Abstract

Java plum pomace is rich in bioactive compounds and has potential to use in numerous ways, where extraction is one of them. Ultrasound assisted extraction (UAE) using acidified aqueous ethanol (1:20 solid:liquid, w/v) acidified with 0.1% HCl was employed to optimize the extraction conditions (ultrasound power, extraction temperature, time, and ethanol concentration) for phytochemicals from java plum fruit pomace using response surface methodology. The mathematical model suggested a high coefficient of determination for optimum conditions as 366.25 W ultrasound power, 37.61 °C temperature for 47.48 min using 70% ethanol for the extraction of phytochemicals. Actual yield of phytochemicals was almost same to predicted yields. While comparing UAE with conventional extraction (CE), phytochemical constituents, antioxidant activities, and minerals except potassium, copper, and manganese were reported higher in UAE as confirmed using HPLC, FTIR, AES and SEM analysis. It can be concluded that the optimized conditions can be used for the better extraction of phytochemicals from java plum pomace and its effective utilization.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Ultrasound assisted extraction of phytochemicals from java plum pomace was carried out. The findings showed that pomace can be used as a source of phytochemicals for health food industry.

Introduction

Berries such as blueberries, mulberry, blackberry, raspberry, and cranberry belong to a diverse group of red, blue and purple colored fruits which are widely consumed due to their aesthetic appeal as well as nutritional profile. These berries are very good source of micronutrients and bioactive compounds i.e., polyphenols, flavonoids and anthocyanins, thus possess numerous therapeutic benefits [1]. Java plum (Sygyzium cumini L.), an underutilized fruit is widely cultivated in tropical and subtropical regions of the world and belongs to the family Myrtaceae [2, 3]. Its utilization is witnessed in Ayurveda and traditional medicure since ages due to its health promoting effects such as antidiabetic, diuretic, stomachic, antiproliferative, antioxidant, antiviral, antiallergic etc.; which is due to the presence of numerous phytochemicals [4]. The commercial utilization of java plum is limited to the juice extraction which results in the generation of approximately 46% waste in the form of peel, seeds and residual pulp (pomace) [2, 5]. Despite of its numerous phytochemicals, the pomace is ignored by the processing industries and thus, responsible for environmental pollution. This waste can be a valuable resource owing to the broad spectrum of bioactive compounds present in it.

Extraction of bioactive compounds from food matrices using suitable extraction method is a very important step prior to their separation and identification. The conventional techniques (soaking, maceration, solvent extraction etc.) are still prevailing at industrial level. Although the cost of these techniques is low but, extraction efficiency is also low. A few other advance techniques namely pulse electric field, microwave assisted extraction, enzyme assisted extraction etc. have been explored recently for the extraction of phytochemicals. However, the lack of comparative results demands alterative, efficient, and sustainable technologies to provide premium quality extracts from plant matrices with high efficiency, better yields, short extraction times with less use of solvents [6, 7]. Ultrasound assisted extraction (UAE) is one of them which allows easy scalability from laboratory to pilot scale, better penetration of solvent into the plant cellular matrix by causing cavitation, thus, improves the recovery of bioactive compounds [6]. Many researchers have studied UAE for the extraction of phytochemicals from mulberry [6], blackberry and sweet cherry [8], Lycium ruthenicum Murr. [9], Maqui berry [10], blueberries [11, 12], orange peel [13], grapefruit [14, 15], carrot pomace [16], strawberry and blackberry [17], açai berries [18], and blueberry pomace [19]. However, no study has been reported on the extraction of phytochemicals from java plum pomace using UAE.

The type of solvent to be used for extraction of phytochemicals from natural sources is one of most studied variable. Different alcohols are most commonly used solvents for the extraction of bioactive compounds, where ethanol is preferably used in food and pharmaceutical applications as it is environmental friendly organic solvent and is being classified as Generally Recognized as Safe (GRAS) by US FDA and FAO/WHO Expert Committee on Food Additives [12]. Apart from this, extraction temperature, time, pH, solid–liquid ratio, particle size also influence the extraction from different plant materials [20,21,22]. However, generalized extraction conditions cannot be applied for all plant matrices. Therefore, the optimization of these variables is highly required for the better extraction of phytochemicals from java plum pomace with minimum solvent utilization. To the best of our knowledge, this is the first study on the ultrasound assisted extraction using different variables (ultrasound power, time, temperature, and ethanol concentration) for the efficient extraction of phytochemicals from java plum pomace.

Materials and Methods

Material

The fresh pomace of java plum was collected from Food Industry Business Incubation Centre, Punjab Agricultural University, Ludhiana, India and brought immediately to the laboratory. The collected pomace was packed in 200 gauge polyethylene bags (5 kg capacity) and stored at − 18 °C till further use. All analytical grade chemicals were purchased from Loba Chemie, India. HPLC grade standards and solvents were purchased from Sigma-Aldrich (St. Louis, MO, U.S.A).

Extraction

Experimental Design for UAE

The relationship between extraction conditions (ultrasound power, extraction temperature, extraction time, ethanol concentration) and responses (total monomeric anthocyanins, percent polymeric color, total phenolic content, total flavonoids, DPPH, and reducing power assay) was investigated using a three level and four factor Box–Behnken design (BBD) to study the combined impact of various variables. The four independent variables and their corresponding levels were as follows: A, ultrasound power (W): 200–400 W; B, extraction temperature (°C): 30–50 °C; C, extraction time (min) 30–60 min; and D, ethanol concentration (%): 30–70%.

