Abstract

Challenges and opportunities of minor cereals with poor viscoelastic value deserve a special attention in breadmaking applications due to their unique nutritional components. In a preliminary stage, the suitability of oat, millet and sorghum in breadmaking was assessed in simple binary wheat flour matrices in which wheat flour was replaced from 0% to 60%. The research allowed the quantification of grains (up to 30% for millet and sorghum and up to 50% for oat of wheat flour replacement) to be incorporated into the binary blended matrices providing minimization of techno-functional impairment and sensory depreciation of breads. Combinations of gluten, vegetable fat and a commercial mix of surfactants, ascorbic acid and antistaling enzymes were used to make breads with 10% increased level of wheat flour replacement by single oat, millet and sorghum in binary mixed samples. The quality profile of binary mixtures of oat–wheat (60:40 w/w), millet–wheat (40:60 w/w) and sorghum–wheat (40:60 w/w) was significantly improved in terms of keepability during storage, mainly for oat–wheat blends which stale at a similar rate than 100% wheat breads. Overall acceptability of highly replaced wheat breads deserved higher scores for oat and sorghum composite breads (7/10) than control wheat breads (6/10). Oat, millet and sorghum represent a viable alternative to make aerated breads with mitigated technological and sensory constraints based on non-viscoelastic cereals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As the core of human nutrition, grains are ubiquitous and multifaceted staple foods addressed to the population worldwide as either a carrier of macro- and micronutrients or tailored foods for specific targeted groups as healthy, convenient and indulgent raw materials providing perfect vectors for diversity and innovation. It raises a great deal of recent interest that minor cereals, ancient crops and pseudocereals, besides wheat, constitute highly nutritional grains with potential breadmaking applications. The concept of using South American, African and Asian traditional raw materials and fermented foods as a template for wheat-, wheat-free- and gluten-free-based foods in Europe and North America is in good accordance with the interest in westernized countries for ethnic foods with revisited value addition. Indigenous foods from different cultures and civilizations with ethnic eating habits are moving in a globalized world with strong immigration movements, encompassing the use of traditional raw materials as ingredients in novel foods. In this context, the challenges and opportunities of minor cereals (rye, oat, sorghum, millet, ancient wheat), pseudocereals (quinoa, amaranth and buckwheat) and Andean crops in breadmaking applications deserve a special attention due to their unique nutritional components—dietary fibre, resistant starch, minerals, vitamins, bioactive compounds—(Skrabanja et al. 2001; Kim et al. 2004; Angioloni and Collar 2011a). In a recent paper (Angioloni and Collar 2011b), the suitability of associated mixtures of minor/ancient cereals (rye, oat, Kamut® wheat, spelt wheat) and pseudocereals (buckwheat) was assessed in multigrain wheat flour highly replaced matrices. A quaternary blend of oat, rye, buckwheat and common wheat flours (20:20:20:40 w/w/w/w) without any additive and/or technological aid in the formulation was proposed to make highly nutritious, modern and innovative baked goods meeting functional and sensory standards in terms of nutritional added value, palatability, convenience and easy handling during processing.

The general growing demand for novel tasty and healthy foods, together with the increasing number of people suffering from celiac disease, have given birth to a new market consisting of cereal products made from grains alternative to wheat and rye. In this challenging market, oat, sorghum and millet have gained a special position. Oats are a health-promoting cereal crop with nutritional advantages including high lipid and β-glucan concentrations and low starch content compared with other cereal grains. Some physiological responses have been linked to the intake of oat products, mainly due to the high concentration of beta-glucans (Wood 2007): (a) a small reduction of serum cholesterol levels in people with elevated cholesterol levels and (b) an attenuation of postprandial glycaemic response. The intake of approximately 3.2 g of beta-glucan per day is capable of lowering cholesterol from −0.13 to −0.16 mmol/L (Truswell 2002). Addition higher than 20 g oat/100 g wheat flour into bread formulations has proven to usually lead to tight, highly moist and gummy unacceptable breads. Recently, Flander et al. (2007) obtained acceptable oat–wheat breads (51:49, w/w) after the recipe optimization by adding a surplus of water (91.5/100 g flour) and a high amount of gluten (15.2/100 g flour).

