Abstract

Komal chawal, meaning soft rice, produced by brown rice parboiling of a low amylose rice variety chokuwa, was studied for its physical, physico-chemical, morphological and structural characteristics. The product was produced by soaking the brown rice at 60 °C for 90 min, followed by steaming and air drying to 12.0% (wb). The two steaming conditions used were: (1) open-steaming at atmospheric pressure for 20 min and (2) pressure-steaming at 1 atm (gauge) for 10 min. The three different drying temperatures used were 40, 50 and 60 °C. When soaked in water at 60 °C for 20 min the product attained a hardness value of cooked rice. The extent of changes in the kernel and flour properties as compared to the raw form were affected by the severity of the steaming condition and drying air temperature. The pressure steamed samples exhibited virtually persistent growth in paste viscosity in the profiles obtained from the rapid viscosity analyzer. X-ray diffraction analysis of flours revealed a loss of A-type pattern and formation of feeble peaks of A + V-type mixed patterns in steam-treated samples. Scanning electron photomicrographs showed the loss of the polygonal shape by starch granules during processing. The values of rehydration ratio, equilibrium moisture content for rehydration, sediment volume, extent of color change as denoted by total color difference, and the percent head rice yield were higher in pressure steamed komal chawal samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Instant foods or instant cooked (convenience) foods are becoming popular due to their advantages in terms of reduced drudgery and preparation-time, improved handling characteristics and improved functional properties such as rapid rehydration (Sindawal and Bhattacharya 2015). Instant rice is a starch rich food as whole grain form possessing instant cooking characteristics which can be prepared in 5 min or so, and has been of interest for investigation since the time of the introduction of the ‘minute rice’ in 1948 (Luh 1991). Production of such an instant rice involves precooking and gelatinization to a desired extent, followed by an abrupt drying and/or puffing under a well thought process condition. The quality of the final product is affected by the process conditions at various stages of production (Prasert and Suwannaporn 2009).

In the North Eastern part of India, a product named komal chawal, meaning soft rice, is produced from a low amylose paddy (named chokuwa) variety simply by hydrothermal treatment, and is consumed without cooking. The product rehydrates to a texture soft enough for consumption on soaking in warm water for 20–30 min (Dutta and Mahanta 2014). Since this preparation time is more than 5 min, it does not meet the specifications for an instant rice mentioned by Sindawal and Bhattacharya (2015). When subjected to cooking, although it is not subjected to cooking for consumption in practice, it attains a texture soft enough for consumption in around 10–12 min. This time requirement is much lower than some reported cooking times for parboiled rice. For example, Ayamdoo et al. (2014) reported 15–20 min of cooking time for parboiled rice. Shiela Marie et al. (2016) similarly reported cooking time of around 27–28 min for parboiled milled rice. The present study thus aims at a quality assessment of komal chawal produced from brown rice of chokuwa paddy under controlled laboratory conditions with particular reference to pressure and temperature.

In the traditional method of production of komal chawal, rough rice (paddy) is hydrothermally treated by soaking in water for 18 h followed by steaming and shade drying to bring the moisture to a safe level (Dutta and Mahanta 2014). Although the brown rice parboiling method has several disadvantages like caking and cracking, reduction of milling yield and deformation (Oli et al. 2014; Parnsakhorn and Noomhorm 2008), yet the benefits in terms of reduction in time and drudgery of processing are worth mentioning (Kar et al. 1999; Parnsakhorn and Noomhorm 2008; Patindol et al. 2008).

A number of quantitative (leachate loss and kernel bursting) and qualitative (color and aroma) changes occur during the process of parboiling. These are attributed to the extent of soaking and steaming (Pillaiyar 1988). Based on the requirement of accomplishing an effective gelatinization of starch during steaming, a moisture level of around 30% was reported to be adequate (Pillaiyar 1988). Steaming is carried out by exposing the soaked grains to steam for a specified duration either at ambient or elevated pressures. The process of steaming is carried out at a pressure close to the atmospheric pressure because of the development of the hard texture (Oli et al. 2014). Further, the process conditions during the drying of hydrothermally treated grains affect the quality of parboiled rice (Elbert et al. 2001).

