Abstract

A potent antioxidant, anti-inflammatory and anti-mutagenic agent; 4-vinyl-2,6-dimethoxyphenol (canolol) was obtained from canola meal in a significant yield via alkaline (NaOH)/enzymatic (ferulic acid esterase) hydrolysis followed by microwave-assisted decarboxylation. The hydrolysis was carried out either through using canola meal directly as a substrate or by using the 70 % aqueous methanolic extract filtrates. The hydrolyzed extracts underwent RP-HPLC analysis which showed that 81.0 and 94.8 % of the total phenolics were hydrolyzed to sinapic acid after the alkaline hydrolysis of the meal and the methanolic extracts, respectively. The enzymatic hydrolysis showed lower conversion rates (49.5 and 58.3 %). The hydrolyzed extracts were consequently decarboxylated using 8-diazabicyclo[5.4.0]undec-7-ene under microwave irradiation at different conditions. The HPLC profiling of decarboxylated extracts showed that using microwave at 300 W of microwave power for 12 min brought the highest sinapic acid conversion to canolol (58.3 %) yielding 4.2 mg canolol from each gram of canola meal suggesting that the process could be commercially economical.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Free radicals induce oxidative damage in vivo causing aging and various diseases [1, 2]. They are also the major cause for deterioration, quality loss, and shelf life reduction in oils/fats and fat-containing systems. There are many studies on the antioxidative effects of natural extracts derived from rapeseed [3, 4], vegetables [5, 6] and olives [7]. Most of these extracts contain water-soluble components as active ingredients. Thus, there is a need for naturally derived lipid-soluble antioxidants for utilization in oil/fat products as well as in vivo. Examples of lipid-soluble antioxidants include butylhydroxyanisole (BHA), butylhydroxytoluene (BHT), tert-butylhydroquinone (TBHQ) and propylgallate (PG). Their safety has been extensively questioned and attempts to eliminate them from human diet continued. Consequently, there is a need for developing highly active fat-soluble antioxidants from natural sources, especially from the under-utilized by-products such as meals.

2,6-Dimethoxy-4-vinylphenol (known as canolol or 4-vinylsyringol) is a well-known lipid-soluble potent antioxidant and antimutagenic compound [1, 2, 8, 9] formed in canola oil via sinapic acid decarboxylation during oil pressing at high temperature and pressure [1, 2]. The anti-radical scavenging activity of canolol is much greater than that of well-known antioxidants, including vitamin C, β-carotene, α-tocopherol, rutin and quercetin [10]. Unluckily, canolol is almost completely lost during oil refining [10, 11] which advocates its isolation from meal and adding it back to the oil. The lipophilic characteristics of canolol might account for its high affinity to the cell membranes and other biological membranes and hence its reactivity inside the body where water-soluble antioxidants are hard to react, thus establishing its outstanding role. The industrial demand of vinyl phenols and canolol is relatively satisfied by chemical synthesis and not from natural sources. Investigations have explored large scale synthesis of 4-vinylphenols through microbial or chemical decarboxylation of cinnamic acids such as p-coumaric acid, ferulic acid, sinapic acid and caffeic acid from plant sources including barley [12], wheat bran [13] and sunflower seeds [14].

Investigations to obtain this bioactive compound from the natural sources are rare and not really successful. Although many attempts were tried, the amounts obtained from this compound from either natural sources or chemical synthesis were not able to meet the ever-increasing industrial demand due to the limited amount of this compound in plant sources and the less yield and high cost in the chemical synthesis. Consequently, there is a growing interest in developing alternative natural sources and more economic procedures to obtain this phenol in significant amounts to fulfill the industry demand.

