move forward with the well-known propylene oxide condensation reaction. This hydroxyalkylation method was used first by industrial starch companies similarly to hydroxypropylation of starch, dextrins, and cellulose to improve their aqueous solubility. The propylene oxide condensation reaction was well applicable for cyclodextrin derivatization, too (Gramera and Caimi 1969; Parmenter et al. 1969). Pitha’s team soon optimized the hydroxypropylation reaction to obtain hydroxypropyl-beta-cyclodextrin with a relatively narrow and symmetrical distribution of the degree of substitution (Pitha 1988). Besides this reaction, they developed methods for purification of hydroxypropyl-beta-cyclodextrins from the contaminating oligopropylene glycols and for reduction of propylene glycol to an acceptable level. It was also reported that these hydroxypropyl-beta-cyclodextrin preparations with lower degree of substitution than 8 could be transformed into non-hygroscopic amorphous powders. The derivatives with a degree of substitution higher than 12–14 were all semi-solids or glassy syrups of lower solubilization power (Pitha et al. 1986).

Soon after the seminal works by Pitha, Szejtli’s group in Chinoin developed and optimized an upscalable industrial synthesis process for hydroxypropyl cyclodextrins. This method applied unique amounts of alkali during hydroxyalkylation step and so resulted in products where the distribution patterns of hydroxypropyl groups along the cyclodextrin ring were different from those obtained by Pitha’s method (Szabó et al. 1991). The hydroxyalkylation was performed between 0 and 35 °C under atmospheric pressure. Once the reaction was completed, the base was removed by neutralization with sulfuric acid and by cation exchange resin. The solution was concentrated by evaporation, then diluted by 2–4-carbon-atom glycols, then evaporated again, and finally diluted with alcohol and acetone to remove polypropylene glycol by-products. The precipitated salt was removed by filtration, and the final product was purified and spray-dried. The process was scaled up to hydroxypropylation of 40 kg beta-cyclodextrin in a reaction unit of 250 L according to the process on flow chart in Fig. 4.14. This optimized manufacturing process by Chinoin served the ground of a Drug Master File Type IV that was completed and used by Janssen Pharmaceutica, for regulatory filings.

Szejtli’s group conducted systematic functional characterization of hydroxypropyl cyclodextrins focusing on the solubilizing and complex-forming properties of these derivatives. The study involved more than 50 different lipophilic drug substances and other natural lipophiles. It was shown for the first time that the solubilizing effect of 2-hydroxypropyl-beta-cyclodextrins strongly depends on both the properties of guest and the number of substituents (the degree of substitution) on the beta-cyclodextrin rim. In other words, not only the cavity size of the cyclodextrins matters but also the chemical environment of the cavity entrance (Szeman et al. 1988). Besides the pharmaceutical chemical characterization of hydroxypropyl cyclodextrins, Szejtli’s team conducted also in-depth studies on the pharmacokinetic (absorption-distribution-metabolism-elimination, ADME) properties of hydroxypropyl-beta-cyclodextrin using 14C-radiolabeled hydroxypropyl-beta-cyclodextrin upon oral and parenteral administration (Gerlóczy et al. 1990). These early studies have been further utilized and supplemented with lege artis pharmacokinetic studies by Janssen Pharmaceutica (Monbaliu et al. 1990; Szathmary et al. 1990).

A unique intellectual property situation with hydroxypropyl-beta-cyclodextrins resulted a long interference process. At the National Institutes of Health, Josef Pitha filed a patent in early 1984 with quite broad claims on the preparation and pharmaceutical use of hydroxypropylated cyclodextrins emphasizing the unobvious amorphousness of the composite products, their enhanced water solubility, and complex-forming characteristics together with the solubilizing potency and low toxicity of these cyclodextrin derivatives (Pitha 1988).

Nearly at the same time, a patenting process started in Germany and in the USA. Company Hoechst disclosed the process of making hydroxypropyl cyclodextrins (Brandt and Felcht 1986; filed in 1983 in Germany). At the Christian-Albrecht University in Kiel was simply claimed the improvement of drug solubility and stability using cyclodextrin derivatives, in particular hydroxypropyl-beta-cyclodextrins (Müller and Brauns 1985, filed in 1983 in Germany and in 1985 in the USA, assigned to Janssen). The co-existence of US patent applications of NIH and Janssen caused a decade-long interference process, since US and European patent policies considered the patents differently: while US NIH patent by Pitha was considered the “first to invent,” Müller’s patent by Janssen was the “first to file” type. The long-lasting interference process was finally settled, and after 35 years of intellectual protection of hydroxypropyl cyclodextrins’ use in the USA, in May 2019, (these days) the use of hydroxypropyl-beta-cyclodextrin as a drug solubility improving excipient becomes free worldwide. No such a turbulent intellectual property situation hampers any more the application of this great multifunctional excipient.