However, the overall impact of hydrothermal treatment, comprising of soaking, steaming and subsequent drying is thoroughly assessed by instrumental measurements on the alterations in the physico-chemical properties of rice. Researchers have reported such changes through the various measurements done in the work of Unnikrishnan and Bhattacharya (1987). Some of such measurements are based on the hypothesis that most of the structural and morphological changes may be attributed to the retrogradation of starch as new polymorphic structures take place. The molecular changes modify the properties of the rice kernel or flour to change (Yu et al. 2010). The wide angle X-ray diffractography (XRD) of raw rice flour produces typical native A-type starch diffraction pattern (Prasert and Suwannaporn 2009). However, parboiled rice flour loses the native pattern and forms newer peaks to affect the diffraction patterns indicating formation of newer crystalline polymorphs. After the hydrothermal treatment of rice, the B-type and C-type (A + B) polymorphs are formed which can be characterized by the XRD peaks at specific 2θ values. Scanning electron microscopy is also used to report the structural and morphological changes due to thermal processing (Leelayuthsoontorn and Thipayarat 2006; Yu et al. 2010). In addition, an assessment of the physical properties of the kernel in terms of texture of the cooked rice and flour paste viscosity are equally important for commercialization of the products (Shittu et al. 2009). Similarly, the benefit in terms of improvement in the percent head rice is also important from a commercial prospect (Ayamdoo et al. 2013).

Hence, in the present study, the physical, physico-chemical, textural, structural and morphological properties were used for the characterization of komal chawal, the product obtained by varying the parboiling process.

Materials and methods

Materials

Low amylose paddy named chokuwa, traditionally grown in Assam, India was collected from a nearby farm. After sun drying to a moisture content of around 12% (wb), the paddy was dehusked to produce brown rice and stored in an airtight container in refrigerated condition until further processing. Images of chokuwa paddy and chokuwa brown rice are given in Fig. S1 (a and b) of the supplementary section. The compositions of the sample were determined by employing AOAC (2016) and the method of Thimmaiah and Thimmaiah (2004) on triplicates samples was used for the determination of amylose and amylopectin (Table S1 of the supplementary file).

Laboratory production of Komal Chawal

The Komal chawal samples were prepared from the dehusked paddy. 100 g of brown rice was soaked in 200 ml of hot water at 60 °C in a beaker, and isothermal condition was ensured by placing the beaker in a water bath. After 90 min of soaking, a duration selected based on the criteria of attaining moisture level of around 30% (wb), the decanted brown rice was steamed in laboratory autoclave. Two different steaming conditions were applied on separate batches of samples, viz., (1) 0 atm (gauge) for open steaming, and (2) 1 atm (gauge) for pressure steaming. Based on the findings of a separate set of experiments for achieving assured degree of gelatinization (% DG) of 98 or above, open steaming was carried out for 20 min, and pressure steaming for 10 min, excluding the vent-off time of autoclave which was around 3 min (applicable in case of pressure steaming).

After removal of steamed brown rice from the autoclave, the sample was air cooled for a while and then dried at 1 m/s air velocity in a laboratory scale tray dryer (Armfield–UOP8-A, UK) to a moisture content of approximately 12% (wb). Three separate drying temperatures of 40, 50 and 60 °C were used to produce different samples. The dried samples were packaged in zipped pouches, and stored in an airtight container in refrigerated condition for further analysis. For identifying samples of komal chawal based on processing condition, samples were coded as explained in the next section.

Coding of komal chawal samples

Alphabet K was used to denote komal chawal indicating gelatinized sample (%DG> 98). For making a distinction between samples of open steamed and the samples of pressure steamed they were coded as K0 (for open steamed) and K1 (for pressure steamed), respectively. Reference to drying temperature was embedded in sample coding whenever it was needed to highlight the temperature effect, by a number within the bracket referring to the temperature in degree Centigrade. Accordingly, both samples K0 and K1 together yielded six samples that were denoted by K0(40), K0(50), K0(60), K1(40), K1(50) and K1(60).

For comparison purpose raw, and under-gelatinized samples were also used for the present study. Raw samples were coded as sample R. The under-gelatinized samples were coded as sample U0, U1 and U2. U0 was hot water soaked sample at 60 °C for 90 min, without steaming. The samples U1 and U2 were the hot soaked with conditions like U0, but were additionally subjected to open steaming: the sample U1 was for 10 min and sample U2 for 15 min. All under-gelatinized samples were dried at 40 °C, and since temperature effects were not studied, the codes used to refer to them remain as U0, U1 and U2.

Methods

Physical dimensions

The length (L), breadth (B), and the ratio L/B of the grain kernels were determined by the method of image processing using a laboratory grain scanner (Model: Canoscan 9000F, Mark-II). The count of grains in such measurements was around 40.

True density, bulk density, and porosity

True density (ρt) of samples was measured by employing a gas pycnometer (PYC-100A). Bulk density (ρb) was estimated by using Eq. 1, for which measurements were made by pouring around 20 g of samples, with a record of exact mass, to a 100 ml measuring cylinder and settling the level by gentle tapping for recording the volume.

Porosity (ε) of grain bulk was determined from Eq. (2).

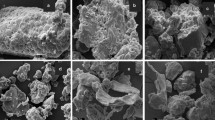

Scanning electron microscopy (SEM)

The scanning electron micrographs of rice samples were captured from transverse cut slices of samples using a scanning electron microscope (Jeol, JSM-6390LV). The changes in the structural morphology during processing and the effect of drying temperature were qualitatively analyzed.

