Abstract

The objectives of this work were to assess the impact of partial-baking process on gluten-free bread, and to study how carboxymethylcellulose (CMC) and xanthan gum addition affected this process. As different from the conventional baking which involves only one baking step (40 min), the part-baking process consisted in an initial-baking step (25 min), storage (7 days, 4°C), and final-baking step (15 min). Bread-specific volume (SV), crumb hardness, and image analysis were assessed on final products of both processes and intermediate products of part-baking process. Breads were stored at room temperature for 72 h and crumb firming and amylopectin retrogradation were monitored. Freezable water (FW) fraction was determined on fresh and stored samples by using differential scanning calorimetry. Part-baked breads showed lower SV and higher crumb hardness. No SV diminution was observed during cold storage. Hydrocolloids, especially CMC, had a positive effect on these parameters, and during bread storage at room temperature, the increase in crumb hardness was mitigated by hydrocolloid addition. Part-baked breads showed smaller cell area than full-baked ones. Overall, crumb structure was more homogeneous for CMC breads. FW showed no significant differences among processes, formulations, or storage time. Amylopectin recrystallization was higher for part-baked breads. Interrupted-baking process affected the final bread quality, but negative effects could be diminished by hydrocolloid addition. Part-baking process is suitable for obtaining gluten-free breads, stored for a week at 4°C, turning them appropriated for home consumption.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coeliac disease (CD) is a chronic inflammatory intestinal disorder with multifactorial etiology. Genetic environment, together with specific dietary peptides from gluten proteins present in wheat, rye, barley and hybrids like triticale, and additional environmental factors are involved in disease development (Periolo and Cherñavsky 2006). Chronic inflammation results in intestinal villous atrophy and flattening of the mucosa (Sollid 2002) which leads to nutrient malabsorption (Thompson 2001). The only effective treatment for CD patients relies on a lifelong gluten-free diet (Feighery 1999). CD is one of the most common human genetic disorders, with a prevalence of 1–2% worldwide, and is apparently increasing in incidence (Cabrera-Chávez and Calderón de la Barca 2010).

Gluten is the protein fraction present in most cereals, and, particularly in wheat, is the main structure-forming protein and is responsible for the elastic properties of the dough (Turabi et al. 2008), required to produce good quality breads. Due to their technological and nutritional quality, cereal products—especially breads—are basic components of the diet in many countries, although CD patients are unable to consume bread and other food products made of traditional flours, like those of wheat and rye. In general, gluten-free bread formulations are complex, comprising several raw materials like different starches and flours such as rice (Gujral and Rosell 2004), corn and buckwheat (Renzetti et al. 2008), cassava (Ribotta et al. 2004), and potato starch (Gambus et al. 2001).

Gluten-free baked goods, particularly bread, are of low technological quality and prone to a rapid staling. Besides, as they are more expensive than their wheat counterparts, economic loss brought about by crumb firming is proportionally higher. An alternative to this problem would be the development of partially baked gluten-free breads, as they are stored at low temperatures and baking is completed according to consumer’s demand. A number of investigations have demonstrated that the partial baking of wheat-bread and its further storage at low temperatures is an effective way of retarding the staling process of the baked products, reducing economic loss produced by crumb firmness (Bárcenas et al. 2004; Fik and Surowka 2002; Vulicevic et al. 2004). Other advantages of part-baking process are the few types of equipment it requires at the bakery and the fast preparation of the final product, since it only needs to be removed from the refrigerator and put into the oven. Nevertheless, technological problems have been described in the production of part-baked wheat breads: storage at 2–5°C favors amylopectin retrogradation (Bárcenas and Rosell 2006), while water migration from the crumb to the crust results in drier breads.

Hydrocolloid addition to wheat-baked goods is an ordinary practice to mitigate these negative effects (Collar et al. 1999; Bárcenas et al. 2003; Mandala et al. 2008). Their use in baking goods is related to their capability to control rheology and texture of aqueous suspensions; and their ability to modify starch gelatinization, extend overall product quality during storage time, and mimic gluten properties, while being used as fat substitute and dietary source (Guarda et al. 2004; Rosell et al. 2001).

