Abstract

The ever-increasing environmental and toxicity concerns have resulted in the widespread development of fluorosurfactants without long perfluorinated chain (≥ C8). The surveys have reported that perfluoroether chains are easier to degrade than fluorinated chains due to the better flexibility of ether bond. Herein, four novel kinds of fluorosurfactants with a perfluorinated branched ether chain were reported, which can be synthesized via a simple and economical route. These surfactants all exhibited extremely high surface activity. The effect of salt and pH on the surface activities of the newly prepared surfactants were studied. The results showed that these surfactants possessed excellent acid and alkali resistance except that the anionic surfactant was slightly sensitive to acid. Interfacial tension of oil/water and thermodynamic properties of the surfactants were further investigated for the purpose of special applications. This series of surfactants had great thermal stability and the fluorinated cationic surfactant can spread on the oil surface under the condition of low concentration. These excellent properties indicate that these surfactants possess good prospect for industrial applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

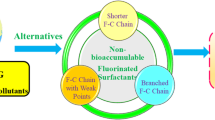

Fluorosurfactants are one of the most widespread used surfactants due to their high surface activity, outstanding thermal stability and excellent chemical stability (Griffiths et al. 2004; Kissa 2001; Munoz et al. 2017). The fluorocarbon chains are both hydrophobic and oleophobic, which endows fluorosurfactants with tremendous potentials in various fields compared to commonly used surfactants (Abe 1999; Fanga et al. 2016). The most frequently used fluorinated surfactants such as perfluorooctanoic acid (PFOA, C7F15COOH) and perfluorooctane sulphonate (PFOS, C8F17SO3X, with X = K, Na, H) are suffering from the toxicity and biodegrade difficulty (Pierozan and Karlsson 2018). Upon the strengthening of environmental protection awareness and worldwide concern about the biodegradation of fluorosurfactants, the international community has gradually enacted agreements to ban and replace the use of fluorosurfactants with a long carbon chain length of ≥ C8 (Sha et al. 2015a, b, c). Therefore, the demand for alternatives to perfluorinated long-chain fluorosurfactants is ever-increasingly urgent. Since the reduction of the surface tension of water is significantly dependent on the fluorosurfactant, the shortening of the length of the fluorine-containing moiety and screening of functional groups are an effective strategy. Recently, the harm to the environment can be ignored when the fluorocarbon chain is equal to four carbons (Gardiner 2015; Dichiarante et al. 2018). Unfortunately, the common short-chain fluorochemicals have poor surface activity, limiting their practical applications. For example, the critical micelle concentration (CMC) and the lowest surface tension of the aqueous solution of sodium perfluorobutanesulfonate were found to be 273 mmol L−1 and 29.72 mN m−1, which cannot be categorized into traditional fluorosurfactants.

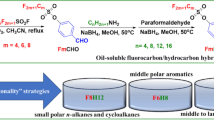

In this respect, our research group systematically developed a series of fluorocarbon surfactants through introducing a branched chain structure (CF3CF2CF2C(CF3)2-) in the fluorinated chain using perfluoro-2-methyl-2-pentene (D2) as starting material (Scheme 1) (Sha et al. 2013, 2014, 2015a, b, c; Lin et al. 2018a, b). These fluorocarbon surfactants exhibited better surface capabilities than CF3(CF2)6COONa under the same conditions. This method was one of the effective strategies to synthesize non-biocompatible alternatives of PFOA. Besides, the literature reported that perfluoroether chains were easier to degrade than fluorinated chains due to the better flexibility of ether bond (Kostov et al. 2009). Therefore, introducing ether bond based on D2 was an efficient and environmentally friendly method to develop fluorinated surfactants in this concern. As a continuous research in our systematical work, we still adopt D2 as a raw material to develop a series of new fluorinated surfactants with perfluorinated branched ether chain. The surface activity, spreading properties and thermodynamic properties of these surfactants were studied. The effect of pH and the added salt on the surface tension of the surfactant were also investigated. The paper aims to further broaden the types of surfactants and provide experimental foundations for the development and application of fluorosurfactants.

