Abstract

The growing consumer exigency and the lack of gluten-free (GF) bakery products with good technological and nutritional characteristics in the market have increase the need of researching in this area. Few studies have analysed the simultaneous influence of different flour fractions from rice dry milling to formulate GF bread and its effects on rheology and product quality. The aim of this study was to characterize the chemical and physical properties of rice milling fractions (flour, coarse, bran); and to evaluate the effect of these fractions on rheology, and quality of GF bread. High fibre content (31.5%) and good hydration and functional properties demonstrated the suitability of bran for food development. A mixture design with three components was used. Pasting parameters, bread specific volume (BSV), firmness and colour intensity (Chr) responses were fitted to linear and quadratic polynomial models. The presence of bran in the blends reduced almost all pasting parameters. The optimal mixture proportion was flour:coarse:bran (45:35:20), presenting a BSV 1.7 ± 0.1 cm3/g; firmness 0.23 ± 0.01 MPa, and Chr 23.8 ± 0.4. A portion (50 g) of GF bread increased four times the dietary fibre intake. The utilization of different rice fractions to formulate GF bread improved the product quality and enhance the nutritional profile.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ingestion of gluten from diet could induce several gastrointestinal disorders, including celiac disease (CD), allergy to wheat (WA) and non-celiac gluten sensitivity (NCGS). CD is an immune-based enteropathy triggered by ingestion of gluten in genetically susceptible individuals resulting from the interaction between genetic and environmental factors, which affects approximately 1% of the population. In NCGS, individuals develop adverse reactions after the ingestion of gluten-containing food, which could be similar to those of CD or irritable/inflammatory bowel syndrome but do not have definite evidence of CD or WA (Henggeler et al. 2017). The incidence of NCGS is expected to be higher than CD and WA, and it is estimated that reach 6% of the population (Czaja-Bulsa 2015).

The GF food market segment is important for individuals with CD or WA or NCGS due to their adherence to a strict diet without the ingestion of prolamins from wheat (gliadin), rye (secalin), and barley (hordein). A recent study has analysed the ingredient list of commercial GF breads from different brands (n = 228) available in the worldwide; highlighting that most of them are mainly starch-based and very few include functional ingredients such as fibre or micronutrients (Roman et al. 2019). In addition, several studies have revealed that GF diet may lead to nutrient deficiencies, especially fibre, vitamins and minerals; and the fact that GF breads are based in refined flours only exacerbate the nutritionally unbalanced diet for GF consumers (Capriles et al. 2016; Vici et al. 2016).

On the other hand, the circular economy is now an irreversible, global mega trend. Circularity means adapting industrial processes in order to improve the material use preventing waste generation and pollutions problems (European Commission 2019). Rice (Oryza sativa) flour is the second most commonly used flour in GF bread-making; nevertheless, it presents technological limitations due to the poor functional properties of its proteins (Capriles and Arêas 2014; Roman et al. 2019). In order to overlap these limitations some researchers have studied different alternatives. For instance, de la Hera et al. (2013, 2014) analysed the influence of the grain type and particle size of rice flour on the dough characteristics and final quality of GF bread. Recently, Cajas Locke et al. (2019) have reported the use of native and modified (partially and totally gelatinised) rice flour in a flour mixture and the effect on GF bread characteristics. In general, dry milling of rice endosperm yield 2.6 times more coarse fraction than flour fraction, being the former, 10% cheaper (personal communication). Rice flour and coarse are composed by 86.5% total starch, 9.8% crude protein and 1% lipid (d.b.) (Qian and Zhang 2013). The rice grain is formed by endosperm (70%), rice husk (20%), bran (8%), and rice germ (2%). Global rice production has been estimated at 769 million tons in 2017, generating around 76.2 million tons of bran (FAO 2017). Therefore, the generation of large quantities of by-products, plus the management and its reprocessing is a critical challenge to the rice industry, and an opportunity for the GF market and consumers.

