Abstract

The functional pattern of wheat flour doughs formulated with hydroxypropylmethylcellulose, a high ester pectin, amylolytic (α-amylase) and non-amylolytic enzymes (xylanase, microbial transglutaminase), and an emulsifier (diacetyl tartaric acid ester of mono-diglycerides) has been investigated during breadmaking stages using a Draper-Lin small composite design for sampling. Measurements were performed at small as well as at large deformations (shear deformation, uniaxial compression, uniaxial extension, biaxial extension) using empirical and fundamental rheological methods, and the resulting rheological parameters correlated. Measurements performed at small deformations (dough development parameters during mixing) showed close relationships with uniaxial compression measurements (textural properties) and with gluten quality descriptors assessed during fermentation and carried out at large deformations. Gluten quantity descriptors and gluten quality definers derived from the dough inflation system, texture profile analysis, gluten acid method and gluten index measurements significantly correlated. Stirring number measurement showed significant relationships with the pasting parameters associated with bread staling kinetics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rheological measurements are increasingly being used as sensitive indicators of polymer molecular structure and predictors of end-use performance [1]. Bread crumb is a porous solid matrix with a cellular structure [2] composed mainly of gluten, starch and water, and minor constituents such as lipids and non-starch polysaccharides in the presence of additives and technological aids. It represents a typical viscoelastic biopolymer foam system [3]. Rheological tests have been successfully applied to bread doughs as indicators of the gluten and starch polymer molecular structure [4] and as predictors of its functional behaviour in breadmaking, using either descriptive empirical techniques or fundamental measurements [5, 6, 7, 8, 9, 10, 11]. Mechanical properties of wheat flour dough play a significant role in the handling properties of dough during processing and in the quality attributes of finished fresh and stored baked goods [12, 13, 14, 15].

Major breadmaking steps significantly change the rheological properties of wheat doughs. During mixing, the distribution of materials, hydration and energy input for stretching and alignment of protein molecules take place [16] involving shear and extensional deformation [17]. During fermentation, the expansion of the air bubbles previously incorporated during mixing provides the characteristic aerated structure of bread, which is relevant to its appeal [18]. During proof and baking, the growth of gas bubbles determines the expansion of the dough and therefore the ultimate volume and texture of the baked product [19].

Most of the studies on doughs have been on the relationships between mixing, rheology and baking performance, because of the rheological changes that occur in the gluten viscoelastic network during mixing and their impact on product quality [4]. The rheological properties of the bubble walls will therefore be important in maintaining stability against premature failure during baking, and also in relation to gas cell stabilisation and gas retention during proof [20]. Although the need for proper understanding of dough properties has been emphasised, few studies have been made on the changing rheological properties during fermentation and baking.

Differences in dough hardness, within doughs of the same farinograph consistency, have been reported [21] and assigned to differences in water content, energy mixing requirements and protein composition. The close relation between hardness and cohesiveness resulted in a similar influence on bread quality and a close dependences on rheological and chemical properties [12]. More cohesive doughs with resistant internal structure to high stress-strains, resulted in higher specific volume and softer breads [5].

Viscoelastic properties of wheat doughs strongly depend on water and protein content [22]. Cohesiveness increased with farinograph water absorption, with maturograph elasticity and with gluten index [5]. Conversely, a negative relationship between stickiness and gluten index has been found. Water absorption is generally accepted to be of major importance in dough stickiness. The higher the farinograph water absorption, the stickier the dough. The gluten index of formulated doughs is a good indicator for fresh bread crumb softness and also influences the limiting modulus [6].

Strain hardening with increasing extension has been shown necessary for stability in any operation involving large extensions [23]. For doughs, strain hardening allows bubbles to inflate to larger volumes and thinner cell walls before failure. Loaf volume for a number of commercial white flour doughs has been directly related to the failure strain of single dough bubbles [23]. Differences in extensional strain hardening between varieties of different baking quality were found to relate to baking quality, with good breadmaking varieties showing greater strain hardening and extensional viscosity [24]. Extensional rheology that is sensitive to polymer chain branching and entanglement interactions between high molecular weight polymers at large deformations [25] generally provides good correlations with the relevant large deformation processing quality parameters such as volume, form ratio, loaf height and overall quality [4]. Significantly relationships between dough tensile and biaxial extensional parameters have been reported [10] providing complementary information for uni- and biaxial rheological behaviour of doughs.

