Abstract

Apricot (Prunus armeniaca L.), which belongs to the genus Prunus, is one of the most commonly commercialized fruits produced in Turkey. Apricot pomace, the most common byproduct of apricot nectar processing, is the press residue of the fruit flesh. Ultrasound assisted extraction (UAE) is known as one of the most efficient techniques for separation of valuable ingredients from raw materials with enhanced extraction yield. In this study, UAE parameters (temperature and time) were optimized by using Response Surface Methodology with a central composite design for maximization of the total phenolic and flavonoid contents as well as the antiradical (DPPH scavenging) activity and extraction yield. Phenolic composition and CUPRAC, ABTS and FRAP values of the extract at the highest extraction yield point was also determined. In the results, the highest phenolic and flavonoid contents, antiradical activity and extraction efficiency were determined as 1.206 mg GAE/g DM, 1.015 mg CE/g DM, 79.85% and 7.86% in apricot pomace samples at 50 °C and 90 min trial points, respectively. HPLC–DAD showed that p-coumaric acid, ferulic acid and rutin were the most abundant phenolics found in the extract. CUPRAC, ABTS and FRAP values of the extract were 30.00, 32.30 and 18.80 mg TE/100 g, respectively. In conclusion, this study provided valuable findings to food industry and other related fields for extraction of valuable bioactive compounds from apricot pomace using UAE as an eco-friendly extraction technique.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

“Food wastes” are organic residues that occur in liquid or solid form when raw materials are processed into foodstuffs. Food waste is known as a cheap and valuable source of ingredients [1]. Food wastes are generally obtained from the beverage industry, the dairy industry, fruit/vegetable production and processing, grain processing and manufacturing, meat products processing and preservation, vegetable and animal fat production and processing [2]. Apricot (Prunus armeniaca L.) fruit, which is included in the Rosaceae family and the Prunus genus, is a subfamily of Prunaidea [3]. Since apricot is a seasonal fruit, it is immediately processed to several products such as apricot juice and nectar, jam and marmalade or several food preservation techniques such as drying, canning, modified/controlled atmosphere packaging etc. are applied to extend its shelf life [4]. During production of apricot juice, a considerable amount of pomace is formed as a by-product in addition to skin, stone, shell, kernel and kernel skin [5]. Approximately 13–15% of the apricot flesh is arisen as pomace as a result of fruit juice processing. This pomace contains high quantities of valuable compounds such as phenolics, dietary fibers and carotenoids etc. which may have positive health benefits and be utilized in food and pharmaceutical industries [6]. Biologically active compounds in apricot pomace have attracted great attention in recent years due to their antioxidant properties and protection against several chronic diseases [3, 7, 8].

UAE has come into prominence in recent years since it has a number of advantages as to be cheaper, faster, simpler and more efficient than the classical solvent extraction method [9]. It is a greener methodology and provides a high reproducibility in shorter time, lowers energy input, decreases organic solvent and temperature requirements [10]. It can be used for different purposes including food processing, preservation and extraction etc. in several industries such as food, pharmaceutical and cosmetics [11].

RSM is a statistical method used for designing trials and optimization of complex processes. By this method, the effects of various factors that optimize the processing variables of the experiments are evaluated more effectively and easily. The advantages of RSM are the determination of the most appropriate conditions for the desired responses, evaluation of the effects of many factors, creating models and decreasing the count of tests [12]. Although several techniques such as solvent extraction, supercritical CO2 extraction, and infrared assisted extraction have been investigated for acquiring of bioactive compounds from apricot pomace [13,14,15,16,17], as far as our examined, no study has been conducted to define the optimum UAE conditions from apricot pomace using RSM. Therefore, in this study, ultrasonic extraction parameters (extraction temperature and period) of apricot pomace were optimized with RSM of a central composite design to get the maximum extraction yield, total phenolic contents, flavonoid contents and antioxidant capacities. HPLC–DAD was also used for determination of the phenolic profile of the apricot pomace extract obtained at optimized conditions.

Materials and methods

Raw material

Apricot pomace was kindly provided from a fruit concentrate manufacturer (Anadolu Etap Penkon Food and Agricultural Products Corp., Mersin, Turkey). The raw and fresh apricot pomace was immediately transferred to laboratory in air-proof plastic bags (~ 5 kg). After determination of the dry matter content of the fresh pomace by drying in the oven (Nuve Incubator EN 120, Ankara, Turkey) at 105 °C until constant weight, it was kept at at − 20 °C prior to the experiments.

Experimental design

In this study, UAE conditions were optimized using RSM and central composite design in terms of total phenolic content, total flavonoid content, extraction yield and DPPH (2,2-diphenyl-1-picryl-hydrazyl) radical scavenging activity as response variables. Extraction temperature (X1) and extraction time (X2) were selected as the independent variables. The center points and the ranges of the independent variables were given in Table 1. As the result, a total of 13 experiments were conducted at 4 factorial points, 4 axial points and 5 replicates of the central points, as seen in Table 2.