Cooking time

The modified objective method presented in Dutta and Mahanta (2014) was followed for estimating the cooking time in raw rice (sample R). Approximately, 10 g of kernels were open cooked in excess water. Five minutes onwards, at an interval of 1 min, 10 kernels were taken out and pressed between two glass slides. The percentage of translucent kernels were noted. The elapsed time from starting of cooking, corresponding to the first sampling instance at which 90% of kernels were translucent was noted as the cooking time.

This modified objective method was not effective for processed samples (viz., U1, U2, K0, and K1). It was because they were already partly or fully gelatinized samples and it was difficult to obtain a translucent portion in kernels. For such samples a method based on texture profile analysis (TPA), as described in the next section, was used to estimate the cooking time.

Textural properties of cooked rice

Textural properties of cooked samples were determined using a texture measuring instrument (TA-HD Plus, Stable Micro Systems, UK). The two-cycle compression test was used. The mean values of parameters, based on replicated measurements were noted. However, before noting the measurements against cooked samples, attainment of cooked condition was validated by comparing the hardness values. For this, sample R was cooked for a duration equal to its cooking time estimated from the procedure described earlier, and the mean hardness value was taken as reference value for the estimation of cooking time for other samples. For estimating the cooking time of a given processed sample, the sample was cooked as mentioned earlier. The texture was measured in samples drawn at intervals of 1 min, in triplicates at each instant. The instant of sampling, at which the sample hardness approximately matched the reference hardness, was noted as the cooking time. Cooking time was estimated for each sample in triplicates and the average of three estimated cooking times was reported. The procedure was repeated for all processed samples. Also, texture parameters were noted for all samples corresponding to the cooked state.

The texture parameters were also measured for rehydrated samples. Rehydration was carried out in excess water at 60 °C for (1) 10 min, (2) 15 min, and (3) 20 min.

Rehydration ratio (RR) and equilibrium moisture content (EMC)

About 3 g of processed rice samples were rehydrated by soaking at three different temperatures (40, 50 and 60 °C) for 3 h and the final weight was recorded after blotting the surface moisture by tissue paper, and the ratio of final to initial weight was represented as RR.

Equilibrium moisture content (EMC) on rehydration for komal chawal was determined by rehydrating the product at room temperature for 24 h by following the method of Kar et al. (1999).

Percent head rice yield (% HRY) on polishing

Komal chawal produced in the present work resembled the traditional product produced by foot pounding which retained the bran. Polished komal chawal from the komal chawal could be obtained by polishing the grains in a polisher. For quantification of the loss of head rice due to polishing of komal chawal Eq. 3 was used. The parameters in the equation were estimated by polishing the komal chawal in a laboratory polisher (Satake, Japan) for 1 min.

Color changes

Color of samples were measured in its ground form prepared in a laboratory grain mill (0.2 mm opening of sieve, Make Fritsch, Germany) using a spectrophotometer (HunterLab, UltraScan VIS). The L*, a* and b* values were used to calculate the total color difference (∆E), using unprocessed rice (R) as the reference sample (Eq. 4).

Degree of gelatinization (% DG)

Amylose-iodine blue method (Kam et al. 2012) was used for estimating % DG on triplicates samples.

Sediment volume (SV)

Following Dutta and Mahanta (2014), SV was determined by placing about 1 g of flour in a measuring cylinder and then adding 15 ml of 0.05 N HCl with agitation, at each interval of 5 min for 1 h. SV was estimated from the level of the flour sediment observed after 4 h.

Pasting properties

Following Klein et al. (2013), viscograms of flour suspensions were obtained from a Rapid Visco Analyzer (RVA Starchmaster 2, Australia). Flour was weighed directly in the RVA-2 canister, and then the required amount of water (based on the moisture correction of samples) was added. The samples were held at 50 °C for 1 min, heated from 50 to 95 °C in 3.5 min, held at 95 °C for 2.5 min followed by cooling to 50 °C in 4 min, and finally held at 50 °C for 2 min. The pasting parameters, namely peak viscosity (PV, equal to maximum viscosity), hot paste viscosity (HPV, equal to minimum viscosity), cold paste viscosity (CPV, equal to final viscosity), breakdown (BD, equal to PV-HPV), setback (SB, equal to CPV-PV), and total setback (SBt, equal to CPV-HPV) were recorded.

