Abstract

A low amylose and hydrothermally treated ready-to-eat rice product that requires no cooking was prepared in the laboratory. Hot soaking for 1–3 min with subsequent variable steaming at open and under pressures remarkably altered the kernel and flour properties. Increase in water absorption and lowering of cooking time with extent of steaming were prominent. Soaking of the product at 50 °C for 20 min gave texture values more similar to cooked samples. The viscosity parameters of hot soaking alone were in between those of hot soaking with open steaming and pressure steaming. Pressure steamed samples exhibited almost constantly increasing slurry viscosity throughout the heating and cooling phases of the rapid viscosity analyzer profile. Steaming variably altered the native A-type X-ray diffraction pattern. Pressure steaming of samples with 3 min hot soaking caused complete loss of the A-type conformation with feeble peaks for B- and V-type patterns. The open steamed samples showed peaks for all A-, B-, and V-type patterns. No endotherms for amylose-lipid complexes were however found in the differential scanning calorimetry of the pressure steamed samples. The raw rice flour was highly resistant to α-amylolysis. In open steamed samples, steaming severity decreased the hydrolysis rate indicating formation of enzyme-resistant fractions, while pressure steamed samples showed higher digestibility with treatment severity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ease of cooking along with economy in fuel and time consumption have made the instant cooking and quick cooking starchy foods much popular in recent times. Instant rice is one, such example (Prasert and Suwannaporn 2009; Rewthong et al. 2011). Rice is principally parboiled or precooked to bring about this peculiar characteristic. Paddy is generally not processed to give a ready-to-eat product that looks like whole parboiled rice.

Parboiling is a unique hydrothermal technique involving soaking of paddy in water followed by steaming, drying, and milling. Hot soaking involving soaking in heated water is also followed by some processors where the steaming step could be omitted (Sareepuang et al. 2008). Parboiled rice possesses many improved properties like higher nutrition, higher head rice yield, lower insect infestation, improved shelling, etc. (Bhattacharya 1985, Lin et al. 2010). Parboiled rice, however, has a lower rate of water uptake during cooking requiring longer time to cook and hence more energy is consumed (Bhattacharya 1985). With increase in severity of parboiling, the time and energy consumption of the parboiled rice is further increased (Unnikrishnan and Bhattacharya 1987).

Parboiled rice flour shows different properties from raw rice flour (Unnikrishnan and Bhattacharya 1987). Gelatinization and retrogradation are the basic phenomena involved behind all these changes. The extent of retrogradation is the principal factor for the end product quality (Yu et al. 2010). Due to formation of newer polymorphic structures during retrogradation, the native structure is never regained. These molecular changes are reflected in the changed properties of the rice kernel as well as the rice flour. Physical properties of kernel like color, appearance, kernel dimensions, density, cooking time, moisture absorption, etc. are very important for commercialization of the products (Shittu et al. 2009). The texture of the cooked rice kernels and the viscosity of the pastes made from their flours also are very important for the consumers’ satisfaction and food uses. Bello et al. (2006) observed harder texture of parboiled cooked rice with lesser stickiness as compared with raw rice. The pasting curves of the flour slurry obtained from the rapid viscosity analyzer (RVA) also give an idea of the end product texture (Goode et al. 2005). Wide angle X-ray diffractography (XRD) of raw rice flour shows peaks at 2Ɵ values near 15°, 17°, 18°, and 23°, which is called the typical A-type starch diffraction pattern (Zobel 1988). However, parboiled rice flour shows altered diffraction patterns with formation of newer peaks and loss of some peaks indicating formation of newer crystalline polymorphs as well as loss of few native crystals. A new peak generally reported at 2Ɵ = 20° depicts formation of amylose-lipid complexes on hydrothermal treatments, which on thermal analysis using the differential scanning calorimeter (DSC), gives an endothermic melting peak (Biliaderis et al. 1993; Mahanta et al. 1989). The B-type polymorphs formed after the hydrothermal modifications are characterized by the XRD peaks at 2Ɵ values near 17.1, 22.0, and 24.0, resulting in a C-type (A+B) crystalline structure in the parboiled rice. Thermal analysis gives the amount of crystalline polymorphs present in the sample based on their melting enthalpies (Lu et al. 1994). Pregelatinized and retrograded starches have different melting enthalpies and DSC is an effective tool for this analysis (Zhou et al. 2010). Another important parameter for all starchy foods is the starch digestibility as the health effects of foods has become a primary concern of the consumers. Hydrothermal processing of starchy foods has been found to be effective in the formation of slowly digestible starch fractions, thereby lowering the glycemic response (Sajilata et al. 2006). However, various conflicting findings have also been reported (Rewthong et al. 2011).