Ultrasound assisted extraction (UAE) process

A temperature controlled ultrasonicator was employed for UAE process at experimental points listed in Table 2. 50% of aqueous ethanol (v:v) was used as solvent. For this purpose, dried apricot pomace (2 g) was incorporated with the solvent (20 mL, solid–liquid ratio of 1:10 w/v) in a glass vial. Following the placing of the vial into the ultrasonic bath (Protech, PMYU12, USA), ultrasonic treatment was conducted. Then the extract was centrifuged at 2000 rpm for 10 min and filtered using a Whatman No 1 filter paper. The extracts were held at − 20 °C until analyses were performed.

Extraction yield

The extracts prepared during the experiments were transferred to petri dishes, allowed to dry at 50 °C and were obtained by dividing the determined amount of dried extract by the amount of sample taken into the initial process. The extract was analyzed in triplicate. Results were stated as average.

Determination of total phenolic content (TPC)

TPCs of the apricot pomace extracts were analyzed based on Folin–Ciocalteu method according to Murakami et al. [18] with slight modifications. For this aim, 0.1 mL of the extract was incorporated with 4.5 mL of distilled water, 0.1 mL of Folin reagent and 0.3 mL of 2% Na2CO3 in a test tube and mixed vigorously. The resulting mixture was kept in dark for 2 h and the absorbance was measured at 760 nm using T60 UV-visible Spectrophotometer (Leicestershire LE17 5BH, UK). The TPC was determined using the calibration equation of the standard gallic acid solution (Y = 0.0013x + 0.0151, R2 = 0.9934) and the results were calculated as mg gallic acid equivalent (GAE)/g dry matter. All trials were carried out in triplicate.

Determination of total flavonoid content (TFC)

Total flavonoid contents (TFCs) of the pomace extracts were analyzed by Zhishen method [19]. For this purpose, 1.25 mL of distilled water and 75 µL of 5% sodium nitrite were incorporated with the 0.25 mL of the extracts. After mixing, the mixture was kept for 6 min at ambient conditions. At the end of this period, 150 µL (10%) AlCl3 was added to the mixture then left for additional 5 min. After incorporation of 0.5 mL of 1 M NaOH solution and 275 µL water into the mixture, the absorbance of the resulting mixture was measured at 510 nm using T60 UV-visible Spectrophotometer (Leicestershire LE17 5BH, UK). The TFC of the pomace extract was calculated using the calibration curve of the standard catechin solution (Y = 0.0023x − 0.0044, R2 = 0.9973) and expressed as mg catechin equivalent (CE)/g dry matter. All trials were applied out in triplicate.

Antiradical activity (DPPH)

Antiradical activity of the apricot pomace extract was determined by measurement of its DPPH (1,1-diphenyl-2-picrylhydrazyl) radical scavenging ability based on the method described by Brand-Williams et. al. [20]. Firstly, 3.9 mL of DPPH solution (20 mg/L in methanol) was incorporated with 0.1 mL of the diluted extract. After incubation of the mixture in dark for 30 min, the absorbance was measured at 517 nm using T60 UV-visible Spectrophotometer (Leicestershire LE17 5BH, UK). The percent antiradical activity was calculated using the following equation:

where A0 and A1 are the absorbance values of DPPH in methanol solution without an antioxidant and in the presence of an antioxidant.

Evaluation of the antioxidant capacity in the highest extraction yield point

ABTS (2,2’‑Azino‑bis (3‑ethylbenzothiazoline‑6‑sulfonic acid) radical scavenging assay

ABTS assay was carried out using an improved ABTS method [21]. ABTS was dissolved in water to 7 mM concentration and was produced by reacting ABTS stock solution with potassium persulfate (2.45 mM final concentration). This solution was kept at room temperature and in a dark closet for 12–16 h. It was then diluted with ethanol (50%) to an absorbance of 0.700. The absorbance reading was recorded at 734 nm 6 min later the addition of 0.1 mL of extract or 2 mL of diluted ABTS reagent and the first mixing.

The result was determined using the formulation:

Abs0 and Abss are the absorbance values of ABTS radical + methanol and ABTS radical + extract, respectively.

CUPRAC (cupric ion reducing antioxidant capacity) assay

CUPRAC assay was determined based on the method described by Apak et al. [22]. One mL distilled water was added on 0.1 mL extract sample. Then, a solution of 10 mM copper chloride, 0.0075 M neocuproin, 1 M C2H7NO2 buffer (pH 7.0) were mixed at a ratio of 1:1:1 to obtain a total reaction volume of 4.1 mL. The mixture was kept in dark for 1 h. Then the absorbance of the sample was determined spectrofometrically (Leicestershire LE17 5BH, UK) at 450 nm. The result was expressed as mg Trolox equivalent (TE)/100 g extract.