Extensibility, resistance to the extension, strain hardening and stress relaxation properties determined at large deformations allowed realistic assessment of the significance of additives and technological aids on dough quality profile, as recently stated [10]. Suitable rheological trends for a high quality bread—optimal resistance to uni-and biaxial extension, high extensibility before break/stretching, great strain hardening in biaxial extension, and longer time of semirelaxation—were closely concerned with dough formula [10]. Bread dough viscosity characteristics derived from the rapid viscoanalyser (RVA) pasting profile during cooking and cooling highly correlate with bread staling kinetic parameters. This is particularly so in the cases of peak viscosity, pasting temperature and setback on cooling that can be considered valuable predictors, at the dough level, of bread firming behaviour during storage [26].

The functional properties of formulated flour-water doughs during breadmaking stages were determined and the resulting rheological parameters correlated. Measurements were performed at small deformations (mixing characteristics) as well as at large deformations (uniaxial compression, uniaxial extension, biaxial extension measurements) using empirical and fundamental rheological methods.

Materials and methods

Basic ingredients and additives

A commercial blend of Spanish wheat flours (13.48% moisture, 0.53% ash content, 13.76% proteins, 51% gluten index, 1.14% fat, 359 s falling number) and commercial compressed yeast (CCY) (1010 cells/g dry matter) were used. Enzymes (Apliena, Spain; Novo Nordisk, Denmark) included transglutaminase (TGM), pentopan mono BG an endo 1.4-beta-xylanase (pentosanase, PTP) and Novamyl 1500 MG a maltogenic bacterial amylase (NMYL). Hydrocolloids (Dow, USA; Copenhagen Pectin, Denmark) were, respectively, METHOCEL K4 M hydroxypropylmethylcellulose (HPMC) and a high ester pectin, GENU pectin type BIG (BIG). Emulsifier (Danisco Ingredients, Denmark) was diacetyl tartaric acid ester of mono-diglycerides (DATEM).

Dough preparation

The basic dough formula for 100 g flour consisted of the amount of water necessary to give a consistency of 500 Brabender Units (BU), salt (1.5 g) and CCY (2 g). Combinations of hydrocolloids, emulsifier and enzymes were added to the basic formula following a Draper-Lin small composite design for sampling (Table 1). Design factors (quantitative independent factors) tested at five levels (1.71885, −1, 0, 1 and 1.71885) included TGM (from 0.078 to 0.422% flour basis), NMYL (from 0.013 to 0.047% flour basis), PTP (from 0.013 to 0.047% flour basis), DATEM (from 0.156 to 0.844% flour basis), HPMC (from 0.028 to 0.372% flour basis), and BIG (from 0.712 to 2.088% flour basis). The model resulted in thirty different formulated bread doughs prepared by mixing ingredients, additives and enzymes in a Brabender farinograph mixer (300 g flour capacity) up to optimum dough development.

Rheological properties

Assessment of dough viscoelasticity during breadmaking was performed by simulation of the breadmaking steps—mixing, fermentation/resting and baking—using specific rheological equipment. Rheological parameters derived from the equipment readings, referred units and references to the applied methods are compiled in Table 2.

Mixing

Dough mixing characteristics were provided by development of the formulated dough samples in a Brabender farinograph [27].

Fermentation/resting

Dough machinability was assessed both by texture profile analysis (TPA) and by dough stickiness determination in a TA-XT2 texturometer using a 5 cm diameter probe, 75 s waiting period, 60% compression and the Chen & Hoseney cell [28], as described previously [12]. The primary textural properties were measured in the absence of dough adhesiveness by using a plastic film on the dough surface to avoid the distortion induced by the negative peak of adhesiveness [7, 8]. Dough adhesiveness was measured separately by running a second TPA without the plastic film and disregarding the other parameters. Extensibility measurements at large deformations were performed for uniaxial (stretching) and biaxial (inflation) extension by using a dough/gluten extensibility rig and a dough inflation system, respectively. Uniaxial extensibility was assessed by the Kieffer dough and gluten extensibility rig developed by Stable Micro Systems for the TA-XT2 texture analyser. The resistance to extension (g) and extensibility (mm) were determined in tension mode by recording the peak force and the distance at the maximum and the extension limit [7, 29]. Biaxial extensibility was measured by Dobraszczyk/Roberts dough inflation system as recently reported [10]. It inflates a sheet of dough by volume displacement of air using a piston driven by a Stable Micro Systems TA-XT2 texture analyser [24]. Stress relaxation assessment was performed after inflating doughs to a fixed volume of 80 mL and measuring the collapse in stress over 20 s [30]. Gluten quantity and quality of fresh formulated samples was determined following ICC methodology [31, 32].

