Abstract

The growth and metabolism of gram-negative microorganisms are widely recognized as important reasons for the spoilage of fish and fish product. Based on antimicrobial activity of lactoperoxidase system (LPOS) against gram-negative bacteria, the present study investigated the effect of incorporation of LPOS at concentrations 0 (control), 1.25, 2.5, 5 and 7.5 % (v/v) into whey protein solution as novel antimicrobial coating strategy for rainbow trout (Oncorhynchus mykiss) preservation under refrigeration temperature (4 ± 1 °C) over a 16-day period. During storage of trout fillets, control and 1.25 % LPOS-treated samples reached undesirable levels of rancidity (p < 0.05) at 12th and 16th days, respectively, whereas the higher concentrations showed to be more efficiently stable (p < 0.05) in sensory, chemical (total volatile basic nitrogen (TVB-N) and pH) and microbiological analyses (mesophilic bacteria, psychrotrophic bacteria, Pseudomonas spp. and specific spoilage bacteria). Lipid oxidation in the fillets was not affected significantly by LPOS treatment. The LPOS-whey protein coating also reduced total specific spoilage organisms (Shewanella putrefaciens and Pseudomonas fluorescens) of the fillets more than 1.5 log by the end of storage. The shelf life of samples was extended approximately from 12 days to at least 16 days in the presence of the LPOS. These results indicated the significant antimicrobial activity of the LPOS-whey protein coating solution for refrigerated fish fillets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Seafoods may undergo physical, chemical and microbiological deterioration during storage and distribution. The important reason for the spoilage of seafood resides in the growth and metabolic activity of limited types of gram-negative microorganisms, recognized as specific spoilage organisms (SSO) (Gram and Dalgaard 2002). According to different literature, Shewanella putrefaciens and Pseudomonas spp. were identified as the SSO forms in any fish, shellfish and crustacean, especially during aerobic chilling storage (Xu et al. 2012). It has been estimated that about one third of the world’s food production is lost annually due to microbial spoilage (Lund et al. 2000).

Nowadays, researchers have focused on the utilization of antimicrobial compounds as an effective way to minimize or delay the development and spread of spoilage and pathogenic microorganisms in meat foodstuffs, maintain nutritional quality and prolong the shelf life of foods (Quintavalla and Vicini 2002). One way to improve product stability is through antimicrobial packaging technologies that can be designed to slow down the microbial diffusion to the surface of food, where the microbial growth is mostly found (Ouattara et al. 2000; Kuorwel et al. 2011). Antimicrobial packaging version is demanded for improving recyclability and biodegradability of packaging and is of great importance of active packaging systems, which can improve the quality of fresh, frozen and processed fish and fishery products by, for instance, delaying moisture loss, reducing lipid oxidation and discolouration, enhancing product appearance and functioning as carrier of food additives (Kuorwel et al. 2011; Cagri et al. 2004; Quintavalla and Vicini 2002). In addition, rather than mixing the antimicrobial compounds directly with food, incorporating them in coating solutions allows the functional effect at the food surface to be localized (Coma 2008).

Various bio-preservatives could be incorporated into edible coatings to broaden their antimicrobial properties. Due to the consumers’ concerns about chemicals, there is a particular interest in food industry to use natural bio-preservatives such as antimicrobial enzymes and bacteriocins for antimicrobial packaging in preference to chemical agents (Devlieghere et al. 2004; Yener et al. 2009). Lactoperoxidase (LPO), a single polypeptide chain found in the milk, saliva and tear secreted in mammary, salivary and lacrimal glands of mammals, is introduced as one of the most important enzymes, applied in the food industry as a bio-antimicrobial agent which possesses a broad antimicrobial spectrum and could be used in food packaging. This enzyme shows bactericidal effect on gram-negative bacteria and bacteriostatic effect on gram-positive bacteria. Moreover, it holds antifungal and antiviral activities (Seifu et al. 2005; Yener et al. 2009). The LPO system (LPOS) consists of the enzyme and two substrates: thiocyanate (SCN−) and hydrogen peroxide (H2O2) in which the enzyme catalyzes the oxidation of SCN− by hydrogen peroxide. As a result, some highly reactive intermediate antimicrobial products, hypothiocyanite (OSCN−) and hypothiocyanous acid (HOSCN), whit the potential inhibition of microorganisms by the oxidation of sulphydryl (−SH) groups in their enzyme systems‚ can be produced (Cissé et al. 2012).