Experimental

Materials

Perfluoro-2-methyl-2-pentene was supplied by Shanghai Aimojinshan Pharmaceutical Company (99% purity). All chemical reagents were AR grade quality. Solvents were AR grade quality and dried by the standard methods before use. 1H NMR, 13C NMR, and 19F NMR spectra were determined on a Brucker AC 400 spectrometer. FT-IR spectra were recorded from Nicolet 380FT-IR instrument was reported in wave numbers (cm−1). LRMS was performed on Agilent 5973 N mass instrument (EI). HRMS was performed on Waters Micromass GTC Premier (EI).

Synthesis

The synthetic paths of potassium perfluoro-2-methyl-2-pentanolate and the surfactants were shown in Schemes 2 and 3.

Synthesis of perfluoro-2-methyl-2-pentanol (2) (Scherer and Terranova 1981)

In a 100-mL three-necked flask, dry KF (5 g, 0.86 mol) was added and the system under Ar atmosphere. Then, 50 mL of DMAC and D2 (17.13 g, 57.1 mmol) were added by sequence. The resulted mixture was stirred in an ice-salt bath (< − 7 °C) for 1 h, followed by the introduction of N2O4 (10.9 g, 118 mmol) under a slight flow of O2. A condenser at − 78 °C (dry ice-ethanol bath) was used to prevent the overflow of N2O4 since the reaction system is an exothermic reaction. Upon the addition of N2O4, the reaction system immediately turned to be dark green. D2 reacted completely after 18 h, and dark green disappeared. O2 was slowly introduced at room temperature, and then NMR spectra showed the formation of intermediate 1b, the system gradually turned pale yellow. The reaction was finished in 48 h. H3PO3 (0.62 g) and 40 mL of water were added to the mixture, whereupon the white solid gradually dissolved in the system and the mixed solution was layered. A small amount of sulfamic acid was slowly added dropwise to the system to remove excess NO2 until the system became clear. Subsequently, the temperature raised to 125 °C at atmospheric pressure, whereat the reaction mixture was distilled and the distillate produced stratified layer. KOH was added to the distillate, whereupon most of the lower phase dissolved in the aqueous layer. A small amount of neutral material was distilled under aspirator pressure into a − 78 °C trap, afterward the excess H2SO4 (1 mol L−1) was added to the remaining fractions. The liquid was separated and 5 mL of H2SO4 (98%) was added. Compound 2 (colorless liquid, 12.129 g, yield = 65.7%, purity of 99%) was condensed by vacuum pump in dry ice receiver. 1H NMR (400 MHz, DMSO-d6) δ 10.93 (d, J = 4.3 Hz, 1H). 19F NMR (376 MHz, DMSO-d6) δ: − 71.45 ~ − 71.86 (m), − 80.09 (d, J = 11.7 Hz), − 115.44 (s), − 124.05 (s). LRMS (EI) m/z (%): 69.1 (100) CF3, 297.0 (36.9) C6F11O [M-H-2F]. The observed physical and spectroscopic properties of compound 2 in the experiment matched the literature reference.

Synthesis of sodium perfluorobutanesulfonate (3)

KOH (0.92 g, 16 mmol) was dissolved in 12 mL of anhydrous ethanol, which was kept stirring under ice-water bath for 0.5 h, followed by the dropwise addition of perfluoro-2-methyl-2-pentanol (5.77 g, 17.2 mmol). The reaction system was allowed to react at room temperature for 2 h and the clarified solution was subjected to distillate under vacuum (3 mba). The resulting residue was vacuum dried with an oil pump at 80 °C to give the white crystals (5.93 g, 16 mmol, yield = 99%). 19F NMR (376 MHz, DMSO-d6) δ: − 73.82 to − 74.13 (m), − 79.33 (t, J = 11.0 Hz), − 115.03 to − 115.53 (m), − 123.04 to − 123.75 (m); LRMS (ESI) m/z: 334.85 [M–K]; HRMS (ESI) calcd. for C6F13O [M–K] 334.9747, found. 334.9740. FT-IR (cm−1): 1341.7, 1204.8, 1142.7, 1114.0, 955.8, 817.0, 751.9, 734.2, 715.0. Anal. calcd. for C6F13OK: C, 19.26; found: C, 19.22.