Baking

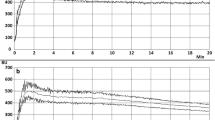

Determination of the stirring number as a measure of the degree of α-amylase activity [33] as well as gelatinisation, pasting and setback properties during cooking and cooling [34] were obtained by recording the pasting profiles in a Newport rapid viscoanalyser (RVA) using freeze-dried formulated dough samples (3.5 g, 14% moisture basis and distilled water 25 mL) as recently reported [26].

Statistical analysis

Multivariate analysis (stepwise regressions and correlation matrix) of rheological variables was performed by using Statgraphics V.7 program (Bitstream, Cambridge, MA, USA, 1992).

Results and discussion

Multivariate data handling of functional dough variables provided information on the significantly correlated rheological properties of formulated bread doughs. Using Pearson correlation analysis, a range of correlation coefficients (r=0.37–0.99) were obtained for the relationship between fundamental, empirical and physico-chemical parameters during breadmaking (Tables 3 and 4) (Figs. 1, 2 and 3). Response surfaces of significantly correlated dependent dough functional variables were estimated by fitting analytical data from Draper-Lin small composite design samples to multiple regression equations using added principles as independent factors.

Although the most accurate measurements of a baking process can be attained at levels of strain and strain rate similar to actual conditions during baking, the empirical Brabender farinograph provides useful information on short-term transient changes in dough rheology during mixing in shear deformation [24]. Farinograph parameters characterising formulated dough development, stability and overmixing until breakdown significantly correlated (0.4>r<0.9) (Table 3). Major correlations concerned the different measurements of dough mechanical breakdown, including degree of softening, mixing tolerance index, time to breakdown and 20 min drop. Dough water absorption positively correlated with development time and arrival time that give an indication of the dough strength and the rate of hydration of the flour, respectively.

Dough stability showed negative relationships with both the arrival time (r=−0.65) and the mixing tolerance index (r=−0.50) but positively correlated with the departure time (r=0.76). In addition, some dough development parameters showed close relationships with textural properties and gluten quality descriptors assessed during resting/fermentation (Fig. 1). Dough stability during mixing positively correlated with dough hardness (r=0.53) and gumminess (r=0.54). Flour water absorption observed significant relationships with both the viscosity at 3 min (r=0.73) and the absolute breakdown (r=0.69) recorded at the RVA by running the gluten acid method [31] adapted from the MacMichael viscosimeter to measure gluten protein quality in soft wheat flour [35, 36].

Lactic acid produces a dilating effect on gluten, the magnitude of swelling as the estimation of the increase in viscosity of a flour-water suspension provides an index to gluten quality. Flours with strong protein exhibit a greater increase in viscosity than flours with weak protein and can thus differentiated by this method. The increase is in direct relation to the swelling properties and quantity of gluten present in the test flour, assuming that changes in viscosity due to starch are relatively constant. An additional heating step to 50 °C was added in the RVA method, producing a breakdown parameter, which may indicate both gluten weakening and starch damage.

Gluten quantity descriptors and gluten quality definers derived from the dough inflation system, texture profile analysis, gluten acid method and gluten index measurements significantly correlated (Fig. 2 and Fig. 3). Gluten index evaluation is considered to be a useful and robust method for gluten quality determination of flours [37, 38] but has been shown to provide contradictory results for breadmaking quality differences in gluten properties due to process and additives [37, 39]. High gluten index values correspond to a strong gluten network. In this research, gluten index values positively correlated with time of semi-relaxation (r=0.41) (Fig. 2) especially for gluten index values above 75% (r=0.69) and with difference of stress (r=0.47) obtained from the stress relaxation test. Time of semi-relaxation has a predictive value of loaf volume [30] and the effect of increasing relaxation time (reported using compression tests [40]) is an indicator of gluten strength. The gluten indices of unfermented doughs were good indicators of fresh bread crumb softness and also influenced the limiting modulus during storage of breads with heterogeneous formulations [6]. Gluten index negatively depended on the simultaneous presence of HPMC/DATEM:

Low addition of DATEM and/or HPMC gave gluten index values above 75. In this work, viscosity at 3 min highly correlated with the absolute breakdown (r=0.89). Both parameters closely depend on dough formulation (Eqs. 2, 3), especially on the presence of hydrocolloids and surfactant that act as dough strengtheners.