It is important to highlight that most of the nutrients, including dietary fibre, vitamins, minerals such as iron, and phenolics compounds are mainly concentrated in the bran. The high content of minerals including iron, phosphorus and magnesium, crude protein (11–13%), fat (20%), dietary fibre (> 28%), mostly insoluble, and antioxidants compounds such as tocopherols, tocotrienol and oryzanol, could convert this underutilized fraction in an efficient option to enhance the nutritional profile of GF bakery products (Gul et al. 2015; Martins et al. 2017; Khir and Pan 2019). Nowadays, rice bran is finding different applications in the food industry. For instance, defatted rice bran was assayed in GF bread formulation by Phimolsiripol et al. (2012). Nevertheless, the simultaneously application of different fractions from rice grain milling for GF bread-making and its effects on the pasting properties and quality of baked product has not yet been reported. Currently, the nutritional quality of GF products in conjunction with improvement of technological properties remains an important task for research and development (Capriles et al. 2016).

The aim of the present study was to analyse the chemical composition and physical properties of different fractions from rice dry milling; and to evaluate the effect of these fractions on the pasting properties, quality parameters and nutritional profile of GF bread through a constrained simplex-centroid design. The optimization of rice proportions in the formulation was also analysed.

Material and methods

Materials

Rice (Gurí INTA CL cultivar) flour, coarse and rice bran were kindly supplied by the local rice milling industry Cooperative Villa Elisa S.A. (Entre Ríos, Argentina). Rice flour and coarse fractions presented a high content of amylose (28.7%) and an average particle size of 180 and 300 µm, respectively. Meanwhile, the rice bran was sieved through a stainless-steel mesh with particle size less than 40 μm, and stored at − 12 °C, until use.

Characterization of rice dry milling fractions

Chemical composition

The content of proteins, lipids, total dietary fibre, ash and moisture of rice flour fractions were determined as described in AOAC (2005) methods 984.13, 923.05, 992.16, 936.07, 925.10, respectively. Carbohydrates was determined by difference.

Physical, functional and hydration properties

The water activity (aw) was measured on rice milling fractions using a hygrometer (HigroLab, Rotronic, Switzerland) at 20 °C. The functional characterization was determined as previously reported by Genevois et al. (2019). Briefly, the apparent density (ρ) and specific volume (υ) were determined by measuring the volume of a weighed sample in a graduated and calibrated glass cylinder (Eq. 1 and 2).

where, \(M_{1}\) represents the weight of original sample, and \(M_{2}\) is the volume occupied by the sample.

Oil holding capacity (OHC) was measured by mixing the sample with sunflower oil and after 18 h at 25 °C, it was centrifuged at 3,600 rpm 20 min (Eppendorf, HH, Germany), the supernatant was discarded and the weight of the sample was recorded to determine the oil retained (Eq. 3).

where, \(M_{1}\) is the original sample weight, and \(O\) represents the weight of sample with the vegetable oil absorbed.

The hydration properties were determined keeping the sample in contact with distilled water for 18 h at 25 °C. Swelling capacity (SC) was determined measuring the final volume attained by the hydrated sample for 18 h at 25 °C.

\(M_{1}\) corresponds to the original sample weight, and \(W_{2}\) represents the volume occupied by the hydrated sample.

Water holding capacity (WHC) and water retention capacity (WRC) were determined recording the weight of water retained by the sample after free or accelerated decantation (30 min at 4,800 rpm, Eppendorf, HH, Germany), respectively. The dry sample weight was evaluated after freeze-drying (Eq. 5 and 6).

where \({\text{W}}_{1}\) represents the freeze-dried sample weight, and \({\text{W}}_{2}\) is the hydrated sample weight after free decantation and \(\text{W}^{\prime}_{2}\) is the hydrated sample weight after accelerated decantation.

Determination of the pasting properties

The viscous behaviour of different flours obtained from milling rice and mixtures from design was measured using a Rheometer (model MCR 302, Anton Paar, Graz, Austria) equipped with a starch stirrer cell (ST24-2D/2 V/2 V-30). All measurements were made in accordance with the method 61-02-01 (2012), with slight modifications. Briefly, 3.2 g of sample were dispersed in 20 mL of distilled water and homogenised for 1 min in a vortex at maximum speed. The viscosity profile was recorded using the following time/temperature regime: holding at 50 °C for 1 min; heating from 50 to 95 °C for 7 min with continuous stirring first at 960 rpm for 10 s and then at 160 rpm throughout the entire assay; holding the paste at 95 °C for 5 min; cooling from 95 to 50 °C for 7 min; and holding the paste at 50 °C for 3 min. From the viscosity profile generated, the following parameters were obtained: pasting temperature (°C), peak viscosity (cp), holding strength (cp), breakdown (cp), final viscosity (cp) and setback from trough (cp).