Synthesis of 2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy} acetate (4)

Toward a sealed tube (25 mL) was added with compound 3 (3.93 g, 10.5 mmol), ethyl bromoacetate (1.67 g, 10 mmol) and anhydrous DMAC (10 mL), the mixture was sealed and stirred at room temperature for 24 h. After the reaction was completed, the mixture was extracted by ether, which was washed by deionized water and saturated brine for several times. The organic phase was dried by sodium sulfate and the solvent was removed. The product was obtained by column chromatography (EtOAc: petroleum = 1:40) as a colorless liquid (3.88 g, yield = 92%). 1H NMR (400 MHz, CDCl3) δ: 4.54 (s, 2H), 4.25 (q, J = 7.2 Hz, 2H), 1.34–1.20 (m, 3H); 19F NMR (376 MHz, CDCl3) δ: − 67.21 to − 67.43 (m), − 80.51 (t, J = 12.1 Hz), − 113.20 to − 113.58 (m), − 123.68 to − 123.96 (m); 13C NMR (101 MHz, CDCl3) δ: 166.02, 65.91, 61.78, 13.86; FT-IR (cm−1): 2962.4, 1777.9, 1179.0, 1116.1, 1031.0, 965.2, 831.4, 740.3, 609.9; LRMS (EI) m/z (%): 349.1(100), 423.1 (0.38); HRMS (EI) m/z (%): calcd for C10H7O3F13 422.0188, found 422.0186.

Synthesis of 2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy} acetic acid (5)

Compound 4 (2.11 g, 5.0 mmol) was dissolved in 50.0 mL of methanol, followed by the addition of sodium hydroxide aqueous solution under ice-water bath (6.0 mL, 1 mol L−1). The mixing system was moved to 60 °C water bath and stirred for 4 h. After the reaction was completed, water was added to the system and washed with diethyl ether. The pH of the solution was adjusted to 3.0 using 6 mol L−1 HCl solution. The aqueous solution was extracted by ether and dried over anhydrous sodium sulfate, filtered and concentrated under reduced pressure to give a colorless oily liquid (1.89 g, yield = 95.9%). 1H NMR (400 MHz, CDCl3) δ: 4.64; 19F NMR (376 MHz, CDCl3) δ: − 67.25 to − 67.45 (m), − 80.54 (t, J = 12.2 Hz), − 113.29 to − 113.57 (m), − 123.91 to − 124.12 (m). 13C NMR (101 MHz, CDCl3) δ: 171.68, 65.11. LRMS (EI) m/z (%): 181.0 (100), 375.1 (0.95); HRMS (EI) m/z (%): calcd for C8H3O3F12 374.9891 [M-F], found 374.9894. FT-IR (cm−1): 2961.9, 2587.6, 1755.3, 1438.8, 1344.9, 1243.6, 824.6, 740.3, 719.4

Synthesis of compound 6 (2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy}-N-[2-(dimethylamino)ethyl]acetamide)

In a 25-mL jacketed reaction flask, compound 5 (0.433 g, 1.10 mmol), DMAP (0.014 g, 0.11 mmol) and EDCI (0.315 g, 1.65 mmol) were sequentially added, 10.0 mL of anhydrous dichloromethane was then added under cooling with ice-water bath and kept stirring for 10 min. Afterwards, N, N-dimethylethylenediamine (0.18 mL, 1.65 mmol) was added dropwise to the system, and the mixture was allowed to react at room temperature for 5 h. The mixture was washed with deionized water and saturated brine successively. The organic phase was dried over anhydrous sodium sulfate, filtered and concentrated. The final product was purified by column chromatography (MeOH:DCM = 1:20) to give the product 0.49 g (0.907 mmol, yield = 82.5%). 1H NMR (400 MHz, CDCl3) δ: 7.07 (s, 1H), 4.52 (s, 2H), 3.35 (dd, J = 11.2, 5.5 Hz, 2H), 2.45–2.38 (m, 2H), 2.21 (s, 6H); 19F NMR (376 MHz, CDCl3) δ: − 67.22 to − 67.47 (m), − 80.55 (t, J = 12.3 Hz), − 113.28 to − 113.58 (m), − 123.74 to − 124.02 (m); 13C NMR (101 MHz, CDCl3) δ 165.27 (s), 67.97 (s), 56.76 (s), 44.59 (s), 36.24 (s); IR (cm−1) :2826.9, 1694.0, 1526.5, 1171.0, 1116.6, 1043.6, 740.0; LRMS (EI) m/z (%): 58.2 (100), 463.2 (4.71); HRMS (EI) m/z (%): calcd for C12H13N2O2F13 464.0769, found 464.0773.