X-ray diffraction pattern

Wide angle X-ray diffractograms were obtained using the X-ray diffractometer (Bruker Axs, Germany). The spectra scanned over a diffraction angles (2θ) of 10°–40° at a step size of 0.05° with a target Cu Kα value of 1.5 Å (λ) at an operating scan speed of 1 degree per second. Using software (OriginPro 8.5), the peak centre, full width half maximum (FWHM) was determined. The interplanar distance d from Bragg Law (d = nλ/2 Sin θ), size of crystallites (γ) using Sherrer’s formula (γ = Kλ/β Cos θ); where K = constant (0.91), β = (FWHM X π/180), and θ = angle of incidence were also obtained. The mean percent crystallinity was determined by following Manful et al. (2008).

Software for statistical analysis

Both Microsoft Excel 2010 and SPSS 20 (IBM SPSS) were used in this work.

Results and discussion

Physical dimensions

Measured physical dimensions, presented in Table 1, indicates that L and B values for raw samples were lesser than that of the processed samples. The L, B and L/B ratio of pressure steamed komal chawal were slightly greater than the open steamed komal chawal samples. This may be due to a high extent of starch under pressure steaming. Similar observations have been reported by Reddy and Chakraverty (2004) and Sareepuang et al. (2008).

True density, bulk density, and porosity

The true density values of samples R and U0 were only slightly different. More significant difference (p < 0.05) was observed for steam processed rice as compared to sample R (Table 1). Bulk density decreases in the komal chawal (samples K0 and K1) as compared to sample R. Saeed et al. (2001) have attributed such changes to the occupied volume of the less uniform structure of parboiled rice. Porosity of sample R is lesser than the samples K0 and K1. The drying temperature does not significantly affect the porosity of pressure steamed rice (K1). The porosity of open steamed sample K0 is marginally higher than K1. It indicates that the direct steam exposure may lead to a non-uniform surface feature. This observation is however, different from the product obtained by paddy parboiling, where the husk keeps the kernel intact and maintains uniformity of structure.

Scanning electron microscopy

Scanning electron micrographs reveal the morphologies of the raw and processed rice samples. Starch granules in the range of 3–5 μm are observed in sample R (Fig. 1a). These granules are non-prominent in sample U0, though the existence of granular crystals is visible (Fig. 1b). A long steaming time makes the granules to disappear, establishing the progress of gelatinization of starch in presence of water and heat (Fig. 1c, d). It leads to swelling of granules and rearrangement among molecules in K0 and K1 samples. Pressure steamed samples are more thermally degraded and gelatinized (Fig. 1g) as compared to open steamed ones (Fig. 1d) as like Leelayuthsoontorn and Thipayarat (2006) and Bualuang et al. (2013). An increase in drying temperature induces surface shrinkage leading to deformation (Fig. 1e, f, h, i).

Cooking time

Raw sample (R) has a cooking time of 18 min, which is similar to reported values for other low amylose rice. Singh et al. (2014) have reported a cooking time of 19 min for a rice with amylose content of 11.5%. From the TP analysis of cooked sample R for 18 min, the hardness is 158 ± 20 g. Taking hardness of cooked R sample as reference hardness, the estimated cooking time of all other samples are given in the Table 1. All these samples have the cooking time of less than 18 min (the cooking time for R sample). Comparison of cooking time of sample U0, U1, U2 and K0(40), shows the progressive increase of % DG resulting from steaming. Thus, cooking time decreases with steaming duration. The combined effect of gelatinization and thermal degradation may have decreased the cooking time. This is in contrast to the belief that surface hardening of rice kernels increases cooking time in parboiled rice. The reduction in cooking time in heat and moisture treated starch of this particular rice variety is perhaps due to its low amylose content, and the extent of retrogradation of the gelatinized starch which may have been restricted during drying (Dutta and Mahanta 2014). Comparison of cooking times of K0 and K1 samples, reveal no significant rise in cooking time with steaming pressure. Within the K0 and K1 samples, there is an increasing trend in cooking time requirement with an increase drying temperature. This may be attributed to the surface hardening of the rice kernels at high temperature of drying.

Texture of cooked and rehydrated samples

The texture property parameters of rehydrated and cooked komal chawal, obtained for samples with varied degree of treatments, are presented in Fig. 2. Cooked samples are those which have attained hardness values equal to that of cooked raw sample, and hence the hardness values are similar for all cooked samples (150–181 g). Similar range of hardness values for low amylose rice have been reported by Sareepuang et al. (2008). In Fig. 2, for the first five samples in the X-axis, i.e., R, U0, U1, U2 and K0(40), there is an increase in the duration of steaming, which reduces the hardness values. For a given sample, the cluster of bars indicates textural parameters for an increased duration of soaking of 10 min, 15 min, and 20 min and that for cooked samples. As the duration of hydration increases, more diffusion of water occurs which decreases the hardness in all samples. For komal chawal (sample K0(40)) the hardness after 20 min of soaking matches the hardness value of cooked sample and is soft enough for consumption. The pattern of changes in hardness values of soaked and cooked samples resulting from differences in drying temperatures can be observed by comparing the hardness values for samples K0(40), K0(50), K0(60) for open steamed samples and K1(40), K1(50), K1(60) for pressure steamed samples. An increase in hardness occurs for decreased soaking duration and with an increase in drying temperatures for both the steaming condition.