Traditional flatbreads from sorghum and millets might be regarded as leavened if they are fermented like injera (Ethiopia), puffed like chapatti/roti (India) or used in proved baked goods as in wheat–sorghum composite breads (Taylor et al. 2006). Sorghum is a potentially important source of nutraceuticals such as antioxidant phenolics and cholesterol-lowering waxes. Cakes, cookies, pasta, a parboiled rice-like product and snack foods have been successfully produced from sorghum and, in some cases, from millets. Leavened sorghum and millet breads remain the main challenge.

In breadmaking applications, the lack of gluten proteins to meet dough viscoelastic and fermentative restrictions has generally constrained the incorporation of substantial amounts of these under-utilised cereals into wheat dough systems to achieve dietary and healthy endorsing effects. High levels of grains other than wheat incorporated into baked products are cost effective and nutritionally advantageous even though technologically very challenging.

The paper is intended to assess the potential ability of oat, millet and sorghum, with low breadmaking profile but prospective nutritional value addition (high mineral content, low digestible starch, high viscous fibre content, source of antioxidants), to be included in mixed matrices with common wheat, to make modern and innovative fermented baked goods meeting viscoelastic and sensory standards. Handling during processing (macroscopic and molecular techno-functional response), palatability (sensory scores) and keepability (firming during storage), of multigrain flours are investigated in doughs and breads thereof. For common wheat flour replacement purposes, refined high-grade wheat flour (70% extraction rate) was used to keep, as much as possible, viscoelasticity and gas retention ability of the basic wheat dough matrix.

Materials and Methods

Materials

Commercial flours from common wheat (WT), oat (OAT), millet (MI) and sorghum (SG) were purchased from the Spanish market. Gluten (Supra Vital wheat gluten [GL]), fat and GRINDSTED®FIBERLine 101(GF101: E471, E472e, E415, E300, enzymatic complex) and GRINDSTED®FIBERLine 103 (GF103: E471, E472e, E415, E300, enzymatic complex) were acquired from Indespan (Spain) and Danisco (Copenhagen, Denmark), respectively. Moisture, protein, ash and fat contents of commercial flours were determined following the International Association for Cereal Chemistry (ICC 1976-1996) methods 110/1, 105/2, 104/1 and 136, respectively (Table 1). Two replicates were made for each flour analysis. Total carbohydrates were calculated by difference.

Flour Viscometric Properties

Pasting profiles (gelatinisation, pasting and setback properties) of flours were obtained with a Rapid Visco Analyser (RVA-4, Newport Scientific, Warriewood, Australia) using ICC standard method 162 as detailed previously (Collar 2003). For each viscometric measurement, three replicates were made.

Dough and Bread Preparation

Bread dough consisted basically of fermented sponge, flour, water and salt. Sponge (sponge dough process) was prepared by mixing basic ingredients—50% of total flour, 8% commercial compressed yeast on a total flour basis and the necessary water to obtain a dough with 200 dough yield—in a 10-kg mixer at 60 revolutions per minute for 8–10 min up to optimum dough development. Sponge was fermented for 2 h at 28 °C, overnight at 5 °C and 1.5 h at 28 °C before adding to the remaining ingredients to make bread dough of a consistency of 500 Brabender units, BU. Fermented doughs were obtained after bulk fermentation (10 min), dividing, moulding and proofing up to maximum volume increment (1 h), and were baked at 175 °C for 20 min to make bread. For the preparation of multigrain breads, wheat flour was replaced, from 10% to 60%, with single oat, millet and sorghum to make binary grain flour blends. Improved breads (wheat 100%, IWT; oat 60% of wheat flour replacement, IOAT; millet 40% of wheat flour replacement, IMI and sorghum 40% of wheat flour replacement, ISG) were prepared with the addition of GL (7%), fat (2%), GF101—wheat, millet and sorghum—(2%), GF103—oat—(2%) and calcium propionate (0.5%) into bread formulation. Samples were packaged into polypropylene bags and stored at 22 °C for 0, 1, 3, 6, 8 and 10 days before analysis. Two trials were performed per baking test.