FRAP (ferric reducing antioxidant power) assay

FRAP assay was applied using the experimental procedure reported by Benzie et al. [23]. Prior to the analysis, the FRAP reagent was prepared by mixing 0.3 M Acetate buffer (pH 3.6), 10 mmol/L 2,4,6-tripyridyl-s-triazine solution (TPTZ) and 0.02 mol/L FeCl3.6H2O (10:1:1 v:v:v). The TPTZ solution was obtained by incorporation of 0,01 M TPTZ with 0.04 M HCl. Following the preparation of stock solutions, 0.1 mL of pomace extract was mixed with 0.9 mL of distilled water and 2 mL of FRAP reagent and the mixture was left in dark for 30 min at room temperature. Then the absorbance was measured at 593 nm using the spectrophotometer (Leicestershire LE17 5BH, UK). The results were given as mg TE/100 g extract.

HPLC–DAD analysis

HPLC–DAD analysis was applied using the experimental procedure reported by Ucar and Karadag [24]. The phenolic composition analyzes of the apricot pomace extracts (the highest yield extraction point) were accomplished using a Shimadzu high performance liquid chromatography (HPLC) system consisting of an online degasser (DGU-20A5R), pump (LC-20AD), detector (model SPDM20A DAD), column oven (CTO-10ASVP), and autosampler (SIL-20A H), CMB-20A communications bus module; Shimadzu, Kyoto, Japan). All samples and also the stock solutions of the reference chemicals were filtered through a 0.45-μm membrane filter before the analyses. Separations of the phenolics were made on Inter-sil® ODS C-18 reversed-phase column (250 × 4.6 mm length, 5 μm particle size) at 40 °C.

For analytical purposes, the solvent system used was a gradient of distilled water/acetic acid [0.1% (v/v) (A) and methanol (B) acetonitrile with 0.1% (v/v) acetic acid and the gradient elution: 10% B (0–2 min), 10–30% B (2–27 min), 30–90% B (27–50 min) and 90–100% B (51–60 min)]. Elution was made with the flow rate (1 min/mL). The chromatograms were obtained at 278, 320, and 360 nm. Identification and quantitative analysis were performed with taking into account of the retention times and were compared with external standards. The standards used for identification and quantification were caffeic acid, chlorogenic acid, catechin, rutin, gallic acid, protocatechuic acid, syringic acid, ellagic acid, p-coumaric acid, o-coumaric, ferulic, kaempferol, quercetin, sinapic, myricetin, chrysin and 4-hydroxybenzoic acid. The amounts of the phenolics were calculated and determined according to the retention time and spectra of the corresponding external standards. The polyphenol concentration of the extracts was figured out from standard curves plotted with analyzing various concentrations of the suitable standards.

Results and Discussion

In this study, UAE conditions were optimized using RSM and central composite design in terms of TPCs, TFCs, DPPH scavenging ability and extraction yield of apricot pomace extract.

Effect of extraction conditions on TPC

Extraction process was performed with extraction time interval between 30 and 90 min, and temperature interval from 30 to 90 °C. Ethanol concentration and solid:liquid ratio were selected as 50% (v/v) and 1:10 (w/v), respectively. Predicted response Y for the TPC was expressed by the second-order polynomial equation given below in terms of coded values:

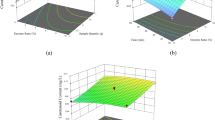

TPC results obtained at the experimental points of the RSM model are given in Table 2. The TPCs of the extracts ranged from 0.532 to 1.206 mg GAE/g DM while the highest result was determined at 50 °C and 90 min at 50% ethanol concentration. Figure 1 shows the response surface and figure graphic for the effects of extraction factors on the total phenolic content. It was clearly seen in the figure that TPC values of the extracts increased with increasing temperature and time. Some studies determined that polyphenolic compounds’ extraction extend with time favours. It is known that temperature is effective on extraction of phenolic compounds. Higher temperature would result in enhancement the solubility of the phenolic compounds, which increase the rate of diffusion, thus giving a higher rate of extraction. As can be seen in the table, the TPC and the extraction factors (temperature and time) were quadratic with a good regression coefficient (R2 = 0.9657). The F value for the lack of fit was insignificant (p > 0.05), which confirms the validity of the model. The value of the adjusted determination coefficient (adjusted R2 = 0.9411) also showed that the model was highly significant. At the same time, a very low value 5.90 of coefficient of the variation (CV) clearly indicated a very high degree of precision and a good deal of reliability of the experimental values. The model p value (Prob > F) was very low (< 0.0001), which implied that the model was significant.

Analysis of variance for the selected quadratic model for extraction of phenolic compounds was given in Table 3 and regression coefficients estimate and their significance test for second-order model was given in Table 4.

Optimum experimental conditions of Central Composite Design for maximum, middle and minimum TPC of the pomace were given in Table 5.

