Abstract

The present study described the encapsulation of nodal segments of Cassia angustifolia Vahl. excised from 1-month-old in vitro raised cultures for short-term conservation and propagation. Various concentrations and combinations of gelling matrix (sodium alginate) and complexing agents (calcium chloride) were tested to prepare uniform beads. The ideal beads were obtained through a combination of 3 % sodium alginate and 100 mM calcium chloride. The maximum conversion response (94 %) of encapsulated beads was obtained in Murashige and Skoog’s medium (MS medium) supplemented with 2.5 μM benzyladenine (BA) and 0.4 μM α-naphthalene acetic acid (NAA) after 6 weeks of culture. The encapsulated and non-encapsulated nodal segments were also stored at 4 °C for different time periods (0, 1, 2, 4, 6 and 8 weeks). The regenerated microshoots were best rooted in optimized rooting medium that comprised half-strength MS + 1.0 μM indole-3-butyric acid (IBA) + 5.0 μM phloroglucinol (PG) for the production of complete plantlets. The regenerated plantlets were successfully hardened and acclimatized in natural conditions with 70 % survival rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The encapsulation technique is an important application of micropropagation that offers the potential of easy handling, exchange of germplasm between laboratories, efficient short- or long-term storage and improves delivery of in vitro regenerated plantlets to the field or to the green house (Piccioni and Standardi 1995; Chand and Singh 2004; Rai et al. 2009). Synseed technology provides a means for the transportation of propagules to distant places as well as to different laboratories without a loss in vigor for shoot organogenesis in micropropagation programs (Rihan et al. 2011; Hung and Trueman 2012; Lata et al. 2012; Reddy et al. 2012). Therefore, appropriate storage conditions and a definite storage period are prerequisites to maintain synseed viability during transportation that leads to successful commercialization of synseed technology (Sharma and Shahzad 2012; Sharma et al. 2013).

Cassia angustifolia Vahl. (commonly known as “senna”) is a valuable medicinal legume, the leaves and pods of the plant contain important alkaloids which are the derivatives of anthraquinone glycosides and generally referred to as “sennosides”. It is employed in the treatment of several diseases like anaemia, amoebic dysentery, bronchitis, cholera, jaundice, leprosy and typhoid, etc. (Anonymous 1992). Due to its medicinal properties, this plant is gaining commercial importance in pharmaceutical industries. Thus, it is necessary to develop an alternative source of propagation and efficient method for easy distribution of in vitro raised quality propagules in the form of small beads to fulfill the demands of pharmaceutical industry. During past years, several reports are available on its in vitro regeneration exploiting different strategies of micropropagation (Agrawal and Sardar 2003, 2006, 2007; Siddique and Anis 2007; Siddique et al. 2010; Parveen and Shahzad 2011; Parveen.et al. 2012). However, till date no protocol has been developed for the production of synthetic or artificial seeds in senna. Hence, the present study was conducted to develop a method of short-term storage as well as germplasm exchange and distribution of C. angustifolia using encapsulation technique.

Materials and methods

Explant source

The certified seeds of C. angustifolia obtained from Prem Nursery and Seed Store, Dehradun, India, were surface sterilized through the procedure adopted by Parveen and Shahzad (2011) and used to raise aseptic seedlings in seed germination medium that comprised half-strength MS (Murashige and Skoog 1962) containing GA3 (5.0 μM) under controlled conditions of light, temperature and humidity (Parveen et al. 2010). The cotyledonary nodes excised from aseptic seedlings were cultured on optimal medium containing MS + BA (5.0 μM) + NAA (0.6 μM) for the establishment of in vitro cultures. Nodal segments (NS) approximately 0.5 cm long were taken from in vitro cultures of C. angustifolia and used as the source of explants for the preparation of synseeds.

Encapsulation matrix and complexing agent

Sodium alginate (Qualigens, India) was used as gelling agent and prepared in double distilled water (DDW) and liquid MS medium (with 3 % sucrose) at different concentrations, i.e., 1, 2, 3, 4 and 5 % (w/v). For complexion, 25, 50, 75, 100 and 200 mM calcium chloride (CaCl2·2H2O) solution was prepared in liquid MS medium. The pH of the gel matrix and the complexing agent was adjusted to 5.8 prior to autoclaving at 121 °C for 20 min.

