Abstract

The objective of this study was to develop a formulation that can retard staling/retrogradation of cheese breads without compromising their texture and expansion properties. During baking the dough expands and becomes soft, with lower density. Binary mixtures of cassava starch (Native + Oxidized) and with guar gum (Oxidized + Guar Gum) as well as a ternary mixture (Native + Oxidized + Guar Gum) were prepared. The mixtures were analyzed for freeze–thaw stability, expansion, pasting, thermal structural and retrogradation properties. The results were compared with those of sour cassava starch (polvilho azedo—PA), native cassava starch (N) and oxidized cassava starch (O). Moreover, cheese breads were prepared with these mixtures and evaluated during storage. The ternary mixture N + O + GG showed superior freeze–thaw stability (syneresis of 4.9, 7.8 and 11.0% in 1st, 2nd and 3rd cycles, respectively); the low retrogradation of this sample was confirmed both by DSC and FTIR analyses. The sample N + O + GG had a high expansion (> 10 mL/g) and the cheese breads developed with this mixture had a slower staling. Our results confirmed that the mixture N + O + GG can improve formulations of gluten-free baked foods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing demand for gluten-free baked foods is parallel to the increase of celiac disease and other restrictions related to gluten consumption (Lazaridou et al. 2007). It mainly involves the use of starches or hydrocolloids to imitate the viscoelastic properties of gluten and improve the structure and acceptability of foods (Lazaridou et al. 2007). Examples of gluten-free baked foods include the cheese breads (cheese rolls, pão de queijo, in Portuguese) that are made with cassava starch and very popular in Brazil.

Cheese bread is a baked product that is expanding to the international market due to dough freezing possibility (Silva et al. 2006). However, it rapidly loses freshness after being baked (bread staling) and in the case of frozen dough, water release (syneresis) can compromise quality (Demirkesen et al. 2014). These problems occur due to retrogradation (Ronda and Roos 2011), which is the re-association in an ordered structure of starch polysaccharides resulting in hard texture, volume reduction and syneresis (Rosalina and Bhattacharya 2002).

The main ingredient to prepare cheese breads is the starchy fraction, usually native cassava starch and/or cassava sour starch, known as polvilho azedo in Brazil. Polvilho azedo is produced by natural fermentation and sun drying of native cassava starch, being considered a special starch with high expansion property (Demiate et al. 2000). However, as its production is carried out by small factories that use natural drying without a good control of the process, the product is often uneven, with hygienic problems and non-standard technological properties. Native cassava starch is used to replace partially or totally polvilho azedo in cheese bread formulations, but despite some advantages like lower syneresis during the 1st freeze–thaw cycle (Aplevicz and Demiate 2007), it has limitations for many applications in the food industry; thus, modifications or addition of other ingredients or additives are required to improve the technological properties of native cassava starch (Kaur et al. 2011).

Oxidation is a chemical modification of starch in which the free hydroxyl groups of glucose monomers are oxidized to carbonyl and carboxyl groups (Sangseethong et al. 2009). The advantage of oxidation is that it causes an increase in starch expansion property that is interesting for use in baked foods (Demiate et al. 2000). Hydrocolloids (gums) have good accessibility, relative low cost, are safe for food use and have also been used in combination with native starches to improve technological properties (Krüger et al. 2003). Guar gum has been recognized for reducing syneresis of starch pastes (Funami et al. 2005; Lee et al. 2002; Sudhakar et al. 1996) and some studies have been conducted to show its potential for application in the baking industry as an anti-staling agent (Shaikh et al. 2008).

Thus, the objective of this study was to develop a mixture of starches and gums able to increase freeze–thaw stability and to retard staling of gluten-free baked foods (cheese bread) without compromising their expansion property.

Materials and methods

Materials

This study was made using native cassava starch supplied by the company “Amidos Pasquini” (Nova Esperança, PR, Brazil). A commercial sample of cassava sour starch was obtained from the local market (Ponta Grossa, PR, Brazil) and was used as a control sample for comparison. The guar gum (pH 6.25) was provided by “Nutract” company (Chapecó, SC, Brazil) and sodium hypochlorite 10–12% (w/v) was purchased from “Cloroquímica” (Curitiba, PR, Brazil).

Starch oxidation

The cassava starch was oxidized according to the method described by Kuakpetoon and Wang (2001), with some modifications. A starch slurry (40%, w/w) was prepared and stirred in an IKA RW 20 digital mixer (Campinas, SP, Brazil) at 450 rpm, and its pH was adjusted to 7.5. A standardized solution of sodium hypochlorite (8.4%, w/v) was slowly added (at an interval of 30 min) to obtain oxidized starch (2% w/v sodium hypochlorite), maintaining the pH at 7.5. After addition of hypochlorite, the suspension was kept at pH 7.5 for 45 min under stirring and then neutralized to pH 7.0. To stop the oxidation sodium metabisulphite was added (200 ppm relative to the initial weight of starch). The precipitate was filtered in a Büchner funnel connected to a vacuum pump (TECNAL TE-058, Piracicaba, SP, Brazil) and washed with 4 L of distilled water. The sample was dried at 40 °C/24 h in an oven with forced air circulation (TECNAL TE-394/2, Piracicaba, SP, Brazil) and then the dry starch was sieved (60 mesh).