Although some part-baked gluten-free bread is available from the market, as far as we know there is no published scientific research supporting the development of these new products.

The aim of this work was to: (1) assess the impact of a partial-baking process on the quality of gluten-free breads as compared to a conventional full-baking process, and (2) to study the effect of different hydrocolloids (carboxymethylcellulose (CMC) and xanthan gum) on this process.

Materials and Methods

Materials

Rice flour was supplied by Nora’s Skills (Buenos Aires, Argentina; 100 g dry flour contained protein, 8.11 g; ash, 0.23 g; lipid, 0.8 g; crude fiber, 0.25 g; carbohydrate, 90.61 g), corn flour was provided by ARCOR S.A. (Arroyito, Argentina; 100 g dry flour contained protein, 6.87 g; ash, 0.49 g; lipid, 6.26 g; crude fiber, 0.22 g; carbohydrate, 86.14 g) and inactive, micronized, and defatted soy flour was provided by CPA S.A. (Hernando, Argentina; 100 g dry flour contained protein, 54.97 g; ash, 7.09 g; lipid, 5.62 g; crude fiber, 1.77 g; carbohydrate, 30.61 g). CMC was purchased by Latinoquímica Amtex S.A. (Buenos Aires, Argentina), and xanthan gum was supplied by Saporiti S.A. (Buenos Aires, Argentina). Shortening (containing 82% total fat, 35% saturated fat, 22% monounsaturated fat, 25% polyunsaturated fat according to the supplier) and compressed yeast were obtained from Dánica (Llavallol, Argentina).

Breadmaking Process

The dough-base formulation used in the preparation of breads is the best of a series of trials (Sciarini et al. 2010a) and is shown in Table 1. It included corn flour, rice flour, inactive soy flour, shortening, salt, compressed yeast, and distilled water. The hydrocolloids used for the different formulations were CMC or xanthan gum (XG). Flour, salt, and eventually hydrocolloids were manually mixed. Then, pre-dispersed yeast, shortening and the rest of water were added and mixed for 3 min at speed 2 (214 rpm, Arno Planetaria mixer, Sao Paulo, Brasil). Seventy-five grams of the resultant batter were poured into individual aluminum cups and fermented for 60 min in a cabinet (Hengel, Le Coteau, France) at 30°C with 85% humidity. For full-baking process, baking was carried out in a single step (oven condo Miwe, Arnstein, Germany) at 200°C for 40 min (these samples were named as full baked bread (FBB)). Partial-baking process was carried out at 200°C for 25 min (first baking step; breads in this step were named as partially baked bread (PBB)). After baking, breads were allowed to cool at room temperature (23 ± 2°C) for 2 h (time for the bread to reach 30°C). Samples were stored in polyethylene bags for 7 days in a cold chamber at 4 ± 1°C (these samples were named as partially baked breads after 7 days of storage (PBB-d7)). After this period, samples were removed from the chamber and allowed to warm up until room temperature was reached, and final baking was carried out at 200°C for 15 min (second baking step; these samples were named as final part-baked bread (FPBB)). Final products of both processes were kept at room temperature for 2 h after baking before analysis. Two replications of breadmaking were performed.

Technological Evaluation of Breads

Specific Loaf Volume (AACC (1995) Approved Method 10–05)

Three bread loaves were weighed 2 h after the end of baking; bread volume was determined by rapeseed displacement. Specific bread volume was then calculated.

Crumb Texture Analysis

Two bread loaves were longitudinally cut using a slice regulator to obtain 15-mm thick slices. Two slices were taken from the center of each loaf and were used to evaluate crumb texture. Texture profile analysis (TPA) was carried out using a TA-TX2i Texture Analyser (Stable Micro Systems, Surrey, UK) equipped with the 25 kg load cell and a 25 mm cylindrical probe. The test was performed at a test speed of 5.0 mm/s to compress the bread crumb to 40% of its original height. TPA was also carried out after 24 and 72 h storage at 25°C.

