Abstract

Rapeseed oil is usually expelled from the seed at high temperatures. Refining removes most of the non-triacylglycerol components, including many sinapic acid derivatives typical for rapeseed. The effect of these phenolic constituents on the oxidative stability of the oil was studied using rapeseed and turnip rapeseed oil samples resulting from different expelling conditions and refinement steps. The polar fraction was isolated, analyzed and tested for antioxidative activity in various lipid oxidation models. The amount of phenols was greatest in the post-expelled crude rapeseed oil, decreasing with an increasing degree of refining. The polar phenol content correlated with oxidative stability. The most active antioxidant component of the polar fraction was identified as vinylsyringol, a decarboxylation product of sinapic acid. This is the first report of vinylsyringol in rapeseed oil. It was abundant in the post-expelled crude oils and apparently responsible for their high phenol content and oxidative stability. Some vinylsyringol was present in the superdegummed oil but not in the fully refined oils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapeseed oil is a highly unsaturated oil, which makes it a healthy choice, but also susceptible to autoxidation. The oxidative stability of rapeseed oil is usually improved by a thorough refining process aimed at removing the pro-oxidant compounds. When oil is expelled from the seed by traditional methods, such as heated screw-pressing and solvent extraction, the resulting dark crude oil contains many non-triacylglycerol components. The proportion of triacylglycerols is 94–98% in crude and cold-pressed rapeseed oils and ~99% in refined oil [1]. The fully refined, bleached and deodorized (RBD) oil is light yellow with a bland aroma.

Virgin olive oil is a cold-pressed, unrefined oil that is protected from autoxidation by various inherent phenolic antioxidants [2, 3]. Studies on olive oil have shown that the phenol concentration decreases with an increasing degree of refinement [4]. Similarly, in our previous study on the oxidative stability of rapeseed oils, we found a pre-expelled crude oil to be more stable than refined oils [5]. The pre-expelled crude oil also contained the highest amount of polar phenols, which were present in the various oils in concentrations ranging from 18 ppm to 99 ppm, expressed as caffeic acid equivalents (CAE) [6]. Rapeseed itself contains more phenolic substances than any other major oilseed [7], but it is not clear whether they are transferred from seed to oil and how they are affected by the refining process.

The aims of the present study were to compare the oxidative stabilities of different types of rapeseed oils, to isolate, identify, and quantify the major antioxidative component(s) in rapeseed oil and to examine the antioxidative properties of sinapic acid derivatives in various models.

Materials and methods

Materials

The turnip rapeseed (Brassica rapa) and rapeseed (Brassica napus) oil samples were donated by Mildola Oy (Kirkkonummi, Finland). Turnip rapeseed samples included a post-expelled crude oil (TPE), a superdegummed oil (SDG), a refined, bleached and deodorized oil (RBD), and an oil refined, bleached and deodorized under modified, milder conditions (MOD). A post-expelled crude rapeseed oil (RPE) was also included in the study. Tocopherol standards and Folin-Ciocalteu's phenol reagent were supplied by Merck (Darmstadt, Germany). The phenolic acids were from Extrasynthèse (Genay, France) and 1,1-diphenyl-2-picrylhydrazyl radical (DPPH) (approx. 90%) from Sigma (St. Louis, Mo.). Solvents (HPLC grade) were purchased from various suppliers. Water was purified with a Milli-Q water purification system (Millipore, Bedford, Mass.).

Analysis of the oils

Peroxide values

Triplicate aliquots (15 g) of oil were placed in open 20-ml glass vials and stored at 60 °C in the dark. Sample aliquots were periodically withdrawn for analysis. Peroxide values (PVs), expressed in milliequivalents (meq) of active oxygen per kilogram of oil, were determined using a colorimetric ferric thiocyanate method [8]. Normal-phase HPLC (NP-HPLC) was used for the quantitative analysis of tocopherols in fresh samples and the monitoring of tocopherol content during virgin-oil autoxidation [9].