Microwave pre-treatment of seeds is a simple and useful method for production of higher quality and more functional vegetable oils. In addition to improving the oil yield and quality, lowering energy consumption and reducing processing time and solvent consumption, it offers better retention and availability of desirable nutraceuticals including phytosterols, tocopherols and phenolic compounds in the extracted oils [15]. In the past few years, microwave-assisted chemical synthesis was used extensively as an environmentally friendly, rapid, and high-yielding technique in a laboratory scale [16]. Currently, efforts are being made to develop bulky reactors that will allow the scaling up of this technique to fit the industrial needs [17]. It is well documented that microwave irradiation has been used to enhance the decarboxylation of organic compounds [18–22]. Nomura et al. [23] reported a base-catalyzed decarboxylation and amide-forming reaction of substituted cinnamic acids via microwave heating. However, in these experimental conditions, the recovery and the yields of the 4-vinylphenols were very low. Bernini et al. [22] described new experimental conditions to achieve satisfactory yield from the decarboxylation of pure sinapic acid under microwave irradiation in the presence of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), aluminum oxide, and hydroquinone.

This paper reports a new procedure for the production of canolol from under-utilized canola meal through a sequence of alkaline/enzymatic hydrolysis followed by decarboxylation of the hydrolyzed substrates under microwave irradiation. The conversion of sinapine and other sinapic acid derivatives to canolol will pave the way for new and unlimited opportunities, especially for by-product utilization, canola oil refining and value-added processing of canola meal.

Materials and Methods

Materials

Canola seeds were procured from commercial suppliers including ADM Bunge Canada (Oakville, ON, Canada), Viterra Canola (Ste. Agathe, MB, Canada), and Formely Canbra Foods Ltd. and currently Richardson (Lethbridge, AB, Canada). Phenolic standards; sinapic, ferulic, caffeic, trans-cinnamic, syringic, p-coumaric, salicylic, vanillic, gallic acid, kaempferol and syringaldehyde were purchased from Sigma-Aldrich (St. Louis, MO, USA). Sinapine thiocyanate was purchased from EPL Bio Analytical Services (Niantic, IL, USA). Authentic standard of synthetic canolol was kindly provided by Dr. Amy Logan, CSIRO Animal Food and Health Sciences, Werribee, Australia and Dr. Bertrand Mathaus, Max Rubner Institute, Germany. Sinapoyl glucose were kindly donated by Dr. A. Baumert, IPB-Halle, Germany. Sinapinaldehyde was purchased from ChromaDex, Inc. (Irvine, CA, USA). Ferulic acid esterase (FAE) was kindly donated by Novozymes (Bagsvaerd, Denmark). All solvents (analytical and HPLC grades) were purchased from Sigma-Aldrich (Oakville, ON, Canada).

Experimental Procedures

Sample Preparation

Canola seeds were cleaned, ground, and sieved through a 1,410-μm screen. The meals were obtained by defatting the seeds using a Soxtec 2050 system (Foss-Tecator, Foss North America, MN, USA) according to FOSFA [24] in two cycles. The meals were de-solventized overnight at room temperature in the fume hood.

Extraction of Canola Meal Phenolics

Phenolic compounds were extracted from the meal according to the procedure of Thiyam et al. [25]. Meal samples (1 g each) were extracted three times with 9 mL of 70 % methanol using ultra-sonication (1 min) followed by centrifugation under refrigerated conditions (10 min at 5,000×g) and filtered through Whatman No. 1 filter paper. The filtrates from the three extractions were combined and made up to a total volume of 25 mL with the extraction solution.

Alkaline Hydrolysis of Phenolic Compounds

Hydrolyzing Phenolic Extracts

Twenty milliliters of 4 M NaOH was added to 20 mL of the 70 % methanolic extract in a disposable 50-mL graduated centrifuge tube. The tubes were filled with N2, instantly capped and shaken in a Barnstead Lab-Line shaker at 150 rpm for 2 h at 20 °C after which the mixture was acidified to pH 2.0 with 6 M HCl. The mixture was then centrifuged at 5,000×g for 10 min at 4 °C. Twenty milliliters of diethyl ether/ethyl acetate mixture was added to a separation funnel followed by the acidified phenolic extract (the supernatant produced after the centrifugation). The separating funnel was capped and shaken well then left to stand for 5 min to get two separated layers. The organic upper layer was separated to a round-bottom flask and the water phase was re-extracted the same way for three times and the upper phases were combined. The organic phase was rotary evaporated followed by N2 flushing. The residue was re-dissolved in 20 mL of 70 % MeOH and stored at −20 °C until further experiments.