Dough Rheological Measurements

Large-Deformation Mechanical Tests

Dough machinability of unfermented dough samples was assessed by texture profile analysis (TPA) in a TA-XTplus texture analyser (Stable Micro Systems, Godalming, UK) using a 5-cm-diameter probe, a 75-s waiting period and 60% compression as described previously (Collar et al. 1999). All measurements were made in triplicate.

Small-Deformation Mechanical Tests

Fundamental rheology of unfermented dough samples was assessed by dynamic oscillation tests on an RS1-controlled stress rheometer equipped with a Phoenix II circulating bath (Haake, Karlsruhe, Germany), as previously described by Angioloni and Collar (2011b). Experimental data were fitted by using the weak gel model equation G*(ω) = A f ω 1/z proposed by Gabriele et al. (2001), where A f is the strength of the interactions between rheological units, and z is the number of the rheological units. All measurements were made in triplicate.

Bread Measurements

Colour

Colour determinations were carried out on bread crumb and crust using a Minolta colorimeter (Minolta CR-400, Konica Minolta Sensing, Inc., Osaka, Japan), and results were expressed in accordance with the Hunter Lab colour space. The parameters determined were L (L = 0 [black] and L = 100 [white]), a (−a = greenness and +a = redness), b (−b = blueness and +b = yellowness), ΔE (total colour difference) (Francis and Clydesdale 1975), BI (browning index) (Ramirez-Jimenez et al. 2001) and WI (whiteness index) (Hsu et al. 2003). All measurements were made in triplicate.

Crumb Grain Characteristics

Crumb grain characteristics were assessed in bread slices using a digital image analysis system. Images were previously acquired with a ScanJet II cx flatbed scanner (Hewlett-Packard, Palo Alto, CA, USA) supported by a Deskscan II software. The analysis was performed on 40 × 40-mm squares taken from the centre of the images. Data were processed using SigmaScan Pro 5 (Jandel Corporation, San Rafael, CA, USA). The crumb grain features evaluated were mean cell area, cells per square centimetre, cell/total area ratio, wall/total area ratio and crumb area/total cell ratio (Angioloni and Collar 2011b).

Texture Profile Analysis

Bread primary and secondary mechanical characteristics (TPA in a double compression cycle) were recorded in a TA-XTplus texture analyser (Stable Micro Systems) using a 10-mm-diameter probe, a 5-kg load cell, 50% penetration depth and a 30-s gap between compressions on slices of 25-mm width. For textural measurements, three slices of two breads were used for each sample at different storage periods. The obtained firming curves were modelled using the Avrami equation, and model factors were estimated by fitting experimental data to the non-linear regression equation \( \theta = \frac{{{T_{\infty }} - {T_t}}}{{{T_{\infty }} - {T_0}}} = {e^{{ - k{t^n}}}} \) where θ is the fraction of the recrystallisation still to occur; T 0, T ∞ and T t are crumb firmness at time zero, ∞ and time t, respectively, k is a rate constant, and n is the Avrami exponent.

Sensory Analysis

Sensory analysis of fresh and aged breads was performed with a panel of eight trained judges (four males and four females aged 24–53) using semi-structured scales, scored 0–10 (lowest, 0; highest, 10) for each sensory attribute. Evaluated attributes were grouped into visual, textural and organoleptic characteristics (Angioloni and Collar 2011b).

Statistical Analysis

Multivariate analysis (MANOVA and factor analysis) of data was performed by using Statgraphics v. 7.1 program (Bitstream, Cambridge, MN).

Results and Discussion

Bread is a complex viscoelastic porous matrix, composed mainly of gluten, starch, lipids and water, whose final quality is multifactor dependent. Basic ingredients, additives and technological and/or processing aids and breadmaking process influence, in variable degree, the overall quality of fresh and stored breads. Physicochemical and techno-functional properties of plant material, dough and final product are taken into account in order to depict the technological profile of complex cereal-based matrices.