The interest in the search of low-cost materials such as whey protein as an appreciated source for biodegradable edible coating which offers new opportunities for the food industry has increased during the last decade. With the addition of plasticizer, heat-denatured whey proteins produce transparent, bland and flexible water-based edible films with excellent oxygen, aroma and oil barrier properties (Gennadios 2002). In addition, according to Min et al. (2005), the tensile properties, oxygen permeability and colour of whey protein films were not significantly changed by incorporation of LPOS; however, the growth prevention of Listeria monocytogenes and total aerobic microorganisms in smoked salmon at different storage condition was found. To the best of our knowledge, due to the acceptability of the antimicrobial packaging technologies to consumers and their effectiveness in packaging or due to their economic and environmental impact, there is a particular interest in the use of antimicrobial bio-preservatives in edible coating to increase food safety, while, in case of seafood, it seems that there is a necessity to develop this technology. Accordingly, in this study, we aimed to develop an antimicrobial or protective coating solution of whey protein as low-cost edible material by incorporation of an antimicrobial enzyme system, LPOS, with either bactericidal or bacteriostatic effects to be applied in improving the antimicrobial quality, mainly in specific spoilage of bacteria, and in extending the shelf life of refrigerated rainbow trout fillets.

Materials and Methods

Materials

LPOS was composed of LPO (120 U/mg, Sigma-Aldrich), glucose oxidase (GO; Sigma-Aldrich); d-(α)-glucose (Glu, Sigma-Aldrich), potassium thiocyanate (KSCN, Bioserae, France) and H2O2 (Merck, Germany). Whey protein (80 % protein) was obtained from DMV Co. (Veghel, the Netherlands). Glycerol, used as a plasticizer to improve coating flexibility, was acquired from Merck (Frankfurt, Germany).

Preparation of LPOS

LPOS was prepared as described by Cissé et al. (2012). The weight ratios of the LPOS components were 1.00, 0.35, 108.70, 1.09 and 2.17 respectively for LPO, GO, Glu, KSCN and H2O2. The components were dissolved separately in 50-mL phosphate buffer (pH 6.2, Sigma-Aldrich); the concentrations of the components were adjusted on the basis of 15.5 mg LPO. LPOS solution was incubated at 23 °C for 24 h under shaking at 160 rpm to increase the antimicrobial activity of LPOS (Min et al. 2007).

Fish Fillet Preparation

Cultured fresh rainbow trout (Oncorhynchus mykiss) with an average weight of 250 ± 25 g were obtained from the trout farm of Artemia and Aquatic Animals Research Institute at Urmia University (West Azerbaijan, Iran). Fish samples were collected in summer (July–September). Immediately after harvesting, fish were de-headed, eviscerated, filleted and washed with tap water to remove adhering blood and slime.

Preparation of Whey Protein Solution and Treatment of Fish Fillets

Whey protein solution (WPS) was prepared by mixing 10 g of whey protein with 100 mL of distilled water and stirred at a controlled temperature of 90 °C until the mixture became clear. The same weight of glycerol as that of whey protein was added to the solution (Min et al. 2005). LPOS concentrations in the whey protein solution were 0, 1.25, 2.5, 5 and 7.5 % (v/v).

A preliminary disc diameter test was conducted to determine the optimum LPOS concentrations in whey protein solution, by preparing concentrations of 0.31, 0.63, 1.25, 2.5, 5, 7.5 and 10 % (v/v) LPOS in whey protein solution. Bacterial suspensions were adjusted to 1 × 107 colony-forming unit (CFU)/mL and spread on the surface of Iron Agar LYNGBY using sterile cotton swabs. Subsequently, filter paper discs (6 mm in diameter) were impregnated with 20 μL of each coating solution and placed on the surface of the inoculated medium. After staying at 4 °C for 2 h, the plates were incubated at 30 °C for 3–4 days. The antibacterial activity was evaluated by measuring the total diameter of the inhibition zone. It was found that LPOS concentration <1.25 % v/v did not produce any zones of inhibition of the growth of the specific spoilage bacteria, while concentration of 10 % had very high viscosity. Therefore, LPOS concentrations in a range of 1.25–7.5 % in whey protein solution were used as coating-forming solutions in this research.