Hydrolyzing Canola Meal

Canola meal samples (one gram each) were hydrolyzed by 20 mL of 4 M NaOH for 4 h at room temperature in the Barnstead Lab-Line shaker at 150 rpm. The tubes were flushed with N2 before the extraction. The hydrolyzed mixture was then centrifuged (5,000×g for 10 min at 4 °C) and the supernatant was acidified to pH 2.0 and extracted the same way as mentioned above.

Enzymatic Hydrolysis of Phenolic Compounds

Enzymatic hydrolysis was conducted on canola meal phenolic extracts as well as on the meal itself. Two milliliters of 70 % methanolic extract was hydrolyzed with 50, 100 or 200 μL of ferulic acid esterase (FAE) at 5.5, 6.5 and 7.5 pH at 37 °C for 4 h. For canola meal, 0.2 g was hydrolyzed with 50 or 100 μL of FAE. The hydrolysis was investigated at the same conditions mentioned above.

Decarboxylation of the Hydrolyzed Extracts

The decarboxylation of sinapic acid was adapted from the procedure of Bernini et al. [22] with some modifications. Briefly, 2 mL of the hydrolyzed extract was put in a 50-mL conical glass flask and 100 μL of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), 5 mg hydroquinone and 2.0 g aluminum oxide were added. The mixture was vortexed and the solvent was completely evaporated under N2 at low pressure. The flasks were then heated in a microwave oven (Panasonic, Model NN-CS597S, 1,000 W) at different power levels (power 1; 100 W to power 7; 700 W) for different times (1–25 min). The flasks were cooled at room temperature, neutralized with 1 M HCl and extracted with 1:1 (v/v) diethyl ether/ethyl acetate mixture (3 × 5 mL) using a refrigerated centrifuge (4 °C) at 5,000×g for 10 min. The organic layers were combined and dried under N2. The dried residues were then re-dissolved in 2 mL of 70 % methanol; syringe filtered and kept at −20 °C until HPLC analysis.

HPLC Analysis

Canola extracts (before hydrolysis, after hydrolysis and after decarboxylation) were analyzed by the reversed-phase HPLC-DAD (Ultimate 3000; Dionex, Sunnyvale, CA, USA) following the procedure of Khattab et al. [26]. Gradient elution was performed using water/methanol (90:10) with 1.2 % o-phosphoric acid as solvent A, and methanol (100 %) with 0.1 % o-phosphoric acid as solvent B using C18 column (Synergi 4 μm Fusion-RP 80 Å; 150 × 4.0 mm 4 μm) (Phenomenex, Canada) at 0, 7, 20, 25, 28, 31 and 40 min with 10, 20, 45, 70, 100, 100 and 10 % B. The column was maintained at 25 °C at 0.8 mL/min flow rate. The chromatograms were acquired at 219, 270, 275 and 330 nm and data were analyzed using Chromeleon software (Version 6.8). Peaks were identified by comparing their relative retention times with those of the authentic standards. The principal constituents; sinapine, sinapoyl glucose, and sinapic acid were quantified based on the calibration curves generated by plotting the concentration of each compound against the area. All phenolics including principal components were detected at 330 nm as previously reported [26]. The content of canolol was expressed as sinapic acid equivalents (SAE) using detection at 270 nm based on the sinapic acid calibration curve generated at 270 nm. Total phenolic content (TP, 330 nm) were quantified as sinapic acid equivalents (SAE) by using all the peaks including unidentified, non-principal phenolics based on the calibration curve generated by using sinapic acid.

Statistical Analysis

The data presented are the means of three replicates ± standard deviations. Data were analyzed using a one factor analysis of variance (ANOVA) and Tukey mean separation for multiple comparisons with the Statistical Analysis System (SAS) Program (SAS Institute, Carey, NC, USA). Significance was accepted at p ≤ 0.05.