Ultrasound assisted extraction was carried out as per the procedure reported by Vázquez-Espinosa et al. [10] using an ultrasonic device (VC 750, Sonics and materials Inc., Newtown, CT, USA) working at a fixed frequency (28 kHz), gap time and out time of 5 and 20 s respectively. This system was coupled with a thermostatic bath (FRIGITERM-100, Barcelona, Spain) to control the temperature. The accurately weighed fresh pomace was mixed with aqueous ethanol [acidified with 0.1% HCl (v/v) in the ratio 1:20 (w/v)] in 250 ml glass beaker. The slurry so prepared was subjected to ultrasonic treatment at 200–400 W for 30–60 min at 30–50 °C. The complete details of the combinations of the variables i.e. treatments is given in Table 1. After completion of sonication, the treated slurry was centrifuged at 2000×g for 20 min at room temperature (ST16R, Thermo Fisher Scientific, Germany) to obtain the supernatant. The obtained supernatant was stored in amber colored glass bottles at 4 ± 1 °C and has been utilized for further analysis. All the experiments were done in triplicates.

Conventional Extraction

Conventional extraction (CE) of the phytochemicals was also performed by mixing the pomace with aqueous ethanol [acidified with 0.1% HCl (v/v) in the ratio 1:20 (w/v)] with the aim of its comparison with UAE. The conditions for the extraction i.e., temperature, time and ethanol concentration were 37.63 °C, 47.53 min and 70%, respectively as optimized for UAE. After extraction, the slurry was centrifuged at 2000×g for 20 min at room temperature to collect the supernatant and was stored at 4 ± 1 °C till further analysis.

Analysis

Phytochemical Analysis

Total monomeric anthocyanin content (TMAC) was estimated by pH differential method using a UV/Vis spectrophotometer (Shimadzu UV-1800, Kyoto, Japan) at 520 and 700 nm taking distilled water as blank [2]. Buffer at pH 1.0 and 4.5 were prepared and pH was adjusted using 0.1 N hydrochloric acid. The total monomeric anthocyanins were calculated as mg cyanidin-3-o-glucoside equivalent (CE)/100 g using the following equation:

where A = (A520 − A700)pH1.0 − (A520 − A700)pH4.5; Mw = 449.2 g/mol (molecular weight of cyanidin-3-glucoside), DF is the dilution factor, ε = 26,900 L/cm mol (molar absorptivity of cyanidin-3-glucoside), and L = 1 cm (standard optical path length); 1000 is the factor to convert grams to milligrams.

The proportion of polymerized anthocyanin compounds (percent polymeric color) in comparison to the monomeric anthocyanins was determined as percent polymeric color [2]. It was calculated as the ratio of polymeric color (polymerized anthocyanins) to color density (total anthocyanins). Diluted sample (2.8 ml) was mixed with 0.2 ml potassium metabisulfite (20%) and double distilled water in the control. The samples were allowed to equilibrate for 30 min at room temperature and then, the absorbance was read at 420 nm, λvis-max (500–510 nm), and 700 nm. Color density was estimated for control, and the polymeric color was estimated for bleached sample using the formula:

Total phenolic content (TPC) was estimated by Folin–Ciocalteu method as described by Kaur and Aggarwal [3]. Extract (0.5 ml) was mixed with 0.5 ml of Folin–Ciocalteu reagent, followed by addition of 1.5 ml of sodium carbonate (20%; w/v) and 7.5 ml double distilled water. The absorbance was taken at 760 nm against a reagent blank after 2 h incubation in dark and the results were expressed as mg gallic acid equivalent (GAE)/100 g (dw).

Total flavonoid content (TFC) of the extracts was determined using standard procedure as outlined by Kaur et al. [23]. 0.5 ml extract was mixed with 3.2 ml double distilled water and 0.15 ml of each i.e. sodium nitrite solution [5% (w/v)] and aluminium chloride solution [10% (w/v)]. To this mixture, 1 ml sodium hydroxide solution (1 M) was added followed by vortex mixing. The absorbance was immediately read at 510 nm and the results were expressed as mg quercetin equivalent (QE)/100 g (dw).

In Vitro Antioxidant Activity Analysis

Free radical scavenging activity of the extract was measured by DPPH method [24]. Diluted extracts (1 ml) were mixed with 1 ml Tris buffer and 2 ml of DPPH reagent. The mixtures were vortexed, followed by incubation in dark for 30 min at room temperature and the absorbance was then read at 517 nm. The results were expressed as mg Butylated hyroxytoluene equivalent (BHT)/100 g (dw). The ability of extracts to reduce ferric ions (Fe3+) was estimated as reducing power assay [3]. One ml of extract was mixed with 2.5 ml phosphate buffer and 2.5 ml potassium ferricyanide (1%), followed by incubation at 50 °C for 20 min. After incubation, 2.5 ml trichloroacetic acid (10%) was added followed by centrifugation at 2000×g. 2.5 ml of the supernatant was mixed with 2.5 ml double distilled water and 0.5 ml ferric chloride (0.1%, w/v), and the absorbance was measured at 700 nm. The results were expressed as mg ascorbic acid equivalent (AAE)/100 g (dw).