According to our results and the previous findings reported by other authors, heating process is an important aspect for the phenolic compounds extraction. Extraction of phenolic compounds increases continuously with heating to a certain extent [25]. Temperatures above 75 °C can cause chemical and/or thermal degradation of certain phenolic compounds, which results in reduction in recovery rate [26]. The reaction between other matrix components with the phenolics also prevents their extraction [27]. Heating may also cause solvent loss through evaporation. Previously, polyphenol content of Lebanese apricot pomace was investigated. In the results, 9.8 mg GAE/g DM of polyphenol value was obtained by extraction with 50% ethanol/water (solvent ratio) at 75 °C (the highest temperature) [16]. In another study conducted by Cheaib et al. [28] who tested the effect of ultrasound, microwave and infrared assisted extraction techniques on bioactive properties and extraction yield of apricot pomace, it was found that infrared was the best influential method with the highest polyphenol content (10 mg GAE/g of dry extract). In another study; the TPC in grape juice pomace (974 ± 48 mg GAE/g of dry extract) was quite higher than that in kiwi pomace (421 ± 12 mg GAE/g of dry extract) [29].

Efficiency of extraction conditions on TFC

The main part of polyphenols in apricot pomace are likely flavonoids, which may describe the results as flavonoids are associated with many biological activities such as antioxidant and antiviral [30]. In this study, RSM was performed to define the appropriate temperature and time for optimization of flavonoid extraction conditions from apricot pomace, as can be seen in Table 2. Increase in temperature and time had an enhancing effect on TFC (Table 2) which reached to its highest value (1.015 mg CE/g DM) at 90 min and 50 °C. It is known that flavonoids from fruits are extracted efficiently with ethanol. The TFC values increased remarkably with the increase of extraction time from 30 to 90 min. The extraction of flavonoids correlated well with the time and temperature factors.

RSM data given in Table 2 represented that the TFC and the parameters of the extraction (temperature and time) were quadratic with a good regression coefficient (R2 = 0.9790). Final equation in terms of coded factors:

The F value for the lack of fit was insignificant (p > 0.05), which confirms the validity of the model. The value of the adjusted determination coefficient (adjusted R2 = 0.9640) also confirmed that the model was highly significant. At the same time, a very low value 4.14 of CV clearly indicated a very high degree of precision and a good deal of reliability of the experimental values. The model p value (Prob > F) was very low (< 0.0001), which implied that the model was significant. Analysis of variance for the selected quadratic model for extraction of flavonoids was given Table 3 while regression coefficients estimate and their significance test for quadratic model were given Table 4. Optimum experimental conditions of Central Composite Design for maximum, middle and minimum TFC of the pomace were given in Table 5. Figure 1 shows the response surface and figure graphic for the effects of extraction factors on the TFC. In one study; the flavonoid content of apricot pomace was determined as 8.9 mg GAE/g DM with the highest temperature (75 °C) and solvent ratio (50% ethanol/water) [16]. Our results were in compatible with the findings obtained by Rajha et al. [31] who revealed that temperature was an effective parameter on flavonoid extraction from grape pomace. Total flavonoids in apple pomace extracts ranged from 0.45 to 1.19 mg/g [32]. In another research, TFCs of ethanolic extract of sweet and bitter apricot kernels were 0.468 mg QUE/g and 8.099 mg QUE/g, respectively [33]. TFC value of apricot kernel roasted by microwave oven was found between as 17.33 mg CE/g DM and 32.45 mg CE/g DM [34]. In another study; the best results for extraction yield and biological activity of the apricot fruit was obtained with Infrared Radiation (IR) Technology when compared with solid/liquid extraction method and thanks to IR Technology, pomace extract obtained the maximum TFC (6.3 mg CE/g DM) [16].

Effect of extraction parameters on antiradical activity

Table 2 shows that the DPPH radical scavenging activity of the apricot pomace extracts on experimental points obtained by RSM approach. The factors (temperature and time) were quadratic with a good regression coefficient (R2 = 0.9754). Final equation in terms of coded factors:

The F value for the lack of fit was insignificant (p > 0.05), which confirms the validity of the model. The value of the adjusted determination coefficient (adjusted R2 = 0.9579) also confirmed that the model was highly significant. A very low value 4.32 of CV clearly indicated a very high degree of precision and a good deal of reliability of the experimental values. The model p value (Prob > F) was very low (< 0.0001), which implied that the model was significant. ANOVA for the selected quadratic model for DPPH radical scavenging activity was given Table 3 and regression coefficients estimate and their significance test for quadratic model were given Table 4. Increase in temperature and time had positive impact on antiradical activity which attained its maximum at 79.85% at the experimental point of 90 min and 50 °C (Table 2). As the extraction time increased, the DPPH radical scavenging activity was greatly increased until the highest activity was reached. Some authors state that the concentration-dependent antiradical activity of phenolic compounds may change and some reports in the literature showed the strong correlation between total phenolic contents and antioxidant activity [31].

Figure 1 shows the response surface and figure plots for the effects of extraction parameters on antiradical activity. Optimum experimental conditions of Central Composite Design for maximum, middle and minimum antiradical activity of the pomace were given in Table 5.