The above characteristics have generally been reported in high and intermediate amylose rice varieties and not in low amylose rice varieties that have 7–20 % amylose according to Juliano (1979).

In the present study, a hydrothermal technique was developed at the laboratory scale to obtain a ready-to-eat, quick cooking product from low amylose paddy and the important properties of the product were characterized.

Materials and Methods

Materials

Pure line Kola Chokua variety paddy from the recent harvest of 2011 was purchased from local farmers of Titabor, Assam. The rice variety falls under low amylose type with 12.6 % (in decibels) apparent amylose content as was determined by the method of Sowbhagya and Bhattacharya (1979). The samples were kept at room temperature for 24 h and then stored at 4 °C until processing.

Methods

Sample Preparation and Coding

Initially, 400 g paddy was added to 10 l water at 100 °C in a vessel kept over flame and the water was constantly stirred for 1 and 3 min. The temperature instantly fell down to 92 ± 1 °C and thereafter increased to 100 °C in 2.5 min. The vessel was covered with a thick gunny bag and kept at room temperature (27 ± 2 °C) for 18 h to allow the paddy to hydrate. The excess water was decanted after 18 h and the soaked paddy was immediately steamed in an autoclave (Equitron 7407ST, India) fitted with a pressure gauge for 10 (mild treatment), 15 (moderate treatment), and 20 min (severe treatment) at open steaming conditions (classified as O) of 101.32 kPa and 100 °C and pressure steaming conditions (classified as P) of 103.42 kPa and 121 °C, respectively. The nonsteamed samples were classified as N. Drying was carried out at room temperature for 48 h followed by milling (8 %, weight basis) in a Satake huller and polisher (Satake, Japan). A portion of each sample was ground into flour in a laboratory grain mill (Fritsch Pulverisette 14) and passed through a 100-μm sieve. All the kernel and flour samples were stored in polypropylene pouches at 4 °C for further analysis. The samples were coded as “classification—soaking time (min) at 100 °C—steaming time (in minutes)” (Table 1).

Grain Color

The CIE L*a*b* color values of all flour samples were obtained by a color measurement spectrophotometer (Hunter Color-Lab Ultrascan Vis). The results for L* (lightness), a* (red-green), and b* (yellow-blue) values using N as reference were used to calculate the corresponding hue angle (H*) and chroma (C*) values (Falade and Onyeoziri 2010) using the relations

L/B Ratio

The length (L) and breadth at the midpoint (B) of the polished kernels were determined using a Vernier calipers and a screw gauge (Mitutoyo, Japan) respectively and the L/B ratio was calculated to measure whether any dimensional changes occurred on parboiling.

Porosity, bulk density, and true density

For porosity (ε) determination, bulk density (ρ b ), and true density (ρ t ) were first determined. For determining ρ b , an established method (Shittu et al. 2009) was slightly modified. Briefly, polished grains were allowed to fall into a measuring cylinder from a constant height up to a known volume. The top level was adjusted by gentle tapping. The weight of the filled grains was determined and ρ b was calculated from the relation

True volume was determined by the toluene displacement method. Briefly, to a known volume of toluene (Merck, India) in a measuring cylinder, polished kernels of known weight were immersed and the volume displaced by the kernels was recorded and the density (ρ t ) was calculated by the relation

The porosity (ε) was determined from Eqs. (3) and (4) by the relation (Jain and Bal 1997)

Cooking Time

Cooking time was determined by an objective method (Juliano 1982). Kernels weighing 20 g were cooked in 200 ml water at 98 °C on a hot plate. After 10 min of cooking, ten kernels were brought out from the middle of the cooked mass and pressed between two clean glass slides. The number of translucent kernels were counted and recorded. The pressing test was repeated after each minute and the time at which 90 % of the kernels were translucent was considered as the cooking time of that sample.

Equilibrium Moisture Content on Soaking at Room Temperature

Equilibrium moisture content (EMCS, in percent, decibels) of polished rice kernels soaked at room temperature for 4 h were determined by the method of Indudhara Swamy et al. (1971).

Sediment Volume

The test for SV (Bhattacharya and Ali 1976) gives an indirect indication of degree of gelatinization of pregelatinized rice flour. Briefly, 1 g each of desiccated flour samples was taken in a measuring cylinder and 15 ml of 0.05 N HCl was added to it with agitation after each 5 min for 1 h. The level of the flour sediment was observed after 4 h and was reported as the SV (in milliliters) of the sample.