Mineral Profiling

Mineral composition of the optimized extracts from UAE as well as CE was estimated using Inductively Coupled Plasma Atomic Emission Spectroscopy (X-Series2, Thermo Scientific, USA). Respective phytochemical extract (0.5 ml) was digested using a mixture of nitric and perchloric acid (3:1) until a clear solution was obtained, followed by volume make up to 25 ml using deionised water and estimation of minerals. The results were expressed as mg/l [25].

Fourier Transform Infrared Spectroscopy (FTIR) Characterization

FTIR spectra of extracts obtained after UAE and CE treatments were recorded using Fourier transform infrared spectrophotometer (Thermo scientific, Nicolet 67000) in 4000–400 cm−1 range with a maximum resolution of 0.50 cm−1. The interpretation was done as per the standards guidelines of Stuart [26].

Scanning Electron Microscopy (SEM) Analysis

To assess the effect of ultrasonication and cavitation, the microstructures of untreated pomace and residue obtained after optimized UAE and CE treatments were subjected to scanning electron microscope (XL30, FEI Philips, France; 25–1,000,000 magnifications). The samples were dried at 35 °C and sputter coated with gold prior to analysis.

HPLC Profiling of Phenolic Compounds

HPLC analysis was carried out using a X-Bridge™ C18 column (250 mm × 4.6 mm, 5 μm) (Waters, USA) equipped with an X-Bridge™ C18 guard column and a Thermoquest HPLC system with a diode array detector. The mobile phase was comprised of solvent A, 0.1% formic acid in water (v/v) and solvent B, 0.1% formic acid in acetonitrile. The column was operated at 33 °C with the mobile phase at constant flow rate of 1.0 ml/min, eluted compounds were detected at 280 nm, and the injection volumes of the standards and sample extracts were 2.0 µl. The solvent gradient in volume ratios was as follows: 0–10 min, 98–80% A; 10–20 min, 80–60% A; 20–25 min, 60–10% A; 25–33 min, 98% A. Each estimation was run in triplicate and the quantification of phenolic compounds was done using external standard method based on the peak area.

Statistical Analysis

Design Expert (version 10.0.1.0, Stat-Ease) was used for the statistical analysis of the data for determination of regression coefficient and ANOVA. R2 was calculated and used to determine the fitness of the statistical equation. Numerical optimization tool was used to determine the optimized run for the maximum extraction of phytochemicals, where all the variables and responses were kept “in range” except phytochemicals (total monomeric anthocyanins, total phenols, and total flavonoids) which were kept at “maximum”. Data obtained from optimized extracts of UAE and CE was presented as mean ± standard deviation using SPSS version 20.0 (Statistical Package for Social Sciences) to differentiate between UAE and CE.

Results and Discussion

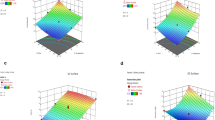

The effect of various independent variables i.e., ultrasound power, temperature, time and ethanol concentration was investigated on the extraction of various phytochemicals and antioxidant of java plum pomace. It was observed that total monomeric anthocyanins varied from 338.79 to 653.09 mg CE/100 g, percent polymeric color from 7.20 to 11.79%, total phenols from 774.69 to 2673.22 mg GAE/100 g, total flavonoids from 659.58 to 1725.40 mg QAE/100 g, DPPH from 78.25 to 93.23 mg BHT/100 g and reducing power assay from 582.35 to 3004.85 mg AAE/100 g (Table 1). The effect of independent variables on the responses at linear, quadratic and interaction levels has been studied and shown in Table S1; the significant (p < 0.05) regression coefficient values were highlighted with asterisk (*), where quadratic response surface model were further used for the statistical analysis. The R2 values for all the responses were more than 0.92 and the lack-of-fit test was found to be highly insignificant, indicating selected model was sufficiently accurate for the prediction of responses.

Effect of UAE on Phytochemicals

Total Monomeric Anthocyanins

In the present study, ultrasound power and extraction time were the most significant (p < 0.05) parameters affecting the extraction of anthocyanins at linear level; ultrasound power and temperature, ultrasound power and time, extraction temperature and ethanol concentration at interaction level, whereas all the parameters significantly affected anthocyanins yield at the quadratic level (Table S1). Figure S1 revealed that with increase in ultrasound power from 200 to 320 W, a significant increase in the anthocyanins yield was observed which might be due to the collapse of cavitation bubbles at the surface of the substrate matrix. This leads to the disruption of plant cell walls and vacuole membranes, resulting in more leaching of anthocyanins into the solvent [27]. However, high intensity acoustic cavitation can contribute to the formation of hydroxyl radicals which degrades the anthocyanins by opening up the rings and simultaneous formation of chalcone [28, 29]. Another reason can be related to the oxidative reactions which are promoted by the interaction of free radicals formed during high ultrasound treatment [30]. Similar effect of ultrasound power was seen in the present study. Also, it can be observed from Table 2 and Fig. S1, that with the increase in ultrasound treatment time, total monomeric anthocyanins increased rapidly and reached a highest at 50 min, this can be due to the dilution of substrate with extracting solvent which takes a certain period of time to reach equilibrium [31].