Preparation of binary and ternary mixtures

Native cassava starch (N) and oxidized cassava starch (O) were mixed in a ratio of 50:50 (w/w) to obtain the mixture coded N + O. The starch-gum mixtures were prepared considering 100% solids, i.e., without water. Oxidized cassava starch (96%) and guar gum (4%) were mixed to obtain binary mixture O + GG. The ternary mixture N + O + GG was prepared with native cassava starch (48%), oxidized cassava starch (48%) and guar gum (4%). The proportions were chosen from preliminary tests (data not shown). The powdered starches were mixed with manual stirring.

Freeze–thaw stability

Syneresis was analyzed according to Aplevicz and Demiate (2007). A starch slurry (8% w/w) (in the case of starch-gum mixtures, concentration of 0.32% of gum with 8% total solids was used) was heated to boiling for 10 min, with constant manual stirring. Then, the samples were stored in plastic bags and frozen at − 18 °C for 72 h. After this period, they were thawed in an oven (TECNAL TE-394/2, Piracicaba, SP, Brazil) at 40 °C for 3 h. Water release was measured gravimetrically and the freeze–thaw process was repeated for three consecutive cycles. The amount of solution released was expressed as percentage of the mass of gelatinized starch used in the analysis.

Expansion during baking

Expansion during baking of starches and their mixtures was done according to Demiate et al. (2000). The baking expansion was determined by rapeseed displacement method and expressed as the specific volume (mL/g) of the biscuits.

Pasting properties

The pasting properties of the starches and their mixtures were analyzed according tothe method 61-02 of AACC (1995) in a Rapid Visco Analyzer (RVA-4, Newport Scientific Pty, Ltd, Warriewood, NSW, Australia).

Thermal properties

Gelatinization properties of the starches and their mixtures were determined using a differential scanning calorimeter (DSC Q-200, TA-Instruments, New Castle, DE, USA) calibrated with indium standard (99.99%) and an empty aluminum pan was used as reference. A 4:1 (water:starch, w/w) mixture was weighed in aluminum pans, sealed and left for 2 h to equilibrate. Samples (2–3 mg) were heated at a rate of 10 °C/min from 20 to 100 °C. The transition temperatures (To, Tp, e Tc) and the gelatinization enthalpy change (ΔHgel) were measured. After thermal analysis, the pans containing the gelatinized sample were frozen at − 18 °C for 15 days, afterward, thawed every 72 h (1 h at room temperature) and then frozen again. After 15 days, the samples were further analyzed for thermal properties after retrogradation. The retrograded samples were heated from 20 to 80 °C at a rate of 5 °C/min.

Fourier-transform infrared (FTIR) spectroscopy

FTIR analysis was performed both with the native and retrograded samples according to the methodology described by Demiate et al. (2000). A Fourier-transform infrared spectrophotometer (FTIR) Shimadzu IR Prestige-21 (Shimadzu Corporation, Kyoto, Japan) was used and the spectra collected in the range 4000–400 cm−1. In the study of retrograded samples, a starch suspension (4% w/w) was heated at 95 °C to complete gelatinization of the granules and, then, films were made. Pellets were produced by mixing 100 mg of KBr and 2 mg of sample and they were placed in a carver hydraulic press. Four replicates (pellets) were made for each sample. After obtaining the spectrum, some transformations (smoothing 15 points and baseline correction) were performed using the IRsolution v.1.4 software (Shimadzu Corporation, Kyoto, Japan).

Preparation of cheese breads

Six different formulations of cheese breads were made, changing only the starchy mixtures (Table 1). The amounts of ingredients were based in Aplevicz and Demiate (2007).

Firstly, the starch mixture scalding was done with boiling water. Secondly, some ingredients (milk, soybean oil, salt and grated mozzarella cheese) were added to the dough and it was homogenized for approximately 1 min. After cooling to room temperature, egg was added and mixed to the dough for an additional minute. The cheese breads were placed in molds and baked in an oven at 200 °C for 15 min.

Cheese bread staling

Cheese bread staling was evaluated by texture analysis in a TA.XT Plus texture analyzer (Stable Micro Systems, Surrey, UK) using a 36 mm probe (P36R), pre-test speed of 1.0 mm/s, test speed of 5.0 mm/s, post-test speed of 5.0 mm/s and 40% deformation. The parameter evaluated was the hardness (N) of the cheese bread crumbs (2 cm thick) at different time intervals: 2, 8, 24 and 30 h after baking. To follow the cheese bread staling, they were stored in plastic bags at room temperature (25 °C) to prevent moisture changes. Six replicates were made for each test.