Encapsulation of explants

Encapsulation was accomplished by mixing the NS with sodium alginate solution and dropping them in CaCl2·2H2O solution using a pipette. The droplets containing the explants were held at least for 25–30 min to achieve polymerization. The alginate beads containing the NS were retrieved from the solution and rinsed twice with sterilized DDW to remove the traces of CaCl2·2H2O and transferred to sterile filter paper in Petri dishes for 5 min under the laminar airflow cabinet to eliminate the excess of water and thereafter transferred to culture vials containing nutrient medium.

Planting media and culture conditions

The encapsulated NS (alginate beads) were transferred to wide mouth culture flask (Borosil, India) containing MS basal without plant growth regulator (PGR) and MS medium supplemented with BA at various concentrations (1.0, 2.5, 5.0 and 10.0 μM) either singly or in combination of NAA (0.2, 0.4 and 0.6 μM). The culture medium was gelled with 0.8 % (w/v) agar and pH was adjusted to 5.8 prior to autoclaving at 121 °C for 20 min. Cultures were maintained at 24 ± 2 °C under 16/8 h light–dark conditions with a photosynthetic photon flux density (PPFD) of 50 μmol m−2 s−1 provided by cool white fluorescent tubes (40 W, Philips, India).

Low temperature storage

Two sets of 50 each, encapsulated NS and non-encapsulated NS were kept in two sterile beakers properly covered with aluminium foil and stored in refrigerator at 4 °C. Six different low temperature exposure times (0, 1, 2, 4, 6 and 8 weeks) were evaluated for conversion of synseeds into plantlets. After each storage period, ten encapsulated and ten non-encapsulated NS were transferred to MS medium containing optimal concentration of PGRs for conversion into plantlets. During storage period the beads were sprayed with sterile DDW after every 2 weeks to ensure the moist conditions so that the beads may not shrink by losing water. The percentage of shoot regeneration of encapsulated NS as well as of non-encapsulated NS was recorded after 6 weeks of culture. The plantlets developed from encapsulated NS were hardened off and acclimatized as specified below.

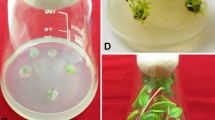

Ex vitro conversion of synthetic seeds into plantlets

Encapsulated NS were also transferred to sterile soilrite for ex vitro conversion and recovery of complete plantlets. The soilrite was regularly moistened with quarter-strength MS salt solution (without vitamins and sucrose) after every 4 days and kept under 16 h photoperiod with a PPFD of 50 μmol m−2 s−1 at 24 ± 2 °C for 6 weeks. The conversion response (%) was recorded after 6 weeks of sowing. To ensure the humid condition, cups were covered with transparent polythene bags with a few perforations for ventilation. After conversion of beads into plantlets, polythene bags were gradually removed in order to acclimatize the plantlets.

Hardening and acclimatization

Plantlets with well-developed root and shoot system were removed from the culture medium and washed gently under running tap water to remove any adherent gel from the roots and transferred to thermocol cups containing sterile soilrite (Keltech Energies Limited, Bengaluru, India). These were kept under similar culture conditions as mentioned earlier and covered with transparent polythene bags to ensure high humidity. These were irrigated after every 3 days with one-fourth strength MS salt solution (without vitamins) for 2 weeks. Polythene bags were removed gradually after 2 weeks in order to acclimatize the plantlets and after 4 weeks they were transferred in earthen pots containing sterilized garden soil and garden manure (1:1) and maintained in green house under normal day length conditions.

Statistical analysis

The regeneration response (%) was calculated as the percent of encapsulated NS showing development of shoots of total number of encapsulated NS. All the experiments were conducted with a minimum of ten replicates per treatment and repeated three times. The data were analyzed statistically using software R (2013) version 3.0.1 (Package ‘agricolae’, version 1.1-4) and the results are expressed as a mean ± SE of three repeated experiments