Percent Polymeric Color

It can be observed from Table 2, that ultrasound power, extraction time and ethanol concentration at linear level, ultrasound power, temperature and time at quadratic level, whereas all the parameters at interaction level except time and ethanol were the most significant (p < 0.05) parameters affecting polymeric color (Table S1). There was a gradual increase in the amount of polymeric color with the increase in ultrasound power till 320 W (Fig. S1) which further became constant (Table 2). Polymerization of anthocyanins is an important reaction which occurs during anthocyanin degradation due to intrinsic factors such as pressure, temperature and pH during processing. The increase in polymerized color content might be due to the formation of an intermediate product of anthocyanins degradation (chalcone). This intermediate is unstable and is quickly degraded to brown colored compounds, resulting in notable increase in polymerized anthocyanins content. Another reason for polymerization can be covalent bonding of anthocyanins with compounds like flavanols, pyruvic acid through ethyl bridges [30]. In present study, PPC of the extract varied from 7.20 to 11.79% after ultrasound treatment which indicates the condensation reactions of anthocyanins due to localized increase in temperature and pressure during sonication. Cao et al. [30] reported ultrasound treatment resulted in increase in PPC content of bayberry juice from 10.5 to 15.7% which was accompanied with the decrease in monomeric anthocyanins content. The extraction time and ethanol concentration positively affected PPC content. This might be probably because polymerized anthocyanins are more readily extracted in the less polar solvent mixture (ethanol is less polar than water) [32].

Total Phenols

Among all the variables under study, ethanol concentration and extraction temperature at linear level, and all the parameters at quadratic level were significant whereas the individual effect of ultrasound power and time was non-significant on the extraction of total phenols (Table S1). The phenolic content increased as the ethanol concentration increased beyond 45%. Ethanol–water mixture extracts phenolic compounds more efficiently than mono component solvent medium as the addition of water into organic solvents increases polarity of the extraction medium, thus, accelerates the extraction of polyphenols [33]. Chaves et al. [29] stated that aqueous ethanol leads to the leaching of bioactive constituents with broad range of polarity particularly suitable for the extraction of polyphenolic compounds. Sun et al. [34] reported the extraction of not only polar but weak polar as well as non-polar phenolic compounds from Propolis with the use of 75% ethanol.

It was observed from Fig. S2 that with increase in temperature from 30 to 40 °C, the phenolic content gradually increased which might be due to the softening of plant tissue which weakens the interaction of phenols with protein and polysaccharides, hence, improves the diffusion of analytes from the solid matrix into solvent. This resulted in more extraction of phenolic compounds [31, 35]. The results were in agreement to the study of González-Centeno et al. [35] who observed increase in phenolic content of grape pomace extract during ultrasound treatment at 20–50 °C. The interactions of ultrasound power and temperature, ultrasound power and ethanol had a significant negative effect on the yield of total phenols while interaction of temperature and ethanol had a significant positive effect (Table S1). The effect of ultrasound on total phenols can be explained as when the cell walls are ruptured due to ultrasound treatment, the impurities suspend in the extraction medium which lowers the permeability of solvent into cell structures. This results in reabsorption of target molecules into the ruptured tissue particles (due to their relatively larger surface areas) and hence, lowers the yield of phenolic compounds [36].

Total Flavonoids

Total flavonoids of java plum pomace extract were significantly affected by ethanol concentration at linear level, ultrasound power and temperature at interaction level, whereas all the variables were significant at quadratic level (Table S1). A sharp increase in flavonoids yield was observed with increase in ethanol concentration as organic solvents (ethanol; non-toxic and biodegradable) are often more suitable for efficient extraction of flavonoids and have been explored by various researchers [29, 37]. The use of acidified aqueous ethanol preserves flavonoids from oxidative degradation by stabilizing free radicals produced during sonication [29]. Bamba et al. [19] reported that ultrasound assisted extraction resulted in highest yield of flavonoids from blueberry pomace using 50% ethanol as solvent at 40 °C for 40 min of treatment time. The effect of ultrasound power at linear level was not statistically significant which might be due to loss of some energy from the equipment to the solvent-plant material medium [38]. The combined effect of ultrasound power and temperature was significant which substantially enhanced the flavonoids extraction (Fig. S2). Karunanithi and Venkatachalam [39] reported that an increase in temperature affects the viscosity as well as vapour pressure (solvent properties) i.e., with the increase in temperature viscosity decreases whereas vapor pressure increases. A rise in vapor pressure causes more solvent vapors to enter the bubble cavity and is responsible for the intensity of collapse, thus, more solvent penetrates the deeper cell structure. Therefore, both the ultrasound and temperature enhanced the mass transfer of target compounds into the solvent medium as discussed in phenolics. Similar results for the ultrasound assisted extraction of total flavonoids from açai berries have been reported by Hanula et al. [18] where the maximum yield was obtained at 45 °C for 25 min.

Effect of UAE on Antioxidant Activities

The antioxidant potential of the extract was studied by two assays i.e. DPPH free radical scavenging activity and reducing power assay as no single method can assess the antioxidant potential of a sample [2]. Extraction temperature, time and ethanol concentration had significant effect at linear level, ultrasound power, extraction temperature and ethanol concentration at quadratic level, whereas extraction temperature and time, extraction temperature and ethanol, time and ethanol at interaction level had significant effect on the antioxidant activity measured in terms of DPPH free radical scavenging activity (Table S1). However, in reducing power assay, all the parameters except ethanol concentration at linear level, ultrasound power, extraction temperature and ethanol concentration at quadratic level, whereas ultrasound power and ethanol at interaction level had significant effect on the antioxidant activities of the extract (Table S1).