Results and Discussion

Alkaline Hydrolysis

The phenolic extracts were hydrolyzed with NaOH to release the esterified phenolics. When the pH was below 2, the released phenolics were available as phenolic acids instead of ionic forms and could be extracted with diethyl ether/ethyl acetate mixture [27, 28]. Insoluble-bound phenolics were not extractable using the normal common extraction procedures and potentially retained in the meal. Their proportion is small, but they can be released from canola by alkaline hydrolysis. As sinapine, the choline ester of sinapic acid, is the major phenolic compound in canola meal extracts, the major role of the alkaline treatment is to break the ester linkage in sinapine thereby liberating sinapic acid and choline (Fig. 1). The released phenolics were extracted with either diethyl ether, or ethyl acetate, or both. The conversion efficiency and the yield obtained were higher with alkaline hydrolysis compared to other methods including enzyme hydrolysis. Alkaline hydrolysis was conducted on the methanolic extracts as well as on the meal itself. Sinapine was the predominant phenolic compound in rapeseed meal, while the amount of sinapic acid was considerably less. Concerning the methanolic extracts, the total phenolic content was 10.6 ± 0.01 mg/g meal (sinapic acid equivalents; SAEs) estimated using the HPLC analysis from the total area under all peaks (Table 1). The results are in accordance with previous work [26, 29]. After hydrolysis, it ranged from 8.1 to 11.0 mg/g reaching its highest value after hydrolyzing for 2 h using 20 mL of 4 M NaOH for 20 mL of the extract. The amount of released sinapic acid showed how efficient different hydrolyzing conditions were in releasing sinapic acid from its esters. Hydrolysis is considered complete if the value of released sinapic acid is 100 % of the total phenolic content in the original extract. Under optimum conditions all phenolics were hydrolyzed to sinapic acid which increased from 0.14 to 10.2 mg/g representing 94.8 % of the total phenolic content in the original extract.

Using canola meal as a substrate for alkaline hydrolysis, the released sinapic acid content was lower compared to using the methanolic extracts (Table 2). The original meal contained 6.8, 1.1, 0.3 and 8.5 mg/g sinapine, sinapoyl glucose, sinapic acid and total phenolics, respectively. After hydrolysis, the released sinapic acid content was 7.1 mg/g (81.0 and 93.9 % of the total phenolics in the original and hydrolyzed meal, respectively).

Enzymatic Hydrolysis

As NaOH is a strong base, the liberated phenolics may undergo further degradation and breakdown and a milder procedure is preferable. Furthermore, if the left-over meal is intended to be used for the food/feed industries, the presence of alkaline residues will make it unsafe and cause adverse effects. Consequently, enzymes can be more specific and environmentally friendly agents. Enzymes have been successfully used for phenolic hydrolysis in cereals [30] and canola meal [31]. In this study we used ferulic acid esterase (FAE) which was reported in the earlier literature [31] to be the most potent for canola hydrolysis. FAE is a Humicola insolens monocomponent enzyme that is able to break the ester bond in sinapine to produce sinapic acid and choline. Results of the enzymatic hydrolysis of canola extracts and canola meal are listed in Tables 3 and 4. FAE was not as effective in hydrolyzing sinapic acid esters as NaOH under optimum conditions. Ideally, it hydrolyzed 58.3 and 49.5 % of the total phenolics in the extracts and meals, respectively to free sinapic acid. The original extract contained 9.01, 0.59, 0.12 and 9.17 mg/g of sinapine (SP), sinapoyl glucose (SG), sinapic acid (SA) and total phenolics (TP), respectively (Table 3). The use of FAE could totally hydrolyze SP and SG. However, the TP content was reduced only by 28.46 % suggesting that the hydrolysis of SP and SG was not straightforward to SA. In addition to SA, this hydrolysis yielded other unidentified phenolics which were counted when calculating the TP content from the total area under all peaks. Sinapic acid content was increased by 45.58 folds as compared to 73 folds in the alkaline hydrolysis. Although, the sinapic acid yield after alkaline hydrolysis was significantly higher compared to the enzymatic hydrolysis, enzyme hydrolysis remains an efficient and an environmentally friendly approach. Despite being lower than that of the alkaline hydrolysis, the conversion rate using enzyme hydrolysis was substantially high.