Cooked Rice Texture

Briefly, 20 g samples from both raw and processed rice kernels were cooked for their cooking times and texture profile analysis (TPA) of the cooked grains was performed using a Texture Analyzer (TA.HD.plus, Stable Micro Systems, UK). A 5-kg load cell fitted with a cylindrical probe of 2 cm diameter was used for performing the two-cycle compression test (Suzuki 1979). A single kernel was collected from the middle of the cooked rice mass and compressed to 70 % at 0.5 mm/s. The time between two chews was 3 s. All the TPA parameters, namely hardness, fracturability, adhesiveness, springiness, and chewiness were determined by the inbuilt software (Exponent Lite). Ten replicates for each sample were run and the mean values for each parameter taken. In addition to this, looking at the quick cooking nature of the product, the samples were soaked in excess water at 20 and 50 °C for 60 and 20 min respectively in a hot water bath (Labtech, India) and the TPA parameter values were compared.

Pasting Properties

The pasting profiles of flour suspensions (12 %, w/w; 28 g total weight) were recorded using a Rapid Visco Analyzer (RVA Starchmaster2, Newport Scientific Instruments). The Rice1 profile of Newport Scientific was used, where the samples were held at 50 °C for 1 min, heated from 50 °C to 95 °C at 12 °C/min, held at 95 °C for 2.40 min followed by cooling to 50 °C at 11.25 °C/min, and finally holding at 50 °C for 1 min. The pasting curves obtained were compared and the pasting parameters, namely peak viscosity (PV), hot paste viscosity (HPV), cold paste viscosity (CPV), breakdown (BD), and total setback (SBt) were recorded. PV = maximum viscosity during heating, HPV = minimum viscosity at 95 °C, CPV = final viscosity at 50 °C, BD = PV-HPV, and SBt = CPV-PV.

X-Ray Diffraction

Wide angle X-ray diffractograms were obtained using a X-ray diffractometer (Rigaku Miniflex, Japan) with a Cu Kα value of 1.5404 A° operating at 30 kV acceleration potential and 15 mA current with a copper target. The scanning range was 10–40° of 2θ values in steps of 0.05°. The total area under the curve and the area under each prominent peak were determined and the percentage crystallinity was calculated (Singh et al. 2006)

Thermal Analysis

A Differential Scanning Calorimeter (model DSC-60; Shimadzu, Tokyo, Japan), periodically calibrated with pure indium for heat flow and temperature was used for thermal profile analysis of the flour samples; 1:2 flour-to-moisture ratio was taken in an aluminum pan and saturated for 12 h at 4 °C. The pan was then hermetically sealed and heated against an empty reference pan from 25–150 °C at a heating rate of 5 °C/min under N2 atmosphere. The onset (T o), peak (T p), and conclusion (T c) temperatures and enthalpy of gelatinization (ΔH, in joules per gram) were obtained from the thermograms using TA-60WS software.

Starch Digestibility Rate

The extent of enzymatic hydrolysis leading to release of glucose from starch gives an indication of digestibility of starchy foods. The amount of glucose liberated on hydrolysis gives a measure of digestible starch fractions present in it. The in vitro starch hydrolysis rates (Goni et al. 1996) of the rice flour samples were estimated. For this, 50 mg of flour samples were first deproteinized using 0.2 ml of a solution containing 1 g of Pepsin in 10 ml of HCI-KCI buffer (pH 1.5) by keeping in a shaking water bath at 40 °C for 1 h. The volume was then made up to 25 ml with Tris-maleate buffer (pH 6.9). To this, 5 ml of a solution of in Tris-maleate buffer containing 2.6 IU pancreatic α-amylase (Sigma-Aldrich) were then added to each sample and incubated at 37 °C. One milliliter aliquot was taken out from each tube after each 30 min from 0 up to 180 min to determine the hydrolysis rate at different times. The aliquots were boiled to inactivate the enzymes and stored under refrigeration for further analysis. Then 3 ml of 0.4 M sodium acetate buffer (pH 4.75) containing 60 μl of amyloglucosidase (Sigma-Aldrich) was added to each aliquot and incubated at 60 °C for 45 min to hydrolyse the digested starch into glucose. The glucose liberated was estimated by the 3,5-dinitrosalicylic acid method and was converted to starch by multiplying by a factor of 0.9. The degree of hydrolysis was calculated as the percentage of starch degraded from the total starch content.

Statistical Analysis

All the experiments were carried out in three or more replicates and the means are reported. Significant differences between the means by Duncan’s multiple range test at a significance level of 0.05 were performed using SPSS 11.5 (SPSS Inc., USA).