Results and discussion

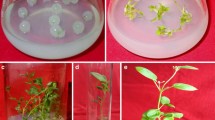

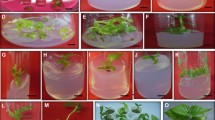

The texture of beads is highly influenced by different concentrations of gelling matrix and complexing agent. Lower concentrations of Na2-alginate below 3 % resulted in the formation of soft and fragile beads which were difficult to handle whereas, concentrations above 3 %, produced isodiametric beads which were hard enough to cause considerable delay in germination. Lower concentrations of CaCl2·2H2O produced soft and fragile beads whereas higher concentrations produced hard beads and adversely affected the bead quality. The optimal combination for the production of uniform, easy to handle, firm and clear beads was found to be 3 % sodium alginate with 100 mM CaCl2·2H2O prepared in liquid MS exhibiting 74.06 ± 1.56 % regeneration response on MS basal medium without any PGR (Table 1; Fig. 1a). Similar results were also obtained in many other plant species such as Tylophora indica (Faisal and Anis 2007); Psidium guajava (Rai et al. 2008); Eclipta alba (Singh et al. 2010) and Vitex negundo (Ahmad and Anis 2010). Nevertheless an encapsulation matrix of 5 % sodium alginate with 50 mM CaCl2·2H2O was found most suitable for the formation of ideal beads in Cannabis sativa (Lata et al. 2009) which is contrary to our results. The synseeds prepared by dissolving sodium alginate in DDW failed to regenerate on all the treatments applied.

Encapsulation of in vitro raised NS of C. angustifolia and their regeneration to produce multiple shoots. a 1-day-old culture showing encapsulated NS on MS basal medium without PGR (bar = 1 cm). b Emergence of microshoots from synseed on MS medium supplemented with 2.5 μM BA, 2 weeks old culture (bar = 0.43 cm). c Production of multiple shoots from a single synseed on MS medium containing BA (2.5 μM) + NAA (0.4 μM), 3 weeks old culture (bar = 0.40 cm). d In vitro rooting of regenerated microshoots in half-strength MS + IBA (1.0 μM) + PG (5.0 μM), after 3 weeks of transfer (bar = 1.13 cm). e Ex vitro conversion of synseed into complete plantlet in sterile soilrite, after 6 weeks of sowing (bar = 1.02 cm)

The most desirable property of the encapsulated explants is their ability to retain viability in terms of regrowth and conversion abilities after encapsulation (Adriani et al. 2000; Micheli et al. 2007). In the present study, the ideal beads produced by encapsulating NS in 3 % sodium alginate and 100 mM CaCl2·2H2O were cultured on MS basal medium without any PGR as well as with various concentrations of BA either singly or in combination with NAA. Synseeds cultured on MS basal medium exhibited 74.06 ± 1.56 % regeneration response and this occurred after 3 weeks of culture. Addition of BA enhanced the regeneration potential of the beads and the shoots emerged out within 2 weeks of inoculation onto the regeneration medium. An average of 2.16 ± 0.44 shoots/bead was produced in the medium containing 2.5 μM of BA with 82.63 ± 1.22 % regeneration response after 6 weeks of culture (Table 1; Fig. 1b). The regenerated microshoots were failed to develop into complete plantlets on the same medium. Addition of NAA (0.4 μM) with optimal concentration of 2.5 μM BA also did not help in the induction of roots from the microshoots, conversely, further improved the regeneration response (94.06 ± 1.56 %) with the production of maximum 5.06 ± 0.29 shoots/bead attaining an average shoot length of 3.06 ± 0.29 cm after 6 weeks of culture (Table 1; Fig. 1c). The synergistic influence of the combination of cytokinin and auxin on synseed regeneration has also been demonstrated in other plants like Dalbergia sissoo (Chand and Singh 2004) and Withania somnifera (Singh et al. 2006). Emergence of single or multiple shoots from the encapsulated explants has also been reported earlier in other medicinal plants (Mandal et al. 2000; Lata et al. 2009; Shrivastava et al. 2009).

The regenerated shoots after attaining suitable length were isolated and transferred to optimized rooting medium that comprised half-strength MS + IBA (1.0 μM) + PG (5.0 μM) for in vitro root induction and development of complete plantlets (Fig. 1d). Similar to our results, Mishra et al. (2011) also described that merely 21.43 % of encapsulated explants of Picrorhiza kurroa exhibited simultaneous production of shoots and roots while rest of the non-rooted shoots were transferred to root induction medium for the development of roots. Ex vitro root induction by pulse treatment with IBA (200 μM) also helped in the development of roots.