The chewiness values show a decreasing pattern with % DG has been observed for the first five samples in the X-axis, i.e., R, U0, U1, U2 and K0(40). Similarly, with soaking duration, there is a decrease in chewiness values, and at 60 °C for around 20 min, the chewiness value is comparable to that of cooked samples. Chewiness values are relatively larger at lower durations of rehydration. It indicates that the less rehydrated samples would require more energy to break the rice grains to a state where it is ready for swallowing. The bar chart for adhesiveness and springiness in Fig. 2 indicates a slight increase in adhesiveness values, and a decrease in springiness values with drying temperature. Steaming pressure lowers adhesiveness as evident from the lower values of adhesiveness in K1 samples than in K0 samples. This probably may be due to an increase in the formation of hot water soluble fractions in open steam samples (K0) and due to thermally degraded starch in pressure steamed samples (K1). A high rehydration time decreases the adhesiveness. Springiness values of K0 and K1 samples are favorably affected by steaming pressure and rehydration time. Pal et al. (2016) have attributed the textural properties of cooked rice to the processes of gelatinization and retrogradation through a discussion on the probable influences of amylose, amylopectin and length of branch chain in amylopectin on retrogradation process in rice. This justifies the influence of rice composition on textural properties of cooked rice (Pal et al. 2016), and is probably be the justification of attaining a soft-enough structure for consumption merely on soaking for the rice under consideration in this study. It is noted that although texture is a multi-dimensional characteristic, yet hardness and adhesiveness are considered important in deciding palatability of cooked rice (Zhou et al. 2002). Since komal chawal rehydrated for 20 min at 60 °C yields matching hardness and adhesiveness values of cooked rice, the rehydration condition is proposed for consumption.

RR and EMC on rehydration of grains

The RR at 40, 50 and 60 °C of rehydration temperature and EMC on rehydration at room temperature, measured for samples K0 and K1, are shown in Table S2 of supplementary file. For representation purpose, RR at 60 °C and EMC are given in Table 1 of the main text. The RR of sample K1 (2.75 ± 0.31 to ≤ 3.89 ± 0.90) is slightly higher than for sample K0 (2.65 ± 0.20 to ≤ 3.84 ± 0.80). This indicates that the severity of processing conditions leads to a high level of thermally degraded starch branching available for water absorption. The RR increases with an increase in the rehydration temperatures. However, RR is affected by drying temperature. Likewise, the EMC is more in sample K1 than that of K0.

Percent HRY on polishing of grain

The % HRY of samples are shown in Table 1. HRY of K1(40) samples (83.83 ± 0.81%) is higher than that of R (69.35 ± 1.25%). Parboiling causes gelatinization of starch that cements all fissures or inter molecular pores of the kernel, and makes it more intact and strong enough to prevent breakage while polishing. The leaching of amylose may be involved as a result K0(40) has % HRY of 73.81 ± 0.63%, which is slightly lower than K1(40). Similar range of % HRY have been reported by Ayamdoo et al. (2013). The only soaked U0 rice exhibits lowest % HRY which may be due to weak kernel structure. Lack of steaming step does not facilitate filling up the fissure or pores inside the kernels. Thus, it weakens the bond between the starch molecules that might have led to high breakage while exposed to polishing process. Further, the quick loss of moisture from the outer surface causes hardening along with fissures at the surface and thus causes a high extent of breakage during polishing. Hence, a reduced % HRY occurs in samples subjected to higher drying temperatures for both K0 and K1 samples.

Color changes

The changes in L*a*b* values, and ∆E are given in Table 2. The L* is maximum in sample R and gradually decreases with the extent of steaming (Table 2). The effect of drying temperatures on L* among open and pressure steamed samples are less significant. In contrast to L*, values of a* and b* are minimum for sample R and increases with an increase of steaming time and pressure. A similar range of L*a*b* values are reported by Kaur et al. (2018) for non-pigmented rice (NPR) grown in the Himalayan region. Similarly, the b* values of brown rice are comparable to report of Pal et al. (2016). The b* values of germinated brown rice reported by these authors are comparable with steamed processed rice of the present study. Oli et al. (2016) have reported a nearby range of L*a*b* values for soaked paddy. However, in the present study, due to involvement of the additional steaming step, the L*a*b* values are slightly higher as compared to the reported one. The change of color at this particular soaking range is due to the migration of bran pigments from the endosperm (Oli et al. 2016). Similarly, Lamberts et al. (2006) have attributed the non-enzymatic browning to be responsible for color changes in parboiled rice. As steam treatment is considered as a severe process, and it favours the formation of a Maillard reaction product named furosine. Hence, the values of ∆E in the komal chawal (samples K0 and K1) are higher than that of the under-gelatinized samples (U0, U1 and U2); the ∆E values increases with the extent of steaming time and pressure. Drying air temperature appears to have a small effect on ∆E values.