Results and Discussion

Color Values

It was observed that the lightness values (L*) decreased on hot soaking alone compared to raw and further with extent of steaming (Table 2). The hue angle (H*) value also exhibited a similar fall indicating increased redness in the samples. These values indicating loss of whiteness and significant rise in the redness may be attributed to the migration of husk and bran pigments into the endosperm (Bhattacharya 2004) as the husk of the paddy LK was highly pigmented (Fig. 1). Additionally, there might have also occurred Maillard browning due to the high heat applied during soaking and steaming. The chroma (C*) value indicative of color purity and clarity increased markedly with extent of processing indicating more uniform product appearance. More drastic changes in the color values were observed in a different study where similar steaming conditions were employed with the same paddy variety after the same soaking duration but without the short-term boiling step (Dutta and Mahanta 2012). An explanation for this may be that the hot soaking causes surface gelatinization of the rice starch accompanied by pigment migration. On cooling, the gelatinized surface starch retrogrades. The retrograded layer has a harder texture as reported by Kadan et al. (2001) and Yu et al. (2010) and hence might have served as a partial barrier resulting in lower migration of pigments during the steaming step.

L/B Ratio

Physical dimensions of L, B, L/B were almost similar in the raw rice, open steam parboiled rice and pressure parboiled rice contrary to the observations of Saeed et al. (2011), Saif et al. (2004), Siddiquee et al. (2002), Sowbhagya et al. (1993), and Igathinathane et al. (2008) in parboiled rice.

Porosity

The pattern of change in porosity on parboiling is dependent on the rice variety and also on the final moisture content of the paddy (Kachru et al. 1994; Reddy and Chakraverty 2004). The changes in bulk and true density were marginal; both properties increased with parboiling. The marginal decrease in porosity with increasing L/B ratio, however, was not in accordance with that reported by Bhattacharya et al. (1972) mentioning positive interrelation of porosity with kernel length. This might be due to the simultaneous decrease of the kernel breadths (B) causing more grains to be accommodated within a unit volume, resulting in increased ρ t value than the raw rice kernels (Table 2). This increase was higher for the pressure parboiled samples indicating better packing properties, hence also exhibiting lower ε values.

Cooking Time

Table 2 shows the values of the cooking times of the different samples. T (cooking time) was highest for the raw N kernels. N required around 18 min to cook. Hot soaking only marginally lowered the T values, which was further reduced on both open and pressure steaming which reflected the effect of gelatinization of starch. P-3-10 exhibited the fastest cooking, with almost half the T value of N. The very low cooking time of severely parboiled rice reflected the effect of both gelatinization and thermal degradation. Although, parboiling is said to increase the cooking time of rice kernels, reduction in cooking time in heat moisture treated starches have also been reported (Kulp and Lorenz 1983; Adebowale et al. 2005). Furthermore, the low cooking time of Chokua parboiled rice may be attributed to the low amylase content of the rice. As amylose content is low, the extent of retrogradation of the gelatinized starch during drying was restricted.

Equilibrium Moisture Content at Soaking at Room Temperature

Marked increases in EMC-S (in percent, decibels) were observed on processing (Fig. 2a). Although N-1-0 and N-3-0 did not vary much in the EMC-S, both open and pressure steaming resulted in higher water uptake by the kernels. This increase was higher in the pressure steaming of 3 min hot-soaked samples than 1 min hot-soaked samples. EMC-S was highest for P-3-20 followed by P-1-20 with values of 259.9 and 236.6 %, respectively. The increased EMC-S was probably due to the thermally degraded starch in the samples.

Sediment Volume

SV also showed a similar pattern as EMC-S, with higher volume increase by the rice flour in acidic solution with increasing severity of processing (Fig. 2b). It was indicative of increased degree of starch gelatinization and subsequent thermal degradation with severity of processing (Bhattacharya and Ali 1976).

Cooked Rice Texture

The textural properties of open pan cooked (100 °C) samples and samples soaked at 20 and 50 °C for 60 and 20 min respectively were studied (Fig. 3). ). Hardness decreased progressively with extent of processing. Adhesiveness of the cooked kernels increased on open steaming which might be attributed to formation of hot water soluble fractions while pressure steaming exhibited decrease with severity of pressure steaming possibly due to thermally degraded starch. Springiness values, however, showed marked increase for both the processing types. The presence and type of amylose and amylopectin fine structures in the starch plays important role in the rice TPA parameters (Ong and Blanshard 1995) creating scope for further research in this area.