Fillet samples were randomly arranged according to five coating formulations to which the following treatments were randomly assigned:

-

1.

Coating formulation (control): 0 % LPOS-WPS

-

2.

Coating formulation: 1.25 % LPOS-WPS

-

3.

Coating formulation: 2.5 % LPOS-WPS

-

4.

Coating formulation: 5 % LPOS-WPS

-

5.

Coating formulation: 7.5 % LPOS-WPS

For each coated lot, approximately 20 trout fillets were immersed in the well-mixed coating solution for 60 s. The ratio of fish to the dipping solution was 1:2 (Erkan et al. 2013). Then, the fish fillets were removed and allowed to drain, and they were then packed in polyethylene bags, tied off and stored at 4 ± 1 °C for 16 days.

Bacteriological Analysis

Samples of 10 g of fish fillets were mixed with 90 mL of 0.1 % peptone water and homogenized in a stomacher (Pulsifier®, UK) for 1 min. In all cases, serial dilutions of the fish homogenates were made in 0.1 % peptone water. All bacterial counts were determined by drop plate method, using the appropriate media. For microbial enumeration, 20 μL of sample serial dilutions of fish homogenates were transferred onto the surface of dry media. Viable mesophilic bacteria were determined using Nutrient Agar (Merck, Darmstadt, Germany) after incubation for 48 h at 37 °C. Psychrotrophic bacteria were determined using King Agar (Merck, Darmstadt, Germany) after incubation for 48 h at 21 °C. H2S-producing bacteria, including S. putrefaciens as black colonies and Pseudomonas fluorescens as white colonies, were determined using Iron Agar LYNGBY (Laboratorios Conda, Madrid, Spain) after incubation for 3–4 days at 30 °C. For the Pseudomonas spp. count, cetrimide agar (Merck, Darmstadt, Germany) was incubated for 48 h at 37 °C. All counts were expressed as log10 CFU/g.

Chemical Analysis

TVB-N

Total volatile basic nitrogen (TVB-N) value was estimated by microdiffusion method of Goulas and Kontominas (2005). The microdiffusion method was performed by distillation after the addition of MgO to homogenize fish samples. The distillate was collected in a flask containing a 3 % aqueous solution of boric acid and a mixed indicator produced from dissolution of 0.1 g of methyl red and 0.1 g of methylene blue in 100 mL of ethanol. Afterwards, the boric acid solution was titrated with a 0.05 M sulphuric acid (H2SO4) solution. The TVB-N value (mg/100 g fish flesh) was determined via the consumption of sulphuric acid.

TBA

Thiobarbituric acid (TBA) was determined according to the method proposed by Tarladgis et al. (1960) and Etemadian et al. (2011). Ten grams of meat was homogenized for 2 min with 97.5 mL distilled water and 2.5 mL 4 N HCl solution, and then, three drops of silicon as antifoam and some boiling stones were added. The blend was distilled until a 50 mL solution was obtained. Five millilitres of the distillate and 5 mL of TBA reagent (0.02 M 2-TBA in 90 % acetic acid) were blended and heated in a boiling water bath for 35 min. After cooling under running water for 1 min, the absorbance was measured at 538 nm against a blank, which was 5 mL of distilled water with 5 mL of TBA reagent. The TBA values were expressed as milligrams malonaldehyde (MA) per kilogram of sample.

pH

The pH value was measured for the homogeneous blends of fish and distilled water (1:10, w/v) by using a pH meter (Eutech® CyberScan, pH 510, Singapore) according to AOAC (2005).

Sensory Analysis

Scoring table described by Erkan (2012) was used for the determination of sensory evaluations in fish muscles. A panel of 12 semi-trained judges (from the laboratory staff and fisheries students) evaluated the sensory attribute of fish muscles. All volunteers were selected based on their interest and availability. Sensory attributes such as colour, odour, texture and general acceptability were evaluated by using 9-point descriptive scale. According to the scoring tables, scores 1–3.9, 4–6.9 and 7–9 indicated the limits of unacceptability, moderate acceptability and high acceptability, respectively.