Flour, Dough and Bread Techno-functional Characteristics of Wheat and Multigrain Blends

A preliminary set of trials were carried out to maximise the degree of wheat flour replacement by oat, millet and sorghum. Wheat flour was replaced from 0% up to 60% by single minor cereals. Classification of samples (oat, millet, sorghum blends and wheat) on the basis of their distinctive and significant responses in terms of viscometric profile (flour level), dynamic and static rheological behaviour (dough level), texture, crumb grain, crumb and crust colour features and sensory ratings (bread level) was achieved by means of multivariate data handling.

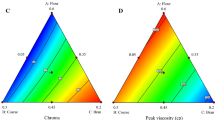

Factor analysis grouped functional dough and bread parameters (up to 60 variables) into four different factors that explained 100% of the cumulative variance, with the first two factors explaining 84.38% of the variability of the results (VE). Factor 1 (61.78% VE) included flour pasting properties, dough mechanical characteristics and bread techno-functional features, while factor 2 (22.60% VE) grouped flour gelling characteristics (Table 2). Factor 1 correlated negatively with dough hardness, storage modulus, loss modulus, complex modulus, complex viscosity, interaction strength between rheological units and bread hardness, and showed positive relationships with peak viscosity, holding strength, breakdown, viscosity at the end 95 °C, dough cohesiveness, overall acceptability, specific volume, crumb whiteness index and bread cohesiveness. Factor 2 correlated positively with final viscosity, total setback and viscosity at 50 °C. Plots of scores of factor 1 vs factor 2 illustrating variable and sample location in the scatterplot are depicted in Fig. 1. Separation of samples along the x axis was observed according to dough and bread techno-functional features. Wheat and blends ≤30% of wheat flour replacement, with higher values for peak viscosity, holding strength, breakdown, viscosity at the end 95 °C, dough cohesiveness, overall acceptability, specific volume, crumb whiteness index and bread cohesiveness, were located in the positive zone of the x axis (Fig. 1). In contrast, blends ≥40% of substitution level, characterised by high values of dough and bread hardness, storage and loss modulus, complex modulus and complex viscosity, were located in the negative zone of the x axis (Fig. 1). It has been widely recognised that dough should convene certain mechanical requests to produce good-quality bread. Those requirements concern a proper combination of small and large rheological properties and viscometric response during breadmaking steps. Suitable rheological trends to perform high-quality baked goods have been closely linked to dough formula (Collar and Bollain 2005). Changes in dough technological properties by using non-wheat/non-gluten cereals may result in different processing performance and associated production problems linked with slack or excessively stiff dough, leading to bread of poorer quality (Collar 2008). Despite the fact that factor 2 explained less than 23% of the cumulative variance, it helps to classify the cases in terms of the viscometric—gelling—characteristics (Fig. 1). Factor 2 was able to distinguish oat blends with wheat flour replacement ≥30%, located in the positive zone of the y axis. Oat blends demonstrated the best flour pasting behaviour during cooling with high values for final viscosity and total setback. Factor 2 does not distinguish all other samples with in-between values for pasting/gelling properties. Viscometric attributes have been strongly associated with bread staling kinetic parameters and can also be considered as helpful predictors at dough level of bread firming behaviour over storage (Collar 2003). The preliminary step of the research allowed the quantification of grains (up to 30% for millet and sorghum and up to 50% for oat of wheat flour replacement) to be incorporated into the binary mixed matrices (basic formulas with only flour, yeast and water) providing minimization of techno-functional impairment and sensory depreciation of the resulting breads (Fig. 1).

Bread Techno-functional Characteristics of Improved Wheat and Selected Multigrain Blends

The technological functionality comprises sense affecting characteristics and manipulative functional properties (Kunzek et al. 2002). Recently, a plural physical approach for bread crumb quality assessment that matches with consumer's perceiveness has been described (Angioloni and Collar 2009). Colour, crumb grain characteristics, mechanical properties, firming kinetics and sensory appreciations were compiled to assess the techno-functional appearance of control and multigrain breads. A combination of gluten (7%), vegetable fat (2%) and a commercial mix of emulsifiers, ascorbic acid and antistaling enzymes (GRINDSTED®FIBERLine 101/103) (2%) was used in order to increase by 10% the level of wheat flour replacement by single oat (60%), sorghum (40%) and millet (40%) in binary mixed breads. Resulting breads were coded IOAT, ISG and IMI, respectively; wheat bread was coded IWT.