Measurements were performed at least in duplicate from independent samples and results are expressed as mean ± standard deviation.

Gluten-free bread making process

Solid ingredients rice flour (45.0–60.0%), coarse (35.0–50.0%), bran (5.0–20.0%), hydroxypropyl methylcellulose (0.5%; Methocel K4M, Dow Chemical, USA), and salt (2.0%; Celusal, Argentina) were mixed with three parts of the total content of water (110%) using a professional stand mixer (Planetaria, Moulinex, Brazil) provided with a dough hook for 2 min at speed 1 (in a scale 1–5 of the mixer). Then, dried yeast (1.5%; LEVEX, Argentina) was mixed with one part of the total water content and incorporated to the rest of the dough. All ingredients were kneaded for 2 min at speed 1. Dough pieces (~ 320 g) were placed into rectangular aluminium pans (45 × 235 × 50 mm) and fermented in a proofing chamber at 30 °C for 40 min; and finally baked in an electric oven (Marshall, Argentina) for 40 min at 200 °C. The breads were removed from the pans, cooled for 60 min at room temperature, and packed in sealed polypropylene bags to prevent dehydration. Analytical measurements were made within 24 h.

Physicochemical characterization of baked gluten-free bread

-

Weight loss of breads was calculated as the difference between the weight of batter placed into the pan (~ 320 g) and the weight of the bread after baking, divided by the weight of batter. Results were expressed as percentage.

-

Bread specific volume (BSV) was determined by rapeseed displacement following the AACC 74–09 method and results were expressed as cm3/g (de Escalada Pla et al. 2013).

-

Instrumental colour was determined on crumb bread using a colorimeter (MiniScan, HunterLab, USA), in the CIE L*a*b* space under illuminant D65 and with an observer angle of 10°. The intensity of colour (chroma) was calculated using the Eq. 7:

$$ {\text{Chroma}} \left( {{\text{Chr}}} \right) = \sqrt {\left( {{\text{a}}^{*} } \right)^{2} + \left( {{\text{b}}^{*} } \right)^{2} } $$(7) -

Texture properties of bread crumb were measured using an Instron Universal testing machine (Model 3342, USA), according to the method 74–09 (1999) with slight modifications. Briefly, bread slices of 25 mm thickness were compressed using a cylindrical probe (diameter 36 mm) at a crosshead speed of 0.3 mm/sec. Force (N)-displacement (sec) curves were recorded up to 25% of the sample deformation. The strain (ε = D/H, being D the displacement and H the initial height of the sample) and the stress (σ = F/A, being the F the force and A the cross sectional area of the crumb bread, normal to the F direction; MPa) were evaluated from the F/D profile. The firmness was calculated from the middle of the first slope as the ratio between σ and ε at 12.5% of deformation and expressed in MPa.

All measurements were performed at least in triplicate from independent samples and reported as mean ± standard deviation.

Experimental design and statistical analysis

A constrained simplex-centroid design was applied. Dependent variable (Ψ) was modelled as function of codified components (\(x_{1}\), \(x_{2}\), \(x_{3}\)) by means of the polynomial model proposed by Scheffe (1963) (Eq. 8):

where, \(\beta_{i} \) represent the effect of components, \(\beta_{ij}\) is the binary effect between components i and j, and \(\beta_{1, 2,3}\) is the ternary effect between components \(x_{1}\), \(x_{2}\) and \(x_{3}\).

Lower and upper constrains were defined by the authors according to previous physical, textural and sensorial assays, stablishing that mixture had at least 45% of flour (\(x_{1}\)), 35% of coarse (\(x_{2}\).) and 5% of bran (\(x_{3}\)). Upper bounds of components were calculated as 60% for \(x_{1}\)., since (\(x_{2}\) + \(x_{3}\)) at least was 40%; 50% for \(x_{2}\), since (\(x_{1}\) + \(x_{3}\)) at least was 50%, and 20% for \(x_{3}\), since (\(x_{1}\) + \(x_{2}\)) at least was 80% (Cornell 2002). The proposed levels are detailed in Table 1. One system was performed in triplicate to estimate the exrimental error. The statistical significance (p ≤ 0.05) of terms in the regression equations was analysed using analysis of variance (ANOVA) for each response, with a significance level of 95.0%. The adequacy of the model was evaluated through the coefficient of determination (R2) and the lack of fit test (p ≥ 0.05). The desirability function was used to optimize several responses simultaneously.