Crumb and Crust Water Content (AACC (1995) Approved Method 44–40)

Two to three grams of crumb or crust were taken from two bread loaves, and were dried in a forced convection oven (Memmert, Schwabach, Germany) at 100°C to constant weight (about 24 h). The samples were cooled in a desiccator and weighed with an analytical balance (sensitivity 0.1 mg). For crust water content determination, 3 mm of the upper section of the loaf were considered.

Crumb Image Analysis

Slices 15-mm thick from three bread loaves were scanned using a Hewlett Packard Scanjet G3010 scanner (HP, Palo Alto, USA) to produce tiff images (2,592 × 2,604 pixels) using HP Photosmart premier 6.5 software. Digital images were analyzed using ImageJ Software (1.41o) according to Ribotta et al. (2010). Cell average area (cm2) and relative cell area (%) were determined.

Bread volume, crumb texture, crumb, and crust moisture content and crumb image analysis were performedon both, breads resulting from full-baking and partial-baking processes, and on intermediate products of part-baking process (after partial baking for 25 min—PBB, cold storage—PBB-d7, and final baking step for 15 min—FPBB), in order to obtain information about the impact of each step on the quality of final products.

Differential Scanning Calorimetry

Samples of partial and full baked final products were analyzed after 2 h (day 0), 24 h (day 1), and 72 h (day 3) after final baking. Three samples of breadcrumb core were taken from each loaf, and pressed manually, and portions of 30 ± 3 mg were weighed in a hermetically sealed stainless steel pan and analyzed with a Pyris 7 differential scanning calorimeter (DSC; Perkin Elmer, USA). The DSC was calibrated using mercury, distilled water and indium. An empty pan was used as reference. Calorimetric assays were made according to Ribotta and Le Bail (2007). Briefly, samples were fast cooled from 25 to −50°C, held at this temperature for 5 min and heated at 2°C/min from −50 to 120°C. The onset (T o) temperature and the transition enthalpy (J/g) of ice melting and amylopectin retrogradation were calculated from thermograms.

Freezable water (FW) weight fraction was obtained from the relationship between the enthalpy of ice melting and latent heat of ice melting (334 J/g). FW weight fraction was determined by using a differential scanning calorimeter (Hamdami et al. 2004). Two bread loaves were used for DSC analysis.

Statistical Analysis

The results are expressed as mean values ± SD. The data obtained were statistically treated by variance analysis, while means were compared by Fisher’s LSD test at a significance level of 0.05. Correlation between variables was determined using Pearson’s coefficient. These tests were carried out using INFOSTAT statistical software (Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba, Argentina).

Results and Discussion

Bread Volume

Specific loaf volume (SV) was higher in full-baked breads than their part-baked counterparts (Table 2). SV of the FPBB varied according to the formulation, being highest for samples with added CMC. For the FBB, no significant differences were found among samples. Similar results were reported for wheat part-baked breads (Bárcenas et al. 2004), where hydroxypropylmethylcellulose addition increased SV, and full-baked breads had higher SV than part-baked ones. Although hydrocolloid effect on bread-specific volume is highly dependent on the formulation used, the level of hydrocolloid incorporation and the origin and source of the gum, in systems with high water content it has been shown that hydrocolloids enhance bread volume through an increase in batter consistency, which facilitates gas retention during mixing and proofing (Sciarini et al. 2010b).

Besides, it has been reported that xanthan gum stabilizes foams in denatured soy protein solution (as those found in the inactive soy flour used in this study) and that both polymers may interact at the air–water interface, influencing the surface rheology and the protein aggregation (Carp et al. 2001). This stabilizing effect may reduce bubbles coalescence during proofing and the first part of baking process.

Concerning CMC, it has been published that in soy protein–CMC blends under heating (50°C) conditions both polymers form a homogeneous, single phase, and this was attributed to the crosslinking introduced by Maillard reaction between both polymers (Su et al. 2010). This close interaction may enhance dough air holding capacity leading to increased bread volume.

Regarding the cold storage of PBB, SV did not change within storage time, i.e. no significant contraction of bread structure was caused by storage at 4°C.