Statistical Analysis

The results were presented as mean ± standard deviation. All data were subjected to one-way analysis of variance (ANOVA) to test the effects of experimental conditions. Data analyses were performed using SPSS (version 18.0 for Window, SPSS, Inc., Chicago, IL, USA). The normality of data was tested using the Shapiro-Wilk’s test and the homogeneity of variance with Levene’s test, accordingly. Data were subjected to Duncan’s post hoc test. Differences were considered statistically significant at p < 0.05.

Results and Discussion

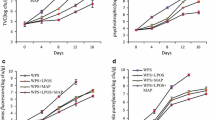

Assessment of Bacteriological Changes

According to the results of the microbial analysis (Fig. 1a–e), the presence of LPOS in the coating materials significantly decelerated the growth of certain microorganisms in fish muscles during storage period; this result was especially because of higher levels of LPOS. According to Min et al. (2005), LPOS containing glucose oxidase, due to continuously generating oxidizing products, possessed extended bactericidal effects. Our results verified the possibility that oxidizing products were continuously generated in the activated LPOS within whey protein coating solution during storage.

For instance, statistically significant (p < 0.05) lower mesophilic counts were found for LPOS-treated samples compared with the control batches (Fig. 1a). On the other hand, the 7.5 % LPOS-treated samples exhibited statistically significant (p < 0.05) lower mesophilic counts than other LPOS-treated batches. The aerobic mesophilic counts for 7.5 % LPOS-treated samples (6.75 log CFU/g) were below 7 log CFU/g at the end of storage. These values were below those generally considered values which were demanded to induce fish spoilage (Gram and Huss 1996).

With respect to the psychrotrophic bacteria, statistically significant (p < 0.05) lower counts were determined for LPOS-treated samples, especially in two high levels, compared with the control batches, and there were no significant differences for psychrotrophic bacteria between two latter batches (Fig. 1b). Nevertheless, on the latest day of storage (day 16), the psychrotrophic counts were not lower than 7 log CFU/g for any of the batches examined.

The growth of Pseudomonas spp. in trout muscle throughout storage is shown in Fig. 1c. The Pseudomonas spp. counts also displayed a statistically significant (p < 0.05) decrease in the growth of the LPOS-treated batches in comparison with the control batch (Fig. 1c). However, no significant differences were found between the 1.25 and 2.5 % LPOS-treated samples until the 12th day of storage. Furthermore, as in the cases of the other aerobic microorganisms, these differences were higher between the 7.5 % LPOS-treated samples and control batch, with differences as high as 1.34 and 2.75 log CFU/g after 4 and 12 days of storage, respectively. Thus, as the cases of the mesophilic and psychrotrophic, activation of LPOS in coating materials resulted in better protection of the microbial quality of trout fillets.

Finally, as other microorganisms, the counts of H2S-producing microorganisms (P. fluorescens (Fig. 1d) and S. putrefaciens (Fig. 1e)) were also significantly (p < 0.05) lower in the LPOS-treated batches, especially with highest level, than those in the control batches, so that the S. putrefaciens and P. fluorescens counts on the last day of storage (16th day) were lower than 7 log CFU/g for the 7.5 % LPOS-treated samples. It is also noteworthy that the differences between the H2S-producing microorganism counts of the 7.5 % LPOS and control batch were greater than 2 log CFU/g on 8th and 12th sampling days, thus revealing a significant inhibition of growth of spoilage microorganisms in the batch containing the highest concentration of LPOS. The role of S. putrefaciens and P. fluorescens as specific spoilage microorganisms in the degradation of fish muscle has been highlighted (Xu et al. 2012; Surendran et al. 1989). Accordingly, the partial inhibition of this microbial group by the activated LPOS as bio-preservative agent tested in this study is another remarkable result in terms of fish quality.

The microbial analysis of our study also supports the results of other authors who reported that in the presence of SCN− and H2O2, LPO generates the OSCN− and HOSCN, which are the main antimicrobial products and strong oxidizing agents that can oxidize essential sulphydryl groups in bacterial proteins and thus inhibit bacterial growth (Kamau et al. 1990a, b).

Our results agreed well with results of Min et al. (2005) that reported the effect of LPOS incorporated in whey protein for inhibition of aerobic bacteria evaluation in smoked salmon during storage. In addition, Yener et al. (2009) found that fish products coated with LPOS-alginate solution exhibited a significant delay in the proliferation of Escherichia coli, Listeria innocua and P. fluorescens.