Ex vitro regeneration of synthetic seeds

Encapsulated NS were sown into the sterilized soilrite for ex vitro regeneration of beads into the plantlets and soilrite was moistened with quarter-strength MS salt solutions. Sowing of synthetic seed directly into the soilrite facilitated the development of shoot as well as roots and production of complete plantlets with 20 % conversion rate after 6 weeks (Fig. 1e). The regenerated plantlets showed 2–3 roots/shoot. Ex vitro conversion of synthetic seeds has also been performed previously in other plants (Mandal et al. 2000; Soneji et al. 2002; Naik and Chand 2006).

Low temperature storage

To evaluate the regeneration of encapsulated NS after storage, the beads were kept at 4 °C for different time periods (0, 1, 2, 4, 6 and 8 weeks). The non-encapsulated NS were also stored at the same temperature and time period. The encapsulated and non-encapsulated NS without cold storage (control) showed maximum regeneration into microshoots on MS + BA (2.5 μM) + NAA (0.4 μM); increasing the storage time, the regeneration response was reduced. The control beads produced the maximum 5.06 ± 0.29 shoots/bead with 94.06 ± 1.56 % regeneration response after 6 weeks of culture (Table 2). The regeneration potential of the encapsulated explants reduced gradually and after 4 weeks of cold storage dropped to 72.30 ± 1.21 % beads regeneration with an average 1.73 ± 0.14 shoots/bead after 6 weeks of culture. Beyond 4 weeks of cold storage, a sudden fall in regeneration potential was observed as after 8 weeks of storage only 43.90 ± 1.79 % beads could show regeneration. However, also the non-encapsulated NS showed a sharp decline in the regeneration response, wherein the control explants exhibited a 96.13 ± 1.38 % regeneration, producing a maximum of 8.73 ± 0.90 shoots/explant on optimal regeneration medium, while, after 4 weeks of cold storage only 33.33 ± 1.35 % nodal explants exhibited shoot regeneration producing merely 1.40 ± 0.30 shoots/explant and remained only 12.80 ± 1.32 % at the end of 8 weeks (Table 2). Our results are in corroboration with the earlier findings of Faisal et al. (2006) who also reported the efficient conversion of encapsulated NS of Rauwolfia tetraphylla up to 4 weeks of cold storage at 4 °C. Similarly short-term storage of germplasm of Decalepis hamiltonii at 4 °C has also been reported by Sharma and Shahzad (2012). Cold temperature (4 °C) is generally used for storing encapsulated explants in several plant species like Dalbergia sissoo, Quercus sp., Withania somnifera and Eclipta alba (Chand and Singh 2004; Tsvetkov and Hausman 2005; Singh et al. 2006; 2010). However, contrary to these reports, storage of Khaya senegalensis (Hung and Trueman 2011) capsule was much less effective at 4 °C (28–84 %) compared to 25 °C (84–92 %).

In the present study, the major regeneration of encapsulated NS in respect to non-encapsulated NS after different periods of cold storage could be attributed to the inclusion of MS salts in the gelling matrix (sodium alginate) which serves as an artificial nutrient to the encapsulated explants as reported by Lulsdorf et al. (1993) and Rao and Bapat (1993). These findings suggested that storage of encapsulated explants for a considerable period of time allows the preservation of germplasm and could be used efficiently for regeneration of plantlets.

Acclimatization

The in vitro regenerated plantlets require a period of transition or acclimatization prior to transfer to the field or green house conditions. The in vitro rooted plantlets of C. angustifolia were carefully isolated from the rooting medium and acclimatized through the process adopted by Parveen et al. (2012) and exhibited 70 % survival in soil.

Conclusion

In conclusion, this is the first report of encapsulation of axillary buds of C. angustifolia in sodium alginate matrix for short-term conservation and regeneration of plantlets. Although, simultaneous rooting was not achieved in regenerated microshoots, yet the regrowth of multiple shoots from the encapsulated beads after different storage periods and subsequent rooting in either in vitro or ex vitro conditions proved to be an efficient strategy for the short-term storage and propagation of this valuable medicinal legume. Further refinement of the protocol is needed to increase the efficiency of conversion of encapsulated propagules to produce complete plantlets in single step.

Author contribution

In the present study Dr. Shahina Parveen conducted the experiments related to the preparation of synthetic seeds in C. angustifolia and its propagation while Dr. Anwar Shahzad provided overall guidance for the experimental work as well as preparation of manuscript.