Statistical analysis of results was performed through ANOVA for a level of significance (α) of 0.05 followed by LSD Fisher post hoc test to identify significant differences among samples.

All statistical analysis, regressions, and correlation analysis were performed using the Design-Expert 11 program (11.1.2.0, USA).

Results and discussion

Physicochemical and functional characterization of rice milling fractions

The results corresponding to the chemical composition, physical, functional and hydration properties of rice milling fractions are detailed in Table 2. Centesimal composition of bran rice showed significant differences respect to flour and coarse rice, especially in a higher content of protein, total dietary fibre and ash. The values obtained in the present study were similar to those reported in defatted rice bran by Daou and Zhang (2011), except for the fat content that was remove by an additional process. In this case, the raw material was obtained from the local rice milling industry, taking advantage of all nutrients present in the milling rice by-products. Water activity did not present differences, being the average value of the three fractions 0.64 ± 0.01. The apparent density was lower in bran compared with rice flour and coarse; inversely, the same tendency was observed in specific volume; the highest lipid content and the lowest water content could explain the lower density shown by the rice brand fraction (Table 2). Some results from functional and hydration properties reported here in, were in the order of values reported previously by the authors for fractions rich in fibre obtained from quince and pumpkin by-products (Genevois et al. 2019).

Rice bran showed the highest oil binding capacity (OHC), being this property dependent on the surface properties and hydrophobic components of the plant tissue (Mora et al. 2013). Moreover, higher specific volume of brand fraction would represent better OHC (de Escalada Pla et al. 2010). The high lipid content of this fraction may also explain the higher OHC when comparing with previous reported data (Genevois et al. 2019).

As regards the hydration properties, a significant difference (p < 0.05) was observed between flour, course, and bran; being the bran fraction with the highest values in SC, WHC and WRC. This fact, could be explained by the water interaction through hydrogen bonding with a higher number of hydroxyl groups which exists in fibre structure (Onipe et al. 2017) and also to the lower apparent density (de Escalada Pla et al. 2010). WRC represents water strongly absorbed that could be retained by some components from fibre even though it is submitted to further processes where fibre fractions could participate as ingredients, for example, during kneading of dough. In this sense, rice bran showed the highest (p < 0.05) WRC. Nevertheless, significant difference is observed between WHC and WRC in rice bran fraction, suggesting that not all the water holding by the sample would remain trapped after excessive mixing (Table 2). Similar values in WHC and WRC have been reported in fractions rich in fibre, for instance in total dietary fibre obtained from defatted bran rice, wheat bran and coconut fibre (Raghavendra et al. 2004; Daou and Zhang 2011; Onipe et al. 2017).

The colour parameters registered significant differences among fractions, being bran the fraction with the lowest L* and highest a* and b* coordinates.

Effect of the different fractions from rice milling on the bread specific volume, crumb colour and texture of GF bread

The application of mixture designs in food formulation is still sparse. Mixture design is an experiment methodology, where the product resultant is an ingredient mixture, and the relative proportions of components are established by models which may be linear, quadratic or cubic (Ferreira et al. 2017).

The results corresponding to the BSV, texture and colour of GB bread are summarized in Table 1; whereas regression coefficients of fitted models are detailed in Table 3. Based on the magnitude of the parameter estimates in Table 3, coefficients of individual components (β1: flour, β2: coarse, β3: bran) were greater than zero, which means that individual rice fractions have direct effect in the response variables. The coefficient of determination > 87% and p value > 0.05 for lack of fit test, confirmed that the fit of the models was adequate to explain the variability of the responses studied.