Synthesis of the fluorinated anionic surfactant 7 (2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy}acetate)

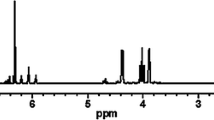

In a 50-mL round bottom flask, 1.00 g (2.54 mmol) of compound 5 and 10.0 mL of methanol were added, and the mixture was stirred to dissolve completely. 0.1 mol/L sodium hydroxide aqueous solution was slowly added dropwise until pH of the system was 7. The solvent was distilled under reduced pressure to obtain a white solid, which was washed with acetone and then dried in vacuo to give 0.90 g (2.16 mmol) of a white powdery product in a yield of 85%. 1H NMR (400 MHz, CD3OD) δ: 4.32; 19F NMR (376 MHz, CD3OD) δ: − 68.33 to − 68.56 (m), − 82.09 (t, J = 12.4 Hz), − 113.70 to − 114.30 (m), − 124.93 to − 125.48 (m); 13C NMR (101 MHz, CD3OD) δ: 171.36, 67.53. LRMS (ESI): 439.00 [M + Na]+; HRMS (ESI): calcd for C8H2O3F13 392.9802[M-Na]−, found 392.9805; IR (cm−1) :1621.6, 1430.0, 1350.8, 1221.8, 1169.0, 739.6, 727.2

Synthesis of the fluorinated cationic surfactant 8 (2-{2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy}acetamido}-N-ethyl-N,N-dimethylethan-1-ammonium iodide)

In a 30-mL sealed tube, 2.0 mmol of compound 6 was added and the mixture was purged with argon three times. 10 mL of anhydrous tetrahydrofuran and 5 mmol of iodoethane were added. The reaction was stirred at 60 °C for 24 h, cooled to room temperature and filtered. The solid was washed with ethyl acetate to give the target compound. Compound 8 was the white solid powder with a yield of 72%. 1H NMR (400 MHz, CD3OD) δ: 4.67 (s, 2H), 3.77 (t, J = 7.0 Hz, 2H), 3.57–3.51 (m, 2H), 3.51–3.44 (m, 2H), 3.20 (s, 6H), 1.45 (t, J = 7.0 Hz, 3H); 13C NMR (101 MHz, CD3OD) δ: 166.70, 67.79, 60.66, 59.95, 49.95, 49.91, 49.87, 32.85, 7.11; 19F NMR (376 MHz, CD3OD) δ − 68.44 to − 68.62 (m), -81.94 (t, J = 12.4 Hz), − 113.88 to − 114.21 (m), − 125.14 to − 125.48 (m); IR (cm−1) :3221.4, 1696.9, 1485.2, 1347.1, 1265.6, 1178.7, 1115.1, 963.2, 717.0; LRMS (ESI): 493.45[M-I]+; HRMS (ESI): calcd for C14H18O2N2F13 493.1155[M-I]+, found 493.1156.

Synthesis of the fluorinated amine oxide surfactant 9 (2-{2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy}acetamido}-N,N-dimethylethan-1-amine oxide)

A 250-mL round bottom flask was charged with 10.0 mmol of compound 6 and 100 mL of 30% hydrogen peroxide. The reaction system became homogeneous after stirring overnight at room temperature. Dichloromethane was extracted twice and the aqueous phase was lyophilized to give the title product. Compound 9 was the clear paste with a yield of 73%. 1H NMR (400 MHz, CD3OD) δ 4.41 (s, 2H), 3.96 – 3.87 (m, 2H), 3.67 (t, J = 5.7 Hz, 2H), 3.45 (s, 6H). 19F NMR (376 MHz, CDCl3) δ − 68.41 to − 68.60(m, 6F), − 81.96 (t, J = 12.5 Hz, 3F), − 113.94 to − 114.14 (m, 2F), − 125.07 to − 125.40 (m, 2F). 13C NMR (101 MHz, d2o) δ 166.96, 67.06, 57.64, 34.21, 32.20; IR (cm−1) :3227.2, 1452.3, 1344.1, 1254.0, 1169.7, 1115.5, 740.1, 717.2; LRMS (ESI): 481.15[M+H]+; HRMS (ESI): calcd for C12H13O3N2F13Na 503.0611 [M+Na]+, found 503.0610.