According to Cheaib et al. [16] the maximum DPPH scavenging activity of apricot pomace was 44%, which was lower than our findings while the sweet apricot kernel extracts showed higher antiradical activity (87.7% and 89.9%) than bitter kernels (3.7 and 20%) [35, 36]. El Darra et al. [37] reported that the antiradical activity of red grape pomaces increased by the increasing flavonoid concentration (catechins and epicatechin) as compared to the phenolic acid compounds. Sharmila et al. [38] reported that the highest DPPH radical scavenging activity (90.5%) for Cassia auriculata leaf extracts was determined at UAE extraction conditions of a 60% solvent concentration, time for 5 min and peak power at 50 W.

Effect of extraction parameters on extraction yield

Increasing temperature and time had a positive effect on extraction efficiency which attained its maximum of 7.86% with 90 min at 50 °C (Table 2). High temperature increases the movement of molecules that aid in extraction. As the heating time and temperature changed at the trial points, the extraction efficiency also varied. For the model fitted, the coefficient of determination (R2) was 0.9666. F-value for the lack of fit was insignificant (p > 0.05) thereby confirming the validity of the model. The value of the adjusted determination coefficient (adjusted R2 = 0.9427) also confirmed that the model was highly significant. At the same time, a very low value 2.71 of CV clearly indicated a very high degree of precision and a good deal of reliability of the experimental values. The model p value (Prob > F) was very low (< 0.0001), which implied that the model was significant. ANOVA for the selected quadratic model for extraction of extraction yield was given Table 3 and regression coefficients estimate and their significance test for quadratic model were given Table 4. Figure 1 shows the response surface and figure plots for the effects of extraction parameters on extraction yield.

Final equation in terms of coded factors:

Optimum experimental conditions of Central Composite Design for maximum, middle and minimum extraction yield of the pomace were given Table 5.

Concerning with extraction processes, the mathematical models can be applied to optimize the process parameters such as time and temperature in order to maximize the extraction yield. The highest extraction yield of lemon peels was obtained 3.56% when extraction parametres were 1:15 (matrix/solvent) ratio, temperature (150 °C) and time (30 min) [39]. The highest extraction yield values from grape biomass waste using Soxhlet extraction and UAE were 17.99% and 12.90%, respectively [40]. Seo and Choi [41] reported that the extraction efficiency was 8.9% in reflux extraction in safflower seed while it reduced to 5.23% in UAE. Extract yield of aqueous UAE from black carrot was found as 8.67%, while it was 8.02% in classical Soxhlet extraction. On the other hand, in the case of acidified ethanolic water (AES) as solvent, the efficiency of UAE increased to 9.25% [42].

Evaluation of the antioxidant capacity at the highest extraction yield point

Several antioxidant activity parameters, namely CUPRAC, ABTS and FRAP values for the apricot pomace extract were analysed at the experimental point where maximum extraction yield was obtained in this study. As can be seen in Fig. 2, CUPRAC, FRAP and ABTS were 30.00, 18.80 and 32.30 mg TE/100 g, respectively. These results were compatible with the study of Thaipong et al. [43] who obtained the antioxidant activity of methanolic extracts of four guava fruits genotypes by ABTS and FRAP assays. Between 22.3 and 37.9 mg TE/100 g and 15.5–33.3 mg TE/100 g, respectively. In one study; FRAP values (as Fe2 + equivalent) of apricot pulp, skin and kernel were found as 3.4 µmol/g, 7.9 µmol/g and 7.2 µmol/g, respectively [44]. Pellegrini et al. [45] determined the FRAP values apricot fruits as 4.02 µmol/g. Halvorsen et al. [46] reported that FRAP values of fresh and dried apricot samples were 5.2 µmol/g and 32.5 µmol/g, respectively. In another study; pulp of six apricot varieties were analysed for their CUPRAC, FRAP and ABTS values while they ranged between 31.4–81.1 mg TE 100/g, 18.3–46.7 mg TE/100 g and 16.4–84.4 mg TE/100 g, respectively [47].

Phenolic composition of the apricot pomace extract at the highest extraction yield point

In this study, phenolic composition of the apricot pomace extract was studied by HPLC at the experimental point where the highest extraction yield (50 °C, 90 min, 50% ethanol concentration) was obtained. The percent presence of the phenolics was given in Table 6. Among the total 17 phenolic compounds investigated, 8 different phenolics were detected. As can be seen in the table, the major phenolic compound identified in the apricot pomace was p-coumaric (9.72 mg/kg), followed by ferulic acid, rutin and chlorogenic acid, respectively. These findings were consistent with the findings of Sultana et al. [48] who stated that main phenolic acid present in apricot is p-coumaric acid (23.6 mg/kg) while the amounts of ferulic, caffeic and gallic acids were 13.9 mg/kg, 6.7 mg/kg and 4.54 mg/kg, respectively. In another study, chlorogenic acid and rutin were detected as the main phenolic compounds in apricot pomace [15]. On the other hand, varying phenolic compounds were determined in apricot pulp (rutin, catechin and epicatechin) and apricot kernel (caffeic and gallic acid) by HPLC [28].