Abbreviations

- CaCl2·2H2O:

-

Calcium chloride

- BA:

-

Benzyladenine

- IBA:

-

Indole-3-butyric acid

- NAA:

-

α-naphthalene acetic acid

- MS:

-

Murashige and Skoog medium

- PG:

-

Phloroglucinol

- PGR:

-

Plant growth regulator

References

Adriani M, Piccioni E, Standardi A (2000) Effect of different treatments on the conversion of ‘Hayward’ kiwifruit synthetic seeds to whole plants following encapsulation of in vitro derived buds. New Zeal J Crop Hort 28:59–67

Agrawal V, Sardar PR (2003) In vitro organogenesis and histomorphological investigations in senna (Cassia angustifolia)—a medicinally valuable shrub. Physiol Mol Biol Plants 9:131–140

Agrawal V, Sardar PR (2006) In vitro propagation of Cassia angustifolia through leaflet and cotyledon derived calli. Biol Plant 50:118–122

Agrawal V, Sardar PR (2007) In vitro regeneration through somatic embryogenesis and organogenesis using cotyledons of Cassia angustifolia Vahl. In Vitro Cell Dev Biol-Plant 43:585–592

Ahmad N, Anis M (2010) Direct plant regeneration from encapsulated nodal segments of Vitex negundo. Biol Plant 54:748–752

Anonymous (1992) The wealth of India: a dictionary of Indian raw materials and industrial products (Vol III). CSIR, New Delhi, pp 354–363

Chand S, Singh AK (2004) Plant regeneration from encapsulated nodal segments of Dalbergia sissoo Roxb., a timber yielding leguminous tree species. J Plant Physiol 161:237–243

Faisal M, Anis M (2007) Regeneration of plants from alginate encapsulated shoots of Tylophora indica (Burm.f.) Merrill, an endangered medicinal plant. J Hort Sci Biotechnol 82:351–354

Faisal M, Ahamd N, Anis M (2006) In vitro plant regeneration from alginate encapsulated microcuttings of Rauvolfia tetraphylla L. Am Eur J Aric Environ Sci 1:1–6

Hung CD, Trueman SJ (2011) Encapsulation technology for short-term preservation and germplasm distribution of the African mahogany Khaya senegalensis. Plant Cell Tiss Organ Cult 107:397–405

Hung CD, Trueman SJ (2012) Alginate encapsulation of shoot tips and nodal segments for short-term storage and distribution of the eucalypt Corymbia torelliana × C. citriodora. Acta Physiol Plant 34:117–128

Lata H, Chandra S, Khan IA, ElSohly MA (2009) Propagation through alginate encapsulation of axillary buds of Cannabis sativa L.—an important medicinal plant. Physiol Mol Biol Plants 15:79–86

Lata H, Chandra S, Mehmedic Z, Khan IA, El-Sohly MA (2012) In vitro germplasm conservation of high D9-tetrahydrocannabinol yielding elite clones of Cannabis sativa L. under slow growth conditions. Acta Physiol Plant 34:743–750

Lulsdorf MM, Tautorus TE, Kikcio SI, Bethuna TD, Dunstan DI (1993) Germination of encapsulated embryos of interior spruce (Picea glauca engelmannii complex) and black spruce (Picea mariana Mill.). Plant Cell Rep 12:385–389

Mandal J, Pattnaik S, Chand PK (2000) Alginate encapsulation of axillary buds of Ocimum americanum L. (Hoary Basil), O. basilicum L. (Sweet Basil), O. gratissimum L. (Shrubby Basil), and O. sanctum L. (Sacred Basil). In Vitro Cell Dev Biol-Plant 36:287–292

Micheli M, Hafiz IA, Standardi A (2007) Encapsulation of in vitro derived explants of olive (Olea europaea L. cv. Moraiolo) II. Effects of storage on capsule and derived shoots performance. Sci Hort 113:286–292

Mishra J, Singh M, Palni LMS, Nandi SK (2011) Assessment of genetic fidelity of encapsulated microshoots of Picrorhiza kurrooa. Plant Cell Tiss Organ Cult 104:181–186

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue culture. Physiol Plant 15:473–497

Naik SK, Chand PK (2006) Nutrient alginate encapsulation of in vitro nodal segments of pomegranate (Punica granatum L.) for germplasm distribution and exchange. Sci Hort 108:247–252

Parveen S, Shahzad A (2011) A micropropagation protocol for Cassia angustifolia Vahl. from root explants. Acta Physiol Plant 33:789–796