Total phenols

An aliquot (3 g) of oil was dissolved in heptane (30 ml) and the polar compounds were extracted into aqueous 80% methanol (3×20 ml) using a separation funnel. The aqueous fractions were combined, washed with heptane (20 ml), filtered and evaporated under vacuum at ~35 °C. The residue was dissolved in methanol (5 ml) and stored in a screw-cap vial at –20 °C in the dark. Each extraction was performed in duplicate.

An aliquot (0.2 ml) of the methanolic extract was evaporated to dryness under nitrogen and redissolved in water. Diluted (1:10) Folin-Ciocalteu's reagent (1 ml) was added. After 3 min, 7.5% sodium carbonate (0.8 ml) was added. After a further 30 min, the absorbance was measured at 765 nm (Perkin-Elmer Lambda 11/Bio UV/Vis spectrometer, Überlingen, Germany). As the sinapic acid standard curve was not completely linear over a sufficient range, caffeic acid was used for the calibration. The results of duplicate analyses are therefore expressed as CAE (parts per million CAE) [10].

HPLC analysis of phenols

In order to remove any remaining non-polar components before reversed-phase HPLC (RP-HPLC) analysis, an aliquot (3 ml) of the methanolic extract was applied to a 500-mg C18 solid phase extraction (SPE) column (Bond Elut, Varian, Harbor City, Calif., USA) conditioned with methanol (2 ml). The analytes were eluted with methanol (10 ml). The eluate was evaporated under nitrogen at 35 °C, redissolved in methanol and filtered.

The purified extracts were immediately analyzed with a Model 1090 Series II liquid chromatograph (Hewlett-Packard) coupled with a UV-Vis diode array detector. The chromatographic separation was achieved on a Nova-Pak® C18 (15 cm×3.9 mm, 4 μm) column (Waters, Millipore, Milford, Mass.), equipped with a C18 guard column. Solvent A was a mixture of 0.02 M ammonium dihydrogen phosphate buffer (pH 2.15) and methanol (75:25); solvent B was methanol. The flow rate was 1 ml/min and the temperature ~27 °C. The gradient profile was: 5% B (0–15 min); 5–35% B (15–20 min); 35–100% B (20–35 min); 100–5% B (45–50 min); and 5% B (50–52 min) with a post-run period of 18 min at 5% B. The chromatograms were recorded at 325 nm, 275 nm, 320 nm and 254 nm, and spectral information was stored automatically (peak-controlled). A standard curve was set up with sinapic acid, for which a linear (r 2=1.000) response was obtained in the range 0.01–100 mg/l. The results are reported as milligrams of sinapic acid per kilogram of oil (parts per million SAE).

Isolation and identification of the unknown component

The TPE was fractionated using SPE and the fractions were tested for antioxidative activity. The most active fraction was fractionated further. The radical scavenging components were located by applying the fractions on a silica (SI) TLC plate, which was first developed and then stained with DPPH solution. To obtain a sufficient amount of material for a definitive structural analysis of the most active component, the following procedure was repeated several times.

An aliquot (1 g) of the oil was dissolved in heptane (1 ml). A 2-g SI SPE column (Bond Elut) was conditioned with heptane (6 ml). The sample was allowed to pass into the column without vacuum. Vacuum was then applied to pass 80 ml of heptane-diethyl ether (90:10) through the column in two steps: the first fraction (50 ml) was discarded; the second (30 ml) collected. Eluates from two columns were combined and evaporated. The residue, containing the analyte of interest, was then dissolved into methanol and applied to a 5-g C18 SPE column conditioned with methanol (7 ml). The analyte was eluted with methanol (7 ml): the first fraction (2 ml) was discarded; the second (5 ml) collected and stored under argon in the dark at –20 °C.