Conclusion

In this study, ultrasonication, an efficient and environmentally method was used for the extraction of bioactive components from apricot pomace and extraction conditions (temperature and time) were optimized by using the RSM. The results stated that the highest extraction yield was obtained with 50 °C and 90 min using 50% ethanol as solvent. At this experiment point, the TPC, TFC, DPPH scavenging activity and extraction yield were 1.206 mg GAE/g DM, 1.015 mg CE/g, 79.85%, and 7.86%, respectively. The major phenolic compounds identified in apricot pomace were p-coumaric, ferulic acid, rutin and chlorogenic acid. In conclusion, apricot pomace could be used as sources of valuable bioactive compounds in the food industry applications as well as in the cosmetics and pharmaceutical industry.

Data availability

Available on request.

Code availability

Not applicable.

References

V. Oreopoulou, W. Russ (eds.), Utilization of By-Products and Treatment of Waste in the Food Industry (Springer, Boston, 2007), pp. 209–232

A. Baiano, Recovery of biomolecules from food wastes—a review. Molecules 19(9), 14821–14842 (2014). https://doi.org/10.3390/molecules190914821

S. Ali, T. Masud, K.S. Abbasi, Physico-chemical characteristics of apricot (Prunus armeniaca L.) grown in Northern Areas of Pakistan. Sci. Horticulturae. 130(2), 386–392 (2011). https://doi.org/10.1016/j.scienta.2011.05.040

E. García-Martínez, M. Igual, M.E. Martín-Esparza, N. Martínez-Navarrete, Assessment of the bioactive compounds, color, and mechanical properties of apricots as affected by drying treatment. Food Bioproc. Tech. 6(11), 3247–3255 (2013). https://doi.org/10.1007/s11947-012-0988-1

Ç.P. Adibelli, M. Serdaroglu, Quality characteristics of frankfurters formulated with apricot pomace obtained from apricot juice processing. J. Agric. Food Chem. 5(3), 281–288 (2017). https://doi.org/10.24925/turjaf.v5i3.281-288.996

E.D. Kasapoglu, S. Kahraman, F. Törnük, Apricot juice processing byproducts as sources of value-added compounds for food industry. Eur. Food Sci. Eng. 1(1), 18–23 (2020)

I. Erdogan-Orhan, M. Kartal, Insights into research on phytochemistry and biological activities of Prunus armeniaca L. (apricot). Food Res. Int. 44(5), 1238–1243 (2011). https://doi.org/10.1016/j.foodres.2010.11.014

E.B. Akin, I. Karabulut, A. Topcu, Some compositional properties of main Malatya apricot (Prunus armeniaca L.) varieties. Food Chem. 107(2), 939–948 (2008). https://doi.org/10.1016/j.foodchem.2007.08.052

F. Chen, M. Zhang, C.H. Yang, Application of ultrasound technology in processing of ready-to-eat fresh food: a review. Ultrason. Sonochem. 63, 104953 (2020). https://doi.org/10.1016/j.ultsonch.2019.104953

J.P. Fan, J. Cao, X.H. Zhang, J.Z. Huang, T. Kong, S. Tong, J.H. Zhu, Optimization of ionic liquid based ultrasonic assisted extraction of puerarin from Radix Puerariae Lobatae by response surface methodology. Food Chem. 135(4), 2299–2306 (2012). https://doi.org/10.1016/j.foodchem.2012.07.038

F. Chemat, M.K. Khan, Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason. Sonochem. 18(4), 813–835 (2011). https://doi.org/10.1016/j.ultsonch.2010.11.023

Z. Wang, J. Sun, X. Liao, F. Chen, G. Zhao, J. Wu, X. Hu, Mathematical modeling on hot air drying of thin layer apple pomace. Food Res. Int. 40(1), 39–46 (2007). https://doi.org/10.1016/j.foodres.2006.07.017

I.S. Sanal, A. Güvenc, U. Salgin, U. Mehmetoglu, A. Calimli, Recycling of apricot pomace by supercritical CO2 extraction. J. Supercrit. Fluids. 32(1–3), 221–230 (2004). https://doi.org/10.1016/j.supflu.2004.02.002

I.S. Sanal, E. Bayraktar, U. Mehmetoglu, A. Calimli, Determination of optimum conditions for SC-(CO2 + ethanol) extraction of β-carotene from apricot pomace using response surface methodology. J. Supercrit. Fluids. 34(3), 331–338 (2005). https://doi.org/10.1016/j.supflu.2004.08.005

F.V. Dulf, D.C. Vodnar, E.H. Dulf, A. Pintea, Phenolic compounds, flavonoids, lipids and antioxidant potential of apricot (Prunus armeniaca L.) pomace fermented by two filamentous fungal strains in solid state system. Chem. Cent. J. 11(1), 92 (2017). https://doi.org/10.1186/s13065-017-0323-z

D. Cheaib, N. El Darra, H.N. Rajha, I. El-Ghazzawi, Y. Mouneimne, A. Jammoul, R.G. Maroun, N. Louka, Study of the selectivity and bioactivity of polyphenols using infrared assisted extraction from apricot pomace compared to conventional methods. Antioxidants 7(12), 174 (2018). https://doi.org/10.3390/antiox7120174