FPBB with added xanthan (XG bread) showed lower SV than partially baked xanthan breads after the first baking step (PBB). This trend was not observed on CMC-added breads and control breads, where SV was similar (Table 2).

Crumb Structure

The crumb structure of bread is an important factor determining the perception of bakery products by the consumer. Regarding wheat bread, in general, a fine crumb structure is appreciated; in some products, like French baguettes and flat breads, a coarse structure is preferred. Generally, gluten-free bread shows high cell wall thickness and a coarse structure caused by the lack of the gluten network to retain CO2. Figure 1 shows the macroscopic structure of gluten-free bread crumbs. A visual inspection of crumb structure shows a coarse and more or less regular structure according to the baking process and formulation. Breads obtained from a part-baking process look denser because of the poor air retention capacity of the matrix. Confirming this observation, crumb image analysis showed that FPBB had a smaller cell average size and a lower cell total area than FBB (Fig. 2), which is related to a lower specific bread volume.

Control crumb structure remained unchangeable during the three-step part-baking process, while breads with hydrocolloids showed small cell average size after the cold storage period.

Among the hydrocolloid added samples, CMC-FPBB presented lower cell average size, showing a more homogeneous structure than control and XG breads. Fermented dough acts as a foam. In wheat dough, gluten network retains the gas produced by the yeast. In gluten-free breads, the addition of a foaming (with the ability to retain gas during mixing and proofing) and stabilizing agent is crucial. CMC is known for being a surface-active polysaccharide, with foaming (emulsifying) ability (Dickinson 2003). Besides, CMC prevents bubbles from aggregating because of the steric stabilization mechanism (Dickinson and Galazka 1992). Thus, breads with CMC addition show numerous small bubbles. Xanthan gum is known to be a good suspension stabilizer, while breads with XG showed no significant differences in cell average size and total cell number in comparison to control bread.

From Fig. 2 it is evident that bread internal structure shrank during storage at 4°C, represented by a decrease in cell average size and a constant cell relative area, even though no changes were detectable on bread volume. Ribotta and Le Bail (2007) reported a similar behavior working with part-baked wheat bread, with a freezing storage in between both baking steps. Although they did not find any difference in bread volume during different times of freezing storage, they observed crumb shrinking during cooling, with the most pronounced slope occurring from room temperature to 3–0°C. Other authors (Lucas et al. 2005) suggested that the retraction of the breadcrumb during cooling/freezing occurred as a result of compression of the gas phase and possibly the active retraction of the macromolecules constituting the dough. Nevertheless, the tensile forces developed because of crumb shrinking may not be necessarily sufficient to provoke a contraction of breadcrust leading to a decrease in SV. Regarding hydrocolloid effect on this phenomenon, data did not show a clear trend.

Crumb and Crust Moisture

Redistribution of moisture during part-baking process was followed by determining crust and crumb moisture (Table 2). Breads from CMC-added flour mix showed lower total water content after the end of part-baking process than no-additive and XG bread. This could be due to the higher SV of CMC-added samples: the larger the exposed surface to oven conditions, the higher the water evaporation from the surface.

The crumb of final products from part-baked breads showed lower moisture contents than final products from full-baked breads, since water migration from the crumb to the crust occurred during the storage at 4°C. PBB crust (first baking step) showed higher water amounts, since it was kept in the oven just for 25 min. During cold storage (7 days, 4°C), water migration occurred from the crumb to the crust, thus increasing crust moisture content. This high amount of water evaporated from the surface when the sample was then subjected to a second baking step (200°C for 15 min). This may be the reason why crust moisture of FPBB was lower than that of FBB. Water migration from the crumb to the crust occurred during cold storage in CMC and no-additive samples, as shown by crumb and crust moisture decrease and increase, respectively (Table 2). This result was expected because of the moisture gradient between crust and crumb produced by part-baking process. Only XG-added samples presented no significant differences between part-baked breads and cold-stored breads, probably because of the high moisture content of crust after the part-baking process in XG samples.