For the identification of the isolated component, spectral (Perkin-Elmer Lambda 11/Bio UV/Vis spectrometer), fluorometric (Hitachi F-4010,), MS (JMS SX102, JEOL USA., Peabody, Mass.), and nuclear magnetic resonance (NMR) (Gemini 200 MHz, Varian, Palo Alto, Calif.) characteristics were determined.

Antioxidative activity of the isolated fraction

Antioxidative activity of the isolated fraction was tested in bulk and emulsified methyl linoleate (MeLo), in bulk and purified rapeseed oil triacylglycerol fraction, and in a liposome model. The concentration of the isolated fraction in the model matrix was calculated as gallic acid equivalents of total phenols, which were determined as described for the methanolic extracts above. The isolated fraction was inserted into the matrix both alone (50 μM) and together with γ-tocopherol (25 μM each). Pure matrix was used as a negative control and γ-tocopherol (50 μM) as a positive control. Duplicate samples were prepared in all experiments.

MeLo model

Spiked samples of bulk MeLo and 10% emulsions (Tween 20) of MeLo in water were stored at 40 °C in the dark, and the formation of hydroperoxides was monitored using NP-HPLC. [11]

Rapeseed triacylglycerol model

The triacylglycerol fraction of rapeseed oil was purified according to the method of Lampi et al. [12]. Sample preparation and test conditions were as described for the MeLo model, but autoxidation was monitored by measuring the peroxide values periodically using the ferric thiocyanate method [8].

Liposome model

The preparation of the lecithin-liposome system has been described previously [13]. The samples were oxidized at 37 °C in the dark by shaking with cupric acetate. Autoxidation was monitored by determining PVs using the ferric thiocyanate method [8].

Results and discussion

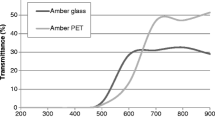

Oil autoxidation

During autoxidation at 60 °C in the dark (Fig. 1), the crude oils RPE and TPE were very stable. The superdegummed SDG had the highest initial concentration of peroxides and was oxidized almost as rapidly as the fully refined oils (RBD and MOD) between which there was no significant difference. In order to explain the good stability of TPE, the oil was fractionated and the fractions were analyzed for phenol content, radical scavenging activity, and antioxidative activity in different models.

Autoxidation of rapeseed oil at 60 °C in the dark. RBD Refined, bleached and deodorized turnip rapeseed oil, MOD turnip rapeseed oil refined, bleached and deodorized under modified, milder conditions, SDG superdegummed turnip rapeseed oil, RPE post-expelled crude rapeseed oil, TPE post-expelled crude turnip rapeseed oil

Antioxidative activity of the polar fraction

The most active polar fraction was tested in various lipid oxidation models to compare its antioxidative properties with those of γ-tocopherol and to study the effect in combination with γ-tocopherol. The results presented in Fig. 2, Fig. 3, Fig. 4, Fig. 5 and Fig. 6 indicate that the isolated fraction, both alone and in combination with γ-tocopherol, is approximately as effective as γ-tocopherol at inhibiting hydroperoxide formation in bulk and emulsified lipids and in the lecithin-liposome system.

Autoxidation of emulsified methyl linoleate at 40 °C in the dark. For abbreviations, see Fig. 2

Autoxidation of purified rapeseed oil triacylglycerols at 40 °C in the dark. For abbreviations, see Fig. 2

Autoxidation of emulsified purified rapeseed oil triacylglycerols at 40 °C in the dark. For abbreviations, see Fig. 2

Oxidation of lecithin-liposomes at 37 °C in the dark with cupric acetate. For abbreviations, see Fig. 2

Vinylsyringol

The component which showed the best radical scavenging activity in the polar fraction was analyzed using NMR spectrometry (Table 1) and mass spectrometry [MS (EI+): 180 (M), 165, 137, 151, 122]. The compound was identified as vinylsyringol (4-hydroxy-3,5-dimethoxy-styrene, or 2,6-dimethoxy-4-vinylphenol). The UV spectrum of this compound is characteristic of benzoic acids, with an absorption maximum occurring at 275 nm, but it also exhibits a strong fluorescence, with an excitation maximum occurring at 273 nm and an emission maximum at 328 nm. Furthermore, it is an effective scavenger of the DPPH radical.