Statistical analysis

Analyses were performed in triplicate and data presented as mean ± standard deviation. Shapiro–Wilk test was applied (p > 0.05 was considered normal) and for the data that did not follow a normal distribution the Box-Cox transformation was used (data not shown). The normal data were evaluated for homogeneity of variances by Brown-Forsythe test (p > 0.05 was considered homogeneous). Normal and homogeneous data were evaluated by analysis of variance (ANOVA) followed by Fisher LSD test. A p < 0.05 value was considered significant and statistical analysis was performed using STATISTICA v.12.7 software (Statsoft, Tulsa, OK, USA).

Principal Component Analysis (PCA) was applied to the FTIR spectra in order to search for similarities between the samples based on the presence of functional groups and also on the effect of retrogradation. The analysis was carried out using the Pirouette v. 4.0 software (Infometrix®, Bothell, WA, USA). PCA was performed on two different data sets. At first, with native samples, the analysis was performed at 700–2000 cm−1 and, then, with the retrograded samples, at 800–1100 cm−1; for both data sets, the spectra were converted to the 1st derivative. The spatial distribution of the samples after the PCA was given by a two-dimensional graph.

Results and discussion

Freeze–thaw stability and expansion property

Retrogradation and syneresis occur quickly at low temperatures and are main concerns in refrigerated and frozen products. Freeze–thaw stability analysis is important to determine the starch applicability in refrigerated and/or frozen foods (Aplevicz and Demiate 2007). The results for syneresis percentage and expansion during baking of samples PA, N, O, N + O, O + GG and N + O + GG are shown in Table 2. The percentage of water release increased in each freeze–thaw cycle for all samples. This increase is expected, since freeze–thawing causes a phase separation in the starch slurry, one rich and another deficient in starch. In each freeze–thaw cycle, the concentration of retrograded amylopectin molecules in the rich starch aqueous phase will increase, increasing water release (Matsuguma et al. 2009).

Water amounts released from pastes of the sample N were significantly smaller than those from pastes of the sample O during the three freeze–thaw cycles (Table 2). Other studies have already shown higher water release in oxidized starch pastes (Aplevicz and Demiate 2007; Matsuguma et al. 2009). Partial depolymerization of starch macromolecules during oxidation facilitates molecular re-association and can explain higher syneresis of oxidized starch pastes, independently from the botanical source (Aplevicz and Demiate 2007). Pastes from sample PA had also larger water release (27.83, 40.88 and 45.84% at 1st, 2nd and 3rd freeze–thaw cycles, respectively) when compared with pastes from sample N (9.70, 19.08 and 30.33%), and this water release was even larger than that of pastes from sample O (18.36, 22.59 and 45.84%). Aplevicz and Demiate (2007) determined the syneresis of pastes from cassava starch of different producers and showed that it ranged 18–68% at the 1st freeze–thaw cycle, 45–72% at the 2nd cycle and 47–73% at the 3rd cycle.

In relation to the N + O binary mixture, its paste had lower syneresis at the 2nd and 3rd freeze–thaw cycles when compared with the pastes of PA, N and O (p < 0.05). It was expected that for the two-component mixtures an intermediate behavior of its individual components would be found, however, it was not what happened in this study (Table 2). Starch mixtures may present additive or non-additive effect on physicochemical properties, depending on starch combination and mixing ratio. The additive effect occurs when each starch has an independent behavior in the mixture, i.e., no interaction occurs between the different starches; on the other hand, in the non-additive effect, changes in one of the starches present in the mixture will influence the behavior of others, resulting in starch interactions (Puncha-Arnon et al. 2008). Thus, based on this theory, it can be concluded that the sample N + O had a non-additive effect for water release property. The sample N and the sample O interacted with each other and the water release was smaller than for each sample alone (N and O).

By observing Table 2, it can be concluded that guar gum was very effective in reducing syneresis of the pastes, both for the binary mixture (O + GG) and for the ternary mixture (N + O + GG). Guar gum acts as a water binder in aqueous suspensions containing starch, depriving amylose and amylopectin to use this water for recrystallization and preventing starch retrogradation even after repeated freeze–thaw cycles (Lee et al. 2002). Guar gum can interact with leached amylose of the starch granules, through hydrogen bonding, hindering amylose chains approximation and consequently reducing retrogradation (Sudhakar et al. 1996).

A feature valued by the food industry is the expansion property of baked foods. Polvilho azedo is well known in Brazil for presenting expansion property during baking (Demiate et al. 2000). As shown in Table 2, the sample PA had a high expansion (specific volume of 10.64 mL/g) whereas the value found for the sample N was 3.98 mL/g, in line with results reported by Demiate et al. (2000) and Marcon et al. (2009). With respect to the sample O, it has a higher expansion property (12.75 mL/g) when compared with samples PA and N. Our results agree with those reported by Aplevicz and Demiate (2007).