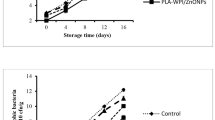

Assessment of TVB-N Changes

TVB-N is a product of bacterial spoilage and endogenous enzymes’ action, and its content is often used as an indicator of fish deterioration (Ozden et al. 2007). As could be observed in Fig. 2, values included in the 11.62–11.91 mg/100 g muscle range were observed in starting raw fillet. Our results agreed well with other authors that reported that the concentration of TVB-N in freshly caught fish is typically between 5 and 20 mg/100 g (Huss 1988; Connell 1995). The TVB-N formation increased with storage time (p < 0.05); thus, good correlation values were obtained between both parameters (TVB-N formation and storage time) (r = 0.96–0.99). The incorporation of LPOS in whey protein solution provided a significant protection against TVB-N formation in comparison with the control batch at all sampling times, indicating that the inclusion of activated LPOS is beneficial in decreasing the production of this volatile basic nitrogen by microorganisms. These lower values of the related samples were due to the antimicrobial effect of the applied LPOS.

Several authors have reported that the limit of acceptability for fresh fish was 30–35 mg TVB-N/100 g of flesh (Kykkidou et al. 2009; Huss 1988). Furthermore, according to Connell (1995) for fish of cold waters, values of 30–40 mg TVB-N/100 g have been proposed as limits of acceptability. In the present study, TVB-N value for control and 1.2 % LPOS batches exceeded the limit of acceptability on 12th and 16th days, respectively, as the times of sensory rejection. TVB-N values for the 2.5, 5 and 7.5 % LPOS-treated samples were remained below the upper limit of acceptability after 16 days. The unacceptable fish for panellists showed a TVB-N value of 30.93 mg/100 g for control group and 41.00 mg/100 g for 1.25 % LPOS-treated samples. These results indicate that TVB-N is a suitable index for the spoilage of trout fillets stored at 4 °C.

Assessment of TBA Changes

TBA was employed for determining the lipid oxidation by measuring malondialdehyde (MDA) content. MDA is a secondary product of oxidation resulting from the degradation of lipid hydroperoxides formed during the oxidation process of polyunsaturated fatty acids (Bensid et al. 2014). According to Kilinc et al. (2009), TBA value in perfect quality material should be less than 3 mg MA/kg and in good quality material; it should not be more than 5 mg MA/kg. As indicated in Fig. 3, at the beginning of the storage period, TBA values of fish samples were found to be 0.87 mg MA/kg (Fig. 3). TBA values of all group samples showed at first an increase and afterwards a decrease, or not significant changes occurred. The increase in TBA indicated formation of secondary lipid oxidation products, while the decrease in TBA values may represent the breakdown of the MA because of tertiary degradation (Ehsani et al. 2013). At each day of testing throughout storage, higher TBA value was found for the LPOS-treated samples in comparison with control group. However, no significant differences (p > 0.05) could be outlined among the different treatments. It is concluded that the presence of activated LPOS inside the whey protein coating solution could not affect the TBA value; however, slight promotion of TBA formation was found. These results are in agreement with those of Wolfson et al. (1994), who reported that oxidative deterioration as measured by TBA values for chicken thigh meat did not significantly differ between control and LPOS-treated chicken legs.

The TBA values of all groups, except for control batch, exceeded the value of 5 mg MA/kg on the 12th day of storage. However, in this same 12-day period, the panellists did not detect any off-odour in the samples. According to these results, it would be difficult to set limits for TBA levels. These TBA values may not yield actual rate of lipid oxidation, since MA can interact with other components of fish such as nucleosides, nucleic acid, proteins and amino acids of phospholipids (Bensid et al. 2014; Aubourg 1993), and produce secondary metabolites that include carbohydrates, furfural, alkenals, alkadienals and other aldehydes and ketones (Bensid et al. 2014; Botsoglou et al. 1994).