Fresh and aged bread crumb mechanical properties are often connected to sensory perception of freshness and elasticity by consumers and also largely influence subsequent purchase. Techno-functional parameters of improved fresh breads (Table 3) and fitted values for instrumental crumb hardness and sensory firmness during storage (Fig. 3) evidenced remarkable differences between samples.

The incorporation of oat, millet and sorghum into binary improved blends based on wheat flour provoked a significant increase in crumb hardness, from 352 g for IWT to 1,058 g for ISG, and a noticeable reduction of bread specific volume and cohesiveness. In particular, IOAT showed the lowest values for both parameters. No significant changes were instead observed for moisture content regardless of the minor cereal used.

As it can be expected, bread colour was affected by the colour characteristics of the raw material (type of flours) included in the formulation (data not shown). IWT bread showed the highest whitening index (crumb) and intermediate browning index (crust) values, respectively compared to all the other samples. As well, significant total colour differences (ΔE) between samples were found in both crust and crumb (Table 3). The absolute values reported were too small to be appreciated by the human eye and big enough to be obvious for the human eye for bread crust and crumb, respectively (Francis and Clydesdale 1975).

Good-quality bread relates a high porosity and an opened crumb structure (Angioloni and Collar 2009). Heterogeneity in cell distribution and in the values for mean cell area, cells per square centimetre, cell to total area ratio (Table 3 and Fig. 2) were found for either control or multigrain breads. IOAT showed the highest values for mean cell area when compared with all the other samples. In addition, IOAT and IWT gave the highest values for cell to total area ratio in breads exhibiting thinner cell walls and larger cells. IMI bread showed the lowest values for cell to total area ratio, evidencing a dense crumb structure. Cell size and structure greatly influence how the crumb feels by touch or in the mouth: thin walled, uniformly sized cells yield a soft and elastic bread texture, properties that are usually welcomed by consumers (Angioloni and Collar 2009).

Data from sensory evaluation regarding firmness and overall acceptability (Table 3) showed that ratings depend on the crumb grain characteristics either in control or multigrain samples. IMI with low-rated crumb cell porosity and closed crumb structure had the lowest and the highest scores for overall acceptability and firmness, respectively. These results seem to support that in these cases, overall acceptability mainly depends on textural characteristics—softness and cell wall density.

Information on crumb hardness and firming kinetics during storage was obtained by modelling the experimental curves according to the Avrami non-linear regression (Fig. 3). Values for Avrami kinetic parameters T∞ (final crumb firmness), k (rate constant), n (Avrami exponent) and T 0 (crumb firmness of fresh bread) allowed to distinguish different staling kinetics for improved control and multigrain breads during ageing. IWT was significantly softer when freshly baked (lower T 0, 1.14 and 371 for firmness and hardness, in that order) and followed an intermediate staling rate during storage when compared with the other samples. IMI—k 0.01 for sensory firmness—and IOAT—k 0.03 for instrumental hardness—showed the lowest values for rate constant giving softer breads with slower staling kinetics during storage, while ISG stands out for high values of both initial and final crumb hardness and for the lowest and the highest values for final crumb firmness (T ∞ ) and Avrami exponent (n), respectively.

Observed (symbols) and fitted (lines) values of crumb instrumental hardness and sensory firmness during storage of improved bread samples. Instrumental hardness: black squares, A; black triangles, B; black diamonds, C; black circles, D. Sensory firmness: white squares, A; white triangles, B; white diamonds, C; white circles, D. A, improved wheat (100% wheat flour); B, improved oat (60% oat flour, 40% wheat flour); C, improved millet (40% millet flour, 60% wheat flour); D, improved sorghum (40% sorghum flour, 60% wheat flour)

Conclusions

Oat, millet and sorghum represent feasible ingredients in the manufacture of highly replaced wheat breads. The quality profile of improved binary mixtures of oat–wheat (60:40 w/w), millet–wheat (40:60 w/w) and sorghum–wheat (40:60 w/w) in terms of handling during processing, keepability and palatability may suggest the viability of these non-viscoelastic cereals to make aerated breads with mitigated technological and sensory constraints.