Thus, if the meal is used only for obtaining canolol, alkaline hydrolysis is recommended as the yield is higher. After alkaline hydrolysis, the left-over meal may be used as a fertilizer. However, if the meal is proposed to be used in the feed industry and production of protein isolates or hydrolysates, enzymatic hydrolysis may be a suitable alternative. Enzymatic hydrolysis is a milder method, despite the lower yield, to produce a bio residue.

Decarboxylation of Sinapic Acid to 4-Vinylsyringol (Canolol)

The use of microwave technology in organic chemistry has been rapidly increasing since the mid-1980s for the synthesis of new compounds. The most recent applications of microwave assisted organic synthesis (MAOS) include N-acylation, alkylation, aromatic and nucleophilic substitution, condensation, cycloaddition, deprotection, protection, esterification, transesterification, heterocycles, olefination, and metathesis [16]. Unlike conventional heating, microwave penetrates inside the material and heat is generated through direct microwave-material interaction. Moreover, volumetric heating, reaction rate acceleration, higher chemical yield, lower energy usage and different reaction selectivity are advantages microwave heating has over conventional methods. The short reaction times provided by microwave synthesis make it ideal for rapid reaction scouting and optimization of reaction conditions, allowing quick progress through the hypotheses–experiment–results iterations, resulting in more decision points per unit of time [32].

In this study the decarboxylation reaction was carried out under microwave irradiation in the presence of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) as a base reagent and hydroquinone as a polymerization inhibitor which were both pre-adsorbed onto the basic aluminum oxide—as a microwave transparent inorganic solid support—prior to microwave heating. This environmentally friendly solvent-free approach in the MAOS has become more prevalent since it allows the safe use of domestic microwave ovens and standard open vessel technology while eliminating the danger of possible explosions [33]. Gedye et al. [34] carried out different types of organic reactions both in sealed Teflon vessels in a microwave oven and under traditional reflux conditions and approximate rate enhancement of between 5 and 1,240 times were recorded. Derivatives which normally required 2–3 h of preparation were effectively synthesized in 2–3 min in microwave oven.

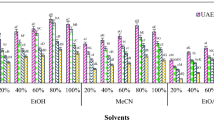

Different experimental conditions were examined to achieve the highest canolol yield from the hydrolyzed canola extracts. To decarboxylate the sinapic acid content in 2 mL of the extract the optimum concentration of the reactants were found to be 100 μL of DBU, 5 mg of hydroquinone and 1 g of aluminum oxide (Fig. 2). The DBU reagent was chosen as diazabicycloalkenes are efficient bases for the decarboxylation of unsaturated acids [35]. Furthermore, DBU has a pKa = 1224 and it was reported that the decarboxylation of cinnamic acids proceeded in better yields with bases having higher basicity (pKa > 7) [23].

The effect of microwave power level and heating times is shown in Table 5. The microwave heating was applied at different power levels; power 1 (100 W) to power 7 (700 W) for 1–25 min. However, the results shown in Table 5 are limited to power 3 (12–15 min), power 4 (4 and 8 min) and power 5 (5 and 7 min) in which the decarboxylation could be achieved and the canolol could be detected. Decarboxylation did not occur at both power 1 and power 2. Furthermore, after 15 min at power 3, 8 min at power 4, and 7 min at power 7 of microwave power, the samples were visibly burnt and no further extraction could be done. Canolol was identified based on its absorbance properties according to the literature. Wijesundera et al. [36] found that canolol had a UV spectrum with maxima at 220 and 270 nm which agree with our findings. Similarly, Koski et al. [1] reported that canolol has an absorption maximum occurring at 275 nm while our study indicated an absorbance maximum at 270 nm.

It was concluded that using the microwave at power 3 of microwave power for 13 min achieved the highest conversion rate (58.4 % of sinapic acid) and canolol yield (4.2 mg/g of canola meal). This canolol yield (4.2 g from each kilogram of canola meal) is outstanding from an economical point of view. Lower power levels were more efficient in decarboxylation which suggests that the conversion of sinapic acid to canolol is more effective under these conditions.