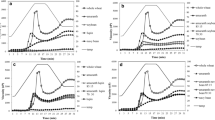

After baking, the GF breads presented an average weight loss of 23 ± 2%. BSV is considered one of the most important criterion in evaluating bread quality since it provides quantitative measurements of baking performance. BSV fitted significantly to a linear model (p < 0.01), demonstrating the effect of pseudo components on the response variable (Table 3). As shown in Fig. 1a, the upper BSV values in GF bread were observed with the highest level of bran and the lowest levels for flour and coarse. It is noteworthy, that bran is characterized by a high content of dietary fibre (31.50 ± 0.04%; w.b.), being one order of magnitude higher compared with flour (1.8 ± 0.5%; w.b.) and coarse (2.3 ± 0.5%; w.b.) (Table 2). The addition of dietary fibre in GF breadmaking process could increase significantly the BSV of the baked product due to the strong interaction between some compounds from the fibre and flour proteins, and as consequence increases the percentage of air retention in the dough (Sabanis et al. 2009; Martínez et al. 2014).

Surface contour plot of a BSV, b firmness, c chroma, d peak viscosity, e final viscosity, and f setback from trough of the respective models, accounting for the effect of the components on the gluten-free bread quality. BSV: bread specific volume. Rice fractions: x1 (A: flour); x1 (B: coarse); x1 (C: bran).  Design experimental points

Design experimental points

Firmness values fit significantly (p < 0.001) to a linear model. Figure 1b shows that softer crumb was observed when bran tend towards upper level and flour and coarse tend to lower levels in GF bread. Accordingly, significant lower values of firmness were observed in system 5, with the maximum proportion of bran in the blend flours (Table 1). Early, the softening of wheat bread was related to an increase in the BSV by Cornford et al. (1964) and / or to a greater cohesion of the mass by Collar et al. (1999). At a macroscopic level, bread comprises crumb cells full of air in a matrix that is a viscoelastic solid. In this sense, de Escalada Pla et al. (2013), reported that independently of loaf volume, crumb tenderness positively correlated with the hydrophilic nature of dietary fibre added; and lower bread firmness was observed when dietary fibre with less hydrophilic behaviour, was added. It is important to highlight that 95% of dietary fibre in bran rice is insoluble (Phimolsiripol et al. 2012). In addition, bran presented the highest lipid content as well as OHC (Table 2), showing a more hydrophobic behaviour, that could interfere with water distribution in GF dough environment and form an amylose–lipid complex during baking, leading to softer bread crumb (Pareyt et al. 2011). Besides, a negative linear correlation was observed between BSV and firmness (PPMC, r = − 0.9676, p < 0.001).

Colour is an important characteristic for baked products because together with texture and flavour, contributes to consumer preference (Sabanis et al. 2009). Experimental values of Chr were significantly (p < 0.001) explained by a quadratic model (Table 3). The coefficient interaction between coarse and bran was significant (p < 0.05) and positive, showing a synergic effect of these fractions on Chr; meanwhile, the others interaction coefficients were non-significant (p > 0.05). Consequently, the maximum Chr values (~ 24) where observed with the highest proportion of bran in the formula (Fig. 1c, Table 1).

In general, the addition of fibres in bread making increase the colour of crust and crumb in baked bread. GF bread usually tend to have a lighter colour than wheat breads; therefore, the darkening of the crust and crumb colour due to the inclusion of fibre is a desirable attribute (Capriles and Arêas 2014). For instance, Martínez et al. (2014) assayed the inclusion of fibre from different sources in GF bread reporting lower L* in crust and higher a* in crumb bread. Authors as Demirkesen et al. (2010) have reported that inclusion of chesnut/rice flour ratio at 30/70 in GF bread increased the colour intensity (Chr ~ 40; mainly due to changes in coordinate a*), showing good sensorial acceptance in consumers. In the present work, the maximum level of rice bran added to GB bread increased significantly the crumb Chr (~ 24); possibly due to the initial colour provided by the fibre incorporated, and in addition, the Maillard reactions and sugar caramelization that occur during the baking stage (Damodaran et al. 2008).

On the other hand, a correlation analysis among dependent variables showed a positive linear correlation between the BSV and Chr (PPMC, r = 0.9242, p < 0.001). A negative linear correlation between Chr and firmness (PPMC, r = − 0.9588, p < 0.001) was determined in addition to that correlation between BSV and firmness previously discussed. These results confirmed that addition of rice bran to GF bread could increase the gas retention in GF dough, resulting in a final product with lower initial firmness, and higher BSV and colour intensity.

Pasting properties of rice blends from different dry milling fractions

Pasting properties is considered an indicator of the processing quality in food technology. For instance, understanding the pasting behaviour in GF dough could help to optimize the ingredient concentrations and temperature–pressure-shear limits (Dang and Copeland 2004).