Assessment of pH Changes

The changes in pH for trout fillets during the 16-day storage period in refrigeration temperature are shown in Fig. 4. The initial pH of the fish samples was 6.25. The pH values of the studied trout burgers decreased and increased respectively during storage period; however, for the control batch, pH increased significantly during the storage time, reaching a value of 6.73 by the end of storage. Increases in the pH of the fish muscle indicate the accumulation of alkaline compounds such as ammonia compounds and trimethylamine, which are principally derived from microorganisms (Hebard et al. 1982). As shown in Fig. 4, the pH values of LPOS-treated samples, except for 1.25 % batch, were significantly (p < 0.05) lower compared with those of the control batch. Hence, the pH differences at the end of the storage period were more than 0.50 pH units, indicating that the incorporation of LPOS to the coating material significantly reduced the microbial and endogenous alkalinizing mechanisms that may limit fish shelf life.

In this sense, it has been suggested that pH values above 7 may limit the shelf life of certain fish species (Ruiz-Capillas and Moral 2001). Based on our results, the pH values of all studied treatments were below the limit of acceptability even at the time of sensory rejection; it could be concluded that pH was not an appropriate quality index.

Assessment of Sensory Score Changes

As shown in Table 1, for all of the examined sensory attributes, a similar pattern of decrease in acceptability was detected by the panel as a result of increasing the storage time. Although at the early days of storage, incorporation of LPOS into whey protein solution, especially at higher levels, resulted in reduction of colour acceptability (p > 0.05), and for all LPOS-treated batches, muscle odour and texture were the sensory parameters by which the activated LPOS-whey protein solution provided the best results.

In this evaluation test, the control batch had significantly lower general appearance scores during the storage period when compared to LPOS-treated groups. LPOS-whey protein solution-treated samples, especially at higher concentration, showed such a high acceptability (p < 0.05) in most of the studied sensory characteristics that these batches retained an acceptable quality even after 16 days of storage. This fact confirms the preservative effect of activated LPOS in the whey protein solution. Control and 1.25 % LPOS-treated samples showed to be the most perishable samples during the storage, respectively; so, these batches retained acceptable quality until 12th and 16th days of storage, respectively. It seems to be mostly due to the absence of antimicrobial agent, LPOS, in the samples. However, the 5 and 7.5 % LPOS maintained high acceptability up to day 16, and the 2.5 % LPOS batch was also considered to be acceptable at that time. In other words, higher concentration of LPOS extended the shelf life by at least 4 days.

Conclusions

The incorporation of LPOS in whey protein solution provided significant protection against TVB-N formation, some bacterial growth and pH changes without any effect on lipid oxidation compared with the control batch at all sampling times. This incorporation occurred so that not only based primarily on sensory attributes but also on microbiological data, and the shelf life of coated fresh rainbow trout fillets with whey protein solution was ca. 12 days during refrigerated storage. In comparison to the control samples, addition of 1.25 % (v/w) LPOS-extended product shelf life by ca. 4 days while 2.5, 5 and 7.5 % LPOS-whey protein coating groups showed moderate to high overall acceptability even until the 16th day of storage period.

In general and according to these results, a significant beneficial effect of the activated LPOS-whey protein solution was found on fish quality and shelf life. This result corroborates the microbiological counts determined in this study, which showed a significant slowing down of microbial growth. Therefore, 7.5 and 5 % LPOS-treated samples were selected as the best samples in both sensory and microbiological analyses.

Abbreviations

- LPOS:

-

Lactoperoxidase system

- SSO:

-

Specific spoilage organisms

- LPO:

-

Lactoperoxidase

- SCN− :

-

Thiocyanate

- H2O2 :

-

Hydrogen peroxide

- OSCN− :

-

Hypothiocyanite

- HOSCN:

-

Hypothiocyanous acid

- −SH:

-

Sulphydryl

- GO:

-

Glucose oxidase

- Glu:

-

d-α-Glucose

- KSCN:

-

Potassium thiocyanate

- WPS:

-

Whey protein solution

- TVB-N:

-

Total volatile basic nitrogen

- TBA:

-

Thiobarbituric acid

- MA:

-

Malonaldehyde

References

AOAC. (2005). Official methods of analysis of the Association of Analytical Chemistry, 18th ed., chapter 39, Pp. 5-8 (code 39.1.15).Association of Official Analytical Chemists, Washington DC, USA.

Aubourg, S. P. (1993). Interaction of malondialdehyde with biological molecules-new trends about reactivity and significance. International Journal of Food Science and Technology, 28(4), 323–335.