The mixture of native cassava starch with oxidized cassava starch resulted in an increase of expansion property, wherein sample N + O had the highest value of all samples (Table 2). In the same way as for freeze–thaw stability analysis the sample N + O had a non-additive effect on expansion property. The sample N interacted with the sample O, and the mixture N + O had a higher expansion property than for each starch counterpart. With respect to the addition of guar gum, there was a decrease of the expansion property of samples O and N + O (Table 2), but the sample N + O + GG showed a similar expansion value to PA (p > 0.05). Both N + O + GG and O + GG had a significantly higher expansion property than N (p < 0.05), showing the expansion potential of binary and ternary mixtures. The expansion during baking is caused by water vapor retention inside the dough when it has the appropriate physical behavior, comparable to the elasticity and extensibility of wheat gluten.

The expansion property is considered low when the specific volume is smaller than 5.0 mL/g, medium when it is between 5.0 and 10.0 mL/g and high when it is larger than 10.0 mL/g (Garcia and Leonel 2005). Thus, the sample N of this study can be classified as low expansion, the sample O + GG as medium expansion and samples PA, O, N + O and N + O + GG could be classified as high expansion.

Pasting properties

The RVA results are shown in Table 3 (supplementary material). The oxidation (sample O) caused a significant reduction in peak viscosity, trough viscosity, and final viscosity; low pasting viscosities were also found for the sample PA. These results are in line with those reported by Kuakpetoon and Wang (2001) for oxidized starches (sodium hypochlorite at 2% w/w) from corn and cassava and by Sandhu et al. (2008) for normal corn starch (oxidized with 1% w/w active chlorine). The reduced viscosities may be attributed to partial degradation of starch chains caused by oxidation, with molar mass reduction (Kuakpetoon and Wang 2001; Sandhu et al. 2008). With respect to polvilho azedo, Aplevicz and Demiate (2007) also observed a decrease in pasting viscosities compared to native cassava starch, due to damages in starch granules possibly caused by action of organic acids (lactic, acetic, propionic and butyric acid) and amylolytic enzymes.

The mixture of starches (sample N + O) provided a significant increase in peak viscosity compared to the single counterparts (N and O) proving the non-additive effect of mixture N + O in the peak viscosity. The addition of 4% guar gum, equivalent to 0.32% of gum in a suspension of 8% total solids, caused an increase in viscosities of the samples O + GG and N + O + GG when they were compared with the samples O and N + O, respectively; the ternary mixture N + O + GG had the highest trough viscosity and peak viscosity of all samples (Table 3). These results agree with others already published (Chaisawang and Suphantharika 2006) because guar gum affects starch pasting properties due to a strong interaction between the gum and starch macromolecules (Rosell et al. 2011).

With respect to setback, considering visco-amylographic analysis, sample N had the highest value (917 cP), followed by the ternary mixture N + O + GG (529 cP) and by the binary mixture N + O (484 cP). The samples O, O + GG and PA showed lower values (38, 71 and 155 cP, respectively). These values disagree with the results obtained in freeze–thaw stability analysis (Table 2) in which the higher freeze–thaw stability (and consequently lower retrogradation) followed the order: N + O + GG > O + GG > N + O > N > O > PA. Several authors have demonstrated that the setback viscosity obtained by RVA analysis and syneresis by freeze-thaw cycles were contradictory (Aplevicz and Demiate 2007; Funami et al. 2005; Lee et al. 2002; Matsuguma et al. 2009).

The setback viscosity is obtained by the difference between final viscosity (paste viscosity at 50 °C) and trough viscosity (paste viscosity at 95 °C). Starch retrogradation is a slow process (recrystallization of amylopectin can take days or weeks, being named long-term retrogradation) (Karim et al. 2000) that occurs more rapidly at temperatures around or below 0 °C (Rosalina and Bhattacharya 2002). The RVA analysis was done considering 50 °C the final temperature, which is not low enough to promote a full reorganization of amylose and amylopectin molecules. Furthermore, the pasting process of heating and cooling in RVA is a rapid procedure (about 23 min) and there is not enough time for macromolecules to reorganize (mainly amylopectin). Freeze–thaw stability was evaluated at temperatures below 0 °C, requiring about 10 days (three freeze–thaw cycles) to completing the analysis. Thus, the temperature is low enough and the starch pastes storage time is long, facilitating recrystallization of macromolecules (mainly amylopectin) and retrogradation phenomenon is easily evidenced by water release (syneresis).

Thermal properties

It is observed in Table 4 that all samples had lower gelatinization enthalpy changes than sample N (N > O > N + O > PA > O + GG > N + O + GG). The decrease of starch gelatinization enthalpy change after oxidation was reported in the literature (Xiao et al. 2012). The lower ΔHgel of polvilho azedo compared to native cassava starch is in line with results reported by Marcon et al. (2009). Gelatinization enthalpy change involves the energy required to cleave hydrogen bonds and other intermolecular interactions existing between the starch molecules. As the starch modification weakens the granular structure, these bonds are limited after modification (Lawal 2004). Therefore, less energy is required to gelatinize starch and ΔHgel values of the samples O and PA were lower than that of the sample N. The lower gelatinization enthalpy changes of samples O + GG (5.94 J/g) and N + O + GG (4.90 J/g) compared with the other samples (Table 4) are related with smaller amount of available water caused by the addition of hydrocolloids that have high water-holding capacity (Funami et al. 2005).