Much later, an unexpected function of hydroxypropyl-beta-cyclodextrin was discovered: it turned out to be more than just an excipient. In 2008, it was accidentally discovered that solubilizing excipient hydroxypropyl-beta-cyclodextrin showed remarkable potency in improving the lifespan of mice suffering from a rare, lysosomal storage disorder, called Niemann-Pick type C disease (Liu et al. 2008, 2009). These early observations were then further supported by other research teams searching for therapies to treat Niemann-Pick type C disease (e.g., Davidson et al. 2009).

Based on these encouraging results, the favorable safety profile, and 20-year-long pharmaceutical application as an excipient in human injectable products, regulatory orphan drug designation was given to hydroxypropyl-beta-cyclodextrin in the USA and in EU for the treatment of Niemann-Pick type C disease. This means that this cyclodextrin derivative today can be considered as safe and efficient solubilizing excipient, as well as an orphan drug for treatment of a rare, lysosomal lipid storage disease. However, the demand is very small for orphan drug applications, although extremely high quality/purity is required, but huge amounts of hydroxypropyl-beta-cyclodextrin have been used in the household toiletries: for deodorizing fabrics especially those dried in drying machines (Trinh et al. 1996).

4.2.5.2 Beta-Cyclodextrin Bead Polymer

Cyclodextrin polymers can be obtained in the form of beads when the reaction of cyclodextrin with polyfunctional compounds is carried out in aqueous phase dispersed in a non-polar solvent (Wiedenhof et al. 1971).

An independent procedure was developed for the preparation of cyclodextrin bead polymer in the second half of the 1970s in the Chinoin Biochemical Research Laboratory in cooperation with the Eötvös University Faculty of Sciences. The invention was based on applying polyvinyl alcohol, polyvinyl acetate, or polyvinyl alcohol-acetate copolymer as a protecting colloid in emulsion polymerization of cyclodextrin using a polyfunctional coupling reactant such as epichlorohydrin and/or other diepoxy compounds. The cross-linking reaction was performed in two steps: first a water-soluble pre-polymer was formed with epichlorohydrin in a homogeneous phase, and then a diepoxy compound under less alkaline conditions was used for further cross-linking in a heterogeneous phase applying toluene as water-immiscible solvent. The development started in 1976 by optimizing the reaction conditions in a laboratory scale (Fenyvesi et al. 1979). A patent was applied in 1978 and then granted in 1981 both in Hungary and in the USA (Szejtli et al. 1981). The aim was a wound healing formulation for veterinary application in the form of spherical beads of 100–300 μm diameter. The healing effect was based on the high swelling of beads which sucked up the wound exudate, thus ensuring clean wound surface and fast healing of otherwise slowly healing, oozing wounds. Utilizing cyclodextrin functioning as a drug carrier, various antiseptic agents such as iodine were added to the formulation (Fenyvesi 1988; Szejtli et al. 1988c). These antiseptic agents were released into the wound in a sustained manner.

Application of the cyclodextrin polymer beads as column packing in gel chromatography was also foreseen. In addition to the analytical applications (Zsadon et al. 1979b, 1981, 1983, 1986, 1987; Cserháti et al. 1983; Szilasi et al. 1985; Ujházi et al. 1989), the use in preparative chromatography was worked out, too. A method was developed for the selective removal of phenylalanine from protein hydrolysate aimed for nourishing patients in phenylketonuria by simply eluting the protein hydrolysate through a cyclodextrin bead polymer column (Szente et al. 1981). Another application was foreseen for the removal of bitter components such as naringin from citrus juices (Ujházi and Szejtli 1989). Based on the similarity to cross-linked dextran polymer of Pharmacia (Sweden) named Sephadex-25, this cyclodextrin polymer was named CDP-25.

The first scaling up was performed at Eötvös University Faculty of Sciences in 1981. The most important step was replacing toluene to less toxic paraffin oil. The resulting 1600 g bead polymers were of the desired size (0.09–0.31 mm), spherical shape and swelling (4.7 mL/g), and cyclodextrin content measured by iodometric titration after acidic hydrolysis (55–60%). The methods for characterization were standardized and documented (Kálóy 1980). The flow chart of preparation and the scanning electron microscopic photo are illustrated in Fig. 4.15 and Fig. 4.16, respectively.