Crumb Aging Properties

Crumb hardening is a complex process caused by simultaneous phenomena. It is known that amylopectin retrogradation is the most important one, but changes occurring in the amorphous regions, water loss and redistribution, amylose recrystallization, and interactions between starch and gluten, also contribute to crumb hardening increase (Zobel and Kulp 1996; León et al. 1997; He and Hoseney 1990; Martin et al. 1991; Czuchajowska and Pomeranz 1989; Gray and Bemiller 2003).

Overall, full-baked breads showed lower crumb hardness than part-baked ones (p < 0.05; Table 3), as the latter showed lower SV. Considering that amylopectin retrogradation enthalpy was negligible 2 h after final baking for both baking processes (data not shown), the difference in crumb hardness could be explained by the formation of amylose aggregates that cannot melt at <150°C (Eberstein et al. 1980). Hydrocolloid addition decreased crumb hardness in both processes.

During storage at room temperature, crumb hardness increased significantly (p < 0.05) with time (Table 3). The final breads from part-baking process showed higher initial crumb hardness than full-baked breads, which can be explained in terms of the lower specific volume, the additional water loss and the structural changes on amylopectin, caused by the interrupted baking process. Water may be an important parameter for the hardening process (a negative correlation was found between crumb moisture and crumb hardness, p < 0.05, r = −0.64). It acts as a plasticizer for the amorphous regions, and may affect the rate and mode of starch crystallization (Davidou et al. 1996).

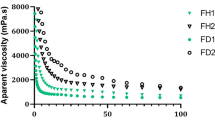

Crumb hardness was monitored during part-baking process (Fig. 3). Hardness values of PBB ranged from 53.4 to 90.3 N. After cold storage period, hardness increased from 130.9 to 173.1 N, which could be mainly related to the amylopectin recrystallization. Similar results were reported by Ribotta and Le Bail (2007), who studied thermo-mechanical profile of wheat part-baked bread during frozen storage. After the final baking step, crumb hardness decreased because the high temperature melted aged amylopectin fraction. However, the crumb hardness values of FPBB were higher than PBB, since higher amount of water was lost and, consequently, more entanglements were formed between starch and protein macromolecules. Wheat bread freshness depends on extent of the staling process in which crumb moisture content, starch composition, and time and temperature of treatment are involved (Zobel and Kulp 1996). Incomplete refreshing of breads that have been reheated can be due to resistant sites being formed, changes in protein structure or crumb moisture redistribution (Pisesookbunterng et al. 1983). This phenomenon is extrapolated to part-baked gluten-free breads, where, during cold storage (7 days), more molecule–molecule interactions are susceptible to be formed, giving rise to these resistant sites.

Several studies have demonstrated the positive effect of hydrocolloid on baked goods quality (Gujral et al. 2004; Lorenzo et al. 2009; Gambus et al. 2001). On the other hand, Lazaridou et al. (2007) observed that crumb hardness was not affected by the addition of hydrocolloids such as pectin, CMC, and agarose. Instead, xanthan (1–2 g/100 g flour basis) had an unfavorable influence on crumb hardness. It is worth to highlight, however, that comparisons between the effects of hydrocolloids on gluten-free breads found in the literature are quite difficult since gluten-free flours vary largely in starch characteristics and protein composition. Besides, as stated above, hydrocolloid effect depends on the source of the gum and the amount of water used. In this study, both xanthan and CMC addition had a positive effect on crumb hardness throughout part-baking process and during storage at 25°C, as it is shown by the lower hardness values compared to control sample (Fig. 3 and Table 3). The softening effect of hydrocolloids was not related to bread volume (Table 2, Fig. 1). The hydrocolloids are added to bakery products to improve their shelf life by keeping the moisture content and retarding the staling (Collar et al. 1999; Bárcenas et al. 2004; Gray and Bemiller 2003). Davidou et al. (1996), working with wheat bread, reported that both, the degree of crumb hardness and the rate of staling during storage, were reduced by adding hydrocolloids. They proposed that gums modified the organization of the amorphous phase of crumb, perhaps by inhibiting protein–starch interactions and/or the development of macromolecular entanglement.