As can be seen in Table 4, dissociation of retrograded starch was also characterized by DSC as an endothermic peak, with enthalpy changes (ΔHret) and transition temperatures (To, Tp and Tc) lower than those found during gelatinization process (supplementary material). This decrease occurred because the branched amylopectin chains recrystallized in a less ordered form than in native granule structure present before gelatinization. Thus, less energy and lower temperatures are required for dissociation of this recrystallized amylopectin (Sandhu and Singh 2007).

According to Karim et al. (2000) the fraction responsible for retrogradation measured by DSC was amylopectin. The samples N + O, O + GG and N + O + GG showed no endothermic peak (supplementary material), what means that amylopectin recrystallization did not occur after 15 days storage at − 18 °C, and consequently transition temperatures values and ΔHret for these samples were absent (Table 4). The sample PA showed the highest ΔHret value (1.09 J/g) followed by the sample O (0.59 J/g) and then sample N (0.43 J/g). These results agree with those found for freeze–thaw stability analysis (Table 2), which showed that the largest percentage of syneresis, and consequently the most intense retrogradation occurred in sample PA. The results also agreed with those reported by Sangseethong et al. (2009) that found ΔHret values of oxidized cassava starch were higher than those of native cassava starch (after storage of 7 days at 4 °C). In general, it was expected that introduction of carboxyl groups (from oxidation) hindered the re-association of the starch chains and minimize retrogradation. However, our results indicated that the carboxyl groups were not enough to prevent retrogradation of amylopectin (Table 4). It was reported that most carboxyl groups were formed close to the branching points of the amylopectin or on the amylose molecules and in such positions, they were not very effective in preventing recrystallization of the amylopectin chains (Kuakpetoon and Wang 2006). Sangseethong et al. (2009) suggested that the increasing in ΔHret value observed in oxidized starches can occur due to amylopectin long chains degradation or even amylose molecules with production of dextrins with adequate length to retrograde.

The reduction in the enthalpy change of dissociation of retrograded starches when they are mixed with gums and other polysaccharides was already reported (Lee et al. 2002; Satrapai and Suphantharika 2007). Thus, it can be stated that most hydrocolloids can reduce retrogradation of starch, either by interacting with amylose molecules competing with the amylose–amylose interactions (Sudhakar et al. 1996), by forming hydrogen bonds with the amylopectin molecules (Satrapai and Suphantharika 2007) or acting as water binding, preventing starch chains recrystallization (Lee et al. 2002).

Fourier transform infrared (FTIR) spectroscopy

The FTIR spectra of the powder (native) samples of all samples showed very similar spectra, with typical polysaccharide profile (supplementary material). The peaks present at extension 900–1100 cm−1 were characteristic of C–O and C–C bonds and those that occurred in 1404–1410 cm−1 are due to the OH bond. The peaks at 1645 cm−1 were due to water bound to the starch, whereas the region 2928–2932 cm−1 was characteristic of the C–H bond. The broad band in the region of 3420–3434 cm−1 was characteristic of the hydrogen bound to the hydroxyl group (O–H), i.e., associated with intra and intermolecular hydrogen bonds (van Soest et al. 1994).

According to Zhang et al. (2012), the oxidation of starch may be evidenced by the presence of a characteristic peak at 1735 cm−1 attributed to the presence of carboxyl groups. Liu et al. (2014) reported that the absorption band at 1609 cm−1 is also characteristic of the carboxyl groups present in the oxidized starch. However, there was no difference between the spectra of the samples (N, PA, O, N + O, O + GG and N + O + GG). Thus, PCA analysis was used to verify the similarity between the samples based on the presence of functional groups (Fig. 1a).

Principal component analysis of FTIR spectra of polvilho azedo (PA), native cassava starch (N), oxidized cassava starch (O), mixture of native cassava starch and oxidized cassava starch (N + O), binary mixture of oxidized cassava starch and guar gum (O + GG) and ternary mixture of native cassava starch, oxidized cassava starch and guar gum (N + O + GG) in powder form (a) and retrograded form (b)

For powdered samples the spectral band 700–2000 cm−1 was considered to eliminate the lack of uniformity of starch and also because the carboxyl groups absorb in the infrared around 1600–1750 cm−1 (Demiate et al. 2000; Liu et al. 2014; Zhang et al. 2012). The principal components 1 (PC1) and 2 (PC2) explained 94.25% of the data variance. Observing the Fig. 1a, it is possible to verify that there was a separation of the samples. The sample N and the sample PA were grouped together, while those containing oxidized starch (O, N + O, O + GG and N + O + GG) were separated.