The antioxidant activities decreased significantly (p < 0.05) with increase in temperature and ethanol concentration. Bamba et al. [19] observed similar effect of increasing concentration of ethanol on the ultrasound assisted extraction of antioxidant activities from blueberry pomace and reported a significant decrease in the yield with the increase in ethanol concentration above 50%. Hu et al. [40] reported higher antioxidant potential in terms of reducing power assay and DPPH free radical scavenging activity of the blueberry pomace when extracted using ultrasound. Antioxidant potential of the extract depends upon the concentration of phytochemicals (anthocyanins, flavonoids, and phenolic compounds) which are heat-labile [2]. Higher ultrasound power, temperature, and longer extraction times can cause irreversible chemical changes i.e., generation of free radicals which triggers radical chain reactions and causes oxidation of phenolic compounds and antioxidants, hence, decreases the antioxidant potential [29]. The reduction effect of extraction temperature and time was more drastic in DPPH free radical scavenging activity; however, the effect of time was statistically insignificant in reducing power assay. However, interactions of different parameters had significant positive effect on the antioxidant potential of the extract which showed that combination of these extraction variables (Fig. S3). D’Alessandro et al. [41] and Ivanovic et al. [42] reported significant increasing effect of temperature and time on the antioxidant potential of black chokeberry waste and blackberry, respectively.

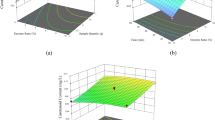

Numerical Optimization

To find out the optimum conditions, goals and intensity was assigned to each variable and response. All the variables and responses were kept in range, whereas the phytochemicals namely total monomeric anthocyanins, phenols and flavonoids were kept at higher side (Table S2a). This advocated an optimized solution i.e. ultrasound power (366.25 W), extraction temperature (37.61 °C), extraction time (47.48 min) and ethanol concentration (70%) with 0.827 desirability. The predicted yields of total monomeric anthocyanin content, total phenolic content and total flavonoids were 649.47 mg CE/100 g, 2266.36 mg GAE/100 g and 1668.43 mg QE100 g, respectively (Table S2b). An experiment was laid using optimized conditions of UAE to check the accuracy of predicted values and a difference was drawn which indicated a non-significant (p > 0.05) difference between predicted and actual values. This indicated accuracy of the experiment at the optimized conditions.

Comparison Between UAE and CE for the Better Extractability

A comparison has been carried out to check the effect of UAE as compared to CE in terms of percentage extractability and the results were presented in Table 3. It was observed that phytochemicals (total monomeric anthocyanins, total phenols, total flavonoids, and polymeric color) and antioxidant activities were better extracted at the optimized conditions of UAE than CE (Table 3). The increase in phytochemicals constituents can be attributed to cavitation phenomena which disrupt the plant tissues and cell walls, thus, enhanced the extractability of bound constituents into the extraction medium. The antioxidant potential of the extract is correlated to the concentration of phytochemicals (anthocyanins, total phenols, and flavonoids) [29]. Hence, the increase in phytochemical compounds significantly improved the antioxidant potential of optimized UAE extract. The quantification of phenolic compounds using HPLC, UAE reported higher concentration of gallic acid, 4-amino benzoic acid, catechin hydrate, 3-hydroxybenzoic acid, vanillic acid, 2,3-dihydroxybenzoic acid, p-coumaric acid, quercetin, kaempferol, and sinapic acid whereas, the quantities of syringic acid, caffeic acid, transferulic acid, and chlorogenic acid were higher in CE (Fig. 1). Sun et al. [43] reported that caffeic acid undergoes decarboxylation and polymerization during UAE. Degradation of syringic acid and caffeic acid has been reported by Qiao et al. [44]. A significant (p < 0.05) increase in all the macro and micro elements in UAE extract was observed as compared to CE except for potassium, copper, and manganese. Similar results related to better release of mineral elements have been reported by Jabbar et al. [45] and Aadil et al. [14].

FT-IR Spectra

FT-IR spectra of both the extracts of UAE and CE showed similar band recognition (Fig. 2) indicating that the similar extraction of bioactive compounds in both the methods, however, the concentration of phytochemicals varied in both the extracts (Table 3). The peaks between 3400 and 2500 cm−1 is attributed to the presence of phenolic compounds and O–H functional group in sugar, which corresponds to the presence of anthocyanin pigment. Stretching band at 1730–1705 cm−1 showed the presence of pyran ring which indicates presence of flavonoid compounds [46]. The absorption peaks in the range of 1396–1379 cm−1, 1247–1242 cm−1 and 1052–1027 cm−1 represents the presence of asymmetrical/symmetrical CH3 stretch, asymmetrical C–O–C stretch and CH–CH, C–CH and C–OH stretching, respectively show the presence of phenolic compounds, whereas peaks in the region of 1260–1240 cm−1 and 1050–700 cm−1 corresponds to P=O and P=S stretching respectively. These stretching indicates the presence of phosphorus compounds.

Scanning Electron Microscopy (SEM) Analysis

SEM was performed to observe the changes in microstructure and morphological characteristics of untreated pomace sample, and the residue obtained after both conventional and ultrasound assisted extraction of phytochemicals. The untreated pomace showed smooth and unbroken cell walls, whereas in CE the cells were wrinkled, rough but not very much broken (Fig. 3A, B). However, after ultrasound treatment, the surface of the pomace was greatly affected and the structure opened up, thereby increased the release of cell components including phytochemicals into the extracting solvent (Fig. 3C). The deformation can be attributed to the propagation of ultrasound waves resulting in the formation and collision of cavitation bubbles [7]. This was evident from the scanning electron microscopy images demonstrating intact structure of pomace as compared to sonicated samples. Karunanithi and Sivakumar [39] observed similar structural changes in the pricky pear peel residue after ultrasonication treatment and reported accelerated extraction of phenolic compounds. Zhou et al. [47] also reported more porous structure with cracked cell walls of Morus alba L. leaves while extracting phenolic compounds using deep eutectic solvents combined with ultrasonic-assisted extraction.