Figure 2 illustrates the representative pasting properties of milling rice blends. Meanwhile the characteristics pasting parameters are summarized in Table 4. The pasting properties of rice blends from milling fractions were different to their counterparts isolated from rice (flour, coarse, bran). It was observed that bran fraction presented the lowest (p < 0.05) values for all the rheology parameters and, in addition, the highest pasting temperature (Table 4); certainly because their lower content of starch granules, as can be observed through the carbohydrate content (Table 2).

In general, the presence of rice bran in the mixture affected the pasting properties depending on its rate in the blend. As can be observed in Fig. 2, system 5 with the maximum content of bran, presented the lowest values for peak viscosity, breakdown, final viscosity and setback from trough. Taking into account the ratios of milling fractions as well as the corresponding centesimal composition (Table 2), nutritional profile for system 5 can be estimated as 7.7% for protein, 3.9% for lipid, 7.9% for dietary fibre and 66.6% for carbohydrates. Therefore, considering that most of carbohydrates in rice fractions come from starch it can be inferred that, in this proportion, the low starch content due to rice flour substitution by rice bran decreased the viscosity in the cooling step. Bran contains only 5% soluble fibre and water-soluble fibre would be the main component to increase the viscosity of the dough. So, despite the good hydration properties of rice bran (Table 2), it could not compensate the starch granules reduction possibly because in this ratio could not retain the water in the mix, as it was previously discussed regarding to WRC.

On the other hand, peak viscosity, final viscosity and setback trough parameters fit to linear models consisting of first-order terms for each of the rice fractions as can be observed on Fig. 1d–f. In general, rice bran reduced these parameters while rice flour and coarse increased them. Authors as Jang et al. (2018) have reported that higher initial pasting viscosity might increase the viscosity of rice bread batter during the baking process and reduce the bread volume expansion. Consequently with these results, a negative correlation was found between peak viscosity and BSV (PPMC, r = − 0.9206, p < 0.001); and a positive correlation was found between firmness and peak and final viscosity (PPMC, r = 0.8494, p < 0.01; r = 0.8741, p < 0.01, respectively). The hydration and functional properties as well as the high fibre and lipid content (Table 2) could explain the effects as previously discussed, and also present evidence that a differential interaction occurs between some rice flour/coarse and bran compounds.

Optimization of rice milling fractions in the GF bread formulation

Based on above results, it can be asserted that the GF bread quality is not dependent on a single main factor and the three independent variables are important in defining the characteristics of the final product. Therefore, optimization of rice fractions was carried out maximizing the BSV and Chr, and minimizing the firmness. The suitable combination obtained was flour 45.0%, coarse 35.0%, and bran 20.0%, with a desirability of 0.99. The predicted values were BSV 1.71 cm3/g, Chr 23.8, and firmness 0.2323 MPa, being these values similar to those obtained in system 5 from the experimental design (Table 1).

It is important to highlight that GF flours and starches are not generally enriched or fortified and GF products may lead to nutritional deficiencies, for instance dietary fibre (Capriles et al. 2016; Vici et al. 2016). Taking into account chemical composition of rice fractions (Table 2), it was calculated the supply of dietary fibre of GF bread elaborated with the optimal rates. Therefore, a portion of GF bread (50 g) would provide ~ 2.3 g of dietary fibre, enhancing the intake of dietary fibre four times compared to GF bread based on starch and rice flours.

Conclusion

All fractions from the milling of rice endosperm as well as rice bran could be successfully used to formulate GF bread with good technological characteristics and enriched in dietary fibre.

The present work highlights that simultaneous use of different fractions from rice milling for GF bread-making affected the dough pasting properties enhancing the final quality characteristics of the bakery. In general, higher bran content, presented the lowest values for peak viscosity, breakdown, final viscosity and setback from trough and simultaneously higher bread volume and lower firmness. Besides the addition of rice bran at a ratio of 20% allowed increase four times the dietary fibre intake. The results obtained in the present work provide the basis for further studies related to formulation of GF bread with improved dietary fibre profile, maximizing the use of rice dry milling fractions.