References

Angioloni, A., & Collar, C. (2009). Bread crumb quality assessment: A plural physical approach. European Food Research and Technology, 229(1), 21–30.

Angioloni, A., & Collar, C. (2011a). Polyphenol composition and “in vitro” antiradical activity of single and multigrain breads. Journal of Cereal Science, 53, 90–96.

Angioloni, A., & Collar, C. (2011b). Nutritional and functional added value of oat, Kamut®, spelt, rye and buckwheat versus common wheat in breadmaking. Journal of the Science of Food and Agriculture, 91, 1283–1292.

Collar, C. (2003). Significance of viscosity profile of pasted and gelled formulated wheat doughs on bread staling. European Food Research and Technology, 216, 505–513.

Collar, C. (2008). Novel high fibre and whole grain breads. In B. Hamaker (Ed.), Technology of Functional Cereal Products (pp. 184–214). Cambridge: Woodhead Publishing.

Collar, C., & Bollain, C. (2005). Relationships between dough functional indicators during breadmaking steps in formulated samples. European Food Research and Technology, 220, 372–379.

Collar, C., Andreu, P., Martínez, J. C., & Armero, E. (1999). Optimization of hydrocolloid addition to improve wheat bread dough functionality: A response surface methodology study. Food Hydrocolloids, 13, 467–475.

Flander, L., Salmenkallio-Marttila, M., Suortti, T., & Autio, K. (2007). Optimization of ingredients and baking process for improved wholemeal oat bread quality. LWT-Food Science and Technology, 40, 860–870.

Francis, F. J., & Clydesdale, F. M. (1975). Food colourimetry: Theory and applications. Wesport: The AVI Publishing Company, Inc.

Gabriele, D., de Cindo, B., & D'Antona, P. (2001). A weak gel model for foods. Rheologica Acta, 40, 120–127.

Hsu, C. L., Chen, W., Weng, Y. M., & Tseng, C. Y. (2003). Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chemistry, 83, 85–89.

ICC Standard Methods of the International Association for Cereal Chemistry (1976–1996). 104/1, 105/2, 110/1, 115/1, 136, 162. Vienna: The Association.

Kim, S. L., Kim, S. K., & Park, C. O. (2004). Introduction and nutritional evaluation of buckwheat sprouts as a new vegetable. Food Research International, 37, 319–327.

Kunzek, H., Müller, S., Vetter, S., & Godeck, R. (2002). The significance of physicochemical properties of plant cell wall materials for the development of innovative food products. European Food Research and Technology, 214, 361–376.

Ramirez-Jimenez, A., Garcia-Villanova, B., & Guerra-Hernandez, E. (2001). Effect of toasting time on the browning of sliced bread. Journal of the Science of Food and Agriculture, 81(5), 513–518.

Skrabanja, V., Kovac, B., Golob, T., Elmståhl, G. M., Björck, I., & Kreft, I. (2001). Effect of spelt wheat flour and kernel on bread composition and nutritional characteristics. Journal of Agriculture and Food Chemistry, 49, 497–500.

Taylor, J. R. N., Schober, T. J., & Bean, S. C. (2006). Novel food and non-food uses for sorghum and millets. Journal of Cereal Science, 44, 251–271.

Truswell, A. S. (2002). Cereal grains and coronary heart disease. European Journal of Clinical Nutrition, 56(1), 1–14.

Wood, P. J. (2007). Cereal beta-glucans in diet and health. Journal of Cereal Science, 46(3), 230–238.

Acknowledgements

The authors acknowledge the financial support of the Spanish institutions Consejo Superior de Investigaciones Científicas (CSIC) (Post Doctoral JAE Contract) and Ministerio de Ciencia e Innovación (Project AGL2011-22669).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Angioloni, A., Collar, C. Suitability of Oat, Millet and Sorghum in Breadmaking. Food Bioprocess Technol 6, 1486–1493 (2013). https://doi.org/10.1007/s11947-012-0786-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0786-9