After the small-scale laboratory experiments for optimizing the reaction conditions in order to get the product of proper shape, size, and swelling, the scaling up was started in Organic Chemistry Development Co. (SzVF, Budapest) in 1983. Instead of paraffin oil, dichloroethane was used as water-immiscible solvent and ethylcellulose as protecting colloid for stabilizing the emulsion. The diepoxy coupling agent in the second step of cross-linking was very expensive; therefore epichlorohydrin was used in this step, too. To improve the flowing properties of the dry beads, they were silylated. Fractionation was performed by a wet technology to replace sieving, and fluid bed dryer was used for drying. In a further development, dichloroethane was replaced by 1-butanol, thus improving the environmental footprint of the technology, and a proper surfactant was selected for stabilizing the emulsion during polymerization.

In-house acute toxicity study on mice and rats in 3000 mg/kg and 5000 mg/kg dose per os demonstrated no toxicity. Dermal toxicity study in Chinoin Toxicological Department showed no irritation when used in 5000 mg/kg dose on depilated skin of male and female rats. According to preliminary microbiological studies, the bead polymer, unlike to starch usually applied in topical powder formulations, was not a substrate for fungi causing dermatomycosis. The tissue compatibility studies by intramuscular injection of bead polymer into rats resulted in no pathological reactions.

In vivo experiments on rats proved the wound healing effect without detecting inflammatory cell reactions. In human trials, therapy-resistant ulcers were treated successfully on nine patients (Felméray et al. 1996). The overinfected, coated wounds became clear on the average in 5 days. Both the depth and the basic area of the ulcers were reduced quickly.

Approximately 130 kg bead polymers of 200–400 μm grain size, 4.7–5.6 mL/g swelling, and 48–62% cyclodextrin content were produced in 16 batches. Instructions for production were compiled, and specification set and methods for qualification worked out. The microscopic photo on the beads (Fig. 4.16) shows the regular shape and narrow size distribution of the product. Option for production and selling was granted to Wacker Chemie (Consortium für elektrochemische Industrie, Germany) by Chinoin based on an agreement in 1986, but it was not realized.

In 1987, the product with 2% iodine content was selected for development under the trade name Chinoderm as wound healing powder for veterinary application by Chinoin. A 3-year expiry date was established based on stability studies which showed no change in iodine content after 30-day storage at 40 and 50 °C, and only 12% decrease at 60 °C. In Chinoin (Nagytétény unit), 20 kg cyclodextrin bead polymer with 2% iodine content was prepared for toxicological and efficacy studies. These studies showed the beneficial effects of the iodine-releasing beads in wound healing on dogs by the University of Veterinary Medicine, Budapest.

4.2.6 The End of the Story

After the political changes in Hungary, Chinoin was sold to Sanofi Aventis in 1991. The new owner was not interested in bioprocesses. So, the fermentation plant was closed, and with this also the enzyme production was finished (Sipos et al. 1996). At that time, the site of cyclodextrin production was at Győr Distillery Co. Ltd. in western Hungary. The management has foreseen difficulties in selling cyclodextrins without the support of a big pharmaceutical company. Therefore, the cyclodextrin production was stopped soon after changing ownership in Chinoin. Although Hungary was one of the first industrial cyclodextrin producers in the world, the high potential of cyclodextrin market (today thousands of tons in a year) was not predicted. At that time, two European cyclodextrin manufacturers have already been on the market: Roquette Frères in France and Wacker Chemie in Germany.

With finishing the cyclodextrin production, the hydroxypropyl-beta-cyclodextrin manufacturing was also given up. Nowadays, both Roquette Frères and Wacker Chemie produce this derivative in extremely high volume. Experimental production of bead polymers was also stopped after the technology transfer to Wacker Chemie (Germany), and they are not produced any more.

Only the cyclodextrin research survived in Hungary by establishing a spin-off company by Professor Szejtli and his co-workers in the Biochemical Research Laboratory in 1989. CycloLab, a small private research company, not only has maintained its leading position in cyclodextrin research, but it has also developed an independent process for the production of sulfobutyl ether beta-cyclodextrin, an alternative parenteral drug carrier, and since 2008 it has been an FDA-approved GMP manufacturer of this excipient with multiple ton annual production (CycloLab 2019).

4.3 Conclusions