Bensid, A., Ucar, Y., Bendeddouche, B., & Ozogul, F. (2014). Effect of the icing with thyme, oregano and clove extracts on quality parameters of gutted and beheaded anchovy (Engraulis encrasicholus) during chilled storage. Food Chemistry, 145, 681–686.

Botsoglou, N. A., Fletouris, D. J., Papageorgiou, G. E., Vassilopoulos, V. N., Mantis, A. J., & Trakatellis, A. G. (1994). Rapid, sensitive, and specific thiobarbituric acid method for measuring lipid peroxidation in animal tissue, food, and feedstuff samples. Journal of Agricultural and Food Chemistry, 42(9), 1931–1937.

Cagri, A., Ustunol, Z., & Ryser, E. T. (2004). Antimicrobial edible films and coatings. Journal of Food Protection, 67(4), 833–848.

Cissé, M., Montet, D., Tapia, M. S., Loiseau, G., & Ducamp-Collin, M. N. (2012). Influence of temperature and relative humidity on the immobilized lactoperoxidase system in a functional chitosan film. Food Hydrocolloids, 28(2), 361–366.

Coma, V. (2008). Bioactive packaging technologies for extended shelf life of meat-based products. Meat Science, 78(1), 90–103.

Connell, J. J. (1995). Control of fish quality. London: Fishing News (Books) Ltd.

Devlieghere, F., Vermeiren, L., & Debevere, J. (2004). New preservation technologies: possibilities and limitations. International Dairy Journal, 14(4), 273–285.

Ehsani, A., Jasour, M. S., Hashemi, M., Mehryar, L., & Khodayari, M. (2013). Zataria multiflora Boiss essential oil and sodium acetate: how they affect shelf life of vacuum‐packaged trout burgers. International Journal of Food Science and Technology, 49(4), 1055–1062.

Erkan, N. (2012). The effect of thyme and garlic oil on the preservation of vacuum-packaged hot smoked rainbow trout (Oncorhynchus mykiss). Food and Bioprocess Technology, 5(4), 1246–1254.

Erkan, N., Dursun, S., Ulusoy, S., Akcay, S., & Yesiltas, M. (2013). Combined effects of protein based edible film coatings and vacuum packaging on the quality of fresh sea bass fillets. Fleischwirtschaft International, 1, 61–68.

Etemadian, Y., Shabanpour, B., SadeghiMahoonak, A. R., Shabani, A., & Alami, M. (2011). Cryoprotective effects of polyphosphates on Rutilus frisii kutum fillets during ice storage. Food Chemistry, 129(4), 1544–1551.

Gennadios, A. (2002). Protein-based films and coatings. Boca Raton: CRC Press.

Goulas, A. E., & Kontominas, M. G. (2005). Effect of salting and smoking-method on the keeping quality of chub mackerel (Scomber japonicus): biochemical and sensory attributes. Food Chemistry, 93(3), 511–520.

Gram, L., & Dalgaard, P. (2002). Fish spoilage bacteria—problems and solutions. Current Opinion in Biotechnology, 13(3), 262–266.

Gram, L., & Huss, H. H. (1996). Microbiological spoilage of fish and fish products. International Journal of Food Microbiology, 33(1), 121–137.

Hebard, C. E., Flick, G. J., & Martin, R. E. (1982). Occurrence and significance of trimethylamine oxide and its derivates in fish and shellfish. In R. E. Martin, G. J. Flick, C. E. Hebard, & D. R. Ward (Eds.), Chemistry and biochemistry of marine food products (pp. 149–304). Westport: Avi Publishing.

Huss, H. H. (1988). Fresh fish-quality and quality changes: A training manual prepared for the FAO/DANIDA training programme on fish technology and quality control. (Vol. 29). FAO.

Kamau, D. N., Doores, S., & Pruitt, K. M. (1990a). Enhanced thermal destruction of Listeria monocytogenes and Staphylococcus aureus by the lactoperoxidase system. Applied and Environmental Microbiology, 56(9), 2711–2716.

Kamau, D. N., Doores, S., & Pruitt, K. M. (1990b). Antibacterial activity of the lactoperoxidase system against Listeria monocytogenes and Staphylococcus aureus in milk. Journal of Food Protection, 53(12), 1010–1014.