Synthesis of the fluorinated amphiphilic surfactant 10 (2-{[2-(2-{[1,1,1,3,3,4,4,5,5,5-decafluoro-2-(trifluoromethyl)pentan-2-yl]oxy}acetamido]ethyl}dimethylammonioacetate)

In a 50-mL round bottom flask, compound 6 (0.42 g, 1.0 mmol), ethyl bromoacetate (0.26 mL, 2.3 mmol) and 10 mL of DCM were added. The mixture was stirred at room temperature for 24 h. The solvent was distilled under reduced pressure, and then strong base ion exchange resin and 15 mL EtOH were mixed for 24 h at room temperature. After filtration, the solvent of filtrate was removed under vacuum. Compound 10 was obtained as a white solid from the recrystallization from acetone and dichloromethane (0.41 g, yield = 79%). 1H NMR (400 MHz, CD3OD) δ: 4.51 (d, J = 12.0 Hz, 2H), 3.78 (s, 2H), 3.71–3.64 (m, 2H), 3.63 (d, J = 5.6 Hz, 2H), 3.22 (d, J = 8.6 Hz, 6H); 13C NMR (101 MHz, CD3OD) δ: 167.10, 166.61, 67.80, 63.94, 61.44, 50.71, 33.03; 19F NMR (376 MHz, CD3OD) δ: − 68.20 to − 68.92 (m), − 81.99 (t, J = 12.4 Hz), − 113.84 to − 114.44 (m), − 124.99 to − 125.84 (m); IR (cm−1):3227.1, 3028.8, 1682.7, 1634.5, 1391.3, 1261.9, 1170.0, 823.4, 739.8, 717.5; LRMS (ESI): 523.10 [M+H]+; HRMS (ESI): calcd for C14H16O4N2F13 523.0897 [M+H]+, found 523.0897.

Surface tension measurement

Surface tensions were tested using a Kruss K100 tensiometer by the Wilhelmy plate method at 25 °C. Solutions were prepared in deionized water. The thickness of the platinum plate was 19.9 mm and 0.2 mm, respectively. The immersion distance was 2 mm.

Interfacial tension measurement

Interfacial tensions between aqueous solution of surfactants and cyclohexane were measured at 25 °C using Kruss K100 tensiometer.

TGA measurement

Simultaneous DSC-TGA instrument was used to characterize the decomposing temperature (Td). The temperature range was from 20 to 600 °C at a heating rate of 15 °C/min with N2 protection.

Results and discussion

Surface activity and influence of salt

Figure 1 shows a plot of surface tension (γ) versus log surfactant molarity (log C) for our fluorocarbon surfactants. There is no minimum near the critical micelle concentration (CMC), indicating no surface active impurities. As summarized in Table 1, the CMC values for compounds 7–10 are 1.64 × 10−2, 1.26 × 10−2, 8.50 × 10−3 and 1.21 × 10−2 mol L−1, respectively. The γcmc values for compounds 7–10 are calculated to be 20.07, 19.70, 19.78 and 19.05 mN m−1, respectively. This proves that these fluorosurfactants have high surface activities, which are superior than C7F15COONa (CMC = 31.2 mmol L−1; γcmc = 24.7 mN m−1) (Zhang et al. 2000).

Surface excess concentration (Гmax) in mol cm−2 and minimum area permolecule (Amin) in Å2 were calculated from the following equation (Rosen and Kunjappu 2012):

where R = 8.31 J mol−1 K−1, T = 298 K, and dγ/dlogC is the slope of the calculated CMC in the surface tension plots. Γmax is the adsorption quantity of surfactant at the air/water interface. The surface area of each molecule can be calculated by the following formula:

where NA is the Avogadro’s constant, Acmc gives the information on the degree of filling of surfactant molecules at the air/water interface. As summarized in Table 1, this series of fluorine surfactants have large saturated adsorption capacity in aqueous solution, and the limit area of the adsorbed molecules is small.