Dough resilience increments corresponded to decreased strain hardening indexes (r=−0.39) and smaller strain at bubble failure (r=−0.45) as well as high cohesive doughs (r=0.74) (Fig. 3). Dependence of both cohesiveness (Eq. 4) and resilience (Eq. 5) on the simultaneous presence of the pair DATEM/BIG in dough formulation explained the extreme values obtained for these mechanical parameters.

Samples containing both additives at lower doses (runs 14, 19 and 20) exhibited the lowest values for dough resilience and cohesiveness. In contrast, higher dosages of both strengtheners (runs 2, 4, 7, 16) provided more cohesive and elastic dough samples. A very narrow range for resilience values was obtained as compared with the range for strain hardening index, cohesiveness and strain at bubble failure (Fig. 3). In spite of the significant correlations obtained, caution should be applied when generalising these relationships to heterogeneous bread dough formulations.

Pasting parameters during cooking and cooling of formulated doughs set at RVA significantly and positively correlated, except for pasting temperature which showed no correlation and breakdown on cooking versus setback on cooling that observed negative relationships (Table 4). In general, correlation coefficients (r) were higher among parameters characterising cooking starch behaviour (0.98>r>0.46) than those for starch cooling (0.50>r<0.60). Parameters derived from pasted and gelled doughs strongly correlated as well (0.99>r<0.47), particularly peak viscosity, viscosity at end of holding, holding, breakdown and final viscosity (r>0.8). In a recent research, the correspondence between staling kinetics (finished bread) and the pasting behaviour (dough level) was statistically significant (α<0.05) showing close relationships between viscoelastic and kinetic parameters [26]. Suitable viscosimetric trends at dough level to delay bread staling include delayed pasting temperature, high viscosities that characterise changes during pasting and gelling and low paste viscosity at 95 °C. These viscosity trends were also in good agreement with high sensory scores of fresh bread, obtained for both crumb and crust eatability.

The stirring number (SN) determination is based on the ability of α-amylase to liquefy a starch gel and is defined as the apparent viscosity at 3 min of stirring a hot aqueous flour suspension undergoing liquefaction. The method has been successfully applied to the testing of sprout damage in barley [41] and wheat [42] and is highly correlated to falling number measurement (r2= 0.97) [42]. SN is mainly associated with peak time (r=0.68), peak viscosity (r=0.55), viscosity at end of 95 °C (r=0.71) and holding strength (r=0.67) characterising pasted dough changes (Table 4).

Dependence on dough formulation was particularly relevant for DATEM and BIG. Positive quadratic and negative linear dependence on BIG allowed minimisation of SN in the presence of the hydrocolloid, up to 0.35 g BIG/100 g flour:

Concluding remarks

Functional parameters of formulated flour-water doughs determined during breadmaking stages (mixing, fermentation/resting and baking) using empirical and fundamental rheological methods significantly correlated. Measurements performed at small deformations (dough development parameters during mixing) showed close relationships with uniaxial compression measurements (textural properties) and with gluten quality descriptors assessed during fermentation and carried out at large deformations.

Gluten quantity descriptors and gluten quality definers derived from the dough inflation system, texture profile analysis, gluten acid method and gluten index measurements significantly correlated. Stirring number measurement showed significant relationships with the pasting parameters associated with bread staling kinetics.

References

Marin G, Montfort JP (1996) Molecular rheology and linear viscosity. In: Rheology for polymer melt processing. Elsevier, Amsterdam

Taranto MV (1983) Structural and textural characteristics of baked goods. In: Peleg M, Bagley E (eds) Physical properties of foods. AVI, Wesport, CT