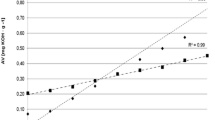

Phenol content

The amount of tocopherols was highest in the crude oils and decreased slightly with an increasing degree of refinement (Table 2). There was a similar, more pronounced decrease of the total hydrophilic phenols, which were completely removed from RBD, and of which only a trace of sinapic acid was found in MOD. RPE contained more phenols, especially vinylsyringol, than TPE. In the RP-HPLC chromatograms, there were two unidentified peaks that eluted before sinapic acid and exhibited simple UV spectra, with the absorption maxima occurring at 325 nm and 307 nm respectively. Identification of a late-eluting compound as vinylsyringol was based on spectral information. The relative concentrations of vinylsyringol calculated from the UV data (RP-HPLC) were consistent with the fluorescence data (NP-HPLC). In addition to vinylsyringol, small amounts of sinapic acid and two unidentified minor polar components were detected in the crude oils.

The phenolic compounds in rapeseed are mainly sinapic acid derivatives, the rest consisting of other phenolic acids and tannins [14]. For the most part, these compounds are present as derivatives such as sinapines, other esters, and glycosides. Glucosyl sinapate, the glucose ester of sinapic acid, has been isolated and identified from rapeseed meal as the component showing the most powerful antioxidative properties [15]. Sinapic acid itself is an effective scavenger of the peroxyl radical [16] and inhibits oxidation in various model systems, including bulk MeLo [17], emulsified MeLo [11], lard [18], methyl esters of lard and sunflower oil [19], and low density lipoprotein in vitro [16].

Sinapic acid was found in the crude oils TPE and RPE. There are no previous reports of phenolic acids in screw-pressed rapeseed oil, but analysis of solvent-extracted rapeseed lipids has resulted in identification of sinapic acid along with its methyl ester (132 and 92 ppm, respectively, in the seed material) [20]. Virgin olive oils usually contain 50–500 ppm, sometimes even 500–1000 ppm hydrophilic phenolic components (determined by the colorimetric Folin-Ciocalteu method as CAE or gallic acid equivalents) [4, 21, 22, 23]. Gutfinger found solvent-extracted olive oil more stable than cold-pressed, and attributed the better stability to the higher concentration of phenolics [2].

Some extra virgin olive oils containing ca. 500 ppm total phenols are less stable than RBD olive oil with only 8 ppm total phenols, even though the latter had a PV of 0.4 meq/kg whereas the former had PVs of 15.6 and 32.5 meq/kg [13]. (The maximum PV in olive oil is set at 20 meq/kg by the European Union.) The contribution of the tocopherol content of olive oils to their stability (as assessed by Rancimat induction) is less clear: Baldioli et al. found no correlation [23] but Salvador et al. found some [24].

The phenolic vinylsyringol seems to be responsible, at least in part, for the better stability of the crude rapeseed oils, since the polar fraction containing vinylsyringol showed lipid antioxidative activity comparable to that of γ-tocopherol. Furthermore, vinylsyringol appears to account for most of the detected total phenol content. The oxidative stability was reduced by superdegumming almost as much as by full refining, probably due to increasing the peroxide concentration. In comparison with the conventional refining, the milder refining conditions did not result in improved oxidative stability.

There is reason to believe that vinylsyringol is formed from sinapic acid via decarboxylation during heat processing (e.g. post-expelling) of the seed. It has been reported that during the heating of soybean flour, 4-vinylguaiacol and 4-vinylphenol are formed from ferulic and p-coumaric acids, and that the volatile vinyl compounds give rise to a specific off-flavor [25].