V. Vorobyova, A. Shakun, O. Chygyrynets, M. Skiba, Determination of the chemical composition of the extract of apricot pomace (Prunus armeniaca L.). Chem. Chem. Technol. 3(3), 391–398 (2019). https://doi.org/10.23939/chcht13.03.391

A.N.N. Murakami, R.D.D.M.C. Amboni, E.S. Prudêncio, E.R. Amante, L. de Moraes Zanotta, M. Maraschin, R.F. Teófilo, Concentration of phenolic compounds in aqueous mate (Ilex paraguariensis A. St. Hil) extract through nanofiltration. LWT Food Sci. Technol. 44(10), 2211–2216 (2011). https://doi.org/10.1016/j.lwt.2011.06.002

J. Zhishen, T. Mengcheng, W. Jianming, Research on antioxidant activity of flavonoids from natural materials. Food Chem. 64, 555–559 (1999)

W. Brand-Williams, M.E. Cuvelier, C.L.W.T. Berset, Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 28(1), 25–30 (1995). https://doi.org/10.1016/s0023-6438(95)80008-5

R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, C. Rice-Evans, Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 26(9–10), 1231–1237 (1999). https://doi.org/10.1016/s0891-5849(98)00315-3

R. Apak, K. Güçlü, M. Özyürek, S.E. Karademir, Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine: CUPRAC method. J. Agric. Food Chem. 52(26), 7970–7981 (2004). https://doi.org/10.1021/jf048741x

I.F. Benzie, J.J. Strain, The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal. Biochem. 239(1), 70–76 (1996). https://doi.org/10.1006/abio.1996.0292

T.M. Ucar, A. Karadag, The effects of vacuum and freeze-drying on the physicochemical properties and in vitro digestibility of phenolics in oyster mushroom (Pleurotus ostreatus). J. Food Meas. Charact. 13(3), 2298–2309 (2019). https://doi.org/10.1007/s11694-019-00149-w

M. Bachir Bey, L. Meziant, Y. Benchikh, H. Louaileche, Deployment of response surface methodology to optimize recovery of dark fresh fig (Ficus carica L., var. Azenjar) total phenolic compounds and antioxidant activity. Food Chem. 162, 277–282 (2014). https://doi.org/10.1016/j.foodchem.2014.04.054

N. Ilaiyaraja, K.R. Likhith, G.R. Sharath Babu, F. Khanum, Optimisation of extraction of bioactive compounds from Feronia limonia (wood apple) fruit using response surface methodology (RSM). Food Chem. 173, 348–354 (2015). https://doi.org/10.1016/j.foodchem.2014.10.035

H.S. Yim, F.Y. Chye, V. Rao, Optimization of extraction time and temperature on antioxidant activity of Schizophyllum commune aqueous extract using response surface methodology. J. Food Sci. Technol. 50, 275–283 (2013). https://doi.org/10.1007/s13197-011-0349-5

D. Cheaib, N. El Darra, H.N. Rajha, I.E. Ghazzawi, R.G. Maroun, N. Louka, Biological activity of apricot byproducts polyphenols using solid–liquid and infrared-assisted technology. J. Food Biochem. 42(5), e12552 (2018). https://doi.org/10.1111/jfbc.12552

M. Zhu, Y. Huang, Y. Wang, T. Shi, L. Zhang, Y. Chen, M. Xie, Comparison of (poly) phenolic compounds and antioxidant properties of pomace extracts from kiwi and grape juice. Food Chem. 271, 425–432 (2019). https://doi.org/10.1016/j.foodchem.2018.07.151

A.S. Awaad, D.J. Maitland, A.E.R.M. Donia, S.I. Alqasoumi, G.A. Soliman, Novel flavonoids with antioxidant activity froma Chenopodiaceous plant. Pharm. Biol. 50(1), 99–104 (2012). https://doi.org/10.3109/13880209.2011.591806

H.N. Rajha, W. Ziegler, N. Louka, Z. Hobaika, E. Vorobiev, H.G. Boechzelt, R.G. Maroun, Effect of the drying process on the intensification of phenolic compounds recovery from grape pomace using accelerated solvent extraction. Int. J. Mol. Sci. 15(10), 18640–18658 (2014). https://doi.org/10.3390/ijms151018640

G. Ćetković, J. Čanadanović-Brunet, S. Djilas, S. Savatović, A. Mandić, V. Tumbas, Assessment of polyphenolic content and in vitro antiradical characteristics of apple pomace. Food Chem. 109(2), 340–347 (2008). https://doi.org/10.1016/j.foodchem.2007.12.046

E.Z. Gomaa, In vitro antioxidant, antimicrobial, and antitumor activities of bitter almond and sweet apricot (Prunus armeniaca L.) kernels. Food Sci. Biotechnol. 22(2), 455–463 (2013). https://doi.org/10.1007/s10068-013-0101-1