Soaking at 50 °C for 20 min gave texture parameter values nearer to that of the open cooked samples as compared with soaking in water at 20 °C for 60 min. This similarity was more prominent for the pressure processed samples. From the TPA results, it is evident that just soaking at 50 °C for 20 min of the hot-water-soaked and pressure steamed low amylose Chokua rice gave similar textural as open pan cooking of such treated rice. Such processing conditions hence obviate the need of cooking and convert the processed Chokua rice into ready-to-eat cereal.

Pasting Properties

Hot-soaked samples (both 1 and 3 min hot soaked) had pasting profile similar to the corresponding raw, however, the viscosity at PV, HPV, and CPV were considerably higher (Fig. 4). PV for N-1-0 was 4.558 Pa s and for N-3-0 was 3.932 Pa s. On open steaming, while PV remained almost constant for the LK1 samples (3.577–4.646 Pa s), minor drop was observed for the processed LK3 samples (4.109–3.375 Pa s), and suggestive of lower thermal stability of the polymeric pattern developed on hot soaking. The CPV for the open steamed samples, O-3-10 (6.924 Pa s), O-3-15 (7.092 Pa s), and O-3-20 (6.682 Pa s) were however higher than O-1-10 (6.246 Pa s), O-1-15′ (6.191 Pa s), and O-1-20 (6.446 Pa s). SBt values were similarly higher. This may be explained as to the formation of short linear molecular chains on thermal degradation which probably was able to reassociate forming retrograded starch. Pressure steaming resulted in gradual yet extensive drop in the PV as was also evident in some earlier works (Himmelsbach et al. 2008; Swasdisevi et al. 2010). This drop is similar to that of acid-thinned starch used in paper and textile industries (Dutta et al. 2011). This was accompanied by very low BD (12–28 cP) with higher CPV. Severe processing causes thermal degradation of starch polymer structure (Mahanta and Bhattacharya 1989). Increase in the final slurry viscosity, hence may be attributed to leaching of the degraded simpler chains causing rise in slurry densities. The almost continuous rise in the slurry viscosity with minor BD throughout the RVA cycle indicated the thickening property of the pressure steamed samples, suggesting its suitability for specific uses.

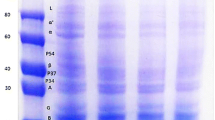

X-Ray Diffraction

The native A-type diffraction pattern of N with characteristic peaks near 15.1, 17.1, 18.3, and 23.2 remained unaltered on hot soaking (Fig. 5a). While both open and pressure steamed samples from 1-min boiled category and only open steamed samples from 3-min boiled category gave mixed patterns with peaks corresponding to all A- (2Ɵ = 15.1°, 23.2°), B- (2Ɵ = 17.3°), and V-type (2Ɵ = 20°), the high pressure processed LK(3) samples exhibited almost amorphous diffractographs with feeble peaks indicating mixed pattern of B- (2Ɵ = 17.3° and 24.1°) and V-type (2Ɵ = 20°). Mahanta et al. (1989) and Xiao et al. (2011) also reported similar diffraction peaks in their parboiled samples. Percent crystallinity was maximum in raw rice. Hot soaking reduced crystallinity. In both 1 and 3 min series of processed samples, open steaming showed gradual increase in percent crystallinity, while for pressure steamed samples, the percent crystallinity was less in 15 min steaming time than 10 and 20 min steaming. Such changes in crystallinity were also reported by Manful et al. (2008) and Yu et al. (2010). Probably the new polymorphic forms (B- and V-type) have increased the percent crystallinity (Fig. 5b).

Thermal Properties

The DSC thermographs of the samples are shown in Fig. 6 and the thermal parameter values presented in Table 3. Hot-soaked sample with no steaming showed marked decrease in melting enthalpy of the rice flour. However, mildly parboiled samples showed higher transition enthalpies with a shift of the melting peak towards higher temperatures. Similar findings in parboiled rice were reported earlier by Lai et al. (2001). Further higher treatment lowered the enthalpy values with a shift of the peak towards lower temperature again as was also evident in the RVA patterns of the samples. This indicates differences in the thermal properties of the different polymorphs formed with different extents of processing and lowering of the thermal stability with processing severity (Ong and Blanshard 1995). Furthermore, hot-soaked N-1-0 and N-3-0, mildly processed O-1-10, and the pressure steamed P-1-15, P-1-20, P-3-10, P-3-15, and P-3-20 did not exhibit any endotherm for amylose-lipid complex melting. The endotherms were observed primarily in the moderately processed samples and all were of type I (melting temperature, <100 °C) as reported by Biliaderis and Galloway (1989). The absence it in the severely processed samples indicates that these complexes formed at higher processing conditions, as were observed in the XRD patterns, melted throughout the period of the DSC profile used, without showing any distinct endotherm. Another probable reason might be that these polymorphs had similar temperature sensitivity and hence have merged with the main peak responsible for the retrograded starch fractions.