Amylopectin retrogradation was assessed after 72 h of bread storage. As expected, the enthalpy of amylopectin retrogradation measured on the center of the crumb increased significantly (p < 0.05) after 3 days of storage (Table 4). The final breads from part-baking process showed higher amount of retrograded amylopectin than full-baked breads, which is in agreement with the hardness trend.

It is described in the literature that, even under optimum conditions, part-baked breads are more prone to stale than full-baked breads (Ribotta 2002). Takaya et al. (2000) working with heat-moisture treated (pre-gelatinized) corn starch, found that retrogradation ratio (dHretr/dHgel) became faster by heat–moisture treatment, concluding that this treatment promoted the retrogradation of corn starch. Likewise, studies carried out in refreshed (rebaked) wheat bread show that, upon staling, breadcrumb is more prone to stale when compared to control breads (without rebaking) (Hug-Iten et al. 2003). Our results are consistent with these findings. It is possible that starch gelatinized during the first baking step (25 min) behaves in a different way when compared to that gelatinized in a one-step process (40 min), i.e. water availability, core temperature, and time of heat exposure are variables to take into account.

In this study, CMC and xanthan addition decreased amylopectin retrogradation after 72 h of storage compared to no-additive bread, and this behavior was found in part-baking process as well as in traditional process. Similar results were obtained by Bárcenas et al. (2004) working with part-baked wheat breads, added with different hydrocolloids.

Freezable Water

The physical state of water in food systems is believed to play an important role in the structural, physical, chemical, and sensory properties of foods. However, the behavior of water during dough mixing and bread baking and aging is not fully understood. Some unfreezable water (Leung and Steinberg 1979) cannot be easily removed by drying. This led these researchers to propose that some portion of water is tightly linked within the dough matrix.

Results for freezable water obtained in the present study are shown in Table 4. No significant differences were found among different formulations, baking processes, or bread storage time. This could be due to both, high water amount used in the recipe and low hydrocolloid level added.

Conclusions

Part-baking process is a suitable process to obtain gluten-free breads. Storage of these breads at 4°C for a week makes them adequate for home consumption, since gluten-free full-baked breads are very prone to stale. Interrupted-baking process diminishes final bread quality (lower specific volume, higher initial crumb firmness, and denser crumb structure) but negative effects can be partially mitigated by hydrocolloid (CMC and xanthan gum) addition. Hydrocolloids, especially CMC, improved specific volume and diminished crumb firmness, and they decreased amylopectin retrogradation as well. Regarding the part-baking process itself, the negative changes in bread characteristics that occurred during storage at 4°C could be reversed in the second baking step.

References

American Association of Cereal Chemist (AACC). (1995). Approved methods of the AACC (9th ed.). St Paul: The Association.

Bárcenas, M. E., & Rosell, C. M. (2006). Effect of frozen storage time on the bread crumb and aging of part-baked bread. Food Chemistry, 95(3), 438–445.

Bárcenas, M. E., Haros, M., Benedito, C., & Rosell, C. M. (2003). Effect of freezing and frozen storage on the staling of par-baked bread. Food Research International, 36(8), 863–869.

Bárcenas, M. E., Benedito, C., & Rosell, M. C. (2004). Use of hydrocolloids as bread improvers in interrupted baking process with frozen storage. Food Hydrocolloids, 18(5), 769–774.

Cabrera-Chávez, F., & Calderón de la Barca, A. M. (2010). Trends in wheat technology and modification of gluten proteins for dietary treatment of coeliac disease patients. Journal of Cereal Science, 52(3), 337–341.

Carp, D. J., Bartholomai, G. B., Relkin, P., & Pilosof, A. M. R. (2001). Effects of denaturation on soy protein–xanthan interactions: comparison of a whipping–rheological and a bubbling method. Colloids and Surfaces B: Biointerfaces, 21, 163–171.

Collar, C., Andreu, P., Martinez, J. C., & Armero, E. (1999). Optimization of hydrocolloid addition to improve wheat bread dough functionality: a response surface methodology study. Food Hydrocolloids, 13(6), 467–475.