The influence of additional salt (0.1 mol L−1 NaCl) on surface activities of surfactants 7–10 under the same conditions was further examined, results were shown in Fig. 2. Comparing the surface tension curves in Fig. 2a with those in Fig. 1, it can be found that both the straight slope and γcmc were close. However, salt addition can significantly decrease the CMC of surfactants 7, 8 and 10, take surfactant 7 for example as shown in Fig. 2b. We speculated that not only Na+ and Cl− had a certain shielding effect on the charge repulsion between the head groups of ionic fluorosurfactants, but also the introduction of 0.1 mol L−1 NaCl brought about a “salting out” effect (Yang et al. 2009). The addition of NaCl deprives the water of the solution so that the effective surfactant concentration is increased, which is consistent with the reduced solubility of surfactants (i.e., enhanced hydrophobicity). Since the fluorosurfactant 9 is non-ionic state, its CMC is almost unchanged.

Table 2 lists the surface activity of fluorinated surfactants with CF3CF2CF2(CF3)2 group as reported, by comparison, it is found that the four fluorinated surfactants synthesized in this paper have similar surface properties with them and are superior to PFOA. Experiment has confirmed that fluorinated surfactants with CF3CF2CF2(CF3)2 group have low toxicity and are non-carcinogenic (Sha et al. 2015c). Besides, the literature reported that perfluoroether chains are easier to degrade than fluorinated chains due to the better flexibility of ether bond (Malinverno et al. 2005; Kostov et al. 2009; Huo et al. 2014; Sha et al. 2015b; Zhang et al. 2018a, b). Therefore, the introduction of perfluoro-branched ether chain can improve the surface properties and further improve the degradation of fluorinated surfactants.

Based on the above results, fluorosurfactant 8 has the lowest critical micelle concentration when the surface tension of the four surfactants is similar. Moreover, it possesses excellent surface properties and salt resistance. Therefore, it is the most potential substitute for PFOA.

Effect of pH on surface properties

The practical applications of industrial cleaning (strong acid washing solution), acid fracturing fluid in the petroleum industry, and drainage aid (Shi et al. 2009) have placed high demands on the acid and alkali resistance of surfactants. Therefore, it is necessary to investigate the effect of pH on surface properties of surfactants. As can be seen in Fig. 3, when the concentration of aqueous solution of fluorinated surfactant is 0.005 mol L−1, the surface tension of carboxylate fluorosurfactant 7 dramatically rises in the acidic environment. The decrease trend has turned to be gentle under alkaline conditions. The reason may be that compound 7 easily precipitates free acid in the acidic environment, resulting in a decrease in the effective concentration of the surfactant, which lead to a reduction in its surface activity (Yang et al. 2009). The alkaline environment brought about the “salting out” effect, improving the concentration of effective surfactant so that its surface tension had been decreased. The cationic fluorinated surfactant 8 and ammonium oxide fluorinated surfactant 9 have stable surface properties in both acidic and alkaline environments while the amphoteric fluorinated surfactant 10 has significantly improved surface properties under strong acid or alkali conditions.

Interfacial tension between cyclohexane and aqueous solution of fluorosurfactant

Low-cost (less amount) and high spreading active fluorosurfactants are an everlasting research topic in the field of fire protection. Cyclohexane (typical oils have a surface tension of 20–30 mN/m, cyclohexane has a surface tension of 25.187 mN/m) is usually used as a standard to investigate the spreading properties of fluorosurfactants. The general surface tension of oil solution (γo) is 20–30 mN/m, and the interfacial tension of pure water and oil solution (γw/o) is 30–40 mN/m. After adding the fluorocarbon surfactants, the surface tension of the surfactant-containing aqueous solution (γw) can be reduced to 15–18 mN/m, and the γw/o can be reduced to 1–2 mN/m. Thus, (γw + γw/o) can be less than 20 mN/m, so the spreading factor (Sw/o = γo − (γw + γw/o)) of the aqueous solution at the oil surface is greater than zero, thus, the surfactant-containing aqueous solution can be spread on the oil surface (Harkins and Feldman 1922). As shown in Table 3, when the concentration of the solution is 8.5 × 10−3 mol L−1, the aqueous solution of compound 8 has good spreading property and can be spread into the water film on the oil surface. Thus, fluorosurfactant 8 is the valuable substance for fire fighting.

Thermal stability

Thermal stability is an important application property for surfactants. At high temperatures, surfactants decompose and lose their activity. The TG curves of fluorosurfactants in nitrogen are shown in Fig. 4, the decomposition temperatures for compounds 7, 8, 9 and 10 are 282.6 °C, 177.0 °C, 189.2 °C, and 158.6 °C, respectively. The high decomposition temperatures indicate good thermal stability and the heat resistance for compound 7. However, the fluorosurfactant 10 has slightly poor temperature resistance and was decomposed at 158.6 °C.