Percent DG of samples

The % DG of all rice samples, determined on prepared rice flour, are given in Table 2. The % DG increases with steaming time and pressure. About 98.99–100% DG has been achieved by exposing the soaked brown rice for 10 min (at 1 atm) while it is about 98.91–99.97% DG for 20 min (at 0 atm). These values can be considered as an optimized condition for the production of parboiled brown rice of low amylose rice variety. The % DG of U1 and U2 samples increases markedly as compared to U0, indicating the progress of gelatinization with the steaming time. Similar values of % DG are obtained in samples K0 and K1.

SV of rice flour

The SV of rice flour (Table 2) reflects the severity of processing. Non-significant difference in SV has been found between R (2.4 ± 0.68 ml) and U0 (3.2 ± 0.89 ml) samples by Duncan’s multiple range test at p < 0.05. The SV increases with the duration of steaming; it increases from 8.01 ± 0.89 ml for U1 (steaming for 10 min) to 10.00 ± 1.10 ml for K0 (steaming for 20 min). The SV values are also high at pressure steamed samples (K1) than in open steamed (K0) samples. The effects of steaming conditions and subsequent drying condition may be attributed to the degree of starch gelatinization with severity of processing, and subsequent thermal degradation and retrogradation process. The highest SV (12.78 ± 0.80 ml) is observed for K1(40) sample.

Viscogram of rice flour batter

The viscogram patterns of rice flour is shown in Fig. 3. An increase in processing condition decreases the peak viscosity (Table 2). The R sample possesses the maximum PV (2731 cP) which decreases slightly in case of U0 (2431 cP). It reflects that a marginal thermal degradation of starch takes place while soaking itself (60 °C for 90 min). During open steaming, when the steaming time is prolonged the PV decreases slightly. However, drying temperature has a small effect on PV. The PV of open steamed samples (K0) is higher than the pressure steamed sample (K1). Sample K1 shows a small magnitude of BD. Similar extensive drop in the PV has been reported by Swasdisevi et al. (2010) and Dutta and Mahanta (2014). The HPV of open steamed rice (K0) is higher than that of pressure steamed sample (K1). The CPV of U2 and K0(40) remains in the similar range. Total setback (SBt) values are higher in open steamed rice as compared to pressure steamed rice samples. In terms of rice composition, Singh et al. (2014) attributes higher setback values to high amylose content in rice cultivars. Also, the setback viscosity is used as an indicator of retrogradation of rice paste. Hence, a lower setback viscosity for komal chawal perhaps due to low amylose content in the cultivar leading to a low retrogradation property of the rice paste. The negligible BD and near continuous rise in the viscosity is possibly due to leaching of short linear molecular chains which induces the thickening property. It indicates the suitability of the sample for the preparation of products like soups, gravies and other dishes.

XRD patterns of rice flour

The FWHM (°), d spacing (nm) and size of crystallites (nm) of raw and processed rice are given in the Table S3 of supplementary file. The FWHM are between 0.63° and 1.95° for raw (R), 0.54°–1.63° for open steamed (K0) and 0.70°–0.90° for pressure steamed (K1) samples. The d spacing of raw and processed rice are between 0.39 and 0.75 nm, and 0.40–0.68 nm, respectively.

The untreated raw starch forms the native A-type diffraction pattern with characteristic strong peaks at 2θ = 15.73°, 18.18°, and 22.68° as shown in Fig. 4. The diffraction pattern of sample U0, involving no steaming but soaking at 60 °C for 90 min is slightly altered in comparison to sample R, and follows a similar A-type pattern with a feeble peak at 12.66°. The changes in the diffraction pattern of all the samples in terms of mean % crystallinity and peaks center are shown in Fig. 4. The number of peaks and the sharpness decrease with increase in steaming time. The native sharp peaks disappear and get altered for both open and pressure steamed samples (K0 and K1) forming amorphous diffractographs with the feeble mixed peaks patterns of A-type at 2θ of nearly 13°, and V-type at 2θ of 19.64°–20°. The finding is in agreement with the XRD patterns of parboiled rice reported by various workers (Prasert and Suwannaporn 2009; Sittipod and Shi 2016). Amylopectin as the retrograded starch in parboiled rice exhibits the mixed A + V patterns. The maximum mean percent crystallinity is observed in sample R followed by hot soaked sample U0. The pressure processed sample (K1) possesses the lowest % crystallinity, which shows the severity of the thermal degradation leading to modification of the crystal’s granular structure. The drying temperature has a small effect on the mean percent crystallinity. Wang et al. (2017) has analyzed the percent crystallinity in the context of drying; probably the new polymorphic forms are formed due to retrogradation of starch so that the percent crystallinity increases.