The graph of loadings of the first derivative of the spectrum (Fig. 1a) showed that the maximum intensity peak occurred at around 1600 cm−1 (PC2), and an inflection occurred at 1730 cm−1 (PC2). Inflections are corresponding with the first derivative of vibration of carboxyl groups according to Liu et al. (2014) and Zhang et al. (2012). PC1 shows an inflection point at around 1000 cm−1, suggesting that the C–O–C bond in the glucose unit was broken due to starch chains degradation caused by oxidation (Liu et al. 2014). Thus, one of the factors that impacted in the separation of the samples was the presence or absence of carboxyl groups.

With respect to retrogradation, bands in 1048 and 1016 cm−1 reflect the values of the crystalline and amorphous region, respectively, while the band 995 cm−1 is very sensitive to water content (van Soest et al. 1994). The PCA analysis for the retrograded samples was performed in the spectral range 800–1100 cm−1 (Fig. 1b), because this region reflects mainly the vibration of C–O and C–C bonds and is sensitive to changes in polymer conformation and starch hydration (Htoon et al. 2009). The principal components 1 (PC1) and 2 (PC2) explained 97.29% of the data variance.

Figure 1b shows that mixtures containing guar gum (O + GG and N + O + GG) were separated from the other samples, being in the upper area of the graph. The graphic of loadings of the first derivative of the spectra showed that the maximum intensity peak occurred around 950–1000 cm−1, the region of choice to show starch retrogradation, particularly related to water content (van Soest et al. 1994). Therefore, samples O + GG and N + O + GG had lower retrogradation due to the presence of guar gum and separated from the others.

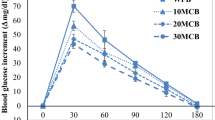

Preparation and evaluation of cheese bread staling

Cheese breads were produced in order to confirm that the developed mixtures were efficient in retarding staling, identified by increased hardness. Bread hardness is related to the force applied to cause sample deformation or disruption evaluated by a mechanical texture analyzer; bread crumb hardening is the main evidence of bread staling (Demirkesen et al. 2014). As bread crumb hardening is caused by starch recrystallization and moisture transfer from the bread crumb, most studies on bread staling has been focused on retrogradation phenomenon due to the starch macromolecules re-association, predominantly amylopectin (Ronda and Roos 2011). Cheese breads staling tendency, expressed as instrumental hardness, is shown in Fig. 2.

Hardness of cheese breads prepared with polvilho azedo (PA), native cassava starch (N), oxidized cassava starch (O), mixture of native cassava starch and oxidized cassava starch (N + O), binary mixture of oxidized cassava starch and guar gum (O + GG) and ternary mixture of native cassava starch, oxidized cassava starch and guar gum (N + O + GG)

After 2 and 8 h of storage cheese breads staling was not very pronounced because the products were still soft. However, it could be better evidenced after 24 h and 30 h of storage. In Fig. 2 it can be observed that the cheese bread made with PA, which was soft when stored for 2 and 8 h, suffered a rapid staling after this period and this was evidenced by the large hardness values of 42.59 and 56.08 N after 24 and 30 h storage, respectively. As can be seen in Fig. 2, products formulated with the sample N showed a less pronounced staling (hardness of 30.47 and 40.63 N after 24 and 30 h of storage, respectively).

The cheese breads produced with the sample O showed the highest hardness between all samples when analyzed after 24 and 30 h storage (Fig. 2). The addition of guar gum to sample O (O + GG) reduced significantly staling, but the cheese breads developed with this mixture were harder than those prepared with the samples PA, N, N + O and N + O + GG. Oxidation promotes starch chains partial degradation, reducing its molar mass (Kuakpetoon and Wang 2001; Lawal 2004). As the starch is composed of glucose monomers, this degradation exposes reducing ends making them susceptible to browning reactions (mainly Maillard reaction) as cheese bread was baked at high temperatures (200 °C). Thus, it can be considered that although the sample O + GG has shown good results for expansion property (Table 2) and retrogradation (Tables 2, 4) it seems not to be the most suitable to be applied in this kind of gluten-free baked food. This cheese bread has undesirable darker crumb when compared with the others (data not shown).

The products formulated with the N + O + GG mixture were the softest between all samples analyzed after 24 and 30 h storage (hardness of 23.71 and 29.59 N, respectively); thus, in this case, guar gum slowed down cheese bread staling. The effect of hydrocolloids for slowing down bread staling was already evidenced by Rodriguez-Sandoval et al. (2015). According to Armero and Collar (1996) hydrocolloids can weaken the starch structure causing a better distribution and retention of water in bread crumb decreasing, consequently, its hardness. Davidou et al. (1996) proposed that hydrocolloid can weaken starch structure due to inhibition of amylose and amylopectin molecules re-association.