Parveen S, Shahzad A, Saema S (2010) In vitro plant regeneration system for Cassia siamea Lam., a leguminous tree of economic importance. Agrofor Syst 80:109–116

Parveen S, Shahzad A, Anis M (2012) Enhanced shoot organogenesis in Cassia angustifolia Vahl.—a difficult-to-root drought resistant medicinal shrub. J Plant Biochem Biotechnol 21:213–219

Piccioni E, Standardi A (1995) Encapsulation of micropropagated buds of six woody species. Plant Cell Tiss Organ Cult 42:221–226

Rai MK, Jaiswal VS, Jaiswal U (2008) Encapsulation of shoot tips of guava (Psidium guajava L.) for short-term storage and germplasm exchange. Sci Hort 118:33–38

Rai MK, Asthana P, Singh SK, Jaiswal VS, Jaiswal U (2009) The encapsulation technology in fruit plants—a review. Biotechnol Adv 27:671–679

Rao PS, Bapat VA (1993) Micropropagation of sandalwood (Santalum album L.) and mulberry (Morus indica L.). In: Ahuja MR (ed) Micropropagation of woody plants. Kluwer, Dordrecht, pp 317–345

Reddy MC, Murthy KSR, Pullaiah T (2012) Synthetic seeds: a review in agriculture and forestry. Afr J Biotechnol 11:14254–14275

Rihan HZ, Al-Issawi M, Burchett S, Fuller MP (2011) Encapsulation of cauliflower (Brassica oleracea var botrytis) microshoots as artificial seeds and their conversion and growth in commercial substrates. Plant Cell Tiss Organ Cult 107:243–250

Sharma S, Shahzad A (2012) Encapsulation technology for short-term storage and conservation of a woody climber, Decalepis hamiltonii Wight and Arn. Plant Cell Tiss Organ Cult 111:191–198

Sharma S, Shahzad A, Teixeira da Silva JA (2013) Synseed technology—a complete synthesis. Biotechnol Adv 31:186–207

Shrivastava V, Khan SA, Banerjee S (2009) An evaluation of genetic fidelity of encapsulated microshoots of the medicinal plant: Cineraria maritima following 6 months of storage. Plant Cell Tiss Organ Cult 99:193–198

Siddique I, Anis M (2007) In vitro shoot multiplication and plantlet regeneration from nodal explants of Cassia angustifolia (Vahl.): a medicinal plant. Acta Physiol Plant 29:233–238

Siddique I, Anis M, Aref IM (2010) In vitro adventitious shoot regeneration via indirect organogenesis from petiole explants of Cassia angustifolia Vahl.—a potential medicinal plant. Appl Biochem Biotechnol 162:2067–2074

Singh AK, Varshney R, Sharma M, Agarwal SS, Bansal KC (2006) Regeneration of plants from alginate-encapsulated shoot tips of Withania somnifera (L.) Dunal, a medicinally important plant species. J Plant Physiol 163:220–223

Singh SK, Rai MK, Asthana P, Sahoo L (2010) Alginate-encapsulation of nodal segments for propagation, short-term conservation and germplasm exchange and distribution of Eclipta alba (L.). Acta Physiol Plant 32:607–610

Soneji JR, Rao PS, Mhatre M (2002) Germination of synthetic seeds of pineapple (Ananas comosus L. Merr.). Plant Cell Rep 20:891–894

Tsvetkov I, Hausman JF (2005) In vitro regeneration from alginate encapsulated microcuttings of Quercus sp. Sci Hort 103:503–507

Acknowledgments

The author Shahina Parveen acknowledges the research assistance provided by UGC under the scheme of Maulana Azad National Fellowship for the award of Senior Research Fellowship (SRF). The author Anwar Shahzad also gratefully acknowledges the financial support promoted by the Council of Science and Technology (UP-CST, vide no. CST/D 3836) and UGC (vide no. 39-369/2010(SR)), Government of India, New Delhi. Prof. Athar A. Khan is also acknowledged for statistical analysis of data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by M. Capuana.

Rights and permissions

About this article

Cite this article

Parveen, S., Shahzad, A. Encapsulation of nodal segments of Cassia angustifolia Vahl. for short-term storage and germplasm exchange. Acta Physiol Plant 36, 635–640 (2014). https://doi.org/10.1007/s11738-013-1441-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11738-013-1441-4