Starch Digestibility Rate

Starch digestibility rapidly increased till 90 min of incubation for all flour samples (Fig. 7), thereafter remained almost constant till 180 min. The raw rice flour showed comparatively lower hydrolysis rate than the rest (69.3 % after 180 min). Hot-soaked samples did not differ in starch digestibility from raw samples in line with the similarity in crystallinity and thermal properties. Probably, hot-soaked samples did not undergo much alteration at the molecular level. Mild open steaming gave higher digestibility than moderate and severe steaming indicating formation of newer indigestible fractions on retrogradation of gelatinized starch as also observed in previous works (Sajilata et al. 2006). Increasing severity of open steaming hence might result in the formation of newer enzyme resistant fractions. The trend was however reversed in pressure steamed samples after 1 and 3 min hot soaking times. Steaming severity increased the digestibility markedly and was highest (93.8 % after 180 min) for P-3-20, also observed by Takahashi et al. (1994) and Niba (2003). Hence, the results were indicative of clear nutritional differences between the products of the two processes.

The Ready-to-Eat Product

The flowchart of the process developed in this study is given in Fig. 8. In order to hasten the water absorption by the kernels, the kernels were given a hot soaking treatment that involved cooking the low amylose Kola Chokua paddy in water for 1–3 min and then allowing the paddy to hydrate overnight in that water at room temperature. The soaked paddy was then steamed at the different conditions mentioned. Pressure steaming gave a better quality product as judged by the texture of the kernels soaked in water. The textural properties of such pressure steamed rice gave soft textured rice kernels on soaking in water for 20 min at 50 °C. Thus, the above processing conditions gave a ready-to-eat rice product that softened easily when soaked in warm water and was suitable for consumption.

Conclusions

The pressure steaming of Kola Chokua paddy after hot soaking treatment gave a quick cooking, ready-to-eat product similar in texture to cooked rice kernels. Such parboiled rice had different physicochemical properties than those obtained from open steaming technique. The changes in properties can be attributed to the effect of gelatinization and thermal degradation of starch which may explain their higher rate of starch digestibility. Thus, pressure steaming of hot-soaked Kola Chokua paddy gives ready-to-eat rice product. On the other hand, the product processed by open steaming of hot-soaked paddy gave enzyme resistant starch. Such samples also recorded high pasting and cooling viscosities. These specific properties can be exploited for specific end uses. The thermal degradation of starch can be further studied at the molecular level.

References

Adebowale, K. O., Olu-Owolabi, B. I., Olayinka, O. O., & Lawal, O. S. (2005). Effect of heat moisture treatment and annealing on physicochemical properties of red sorghum starch. African Journal of Biotechnology, 9, 928–933.

Bello, M., Baeza, R., & Tolaba, M. P. (2006). Quality characteristics of milled and cooked rice affected by hydrothermal treatment. Journal of Food Engineering, 72, 124–133.

Bhattacharya, K. R. (2004). Parboiling of rice. In N. E. T. Champagne (Ed.), Rice chemistry and technology (pp. 329–404). St. Paul: American Association of Cereal Chemists, Inc.

Bhattacharya, K. R., Sowbhagya, C. M., & Indudhara Swamy, Y. M. (1972). Some physical properties of paddy and rice and their interrelations. Journal of the Science of Food and Agriculture, 23, 171–186.

Bhattacharya, K. R., & Ali, S. Z. (1976). A sedimentation test for pregelatinized rice products. LWT-Food Science and Technology, 9, 36–37.

Bhattacharya, K. R. (1985). Parboiling of rice. In B. O. Juliano (Ed.), Rice chemistry and technology (pp. 289–348). St. Paul: American Association of Cereal Chemists, Inc.

Biliaderis, C. G., & Galloway, G. (1989). Crystallization behaviour of amylose-V complexes: structure property relationships. Carbohydrate Research, 189, 31–48.

Biliaderis, C. G., Tonogai, J. R., Perez, C. M., & Juliano, B. O. (1993). Thermophysical properties of milled rice starch as influenced by variety and parboiling method. Cereal Chemistry, 70(5), 512–516.

Dutta, H., Paul, S. K., Kalita, D., & Mahanta, C. L. (2011). Effect of acid concentration and treatment time on acid–alcohol modified jackfruit seed starch properties. Food Chemistry, 128, 284–291.

Dutta, H., & Mahanta, C. L. (2012). Effect of hydrothermal treatment varying in time and pressure on the properties of the parboiled rices with different amylose content. Food Research International, 49, 655–663.