Conclusion

The mixture N + O + GG was the most effective in slowing down staling of cheese bread when compared with the other samples (PA, N, O, N + O, O + GG) and this desirable effect occurred because of lower retrogradation of this sample, evidenced by freeze–thaw stability, DSC and FTIR analyses. Furthermore, despite its expansion property was smaller than for the samples N + O and O, it did not differ significantly from PA and was significantly larger than sample N (specific volume > 10 mL/g). Thus, it can be concluded that the ternary mixture N + O + GG can be used to replace polvilho azedo and/or native cassava starch in formulations of gluten-free baked foods with high expansion during baking and retarded staling.

References

AACC (1995) American association of cereal chemists: approved methods of the AACC. (9th edn) Method 61-02

Aplevicz KS, Demiate IM (2007) Characterization of native and modified cassava starches and their use in baked products. Food Sci Technol 27:478–484. https://doi.org/10.1590/S0101-20612007000300009

Armero E, Collar C (1996) Antistaling additive effects on fresh wheat bread quality. Food Sci Tech Int 2:323–333. https://doi.org/10.1177/108201329600200506

Chaisawang M, Suphantharika M (2006) Pasting and rheological properties of native and anionic tapioca starches as modified by guar gum and xanthan gum. Food Hydrocoll 20:641–649. https://doi.org/10.1016/j.foodhyd.2005.06.003

Davidou S, Le Meste M, Debever E, Bekaert D (1996) A contribution to the study of staling of white bread: effect of water and hydrocolloid. Food Hydrocoll 10:375–383. https://doi.org/10.1016/S0268-005X(96)80016-6

Demiate IM, Dupuy N, Huvenne JP, Cereda MP, Wosiacki G (2000) Relationship between baking behavior of modified cassava starches and starch chemical structure determined by FTIR spectroscopy. Carbohydr Polym 42:149–158. https://doi.org/10.1016/S0144-8617(99)00152-6

Demirkesen I, Campanella OH, Sumnu G, Sahin S, Hamaker BR (2014) A study on staling characteristics of gluten-free breads prepared with chestnut and rice flours. Food Bioprocess Tech 7:806–820. https://doi.org/10.1007/s11947-013-1099-3

Funami T, Kataoka Y, Omoto T, Goto Y, Asai I, Nishinari K (2005) Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll 19:1–13. https://doi.org/10.1016/j.foodhyd.2004.04.024

Garcia ACDB, Leonel M (2005) Effect of lactic acid concentration on expansion property of photochemically modified starches. Cienc Agrotec 29:629–634. https://doi.org/10.1590/S1413-70542005000300018

Htoon A, Shrestha AK, Flanagan BM, Lopez-Rubio A, Bird AR, Gilbert EP, Gidley MJ (2009) Effects of processing high amylose maize starches under controlled conditions on structural organisation and amylase digestibility. Carbohydr Polym 75:236–245. https://doi.org/10.1016/j.carbpol.2008.06.016

Karim AA, Norziah MH, Seow CC (2000) Methods for the study of starch retrogradation. Food Chem 71:9–36. https://doi.org/10.1016/S0308-8146(00)00130-8

Kaur M, Oberoi DPS, Sogi DS, Gil BS (2011) Physicochemical, morphological and pasting properties of acid treated starches from different botanical sources. J Food Sci Tech Mys 48:460–465. https://doi.org/10.1007/s13197-010-0126-x

Krüger A, Ferrero C, Zaritzky NE (2003) Modelling corn starch swelling in batch systems: effect of sucrose and hydrocolloids. J Food Eng 58:125–133. https://doi.org/10.1016/S0260-8774(02)00337-0

Kuakpetoon D, Wang YJ (2001) Characterization of different starches oxidized by hypochlorite. Starch Starke 53:211–218. https://doi.org/10.1002/1521-379X(200105)53:5<211::AID-STAR211>3.0.CO;2-M

Kuakpetoon D, Wang YJ (2006) Structural characteristics and physicochemical properties of oxidized corn starches varying in amylose content. Carbohydr Res 341:1896–1915. https://doi.org/10.1016/j.carres.2006.04.013

Lawal OS (2004) Composition, physicochemical properties and retrogradation characteristics of native, oxidised, acetylated and acid-thinned new cocoyam (Xanthosomas agittifolium) starch. Food Chem 87:205–218. https://doi.org/10.1016/j.foodchem.2003.11.013

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng 79:1033–1047. https://doi.org/10.1016/j.jfoodeng.2006.03.032

Lee MH, Baek MH, Cha DS, Park HJ, Lim ST (2002) Freeze–thaw stabilization of sweet potato starch gel by polysaccharide gums. Food Hydrocoll 16:345–352. https://doi.org/10.1016/S0268-005X(01)00107-2

Liu J, Wang B, Lin L, Zhang J, Liu W, Xie J, Ding Y (2014) Functional, physicochemical properties and structure of cross-linked oxidized maize starch. Food Hydrocoll 36:45–52. https://doi.org/10.1016/j.foodhyd.2013.08.013