Wang FC, Sun XS (2002) Cereal Chem 79:108–114

Dobraszczyk BJ, Morgenstern MP (2003) J Cereal Sci 38:229–245

Collar C, Armero E (1996) Rec Res DevNutr 1:115–143

Armero E, Collar C (1998) J Cereal Sci 28:165–174

Collar C, Andreu P, Martínez JC, Armero E (1999) Food Hydrocolloids 13:467–475

Collar C, Martínez JC, Andreu P, Armero E (2000) Food Sci Technol Int 6:217–226

Martínez JC, Andreu P, Collar C (1999) Leatherhead Food Ra Food Ind J 2:133–149

Bollaín C, Collar C (2004) Food Hydrocolloids 18:499–507

Collar C, Bollaín C (2004) Eur Food Res Technol 218:139–146

Armero E, Collar C (1997) Z Lebensm Unters Forsch 204:136–145

Collar C, Andreu P, Martínez Anaya MA (1998) Z Lebensm Unters Forsch 207:133–139

Khatkar BS, Bell AE, Schofield JD (1996) J Sci Food Agric 72:71–85

Anemiya JL, Menjivar JA (1992) J Food Eng 16:91–108

Bloksma AH, Bushuk W (1988) Rheology and chemistry of dough. In: Pomeranz Y (ed) Wheat chemistry and technology II. AACC, St. Paul, MN

Schluentz EJ, Steffe JF, Ng PKW (2000) J Texture Stud 31:41–54

Dobraszczyk BJ, Campbell GM, Gan Z (2001) Bread: a unique food. In: Dobraszczyk BJ, Dendy W (eds) Cereals and cereal products: technology and chemistry. Aspen, USA

He H, Hoseney RC (1991) Cereal Chem 68:334–336

Dobraszczyk BJ, Smewing J, Albertini M, Maesmans G, Schofield JD (2003). Cereal Chem 80:218–224

Ram BP, Nigan SN (1983) J Texture Stud 14:245

Navickis LL, Anderson RA, Bagley EB, Jasberg BK (1982) J Texture Stud 13:249–264

Dobraszczyk BJ, Roberts CA (1994) J Cereal Sci 20:265–274

Dobraszczyk BJ (1997) Cereal Foods World 42:516–519

Wagner MH, Bastian H, Hachmann P, Meissner J, Kurzbeck S, Münstedt H, Langouche F (2000) Rheologica Acta 39:97 109

Collar C (2003) Eur Food Res Technol 216:505–513

International Association for Cereal Chemistry (1992) ICC standard no 115/1 1992. ICC, Detmold, Germany

Hoseney RC, Chen WZ (1994) US Patent 5 280 616

Smewing J. (1995). The measurement of dough and gluten extensibility using the SMS/Kieffer rig and the TA.XT2 texture analyser. Stable Micro Systems, Surrey, UK

Launay B (1979) Industries Alimentaires et Agricoles 96:617–623

Newport Scientific Methods (1997) Standard no 21 ver 2, December 1997. Warriewood, Australia

International Association for Cereal Chemistry (1994) ICC standard no 155. Approved 1994. ICC, Detmold, Germany

International Association for Cereal Chemistry (1996) ICC standard no 161. Approved 1996. ICC, Detmold, Germany

International Association for Cereal Chemistry (1996) ICC standard no 62. Approved 1996. ICC, Detmold, Germany

Association of Official Analytical Chemists (1980) Official methods of analysis, 13th edn. Sects. 14.056–14.059. AOAC, p 220

American Association of Cereal Chemists (1982) AACC method 56–80. Approved 1961; revised 1982. AACC, USA

Perten H (1990) Cereal Foods World 35:401–403

Ranhotra GS, Gelroth JA, Eisenbraun GJ (1992) Cereal Foods World 37:261–264

Wadhawan CK, Bushuk W (1969) Cereal Chem 66:456–461

Gerrard JA, Fayle SE, Wilson AJ, Newberry MP, Ross M, Kavale S (1998) J Food Sci 63:472–475

Bason ML, Ronalds JA, Wrigley CW, Hubbard LJ (1993) Cereal Chem 70:269–272

Ross AS, Walker CE, Booth RI, Orth RA, Wrigley CW (1987) Cereal Foods World 32:827–829

Acknowledgements

The authors acknowledge the financial support of the Spanish Ministerio de Ciencia y Tecnología (Project AGL2001–1273) and Generalitat Valenciana (C. Bollaín Predoctoral fellowship).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Collar, C., Bollaín, C. Relationships between dough functional indicators during breadmaking steps in formulated samples. Eur Food Res Technol 220, 372–379 (2005). https://doi.org/10.1007/s00217-004-1039-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-1039-6