Conclusion

Ultrasound assisted extraction of phytochemicals using acidified aqueous ethanol was carried out using three level, four factor BBD design and the optimized conditions for the extraction of phytochemicals were 366.25 W ultrasound power at 37.61 °C for 47.48 min using 70% ethanol as solvent with 0.827 desirability. Upon comparison, the better extraction in UAE was observed as compared to CE for phytochemicals, antioxidant activities, and phenolic compounds except syringic acid, caffeic acid, transferulic acid, chlorogenic acid, and minerals except potassium, copper, and manganese. The findings have the potential for the effective utilization of java plum pomace for the better extraction of bioactive compounds which can be used as a source of phytochemicals for health food industry.

Data Availability

The datasets generated during and/or analyzed during the current study are included in this article.

References

Mazzoni, L., Perez-Lopez, P., Giampieri, F., Alvarez-Suarez, J.M., Gasparrini, M., Forbes-Hernandez, T.Y., Quiles, J.L., Mezzetti, B., Battino, M.: The genetic aspects of berries: from field to health. J. Sci. Food Agric. 96, 365–371 (2016). https://doi.org/10.1002/jsfa.7216

Kaur, N., Aggarwal, P., Kumar, V., Kaur, S.: Influence of different extraction techniques on the extraction of phytochemicals and antioxidant activities from Syzygium cumini (jamun) pomace using Taguchi orthogonal array design: a qualitative and quantitative approach. Biomass Convers. Biorefin. (2022). https://doi.org/10.1007/s13399-022-02826-1

Kaur, N., Aggarwal, P.: Development and characterization of packing, microstructural, physico- and phytochemical attributes of potential functional jamun (Syzygium cumini) pomace powder for direct compression: high antioxidant nutraceutical tablets. Int. J. Food Sci. Technol. (2022). https://doi.org/10.1111/ijfs.15933

Pietta, P.G.: Flavonoids as antioxidants. J. Nat. Prod. 63, 1035–1042 (2000). https://doi.org/10.1021/np9904509

Suradkar, N.G., Pawar, V.S., Shere, D.M.: Physicochemical, proximate and bioactive composition of jamun (Syzygium cuminii L.) fruit. Int. J. Chem. Stud. 5, 470–472 (2017). https://doi.org/10.1007/s13197-011

Espada-Bellido, E., Ferreiro-González, M., Carrera, C., Palma, M., Barroso, C.G., Barbero, G.F.: Optimization of the ultrasound-assisted extraction of anthocyanins and total phenolic compounds in mulberry (Morus nigra) pulp. Food Chem. 219, 23–32 (2017). https://doi.org/10.1016/j.foodchem.2016.09.122

Chemat, F., Rombaut, N., Sicaire, A.G., Meullemiestre, A., Fabiano-Tixier, A.S., Abert-Vian, M.: Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34, 540–560 (2017). https://doi.org/10.1016/j.ultsonch.2016.06.035

Oancea, S., Grosu, C., Ketney, O., Stoia, M.: Conventional and ultrasound-assisted extraction of anthocyanins from blackberry and sweet cherry cultivars. Acta Chim. Slov. 60, 383–389 (2013)

Qin, B., Liu, X., Cui, H., Ma, Y., Wang, Z., Han, J.: Aqueous two-phase assisted by ultrasound for the extraction of anthocyanins from Lycium ruthenicum Murr. Prep. Biochem. Biotechnol. 47, 881–888 (2017). https://doi.org/10.1080/10826068.2017.1350980

Vázquez-Espinosa, M., de Peredo, A.V.G., Ferreiro-González, M., Carrera, C., Palma, M., Barbero, G.F., Espada-Bellido, E.: Assessment of ultrasound assisted extraction as an alternative method for the extraction of anthocyanins and total phenolic compounds from maqui berries (Aristotelia chilensis (Mol.) Stuntz). Agronomy 9, 1–17 (2019). https://doi.org/10.3390/agronomy9030148

Aliaño-González, M.J., Jarillo, J.A., Carrera, C., Ferreiro-González, M., Álvarez, J.Á., Palma, M., Ayuso, J., Barbero, G.F., Espada-Bellido, E.: Optimization of a novel method based on ultrasound-assisted extraction for the quantification of anthocyanins and total phenolic compounds in blueberry samples (Vaccinium corymbosum L.). Foods 9, 1763 (2020). https://doi.org/10.3390/foods9121763

Dibazar, R., Bonat Celli, G., Brooks, M.S.L., Ghanem, A.: Optimization of ultrasound-assisted extraction of anthocyanins from lowbush blueberries (Vaccinium angustifolium Aiton). J. Berry Res. 5, 173–181 (2015). https://doi.org/10.3233/JBR-150100

Khan, M.K., Abert-Vian, M., Fabiano-Tixier, A.S., Dangles, O., Chemat, F.: Ultrasound-assisted extraction of polyphenols (flavanone glycosides) from orange (Citrus sinensis L.) peel. Food Chem. 119, 851–858 (2010). https://doi.org/10.1016/j.foodchem.2009.08.046