Since the early days of microwave synthesis, the observed rate-accelerations and sometimes altered product distributions compared to conventional heating led to speculation on the existence of so-called “specific” or “non-thermal” microwave effects [37]. Such effects were claimed when the outcome of a synthesis performed under microwave conditions was different from the conventionally heated counterpart at the same apparent temperature. Scientists agree that the reason for the observed rate enhancements is a purely thermal/kinetic effect, that is, a consequence of the high reaction temperatures that can rapidly be attained when irradiating polar materials in a microwave field, although clearly effects that are caused by the uniqueness of the microwave dielectric heating mechanism (specific microwave effects) must also be considered [32].

Using the lower power level (300 W) of microwave power might prove to be an asset in energy saving and associated costs especially for industrial use. The major advantage of the present work is the use of the under-utilized meal as the substrate rather than the oil which is the valuable product in the canola oil industry. More work is needed to enhance the conversion rate, extractability and final yield of canolol based on modifying the experimental conditions given our first novel findings reported here. The HPLC chromatograms of the original, hydrolyzed and decarboxylated extracts are shown in Fig. 3. Around 96.1 % of the total phenolics in canola meal was converted to sinapic acid of which 58.3 % was decarboxylated to canolol. This yield of 4.2 g of canolol for each kg of canola meal represents a significantly higher yield of canolol compared to other reported values [22, 38]. Niu et al. [39] found that the concentration of canolol in rapeseed increased nearly six times after 7 min of microwave toasting accompanied by a decrease in both sinapine and sinapic acid suggesting that these compounds are chemically degraded by microwave heating. Herstad and Benneche [21] used the decarboxylation in the synthesis of 4-alkyl-, 4-alkenyl- and 4-acylpyrimidines through both pure thermally and microwave-induction. They concluded that the time needed to get complete decarboxylation was greatly reduced using the microwave irradiation. The pure thermal decarboxylation at 111 °C took from 48 to 72 h compared to 20 min only under microwave irradiation. Similarly, microwave-enhanced decarboxylation of aromatic carboxylic acids was found to occur very rapidly and complete within 4 min at 300 W microwave power [18].

Conclusions and Future Perspectives

The present work discloses a simple technique for obtaining canolol from canola meal using microwave irradiation as an environmentally friendly process for the first time according to the best of our knowledge. The optimum condition for microwave treatment is power 3 (300 W of microwave power) for a total treatment of 13 min. Hydrolysis is best acheived using FAE. Parts of this study were reported in the Annual Meeting of the American Oil Chemist’s Society in 2009 and 2010. Further studies to scale up and commercialize this technology are essential to pursue value addition to both canola oil and canola meal. The canolol obtained could be added back to vegetable oils, oil-containing systems, snack foods, and other supplementary foods, for better nutritional/nutraceutical quality. Utilizing canola meal could provide additional economic benefits to canola growers and crushers. The lower chemical and solvent consumption involved in the extraction, hydrolysis and decarboxylation makes it a more environmentally friendly process. Results of this research may create new integrated techniques for processing canola seed and canola meal that might include microwave treatments and hydrolysis for the extraction of this nutraceutical.

References

Koski A, Pekkarinen S, Hopia A, Wahala K, Heinonen M (2003) Processing of rapeseed oil: effects on sinapic acid derivative content and oxidative stability. Eur Food Res Technol 217:110–114

Kuwahara H, Kanazawa A, Wakamatu D, Morimura S, Kida K, Akaide T, Maeda H (2004) Antioxidant and antimutagenic activities of 4-vinyl-2,6-dimethoxyphenol (canolol) isolated from canola oil. J Agric Food Chem 52:4380–4387

Nowak H, Kujawa K, Zadernowski R, Roczniak B, Kozlowska H (1992) Antioxidative and bactericidal properties of phenolic compounds in rape seeds. Fett Wissenschaft Technol 94:149–152

Wanasundara U, Amarowicz R, Shahidi F (1994) Isolation and identification of an antioxidative component in canola meal. J Agric Food Chem 42:1285–1290