Marcon MJA, Kurtz DJ, Raguzzoni JC, Delgadillo I, Maraschin M, Soldi V, Reginatto V, Amante ER (2009) Expansion properties of sour cassava starch (Polvilho Azedo): variables related to its practical application in bakery. Starch Starke 61:716–726. https://doi.org/10.1002/star.200900132

Matsuguma LS, Lacerda LG, Schnitzler E, Carvalho Filho MAS, Franco CML, Demiate IM (2009) Characterization of native and oxidized starches of two varieties of Peruvian carrot (Arracacia xanthorrhiza, B.) from two production areas of Parana state, Brazil. Braz Arch Biol Technol 52:701–713. https://doi.org/10.1590/S1516-89132009000300022

Puncha-Arnon S, Pathipanawat W, Puttanlek C, Rungsardthong V, Uttapap D (2008) Effects of relative granule size and gelatinization temperature on paste and gel properties of starch blends. Food Res Int 41:552–561. https://doi.org/10.1016/j.foodres.2008.03.012

Rodriguez-Sandoval E, Cortes-Rodriguez M, Manjarres-Pinzon K (2015) Effect of hydrocolloids on the pasting profiles of tapioca starch mixtures and the baking properties of gluten-free cheese bread. J Food Process Preserv 39:1672–1681. https://doi.org/10.1111/jfpp.12398

Ronda F, Roos YH (2011) Staling of fresh and frozen gluten-free bread. J Cereal Sci 53:340–346. https://doi.org/10.1016/j.jcs.2011.02.004

Rosalina I, Bhattacharya M (2002) Dynamic rheological measurements and analysis of starch gels. Carbohydr Polym 48:191–202. https://doi.org/10.1016/S0144-8617(01)00235-1

Rosell CM, Yokoyama W, Shoemaker C (2011) Rheology of different hydrocolloids–rice starch blends. Effect of successive heating–cooling cycles. Carbohydr Polym 84:373–382. https://doi.org/10.1016/j.carbpol.2010.11.047

Sandhu KS, Singh N (2007) Some properties of corn starches II: physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem 101(4):1499–1507. https://doi.org/10.1016/j.foodchem.2006.01.060

Sandhu KS, Kaur M, Singh N, Lim ST (2008) A comparison of native and oxidized normal and waxy corn starches: physicochemical, thermal, morphological and pasting properties. LWT Food Sci Technol 41:1000–1010. https://doi.org/10.1016/j.lwt.2007.07.012

Sangseethong K, Lertphanich S, Sriroth K (2009) Physicochemical properties of oxidized cassava starch prepared under various alkalinity levels. Starch Starke 61:92–100. https://doi.org/10.1002/star.200800048

Satrapai S, Suphantharika M (2007) Influence of spent brewer‘s yeast β-glucan on gelatinization and retrogradation of rice starch. Carbohydr Polym 67:500–510. https://doi.org/10.1016/j.carbpol.2006.06.028

Shaikh IM, Ghodke SK, Ananthanarayan L (2008) Inhibition of staling in chapati (Indian unleavened flat bread). J Food Process Preserv 32:378–403. https://doi.org/10.1111/j.1745-4549.2008.00185.x

Silva GO, Takizawa FF, Pedroso RA, Franco CML, Leonel M, Sarmento SBS, Demiate IM (2006) Physicochemical characteristics of modified food starches commercialized in Brazil. Food Sci Technol (Campinas) 26:188–197. https://doi.org/10.1590/S0101-20612006000100030

Sudhakar V, Singhal RS, Kulkarni PR (1996) Starch-galactomannan interactions: functionality and rheological aspects. Food Chem 55:259–264. https://doi.org/10.1016/0308-8146(95)00127-1

van Soest JJG, Wit D, Tournois H, Vliegenthart JFG (1994) Retrogradation of potato starch as studied by Fourier transform infrared spectroscopy. Starch Starke 46:453–457. https://doi.org/10.1002/star.19940461202

Xiao HX, Lin QL, Liu GQ, Yu FX (2012) A comparative study of the characteristics of cross-linked, oxidized and dual-modified rice starches. Molecules 17:10946–10957. https://doi.org/10.3390/molecules170910946

Zhang YR, Wang XL, Zhao GM, Wang YZ (2012) Preparation and properties of oxidized starch with high degree of oxidation. Carbohydr Polym 87:2554–2562. https://doi.org/10.1016/j.carbpol.2011.11.036

Acknowledgements

The authors thank to the Brazilian government official agencies (Coordination for the Improvement of Higher Education Personnel/CAPES; National Council for Scientific and Technological Development/CNPq) for financial support. AN, ES and IMD are research fellows from CNPq.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Granza, A.G., Hornung, P.S., Zielinski, A.A.F. et al. Gluten-free baked foods with extended shelf-life. J Food Sci Technol 55, 3035–3045 (2018). https://doi.org/10.1007/s13197-018-3225-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3225-8