Kilinc, B., Cakli, S., Dincer, T., & Tolasa, S. (2009). Microbiological, chemical, sensory, color, and textural changes of rainbow trout fillets treated with sodium acetate, sodium lactate, sodium citrate, and stored at 4 C. Journal of Aquatic Food Product Technology, 18(1–2), 3–17.

Kuorwel, K. K., Cran, M. J., Sonneveld, K., Miltz, J., & Bigger, S. W. (2011). Antimicrobial activity of biodegradable polysaccharide and protein‐based films containing active agents. Journal of Food Science, 76(3), R90–R102.

Kykkidou, S., Giatrakou, V., Papavergou, A., Kontominas, M. G., & Savvaidis, I. N. (2009). Effect of thyme essential oil and packaging treatments on fresh Mediterranean swordfish fillets during storage at 4 C. Food Chemistry, 115(1), 169–175.

Lund, B., Baird-Parker, T. C., & Gould, G. W. (2000). Microbiological safety and quality of food. Gaithersburg: Aspen Publishers.

Min, S., Harris, L. J., & Krochta, J. M. (2005). Listeria monocytogenes inhibition by whey protein films and coatings incorporating the lactoperoxidase system. Journal of Food Science, 70(7), m317–m324.

Min, S., Krochta, J. M., & Rumsey, T. R. (2007). Diffusion of thiocyanate and hypothiocyanite in whey protein films incorporating the lactoperoxidase system. Journal of Food Engineering, 80(4), 1116–1124.

Ouattara, B., Simard, R. E., Piette, G., Bégin, A., & Holley, R. A. (2000). Inhibition of surface spoilage bacteria in processed meats by application of antimicrobial films prepared with chitosan. International Journal of Food Microbiology, 62(1), 139–148.

Ozden, O., Inugur, M., & Erkan, N. (2007). Preservation of iced refrigerated sea bream (Sparus aurata) by irradiation: microbiological, chemical and sensory attributes. European Food Research and Technology, 225(5–6), 797–805.

Quintavalla, S., & Vicini, L. (2002). Antimicrobial food packaging in meat industry. Meat Science, 62(3), 373–380.

Ruiz-Capillas, C., & Moral, A. (2001). Correlation between biochemical and sensory quality indices in hake stored in ice. Food Research International, 34(5), 441–447.

Seifu, E., Buys, E. M., & Donkin, E. F. (2005). Significance of the lactoperoxidase system in the dairy industry and its potential applications: a review. Trends in Food Science & Technology, 16(4), 137–154.

Surendran, P. K., Joseph, J., Shenoy, A. V., Perigreen, P. A., Mahadeva Iyer, K., & Gopakumar, K. (1989). Studies of spoilage of commercially important tropical fishes under iced storage. Fisheries Research, 7(1), 1–9.

Tarladgis, B. G., Watts, B. M., Younathan, M. T., & Dugan, L., Jr. (1960). A distillation method for the quantitative determination of malonaldehyde in rancid foods. Journal of the American Oil Chemists Society, 37(1), 44–48.

Wolfson, L. M., Sumner, S. S., & Froning, G. W. (1994). Inhibition of Salmonella typhimurium on poultry by the lactoperoxidase system. Journal of Food Safety, 14(1), 53–62.

Xu, Y., Lin, H., Sui, J., & Cao, L. (2012). Effects of specific egg yolk antibody (IgY) on the quality and shelf life of refrigerated Paralichthys olivaceus. Journal of the Science of Food and Agriculture, 92(6), 1267–1272.

Yener, F. Y., Korel, F., & Yemenicioglu, A. (2009). Antimicrobial activity of lactoperoxidase system incorporated into cross‐linked alginate films. Journal of Food Science, 74(2), M73–M79.

Acknowledgments

This work was financially supported by the Urmia University (Urmia, Iran). The authors thank Ms. Seyedeh-Samaneh Naghibi for her excellent technical assistance. The facilities provided by the Artemia and Aquatics’ Research Institute is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shokri, S., Ehsani, A. & Jasour, M.S. Efficacy of Lactoperoxidase System-Whey Protein Coating on Shelf-life Extension of Rainbow Trout Fillets During Cold Storage(4 °C). Food Bioprocess Technol 8, 54–62 (2015). https://doi.org/10.1007/s11947-014-1378-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1378-7