Pratt DE, Watts BMJ (1964) The antioxidant activity of vegetable extracts. 1. Flavone aglycones. J Food Sci 29:27–33

Kähkönen MP, Hopia AI, Vuorela HJ, Rauha JP, Pihlaja K, Kujala TS, Heinonen M (1999) Antioxidant activity of plant extracts containing phenolic compounds. J Agric Food Chem 47:3954–3962

Noriyasu K, Miho M (2001) Antioxidant. Japan Patent No. 181632. Japanese Patent Office (JPO), Publication Number: 2001-181632

Vuorela S, Meyer AS, Heinonen M (2004) Impact of isolation method on the antioxidant activity of rapeseed meal phenolics. J Agric Food Chem 52:8202–8207

Fujioka K, Shibamoto T (2006) Quantitation of volatiles and nonvolatile acids in an extract from coffee beverages: correlation with antioxidant activity. J Agric Food Chem 54:6054–6058

Wakamatsu D, Morimura S, Sawa T, Kida K, Nakai C, Maeda H (2005) Isolation, identification, and structure of a potent alkyl-peroxyl radical scavenger in crude oil, canolol. Biosci Biotechnol Biochem 69:1568–1574

Zacchi P, Eggers R (2008) High-temperature pre-conditioning of rapeseed: a polyphenol-enriched oil and the effect of refining. Eur J Lipid Sci Technol 110:111–119

Hernanz D, Nunez V, Sancho AI, Faulds CB, Williamson G, Bartolome B, Gomez-Cordoves C (2001) Hydroxycinnamic acids and ferulic acid dehydrodimers in barley and processed barley. J Agric Food Chem 49:4884–4888

Kim KH, Tsao R, Yang R, Cui SW (2006) Phenolic acid profiles and antioxidant activities of wheat bran extracts and the effect of hydrolysis conditions. Food Chem 95:466–473

Pedrosa MM, Muzquiz M, Garcia-Vallejo C, Burbano C, Cuadrado C, Ayet G, Robredo LM (2000) Determination of caffeic and chlorogenic acids and their derivatives in different sun flowers seeds. J Sci Food Agric 80:459–464

Azadmard-Damirchi S, Alirezalu K, Achachlouei BF (2011) Microwave pretreatment of seeds to extract high quality vegetable oil. World Acad Sci Eng Technol 57:72–75

Lidstrom P, Tierney J, Wathey B, Westman J (2001) Microwave assisted organic synthesis—a review. Tetrahedron 57:9225–9283

Kremsner JM, Stadler A, Kappe CO (2006) The scale-up of microwave-assisted organic synthesis. Top Curr Chem 266:233–278

Frederiksen LB, Grobosch TH, Jones JR, Lu SY, Zhao CC (2000) Microwave enhanced decarboxylations of aromatic carboxylic acids: improved deuteration/tritiation potential. J Chem Res 1:42–43

Zara CL, Jin T, Giguere RJ (2000) Microwave heating in organic synthesis: decarboxylation of malonic acid derivatives in water. Synth Commun 30:2099–2104

Kuang CX, Senboku H, Tokuda M (2001) Convenient and stereoselective synthesis of (Z)-1-bromo-1-alkenes by microwave-induced reaction. Tetrahedron Lett 42:3893–3896

Herstad G, Benneche T (2003) Decarboxylation in the synthesis of 4-alkyl-, 4-alkenyl- and 4-acylpyrimidines. J Heterocycl Chem 40:219–224

Bernini R, Mincione E, Barontini M, Provenzanoa G, Settib L (2007) Obtaining 4-vinylphenols by decarboxylation of natural 4-hydroxycinnamic acids under microwave irradiation. Tetrahedron 63:9663–9667

Nomura E, Hosoda A, Mori H, Taniguchi H (2005) Rapid base-catalyzed decarboxylation and amide-formation reaction of substituted cinnamic acids via microwave heating. Green Chem 7:863–866

FOSFA International Official Method (1998) Determination of oil content in oilseeds: solvent extraction (reference method) FOSFA International Manual, Part 2. Standard Contractual Method 45–50:283–288