Falade, K. O., & Onyeoziri, N. F. (2010). Effects of Cultivar and drying method on color, pasting and sensory attributes of instant yam (Dioscorea rotundata) flours. Food and Bioprocess Technology. doi:10.1007/s11947-010-0383-8.

Goni, I., Garcia-Alonso, A. F., & Saura-Calixto, F. (1996). Analysis of resistant starch: a method for foods and food products. Food Chemistry, 56, 445–449.

Goode, D. L., Wiltschko, E. A., Ulmer, H. M., & Arendt, E. K. (2005). Application of the rapid visco analyser as a rheological tool for the characterisation of mash viscosity as affected by the level of barley adjunct. Journal of the Institute of Brewing, 111, 165–175.

Himmelsbach, D. S., Manful, J. T., & Coker, R. D. (2008). Changes in rice with variable temperature parboiling: thermal and spectroscopic assessment. Cereal Chemistry, 85(3), 384–390.

Igathinathane, C., Chattopadhyay, P. K., & Pordesimo, L. O. (2008). Moisture diffusion modeling of parboiled paddy accelerated tempering process with extended application to multi-pass drying simulation. Journal of Food Engineering, 88, 239–253.

Indudhara Swamy, Y. M., Ali, S. Z., & Bhattacharya, K. R. (1971). Hydration of raw and parboiled rice and paddy at room temperature. Journal of Food Science and Technology, 8, 20–22.

Jain, R. K., & Bal, S. (1997). Properties of pearl millet. Journal of Agricultural Engineering Research, 66, 85–91.

Juliano, B.O. (1979). The chemical basis of rice quality. In: Proceedings of the Workshop on Chemical Aspects of Rice Grain Quality, International Rice Research Institute, pp. 69–90

Juliano, B.O. (1982). An international survey of methods used for evaluation of cooking and eating qualities of milled rice. International Rice Research Institute Paper Series, 77, Manila, Philippines.

Kachru, R. P., Gupta, R. K., & Alam, A. (1994). Physico-chemical constituents and engineering properties of food crops. Jodhpur: Scientific Publishers.

Kadan, R. S., Robinson, M. G., Thibodeaux, D. P., & Pepperman, A. B., Jr. (2001). Texture and other physicochemical properties of whole rice bread. Journal of Food Science, 66, 940–944.

Kulp, K., & Lorenz, K. (1983). Physicochemical properties of defatted heat moisture treated starches. Starch/Starke, 35, 123–129.

Lai, V. M. F., Shen, M. C., Yeh, A. I., Juliano, B. O., & Lii, C. (2001). Molecular and gelatinization properties of rice starches from IR24 and Sinandomeng cultivars. Cereal Chemistry, 78, 596–602.

Lin, P., Chen, Y., & He, Y. (2010). Identification of broken rice kernels using image analysis techniques combined with velocity representation method. Food Bioprocess Technology. doi:10.1007/s11947-010-0454-x.

Lu, S., Fang, W. T., & Lii, C. Y. (1994). Studies on the effects of different hydrothermal treatment on the physicochemical properties of non-waxy and waxy rices. Journal of Chinese Agricultural and Chemical Society, 32, 372.

Mahanta, C. L., Ali, S. Z., Bhattacharya, K. R., & Mukherjee, P. S. (1989). Nature of starch crystallinity in parboiled rice. Starch/ Starke, 41, 171–176.

Mahanta, C. L., & Bhattacharya, K. R. (1989). Thermal degradation of starch in parboiled rice. Starch/Starke, 41(3), 91–94.

Manful, J. T., Grimm, C. C., Gayin, J., & Coker, R. D. (2008). Effect of variable parboiling on crystallinity of rice samples. Cereal Chemistry, 85(1), 92–95.

Niba, L. L. (2003). Processing effects on susceptibility of starch to digestion in some dietary starch sources. International Journal of Food Sciences and Nutrition, 54(1), 97–109.

Ong, M. H., & Blanshard, J. M. V. (1995). Texture determinants of cooked parboiled rice II: rice starch amylose and the fine structure of amylopectin. Journal of Cereal Science, 21, 261–269.

Prasert, W., & Suwannaporn, P. (2009). Optimization of instant jasmine rice process and its physicochemical properties. Journal of Food Engineering, 95(1), 54–61.

Reddy, B. S., & Chakraverty, A. (2004). Physical properties of raw and parboiled paddy. Biosystems Engineering, 88, 461–466.

Rewthong, O., Soponronnarit, S., Taechapairoj, C., Tungtrakul, P., & Prachayawarakorn, S. (2011). Effects of cooking, drying and pretreatment methods on texture and starch digestibility of instant rice. Journal of Food Engineering, 103, 258–264.