Aadil, R.M., Zeng, X.A., Han, Z., Sun, D.W.: Effects of ultrasound treatments on quality of grapefruit juice. Food Chem. 141, 3201–3206 (2013). https://doi.org/10.1016/j.foodchem.2013.06.008

Carrera, C., Ruiz-Rodríguez, A., Palma, M., Barroso, C.G.: Ultrasound assisted extraction of phenolic compounds from grapes. Anal. Chim. Acta 732, 100–104 (2012). https://doi.org/10.1016/j.aca.2011.11.032

Jabbar, S., Abid, M., Wu, T., Hashim, M.M., Saeeduddin, M., Hu, B., Lei, S., Zeng, X.: Ultrasound-assisted extraction of bioactive compounds and antioxidants from carrot pomace: a response surface approach. J. Food Process. Preserv. 39, 1878–1888 (2015). https://doi.org/10.1111/jfpp.12425

Agnieszka, M., Michał, S., Robert, K.: Selection of conditions of ultrasound-assisted, three-step extraction of ellagitannins from selected berry fruit of the rosaceae family using the response surface methodology. Food Anal. Methods 13, 1650–1665 (2020). https://doi.org/10.1007/s12161-020-01762-y

Hanula, M., Wyrwisz, J., Moczkowska, M., Horbańczuk, O.K., Pogorzelska-Nowicka, E., Wierzbicka, A.: Optimization of microwave and ultrasound extraction methods of açai berries in terms of highest content of phenolic compounds and antioxidant activity. Appl. Sci. 10, 1–12 (2020). https://doi.org/10.3390/app10238325

Bamba, B.S.B., Shi, J., Tranchant, C.C., Xue, S.J., Forney, C.F., Lim, L.T.: Influence of extraction conditions on ultrasound-assisted recovery of bioactive phenolics from blueberry pomace and their antioxidant activity. Molecules 23, 1–17 (2018). https://doi.org/10.3390/molecules23071685

Ryu, D., Koh, E.: Application of response surface methodology to acidified water extraction of black soybeans for improving anthocyanin content, total phenols content and antioxidant activity. Food Chem. 261, 260–266 (2018). https://doi.org/10.1016/j.foodchem.2018.04.061

Ang, Y.K., Sia, W.C., Khoo, H.E., Yim, H.S.: Antioxidant potential of Carica papaya peel and seed. Focus Mod. Food Ind. 1, 11–16 (2012)

Papoutsis, K., Pristijono, P., Golding, J.B., Stathopoulos, C.E., Bowyer, M.C., Scarlett, C.J., Vuong, Q.V.: Screening the effect of four ultrasound-assisted extraction parameters on hesperidin and phenolic acid content of aqueous citrus pomace extracts. Food Biosci. 21, 20–26 (2018). https://doi.org/10.1016/j.fbio.2017.11.001

Kaur, N., Aggarwal, P., Kaur, N., Kaur, S.: Nutritional improvement of Bhujia by incorporating coloured bell peppers. J. Food Process. Preserv. (2022). https://doi.org/10.1111/jfpp.16569

Kaur, S., Aggarwal, P., Kaur, N.: Formulations for preparation of ‘Aloo bhujia’ from medium and high sugar potato varieties. Agric. Res. J. 56, 288 (2019). https://doi.org/10.5958/2395-146x.2019.00045.0

Aggarwal, P., Kaur, S., Kaur, N.: Intermediate moisture kinnow bar from low grade kinnow mandarins: phytonutritional profile, morphological characterization, and storage stability. Food Biosci. (2022). https://doi.org/10.1016/j.fbio.2022.101837

Stuart, B.H.: Infrared Spectroscopy: Fundamentals and Applications. Wiley, Chichester (2004)

Esclapez, M.D., García-Pérez, J.V., Mulet, A., Cárcel, J.A.: Ultrasound-assisted extraction of natural products. Food Eng. Rev. 3, 108–120 (2011). https://doi.org/10.1007/s12393-011-9036-6

Kidak, R., Ince, N.H.: Ultrasonic destruction of phenol and substituted phenols: a review of current research. Ultrason. Sonochem. 13, 195–199 (2006). https://doi.org/10.1016/j.ultsonch.2005.11.004

Chaves, J.O., de Souza, M.C., da Silva, L.C., Lachos-Perez, D., Torres-Mayanga, P.C., da Fonseca Machado, A.P., Forster-Carneiro, T., Vázquez-Espinosa, M., González-de-Peredo, A.V., Barbero, G.F., Rostagno, M.A.: Extraction of flavonoids from natural sources using modern techniques. Front. Chem. 8, 507887 (2020). https://doi.org/10.3389/fchem.2020.507887

Cao, X., Cai, C., Wang, Y., Zheng, X.: Effects of ultrasound processing on physicochemical parameters, antioxidants, and color quality of bayberry juice. J. Food Qual. (2019). https://doi.org/10.1155/2019/7917419

Tan, M.C., Tan, C.P., Ho, C.W.: Effects of extraction solvent system, time and temperature on total phenolic content of henna (Lawsonia inermis) stems. Int. Food Res. J. 20, 3117–3123 (2013)

Wang, W., Jung, J., Tomasino, E., Zhao, Y.: Optimization of solvent and ultrasound-assisted extraction for different anthocyanin rich fruit and their effects on anthocyanin compositions. LWT 72, 229–238 (2016). https://doi.org/10.1016/j.lwt.2016.04.041