Czuchajowska, Z., & Pomeranz, Y. (1989). Differential scanning calorimetry, water activity, and moisture contents in crumb center and near-crust zones of bread during storage. Cereal Chemistry, 66(4), 305–309.

Davidou, S., Le Meste, M., Debever, E., & Becaert, D. A. (1996). Contribution to the study of staling of white bread: effect of water and hydrocolloid. Food Hydrocolloids, 10(4), 375–383.

Dickinson, E. (2003). Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocolloids, 17(1), 25–39.

Dickinson, E., & Galazka, V. B. (1992). Emulsion stabilization by protein/polysaccharide complexes. In G. O. Phillips, D. J. Wedlock, & P. A. Williams (Eds.), Gums and stabilisers for the food industry, Vol 6 (pp. 351–362). Oxford, UK: Pergamon Press Ltd.

Eberstein, K., Hoepcke, R., Konieczny-Janda, G., & Stute, R. (1980). DSC-Untersuchungen Staerk. Starch, 32(12), 397–404.

Feighery, C. (1999). Celiac disease. British Medical Journal, 319(7204), 236–239.

Fik, M., & Surowka, K. (2002). Effect of prebaking and frozen storage on the sensory quality and instrumental texture of bread. Journal of the Science of Food and Agriculture, 82(11), 1268–1275.

Gambus, H., Nowotna, A., Ziobro, R., Gumul, D., & Sikora, M. (2001). The effect of use of guar gum with pectin mixture in gluten-free bread. Electronic Journal of Polish Agricultural Universities, 4(2), 1–13.

Gray, J. A., & Bemiller, J. N. (2003). Bread staling: molecular basis and control. Comprehensive Reviews in Food Science and Food Safety, 2(1), 1–21.

Guarda, A., Rosell, C. M., Benedito, C., & Galotto, M. J. (2004). Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocolloids, 18(2), 241–247.

Gujral, H. S., & Rosell, C. M. (2004). Improvement of the breadmaking quality of rice flour by glucose oxidase. Food Research International, 37(1), 75–81.

Gujral, H. S., Haros, M., & Rosell, C. M. (2004). Improving the texture and delaying staling in rice flour chapati with hydrocolloids and α-amylase. Journal of Food Engineering, 65(1), 89–94.

Hamdami, N., Monteau, J.-Y., & Le Bail, A. (2004). Thermophysical properties evolution of French partly-baked bread during freezing. Food Research International, 37(7), 703–713.

He, H., & Hoseney, R. C. (1990). Changes in bread firmness and moisture during long-term storage. Cereal Chemistry, 67(6), 603–605.

Hug-Iten, S., Escher, F., & Conde-Petit, B. (2003). Staling of bread: role of amylose and amylopectin and influence of starch-degrading enzymes. Cereal Chemistry, 80(6), 654–661.

Lazaridou, A., Duta, D., Papageorgiou, M., Belc, N., & Biliaderis, C. G. (2007). Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. Journal of Food Engineering, 79(3), 1033–1047.

León, A. E., Durán, E., & Benedito de Barber, C. (1997). Firming of starch gels and amylopectin retrogradation as related to dextrin production by α-amylase. Zeitschrift fur Lebensmittel-Untersuchung und -Forschung, 205(2), 131–134.

Leung, H. K., & Steinberg, M. P. (1979). Water binding of food constituents as determined by NMR, freezing, sorption and dehydration. Journal of Food Science, 44(4), 1212–1216.

Lorenzo, G., Zaritzky, N. E., & Califano, A. N. (2009). Rheological characterization of refrigerated and frozen non-fermented gluten-free dough: effect of hydrocolloids and lipid phase. Journal of Cereal Science, 50(2), 255–261.

Lucas, T., Quellec, S., Le Bail, A., & Davenel, A. (2005). Chilling and freezing of part-baked bread. Part II: experimental assessment of water phase changes and structure collapse. Journal of Food Engineering, 70(2), 151–164.

Mandala, I., Kapetanakou, A., & Kostaropoulos, A. (2008). Physical properties of breads containing hydrocolloids stored at low temperature: II—effect of freezing. Food Hydrocolloids, 22(8), 1443–1451.