Thiyam U, Stöckmann H, Schwarz K (2006) Antioxidative effect of main sinapic acid derivatives from rapeseed and mustard oil by-products. Eur J Lipid Sci Tech 108:239–248

Khattab R, Eskin M, Aliani M, Thiyam U (2010) Determination of sinapic acid derivatives in canola extracts using high-performance liquid chromatography. J Am Oil Chem Soc 87:147–155

Naczk M, Shahidi F (1989) The effect of methanol-ammonia-water treatment on the content of phenolic acids of canola. Food Chem 31:159–164

Naczk M, Wanasundara PKJPD, Shahidi F (1992) Facile spectrophotometric quantification method of sinapic acid in hexane-extracted and methanol-ammonia-water treated mustard and rapeseed meals. J Agric Food Chem 40:444–448

Cai R, Arntfield SD (2001) A rapid high-performance liquid chromatographic method for the determination of sinapine and sinapic acid in canola seed and meal. J Am Oil Chem Soc 78:903–910

Faulds CB, Sancho AI, Bartholomé B (2002) Mono- and dimeric acid from brewer’s spent grain by fungal feruloyl esterases. Appl Microbiol Biotechnol 60:489–493

Vuorela S, Meyer AS, Heinonen M (2003) Quantitative analysis of the main phenolics in rapeseed meal and oils processed differently using enzymatic hydrolysis and HPLC. Eur Food Res Technol 217:517–523

Kappe CO, Dallinger D, Murphree SS (2009) Practical microwave synthesis for organic chemists: strategies, instruments, and protocols. Wiley-VCH, Weinheim, pp 1–9

Varma RS, Ju Y (2006) Organic synthesis using microwaves and supported reagents. In: Loupy A (ed) Microwaves in organic synthesis, 2nd edn. Wiley-VCH, Weinheim, pp 362–415

Gedye RN, Smith FE, Westaway KC (1988) The rapid synthesis of organic compounds in microwave ovens. Can J Chem 66:17–26

Hori Y, Nagano Y, Taniguchi HUS (1981) Decarboxylation process. U.S. Patent 4,262,157

Wijesundera C, Ceccato C, Fagan P, Shen Z (2008) Seed roasting improves the oxidative stability of canola (B. napus) and mustard (B. juncea) seed oils. Eur J Lipid Sci Technol 110:360–367

Perreux L, Loupy A (eds) (2006) Microwaves in organic synthesis, 2nd edn. Wiley-VCH, Weinheim, pp 134–218

Shigeru M, Kenji K, Hiroshi M, Fumi Y, Daisuke W, Jun T, Chiaki N (2004) Antiradicals and fat compositions, foods, drinks, drugs, or feeds containing the antiradicals. European Patent Office, International publication number: WO 2003/030888 (17.04.2003 Gazette 2003/16) date of publication: 28. 07. Bulletin 2004/31

Niu Y, Jiang M, Wan C, Yang M, Hu S (2013) Effect of microwave treatment on sinapic acid derivatives in rapeseed and rapeseed meal. J Am Oil Chem Soc 90:307–313

Acknowledgments

Dr. Amy Logan, CSIRO, Food and Nutrition Sciences Australia and Dr Bertrand Mathaus, Max Rubner-Institute Germany are kindly acknowledged for the authentic canolol standard synthesized in their laboratories. The authors would like to acknowledge the technical assistance of Yougui Chen and Ayyapan Appukutan in this manuscript. This work was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC), the Canola Council of Canada, and Syngenta Crop Protection Inc, Canada. The Post-doctoral fellowship of Dr. R. Khattab at the University of Manitoba is sincerely acknowledged.

Conflict of interest

The authors have declared no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Khattab, R.Y., Eskin, M.N.A. & Thiyam-Hollander, U. Production of Canolol from Canola Meal Phenolics via Hydrolysis and Microwave-Induced Decarboxylation. J Am Oil Chem Soc 91, 89–97 (2014). https://doi.org/10.1007/s11746-013-2345-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-013-2345-6