In summary, the fluorinated cationic surfactant 8 with perfluorinated branched ether chain shows excellent surface activity. It possesses acid and alkali resistance, high temperature resistance. Besides, it has good spreading properties under the condition of low concentration and is not affected by salt. This makes it the most potential fluorinated surfactant.

Conclusion

A series of fluorosurfactants containing perfluorinated branched ether chain with high surface activity were prepared using perfluoro-2-methyl-2-pentene as starting material. All the synthetic routes were easy to handle under mild reaction conditions, together with high yields and low cost. The series of surfactants have a reduced surface tension of water as low as 20 mN/m. Compared with that of sodium perfluorooctanoate, they show excellent surface properties. The addition of salt can reduce the cmc of ionic surfactants, which significantly improve the performance of them. These surfactants have good acid and alkali resistance except for 7. All the fluorosurfactants exhibit good thermal stability, and carboxyl fluorosurfactants 7 can even be applied to high temperature systems of 282.6 °C. Particularly, the fluorinated cationic surfactant 8 shows an excellent efficiency to reduce the surface tension of water (Cmc = 8.5 × 10−3 mol L−1), and has good spreading properties under the condition of low concentration, which can be applied in firefighting field.

The four types of fluorosurfactants are more environmentally friendly than common long-chain liner perfluorinated surfactants due to the fluorocarbon ether short-chain, and can be used as substitutes for PFOA or PFOS since they are highly surface-activated, easy-prepared and cheap. The synthetic strategy we proposed in this work is a significant direction for the development of fluorosurfactant.

References

Abe M (1999) Synthesis and applications of surfactants containing fluorine. Curr Opin Colloid in 4:354–356

Dichiarante V, Milani R, Metrangolo P (2018) Natural surfactants towards a more sustainable fluorine chemistry. Green Chem 20:13–27. https://doi.org/10.1039/c7gc03081a

Fanga C, Megharaj M, Naidu R (2016) Electrochemical detection of thioether-based fluorosurfactants in aqueous film-forming foam (AFFF). Electroanalysis 29:1095–1102. https://doi.org/10.1002/elan.201600724

Gardiner J (2015) Fluoropolymers: origin, production, and industrial and commercial applications. Aust J Chem 68:13–22. https://doi.org/10.1071/CH14165

Griffiths PC, Cheung AYF, Jenkins RL, Howe AM, Pitt AR, Heenan RK, King SM (2004) Interaction between a partially fluorinated alkyl sulfate and gelatin in aqueous solution. Langmuir 20:1161–1167. https://doi.org/10.1021/la035956c

Harkins WD, Feldman A (1922) Films. The spreading of liquids and the spreading coefficient. J Am Chem Soc 44:2665–2685

Huo T, Huang Y, Meng WD (2014) Preparation of perfluoropolyether-containing poly-methacrylate emulsion and their application on cotton fabrics. J Donghua Univ 40:90–98. https://doi.org/10.3969/j.issn.1671-0444.2014.01.016

Kissa E (2001) Fluorinated surfactants and repellents. Marcel Dekker Inc, New York

Kostov G, Boschet F, Ameduri B (2009) Original fluorinated surfactants potentially non-bioaccumulable. J Fluorine Chem 130:1192–1199. https://doi.org/10.1016/j.jfluchem.2009.08.002

Lin C, Pan RM, Xin P, Jiang B (2018a) Synthesis and combined properties of novel fluorinated cationic surfactants with CF3CF2CF2C(CF3)2- group. Chin Chem Lett. https://doi.org/10.1016/j.cclet.2018.04.017 in press

Lin C, Pan RM, Xin P, Jiang B (2018b) Synthesis and surface activity study of novel branched zwitterionic heterogemini fluorosurfactants with CF3CF2CF2C(CF3)2 group. J Fluorine Chem 214:35–41. https://doi.org/10.1016/j.jfluchem.2018.07.015

Malinverno G, Colombo I, Visca M (2005) Toxicological profile of hydrofluoropolyethers. Regul Toxicol Pharm 41:228–239