F.A. Juhaimi, M.M. Özcan, K. Ghafoor, E.E. Babiker, The effect of microwave roasting on bioactive compounds, antioxidant activity and fatty acid composition of apricot kernel and oils. Food Chem. 243, 414–419 (2018). https://doi.org/10.1016/j.foodchem.2017.09.100

G. Korekar, T. Stobdan, R. Arora, A. Yadav, S.B. Singh, Antioxidant capacity and phenolics content of apricot (Prunus armeniaca L.) kernel as a function of genotype. Plant Foods Hum. Nutr. 66(4), 376–383 (2011). https://doi.org/10.1007/s11130-011-0246-0

D. Yigit, N. Yigit, A. Mavi, Antioxidant and antimicrobial activities of bitter and sweet apricot (Prunus armeniaca L.) kernels. Braz. J. Med. Biol. Res. 42(4), 346–352 (2009). https://doi.org/10.1590/S0100-879X2009000400006

N. El Darra, N. Grimi, E. Vorobiev, N. Louka, R. Maroun, Extraction of polyphenols from red grape pomace assisted by pulsed ohmic heating. Food Bioproc. Tech. 6(5), 1281–1289 (2013). https://doi.org/10.1007/s11947-012-0869-7

G. Sharmila, V.S. Nikitha, S. Ilaiyarasi, K. Dhivya, V. Rajasekar, N.M. Kumar, C. Muthukumaran, Ultrasound assisted extraction of total phenolics from Cassia auriculata leaves and evaluation of its antioxidant activities. Ind. Crops Prod. 84, 13–21 (2016). https://doi.org/10.1016/j.indcrop.2016.01.010

C.G. Lopresto, F. Petrillo, A.A. Casazza, B. Aliakbarian, P. Perego, V. Calabrò, A non-conventional method to extract d-limonene from waste lemon peels and comparison with traditional soxhlet extraction. Sep. Purif. Technol. 137, 13–20 (2014). https://doi.org/10.1016/j.seppur.2014.09.015

M.L. de Menezes, G. Johann, A. Diório, N.C. Pereira, E.A. da Silva, Phenomenological determination of mass transfer parameters of oil extraction from grape biomass waste. J. Clean. Prod. 176, 130–139 (2018). https://doi.org/10.1016/j.jclepro.2017.12.128

I.H. Seo, S.W. Choi, Preparation of high quality safflower (Carthamus tinctorius L.) seed extract by high-pressure extraction process. Prev. Nutr. Food Sci. 14(4), 373–377 (2009). https://doi.org/10.3746/jfn.2009.14.4.373

L. Ekici, Determination of some biological properties of anthocyanin based pigments extracted from grape skin, black carrot and red cabbage and their usage in some food products as colorants, Erciyes University, Graduate School of Natural and Applied Sciences. Ph.D. Thesis, June 2011

K. Thaipong, U. Boonprakob, K. Crosby, L. Cisneros-Zevallos, D.H. Byrne, Comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. J. Food Compost. Anal. 19(6–7), 669–675 (2006). https://doi.org/10.1016/j.jfca.2006.01.003

C. Guo, J. Yang, J. Wei, Y. Li, J. Xu, Y. Jiang, Antioxidant activities of peel, pulp and seed fractions of commonfruits as determined by FRAP assay. Nutr. Res. 23, 1719–1726 (2003). https://doi.org/10.1016/j.nutres.2003.08.005

N. Pellegrini, M. Serafini, B. Colombi, D. Del Rio, S. Salvatore, M. Bianchi, F. Brighenti, Total antioxidant capacity of plant foods, beverages and oils consumed in Italy assessed by three different in vitro assays. J. Nutr. 133(9), 2812–2819 (2003). https://doi.org/10.1093/jn/133.9.2812

B.L. Halvorsen, K. Holte, M.C.W. Myhrstad, A systematic screening of total antioxidants in dietary plants. J. Nutr. 132, 461–471 (2002). https://doi.org/10.1093/jn/132.3.461

X. Fan, W. Jiao, X. Wang, J. Cao, W. Jiang, Polyphenol composition and antioxidant capacity in pulp and peel of apricot fruits of various varieties and maturity stages at harvest. J. Food Sci. Technol. 53(2), 327–336 (2018). https://doi.org/10.1111/ijfs.13589

B. Sultana, F. Anwar, M. Ashraf, N. Saari, Effect of drying techniques on the total phenolic contents and antioxidant activity of selected fruits. J. Med. Plant Res. 6(1), 161–167 (2012). https://doi.org/10.5897/JMPR11.916

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

EDK: Formal analysis, Data curation, Writing—original draft. SK: Formal analysis, Data curation. FT: Investigation, Data curation.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there is no conflict of interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kasapoğlu, E.D., Kahraman, S. & Tornuk, F. Optimization of ultrasound assisted antioxidant extraction from apricot pomace using response surface methodology. Food Measure 15, 5277–5287 (2021). https://doi.org/10.1007/s11694-021-01089-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-01089-0