Abbreviations

- CD:

-

Celiac disease

- GF:

-

Gluten-free

- aw :

-

Water activity

- ρ:

-

Apparent density

- υ:

-

Specific volume

- OHC:

-

Oil holding capacity

- SC:

-

Swelling capacity

- WHC:

-

Water holding capacity

- WRC:

-

Water retention capacity

- BSV:

-

Bread specific volume

- Chr:

-

Chroma

- PPMC:

-

Pearson product–moment correlation

References

AOAC (2005) Official methods of analysis of the association of official analytical chemists, 18th edn. AOAC Inc., USA

Cajas Locke JE, González LC, Loubes MA, Tolaba MP (2019) Optimization of rice bread formulation by mixture design and relationship of bread quality to flour and dough attributes. LWT Food Sci Technol 113:108299. https://doi.org/10.1016/j.lwt.2019.108299

Capriles VD, Arêas JAG (2014) Novel approaches in gluten-free breadmaking: Interface between food science, nutrition, and health. Compr Rev Food Sci Food Saf 13:871–890. https://doi.org/10.1111/1541-4337.12091

Capriles VD, dos Santos FG, Arêas JAG (2016) Gluten-free breadmaking: improving nutritional and bioactive compounds. J Cereal Sci 67:83–91. https://doi.org/10.1016/j.jcs.2015.08.005

Collar C, Andreu P, Martínez JC, Armero E (1999) Optimization of hydrocolloid addition to improve wheat bread dough functionality: a response surface methodology study. Food Hydrocoll 13:467–475. https://doi.org/10.1016/S0268-005X(99)00030-2

Cornell JA (2002) Experiments with mixture-designs, models and the analysis of mixture data. Wiley, New Jersey, p 631

Cornford SJ, Axford DWE, Elton GAH (1964) Elastic modulus of bread crumb in linear compression in relation to staling. Cereal Chem 41:216–229

Czaja-Bulsa G (2015) Non coeliac gluten sensitivity—a new disease with gluten intolerance. Clin Nutr 189–194. https://doi.org/10.1016/j.clnu.2014.08.012

Damodaran S, Parkin K, Fennema O (2008) Fennema’s food chemistry, 4th edn. CRC Press, Boca Raton

Dang JMC, Copeland L (2004) Genotype and environmental influences on pasting properties of rice flour. Cereal Chem 81:486–489. https://doi.org/10.1094/CCHEM.2004.81.4.486

Daou C, Zhang H (2011) Physico-chemical properties and antioxidant activities of dietary fiber derived from defatted rice bran. Adv J Food Sci Technol 3:339–347

de Escalada Pla M, Rojas AM, Gerschenson LN (2013) Effect of butternut (Cucurbita moschata Duchesne ex Poiret) fibres on bread making, quality and staling. Food Bioprocess Technol 6:828–838. https://doi.org/10.1007/s11947-011-0744-y

de Escalada Pla MF, Uribe M, Fissore EN et al (2010) Influence of the isolation procedure on the characteristics of fiber-rich products obtained from quince wastes. J Food Eng 96:239–248. https://doi.org/10.1016/j.jfoodeng.2009.07.018

de la Hera E, Martinez M, Oliete B, Gómez M (2013) Influence of flour particle size on quality of gluten-free rice cakes. Food Bioprocess Technol 6:2280–2288. https://doi.org/10.1007/s11947-012-0922-6

de la Hera E, Rosell CM, Gomez M (2014) Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem 151:526–531. https://doi.org/10.1016/j.foodchem.2013.11.115

European Commission (2019). Circular Economy. Implementation of the Circular Economy Action Plan. https://ec.europa.eu/environment/circular-economy/ Accessed 26 February 2020

Demirkesen I, Mert B, Sumnu G, Sahin S (2010) Utilization of chesnut flour in gluten-free bread formulations. J Food Eng 101:329–336. https://doi.org/10.1016/j.jfoodeng.2010.07.017

Food and Agriculture Organization (FAO). 2017. FAOSTAT Data. https://www.fao.org/faostat/en/#data/QC Accessed 26 February 2020

Ferreira SLC, Silva Junior MM, Felix CSA et al (2017) Multivariate optimization techniques in food analysis—a review. Food Chem. https://doi.org/10.1016/j.foodchem.2017.11.114

Genevois C, Pieniazek F, Messina V et al (2019) Bioconversion of pumpkin by-products in novel supplements supporting Lactobacillus casei. Lwt 105:23–29. https://doi.org/10.1016/j.lwt.2019.01.057