Munoz G, Desrosiers M, Duy SV, Labadie P, Budzinski H, Liu J, Sauvé S (2017) Environmental occurrence of perfluoroalkyl acids and novel fluorotelomer surfactants in the freshwater fish catostomus commersonii and sediments following firefighting foam deployment at the Lac-Mégantic railway accident. Enviro Sci Technol 51:1231–1240. https://doi.org/10.1021/acs.est.6b05432

Pierozan P, Karlsson O (2018) PFOS induces proliferation, cell-cycle progression, and malignant phenotype in human breast epithelial cells. Arch Toxicol 92:705–716. https://doi.org/10.1007/s00204-017-2077-8

Rosen MJ, Kunjappu JT (2012) Surfactants and interfacial phenomena, 4th edn. JohnWiley & Son, NewYork

Scherer KV Jr, Terranova TF (1981) F-2-methyl-2-pentanol. An easily prepared perfluorinated tertiary alcohol. J Org Chem 46:2379–2381

Sha M, Pan RM, Jiang B (2013) One-Pot catalytic epoxidation reaction of perfluoro-2-methyl-2-pentene with tri-n-butylamine N-oxide or N, N-dimethylcyclohexylamine N-oxide. Adv Mater Res 685:357–361. https://doi.org/10.4028/www.scientific.net/AMR.685.357

Sha M, Pan R, Zhan L, Xing P, Jiang B (2014) Synthesis and surface activity study of a novel branched fluorinated anion surfactant with CF3CF2CF2C(CF3)2 group. Chin J Org Chem 32:995–998. https://doi.org/10.1002/cjoc.201400377

Sha M, Pan R, Xing P, Jiang B (2015a) Synthesis and surface activity study of branched fluorinated cationic (FCS), gemini (FGS) and amphoteric (FAS) surfactants with CF3CF2CF2C(CF3)2 group. J Fluorine Chem 169:61–65. https://doi.org/10.1016/j.jfluchem.2014.11.005

Sha M, Xing P, Jiang B (2015b) Strategies for synthesizing non-bioaccumulable alternatives to PFOA and PFOS. Chin Chem Lett 26:491–498. https://doi.org/10.1016/j.cclet.2015.03.038

Sha M, Zhang D, Pan RM, Xin P, Jiang B (2015c) Synthesis and properties study of novel branched fluorinated surfactants with CF3CF2CF2C(CF3)2 group. Acta Chim Sinica 73:395–402. https://doi.org/10.6023/a15030174

Shi HX, Zhao LJ, Xiang JP, Gao LD, Shen HM (2009) Application of fluorinated surfactants in oil field. Fine Chem 26:331–335 (in Chinese)

Yang BQ, Xing H, Xiao JX (2009) Perfluorobutyl-based fluorinated surfactant with high surface activity. Acta Phys Chim Sin 25:2409–2412. https://doi.org/10.3866/PKU.WHXB20091204

Zhang Q, Luo Z, Curran DP (2000) Separation of “Light Fluorous” reagents and catalysts by fluorous solid-phase extraction: synthesis and study of a family of triarylphosphines bearing linear and branched fluorous tags. J Org Chem 65:8866–8873. https://doi.org/10.1021/jo000464f

Zhang D, Sha M, Pan RM, Lin XY, Xing P, Jiang B (2018a) Design and synthesis of the novel branched fluorinated surfactant intermediates with CF3CF2CF2C(CF3)2 group. Chin Chem Lett. https://doi.org/10.1016/j.cclet.2018.11.014 (in press)

Zhang D, Sha M, Pan RM, Lin XY, Xing P, Jiang B (2018b) Synthesis and properties study of novel fluorinated surfactants with perfluorinated branched ether chain. J Fluorine Chem. https://doi.org/10.1016/j.jfluchem.2018.11.001 (in press)

Acknowledgements

This project was financially supported by the National Natural Science Foundation of China (NSFC2167020782).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

11696_2019_701_MOESM1_ESM.doc

Supplementary material 1 (DOC 1166 kb) 1H NMR, 19F NMR, 13C NMR for the novel compounds fluorinated surfactants and all the intermediates are provided

Rights and permissions

About this article

Cite this article

Zhang, D., Sha, M., Pan, R. et al. CF3CF2CF2C(CF3)2-based fluorinated surfactants with high surface activity. Chem. Pap. 73, 1499–1508 (2019). https://doi.org/10.1007/s11696-019-00701-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00701-4