To conclude, post-expelled crude rapeseed oil contains both hydrophobic and hydrophilic phenolic substances. The amount of tocopherols is reduced in the refining process, but the loss is less pronounced in the modified (milder) conditions. The phenol concentration decreases step-by-step during processing, so that the fully refined oil does not contain any polar phenols. There is a direct correlation between the concentration of polar phenols and the resistance to autoxidation. The phenol content of crude post-expelled oils appears to be due to vinylsyringol, which is reported for the first time in rapeseed oil. It is probably formed by cleavage of sinapic acid derivatives during heated screw-pressing (expelling) of the seed. Vinylsyringol seems to explain the relatively good oxidative stability of crude oils, but it is completely removed from the oil during the refining process. Sinapic acid and two unidentified minor polar components were also detected in the crude oils.

References

McGinley L (1991) Analysis and quality control for processing and processed fats. In: Rossell JB, Pritchard LR (eds) Analysis of oilseeds, fats and fatty foods. Elsevier, England, pp 441–498

Gutfinger T (1981) J Am Oil Chem Soc 11:966–968

Tsimidou M, Papadopoulos G, Boskou D (1992) Food Chem 45:141–144

Satue MT, Huang SW, Frankel EN (1995) JAOCS 72:1131–1137

Pekkarinen S, Hopia A, Heinonen M (1998) Fett/Lipid 100:69–74

Pekkarinen S, Hopia A, Heinonen M (1999) Rapeseed oil antioxidative compounds. In: Tuure VM (ed) Bioproducts for the next millennium. Yliopistopaino, Helsinki, p 82

Naczk M, Amarowicz R, Sullivan A, Shahidi F (1998) Food Chem 62:489–502

Ueda S, Hayashi T, Namiki M (1986) Agric Biol Chem 50:1–7

Haila K, Heinonen M (1994) Lebensm Wiss Technol 27:573–577

Singleton VL, Rossi JA (1965) J Enol Vitic 16:144–158

Pekkarinen SS, Stöckmann H, Schwarz K, Heinonen IM, Hopia AI (1999) J Agric Food Chem 47:3036–3043

Lampi AM, Hopia A, Ekholm P, Piironen V (1992) Lebensm Wiss Technol 25:386–388

Satué-Gracia MT, Heinonen M, Frankel EN (1997) J Agric Food Chem 45:3362–3367

Naczk M, Wanasundara PKJPD Shahidi F (1992) J Agric Food Chem 40:444–448

Wanasundara UN, Shahidi F (1994) Food Chem 50:393–396

Natella F, Nardini M, di Felice M, Scaccini C (1999) J Agric Food Chem 47:1453–1459

Cuvelier ME, Richard H, Berset C (1992) Biosci Biotech Biochem 56:324–325

Marinova EM, Yanishlieva NV (1992) Fett Wiss Technol 94:428–432

Marinova EM, Yanishlieva NV (1994) JAOCS 71:427–434

Noda M, Matsumoto M (1971) Biochim Biophys Acta 231:131–133

Tsimidou M (1999) Semin Food Anal 4:13–29

Montedoro G, Servili M, Baldioli M, Miniati E (1992) J Agric Food Chem 40:1571–1576

Baldioli M, Servili M, Perretti G, Montedoro GF (1996) J Am Oil Chem Soc 73:1589–1593

Salvador MD, Aranda F, Fregapane G (1999) JAOCS 76:427–432

Olsen HS, Adler-Nissen J (1979) Process Biochem 14:7–10

Acknowledgements

Financial support by the Finnish national technology agency TEKES is gratefully acknowledged. The authors would also like to thank the Finnish rapeseed oil company Mildola Oy (Kirkkonummi, Finland) for the donation of the oil samples and Christina Anastasopoulou for her technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koski, A., Pekkarinen, S., Hopia, A. et al. Processing of rapeseed oil: effects on sinapic acid derivative content and oxidative stability. Eur Food Res Technol 217, 110–114 (2003). https://doi.org/10.1007/s00217-003-0721-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-003-0721-4