Martin, M. L., Zeleznak, K. J., & Hoseney, R. C. (1991). A mechanism of bread firming. I. Role of starch swelling. Cereal Chemistry, 68(5), 498–503.

Periolo, N., & Cherñavsky, A. C. (2006). Coeliac disease. Autoimmunity Reviews, 5(3), 202–208.

Pisesookbunterng, W., D’Appolonia, B., & Kulp, K. (1983). Bread staling studies. II. The role of refreshening. Cereal Chemistry, 60(4), 301–305.

Renzetti, S., Dal Bello, F., & Arendt, E. K. (2008). Microstructure, fundamental rheology and baking characteristics of batters and breads from different gluten-free flours treated with a microbial transglutaminase. Journal of Cereal Science, 48(1), 33–45.

Ribotta, P. D. (2002). PhD Thesis: Estudio de las transformaciones físico-químicas que se producen durante el procesamiento de las masas congeladas. Facultad de Ciencias Exactas, Universidad Nacional de La Plata, pp 166.

Ribotta, P. D., & Le Bail, A. (2007). Thermo-physical and thermo-mechanical assessment of partially baked bread during chilling and freezing process: impact of selected enzymes on crumb contraction to prevent crust flaking. Journal of Food Engineering, 78(3), 913–921.

Ribotta, P. D., Ausar, S. F., Morcillo, M. H., Pérez, G. T., Beltramo, D. M., & León, A. E. (2004). Production of gluten-free bread using soybean flour. Journal of the Science of Food and Agriculture, 84(14), 1969–1974.

Ribotta, P. D., Pérez, G. T., Añón, M. C., & León, A. E. (2010). Optimization of additive combination for improved soy-wheat bread quality. Food and Bioprocess Technology, 3(3), 395–405.

Rosell, C. M., Rojas, J. A., & Benedito de Barber, C. (2001). Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids, 15(1), 75–81.

Sciarini, L. S., Ribotta, P. D., León, A. E., & Pérez, G. T. (2010a). Influence of gluten-free flours and their mixtures on batter properties and bread quality. Food and Bioprocess Technology, 3(4), 577–585.

Sciarini, L. S., Ribotta, P. D., León, A. E., & Pérez, G. T. (2010b). Effect of hydrocolloids on gluten-free batter properties and bread quality. International Journal of Food Science and Technology, 45(11), 2306–2312.

Sollid, L. (2002). Coeliac disease: dissecting a complex inflammatory disorder. Nature Reviews, 2, 647–655.

Su, J.-F., Huang, Z., Yuan, X.-Y., Wanga, X.-Y., & Li, M. (2010). Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydrate Polymers, 79(1), 145–153.

Takaya, T., Sano, C., & Nishinari, K. (2000). Thermal studies on the gelatinisation and retrogradation of heat–moisture treated starch. Carbohydrate Polymers, 41(1), 97–100.

Thompson, T. (2001). Wheat starch, gliadin and the gluten free diet. Journal of the American Dietetic Association, 101(12), 1456–1459.

Turabi, E., Sumnu, G., & Serpil Sahin, S. (2008). Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food and Bioprocess Technology, 1(1), 64–73.

Vulicevic, I. R., Abdel-Aal, E.-S. M., Mittal, G. S., & Lu, X. (2004). Quality and storage life of par-baked frozen breads. LWT Food Science and Technology, 37(2), 205–213.

Zobel, H., & Kulp, K. (1996). The staling mechanism. In H. Zobel (Ed.), Baked goods freshness (pp. 1–64). New York: Marcel Dekker.

Acknowledgment

The authors would like to acknowledge CONICET-CNRS (International Cooperation Project) and to EGIDE for the support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sciarini, L.S., Pérez, G.T., de Lamballerie, M. et al. Partial-Baking Process on Gluten-Free Bread: Impact of Hydrocolloid Addition. Food Bioprocess Technol 5, 1724–1732 (2012). https://doi.org/10.1007/s11947-011-0529-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0529-3