Conclusion

Komal chawal production by brown rice parboiling method from a low amylose rice variety chokuwa was achieved by soaking at 60 °C for 90 min, and steaming in both open (20 min) and pressure (10 min) samples. Drying condition of 40 °C was found to be favorable for both of these steaming conditions. Drying temperature has a moderate effect on the cooking time and rehydration ratio values, and a low temperature (40 °C) was beneficial. The rehydration for 20 min at 60 °C gave hardness values that were comparable to that of cooked rice. The physico-chemical properties of pressure processed samples are significantly different to that of open processed. Severity in steaming and drying conditions affected the appearance and texture of parboiled rice. The high pasting and cooling viscosities of open steamed rice flour was the specific property that could be a suitable for developing specific end products. Most of the changes in properties was expected to have a positive impact on the acceptability of the products and the present study might pave the way for exploring komal chawal rice as a carrier of micronutrients in fortification programs.

References

AOAC (2016) Official methods of analysis, 20th edn. Association of Official Analytical Chemists, Washington

Ayamdoo AJ, Demuyakor B, Dogbe W, Owusu R, Ofosu MA (2013) Effect of varying parboiling conditions on physical qualities of Jasmine 85 and Nerica 14 rice varieties. Am J Food Technol 8:31–42. https://doi.org/10.3923/ajft.2013.31.42

Ayamdoo JA, Demuyakor B, Saalia FK, Addy F (2014) Effect of varying parboiling conditions on the cooking and eating/sensory characteristics of Jasmine 85 and Nerica14 Rice varieties. Am J Food Technol 9:1-14. https://doi.org/10.3923/ajft.2014.1.14

Bualuang O, Tirawanichakul Y, Tirawanichakul S (2013) Comparative study between hot air and infrared drying of parboiled rice: kinetics and qualities aspects. J Food Process Preserv 37:1119–1132. https://doi.org/10.1111/j.1745-4549.2012.00813.x

Dutta H, Mahanta CL (2014) Laboratory process development and physicochemical characterization of a low amylose and hydrothermally treated ready-to-eat rice product requiring no cooking. Food Bioprocess Technol 7:212–223. https://doi.org/10.1007/s11947-012-1037-9

Elbert G, Tolaba MP, Suárez C (2001) Effects of drying conditions on head rice yield and browning index of parboiled rice. J Food Eng 47:37–41. https://doi.org/10.1016/s0260-8774(00)00097-2

Kam K, Arcot J, Ward R (2012) Fortification of rice with folic acid using parboiling technique: effect of parboiling conditions on nutrient uptake and physical characteristics of milled rice. J Cereal Sci 56:587–594. https://doi.org/10.1016/j.jcs.2012.08.010

Kar N, Jain RK, Srivastav PP (1999) Parboiling of dehusked rice. J Food Eng 39:17–22. https://doi.org/10.1016/s0260-8774(98)00138-1

Kaur P, Singh N, Pal P, Kaur A (2018) Variation in composition, protein and pasting characteristics of different pigmented and non pigmented rice (Oryza sativa L.) grown in Indian Himalayan region. J Food Sci Technol. https://doi.org/10.1007/s13197-018-3361-1

Klein B, Pinto VZ, Vanier NL, Zavareze ER, Colussi R, Evangelho JA, Gutkoski LC, Dias ARD (2013) Single and dual heat-moisture treatment: impact on the properties of starches from different botanical sources. Carbohydr Polym 98:1578–1584. https://doi.org/10.1016/j.carbpol.2013.07.036

Lamberts L, Brijs K, Mohamed R, Verhelst N, Delcour JA (2006) Impact of browning reactions and bran pigments on color of parboiled rice. J Agric Food Chem 54:9924–9929. https://doi.org/10.1021/jf062140j

Leelayuthsoontorn P, Thipayarat A (2006) Textural and morphological changes of Jasmine rice under various elevated cooking conditions. Food Chem 96:606–613. https://doi.org/10.1016/j.foodchem.2005.03.016

Luh BS (1991) Quick-cooking rice. In: Luh BS (ed) rice. Springer, Boston, pp 540–565. https://doi.org/10.1007/978-1-4899-3754-4_17

Manful JT, Grimm CC, Gayin J, Coker RD (2008) Effect of variable parboiling on crystallinity of rice samples. Cereal Chem 85:92–95. https://doi.org/10.1094/cchem-85-1-0092