Gul K, Yousuf B, Singh AK et al (2015) Rice bran: Nutritional values and its emerging potential for development of functional food—A review. Bioact Carbohydr Diet Fibre 6:24–30. https://doi.org/10.1016/j.bcdf.2015.06.002

Henggeler JC, Veríssimo M, Ramos F (2017) Non-coeliac gluten sensitivity: a review of the literature. Trends Food Sci Technol 66:84–92. https://doi.org/10.1016/j.tifs.2017.05.018

Jang K, Hong YE, Moon Y et al (2018) Exploring the applicability of tamarind gum for making gluten-free rice bread. Food Sci Biotechnol 27:1639–1648. https://doi.org/10.1007/s10068-018-0416-z

Khir R, Pan Z (2019) Rice. In: Pan Z, Zhang R, Zicari S (eds) Integrated processing technologies for food and agricultural by-products. Elsevier Inc., Amsterdam, pp 21–58

Martínez MM, Díaz Á, Gómez M (2014) Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J Food Eng 142:49–56. https://doi.org/10.1016/j.jfoodeng.2014.06.020

Martins ZE, Pinho O, Ferreira IMPLVO (2017) Food industry by-products used as functional ingredients of bakery products. Trends Food Sci Technol 67:106–128. https://doi.org/10.1016/j.tifs.2017.07.003

Mora YN, Contreras JC, Aguilar CN et al (2013) Chemical composition and functional properties from different sources of dietary fiber. Am J Food Nutr Nutr 1:27–33. https://doi.org/10.12691/ajfn-1-3-2

Onipe OO, Beswa D, Jideani AIO (2017) Effect of size reduction on colour, hydration and rheological properties of wheat bran. Food Sci Technol 37:389–396. https://doi.org/10.1590/1678-457x.12216

Pareyt B, Finnie SM, Putseys JA, Delcour JA (2011) Lipids in bread making: sources, interactions, and impact on bread quality. J Cereal Sci 54:266–279. https://doi.org/10.1016/j.jcs.2011.08.011

Phimolsiripol Y, Mukprasirt A, Schoenlechner R (2012) Quality improvement of rice-based gluten-free bread using different dietary fibre fractions of rice bran. J Cereal Sci 56:389–395. https://doi.org/10.1016/j.jcs.2012.06.001

Qian H, Zhang H (2013) Rice flour and related products. In: Bhandari B, Bansal N, Zhang M, Schuch P (eds) Handbook of Food Powders: Processes and Properties. Woodhead Publishing Limited, pp 553–575

Raghavendra SN, Rastogi NK, Raghavarao KSMS, Tharanathan RN (2004) Dietary fiber from coconut residue: effects of different treatments and particle size on the hydration properties. Eur Food Res Technol 218:563–567. https://doi.org/10.1007/s00217-004-0889-2

Roman L, Belorio M, Gomez M (2019) Gluten-free breads: the gap between research and commercial reality. Compr Rev Food Sci Food Saf 18:690–702. https://doi.org/10.1111/1541-4337.12437

Sabanis D, Lebesi D, Tzia C (2009) Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT Food Sci Technol 42:1380–1389. https://doi.org/10.1016/j.lwt.2009.03.010

Scheffe H (1963) The simplex-centroid design for experiments with mixtures. J R Stat Soc Ser B (Methodological) 25:235–263

Vici G, Belli L, Biondi M, Polzonetti V (2016) Gluten free diet and nutrient deficiencies: a review. Clin Nutr 35:1236–1241. https://doi.org/10.1016/j.clnu.2016.05.002

Acknowledgements

The authors acknowledge the financial support from Universidad de Buenos Aires (UBACyT- 2018-2020 20020170100092), from Universidad Nacional de Entre Ríos (PID UNER 9112) the National Agency of Scientific and Technical Research (PICT 2016-3552; PICT 2018-01019) and National Scientific and Technical Research Council of Argentina (CONICET) and Cooperative Villa Elisa.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Genevois, C.E., Grenóvero, M.S. & de Escalada Pla, M.F. Use of different proportions of rice milling fractions as strategy for improving quality parameters and nutritional profile of gluten-free bread. J Food Sci Technol 58, 3913–3923 (2021). https://doi.org/10.1007/s13197-020-04852-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04852-1