Goula, A.M., Thymiatis, K., Kaderides, K.: Valorization of grape pomace: drying behavior and ultrasound extraction of phenolics. Food Bioprod. Process. 100, 132–144 (2016). https://doi.org/10.1016/j.fbp.2016.06.016

Sun, C., Wu, Z., Wang, Z., Zhang, H.: Effect of ethanol/water solvents on phenolic profiles and antioxidant properties of Beijing propolis extracts. Evid. Based Complement. Altern. Med. (2015). https://doi.org/10.1155/2015/595393

González-Centeno, M.R., Comas-Serra, F., Femenia, A., Rosselló, C., Simal, S.: Effect of power ultrasound application on aqueous extraction of phenolic compounds and antioxidant capacity from grape pomace (Vitis vinifera L.): experimental kinetics and modeling. Ultrason. Sonochem. 22, 506–514 (2015). https://doi.org/10.1016/j.ultsonch.2014.05.027

Kaderides, K., Goula, A.M., Adamopoulos, K.G.: A process for turning pomegranate peels into a valuable food ingredient using ultrasound-assisted extraction and encapsulation. Innov. Food Sci. Emerg. Technol. 31, 204–215 (2015). https://doi.org/10.1016/j.ifset.2015.08.006

Fu, X., Belwal, T., Cravotto, G., Luo, Z.: Sono-physical and sono-chemical effects of ultrasound: primary applications in extraction and freezing operations and influence on food components. Ultrason. Sonochem. 60, 104726 (2020). https://doi.org/10.1016/j.ultsonch.2019.104726

De Luna, S.L.R., Ramírez-Garza, R.E., Serna Saldívar, S.O.: Environmentally friendly methods for flavonoid extraction from plant material: impact of their operating conditions on yield and antioxidant properties. Sci. World J. (2020). https://doi.org/10.1155/2020/6792069

Karunanithi, A., Venkatachalam, S.: Ultrasonic-assisted solvent extraction of phenolic compounds from Opuntia ficus-indica peel: phytochemical identification and comparison with soxhlet extraction. J. Food Process Eng. (2019). https://doi.org/10.1111/jfpe.13126

Hu, A.J., Hao, S.T., Zheng, J., Chen, L., Sun, P.P.: Multi-frequency ultrasonic extraction of anthocyanins from blueberry pomace and evaluation of its antioxidant activity. J. AOAC Int. 104, 811–817 (2021). https://doi.org/10.1093/jaoacint/qsaa150

Galván D’Alessandro, L., Dimitrov, K., Vauchel, P., Nikov, I.: Kinetics of ultrasound assisted extraction of anthocyanins from Aronia melanocarpa (black chokeberry) wastes. Chem. Eng. Res. Des. 92, 1818–1826 (2014). https://doi.org/10.1016/j.cherd.2013.11.020

Ivanovic, J., Tadic, V., Dimitrijevic, S., Stamenic, M., Petrovic, S., Zizovic, I.: Antioxidant properties of the anthocyanin-containing ultrasonic extract from blackberry cultivar “Čačanska Bestrna.” Ind. Crops Prod. 53, 274–281 (2014). https://doi.org/10.1016/j.indcrop.2013.12.048

Sun, Y., Qiao, L., Ye, X., Liu, D., Zhang, X., Huang, H.: The sonodegradation of caffeic acid under ultrasound treatment: relation to stability. Molecules 18, 561–573 (2013). https://doi.org/10.3390/molecules18010561

Qiao, L., Ye, X., Sun, Y., Ying, J., Shen, Y., Chen, J.: Sonochemical effects on free phenolic acids under ultrasound treatment in a model system. Ultrason. Sonochem. 20, 1017–1025 (2013). https://doi.org/10.1016/j.ultsonch.2012.12.007

Jabbar, S., Abid, M., Hu, B., Wu, T., Hashim, M.M., Lei, S., Zhu, X., Zeng, X.: Quality of carrot juice as influenced by blanching and sonication treatments. LWT 55, 16–21 (2014). https://doi.org/10.1016/j.lwt.2013.09.007

Pereira, V.A., de Arruda, I.N.Q., Stefani, R.: Active chitosan/PVA films with anthocyanins from Brassica oleraceae (red cabbage) as time-temperature indicators for application in intelligent food packaging. Food Hydrocoll. 43, 180–188 (2015). https://doi.org/10.1016/j.foodhyd.2014.05.014

Zhou, P., Wang, X., Liu, P., Huang, J., Wang, C., Pan, M., Kuang, Z.: Enhanced phenolic compounds extraction from Morus alba L. leaves by deep eutectic solvents combined with ultrasonic-assisted extraction. Ind. Crops Prod. 120, 147–154 (2018). https://doi.org/10.1016/j.indcrop.2018.04.071

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Conceptualization: [NK, PA]; Methodology: [NK]; Formal analysis and investigation: [NK]; Writing—original draft preparation: [NK]; Writing—review and editing: [NK, VK, SK]; Funding acquisition: [PA]; Resources: [PA]; Supervision: [PA].

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, N., Aggarwal, P., Kumar, V. et al. Ultrasound-Assisted Extraction of Phytochemicals from Java Plum (Syzygium cumini L.) Pomace: Process Optimization, Phytochemical Characterization Using HPLC, FTIR, SEM and Mineral Profiling. Waste Biomass Valor 14, 949–961 (2023). https://doi.org/10.1007/s12649-022-01915-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01915-6