Oli P, Ward R, Adhikari B, Torley P (2014) Parboiled rice: understanding from a materials science approach. J Food Eng 124:173–183. https://doi.org/10.1016/j.jfoodeng.2013.09.010

Oli P, Ward R, Adhikari B, Torley P (2016) Colour change in rice during hydration: effect of hull and bran layers. J Food Eng 173:49–58. https://doi.org/10.1016/j.jfoodeng.2015.10.036

Pal P, Singh N, Kaur P, Kaur A, Virdi AS, Parmar N (2016) Comparison of composition, protein, pasting, and phenolic compounds of brown rice and germinated brown rice from different cultivars. Cereal Chem 93:584–592. https://doi.org/10.1094/cchem-03-16-0066-r

Parnsakhorn S, Noomhorm A (2008) Changes in physicochemical properties of parboiled brown rice during heat treatment. Agric Eng Int CIGR J 10:1–20

Patindol J, Newton J, Wang YJ (2008) Functional properties as affected by laboratory-scale parboiling of rough rice and brown rice. J Food Sci 73:370–377. https://doi.org/10.1111/j.1750-3841.2008.00926.x

Pillaiyar P (1988) Parboiling. Rice—post production manual. Wiley Eastern Ltd. Publishers, New Delhi, pp 166–229

Prasert W, Suwannaporn P (2009) Optimization of instant jasmine rice process and its physicochemical properties. J Food Eng 95:54–61. https://doi.org/10.1016/j.jfoodeng.2009.04.008

Reddy BS, Chakraverty A (2004) Physical properties of raw and parboiled paddy. Biosyst Eng 88:461–466. https://doi.org/10.1016/j.biosystemseng.2004.05.002

Saeed F, Pasha I, Anjum FM, Suleria HAR, Farooq M (2001) Effect of parboiling on physico-chemical and cooking attributes of different rice cultivars. Internet J Food Saf 13:237–245

Sareepuang K, Siriamornpun S, Wiset L, Meeso N (2008) Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. WJAS 4:409–415

Shittu TA, Olaniyi MB, Oyekanmi AA, Okeleye KA (2009) Physical and water absorption characteristics of improved rice varieties. Food Bioprocess Technol 5:298–309. https://doi.org/10.1007/s11947-009-0288-6

Sindawal S, Bhattacharya S (2015) Instantization and agglomeration of foods. In: Bhattacharya S (ed) Conventional and advanced food processing technologies. Wiley, New York, pp 313–336. https://doi.org/10.1002/9781118406281.ch13

Singh N, Paul P, Virdi AS, Kaur P, Mahajan G (2014) Influence of early and delayed transplantation of paddy on physicochemical, pasting, cooking, textural, and protein characteristics of milled rice. Cereal Chem 91:389–397. https://doi.org/10.1094/cchem-09-13-0193-r

Sittipod S, Shi YC (2016) Changes of starch during parboiling of rice kernels. J Cereal Sci 69:238–244. https://doi.org/10.1016/j.jcs.2016.03.015

Swasdisevi T, Sriariyakula W, Tia W, Soponronnarit S (2010) Effect of pre-steaming on production of partially-parboiled rice using hot-air fluidization technique. J Food Eng 96:455–462. https://doi.org/10.1016/j.jfoodeng.2009.08.026

Thimmaiah SK, Thimmaiah SK (2004) Standard methods of biochemical analysis. Kalyani Publishers, Ludhiana

Unnikrishnan KR, Bhattacharya KR (1987) Properties of pressure-parboiled rice as affected by variety. Cereal Chem 64:321–323

Villota SMA, Tuates AM Jr, Capariño OA (2016) Cooking qualities and nutritional contents of parboiled milled rice. AJAS 04:1172–1178

Wang R, Chen C, Guo S (2017) Effects of drying methods on starch crystallinity of gelatinized foxtail millet (α-millet) and its eating quality. J Food Eng 207:81–89. https://doi.org/10.1016/j.jfoodeng.2017.03.018

Yu S, Ma Y, Liu T, Menager L, Sun DW (2010) Impact of cooling rates on the staling behavior of cooked rice during storage. J Food Eng 96:416–420. https://doi.org/10.1016/j.jfoodeng.2009.08.019

Zhou Z, Robards K, Helliwell S, Blanchard C (2002) Ageing of stored rice: changes in chemical and physical attributes. J Cereal Sci 35:65–78. https://doi.org/10.1006/jcrs.2001.0418

Acknowledgement

Authors thank the University Grant Commission (UGC) for the National Fellowship Programme to conduct the doctoral investigation.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wahengbam, E.D., Hazarika, M.K. Quality of ready-to-eat komal chawal produced by brown rice parboiling method. J Food Sci Technol 56, 187–199 (2019). https://doi.org/10.1007/s13197-018-3472-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3472-8