Saeed, F., Pasha, I., Anjum, F. M., Suleria, H. A. R., & Farook, M. (2011). Indian Journal of Food Safety, 13, 237–245.

Saif, S. M. H., Suter, D. A., & Lan, Y. (2004). Effects of processing conditions and environmental exposure on the tensile properties of parboiled rice. Biosystems Engineering, 89, 321–330.

Sajilata, M. G., Singhal, R. S., & Kulkarni, P. K. (2006). Resistant starch: a review. Comprehensive Reviews in Food Science and Food Safety, 5, 1–17.

Sareepuang, K., Siriamornpun, S., Wiset, L., & Meeso, N. (2008). Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. World Journal of Agricultural Sciences, 4, 409–415.

Shittu, T. A., Olaniyi, M. B., Oyekanmi, A. A., & Okeleye, K. A. (2009). Physical and water absorption characteristics of improved rice varieties. Food and Bioprocess Technology, 5, 298–309.

Siddiquee, M. A., Biswas, S. K., Kabir, K. A., Mahbub, A. A., Dipti, S. S., Ferdous, N., Biswas, J. K., & Banu, B. (2002). Pakistan Journal of Biological Sciences, 5, 550–552.

Singh, V., Ali, S. Z., Somashekar, R., & Mukherjee, P. S. (2006). Nature of crystallinity in native and acid modified starches. International Journal of Food Properties, 9, 845–854.

Sowbhagya, C. M., Ali, S. Z., & Ramesh, B. S. (1993). Effect of parboiling on grain dimensions of rice. Journal of Food Science and Technology, 30, 459–461.

Sowbhagya, C. M., & Bhattacharya, K. R. (1979). Simplified determination of amylose in milled rice. Starch/Starke, 31, 159–163.

Suzuki, H. (1979). Use of Texturometer for measuring the texture of cooked rice. In: Chemical Aspects of Rice Quality. International Rice Research Institute, Los Bannos, Laguna, Philippines, pp. 327–341

Swasdisevi, T., Sriariyakula, W., Tia, W., & Soponronnarit, S. (2010). Effect of pre-steaming on production of partially-parboiled rice using hot-air fluidization technique. Journal of Food Engineering, 96, 455–462.

Takahashi, T., Kawauchi, S., Suzuki, K., & Nakao, E. (1994). Bindability and digestibility of high-pressure-treated starch with glucoamylases from Rhizopus sp. Journal of Biochemistry., 116, 1251–1256.

Unnikrishnan, K. R., & Bhattacharya, K. R. (1987). Properties of pressure-parboiled rice as affected by variety. Cereal Chemistry, 64, 321–323.

Xiao, H., Lin, Q., Liu, G., Wu, Y., Tian, W., Wu, W., et al. (2011). Effect of green tea polyphenols on the gelatinization and retrogradation of rice starches with different amylose contents. Journal of Medicinal Plants Research, 5(17), 4298–4303.

Yu, S., Ma, Y., Liu, T., Menager, L., & Sun, D. W. (2010). Impact of cooling rates on the staling behavior of cooked rice during storage. Journal of Food Engineering, 96, 416–420.

Zhou, X., Baik, B., Wang, R., & Lim, S. (2010). Retrogradation of waxy and normal corn starch gels by temperature cycling. Journal of Cereal Science, 51, 57–65.

Zobel, H. F. (1988). Starch crystal transformations and their industrial importance. Starch/Starke, 40, 1–7.

Acknowledgment

The authors acknowledge Department of Science and Technology, New Delhi for providing financial assistance for carrying out this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dr. Charu Lata Mahanta applied for an Indian patent.

Rights and permissions

About this article

Cite this article

Dutta, H., Mahanta, C.L. Laboratory Process Development and Physicochemical Characterization of a Low Amylose and Hydrothermally Treated Ready-to-Eat Rice Product Requiring No Cooking. Food Bioprocess Technol 7, 212–223 (2014). https://doi.org/10.1007/s11947-012-1037-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1037-9

), 50 °C for 20 min (

), 50 °C for 20 min ( ), and 20 °C for 60 min (

), and 20 °C for 60 min ( )

)

), hot soaked and nonsteamed (

), hot soaked and nonsteamed ( ), open steamed O-10 (

), open steamed O-10 ( ), O-15 (

), O-15 ( ), O-20 (

), O-20 ( ), and pressure steamed P-10 (

), and pressure steamed P-10 ( ), P-15 (

), P-15 ( ), and P-20 (

), and P-20 ( )

)