Abstract

The process conditions of dielectric barrier discharge cold plasma using nonlinear regression analysis for enhanced shelf life of tender coconut water (TCW) were optimized. Face centre composite design was used to optimise process condition of cold plasma treatment and desirability of treated TCW was determined on the basis of microbial load, DPPH scavenging activity, free fatty acid content and transmittance. Microbial load, DPPH scavenging activity and transmittance decreased with plasma treatment time and voltage whereas fatty acid content increased. However, TCW developed ‘chemical’ odour at the optimized cold plasma treatment condition of 18.00 kV voltage and 1.75 min treatment time. Pasteurized orange juice (1–4%) was added to the cold plasma treated coconut water to counter the off flavour and the developed blended beverage was subjected to sensory optimization using fuzzy logic. From the application of fuzzy logic, it was determined that cold plasma treated TCW with 1% orange juice has acceptable sensory properties. The study revealed that cold plasma was helpful in reducing microbial load of TCW and its blending with 1% orange juice gave beverage that was acceptable for sensory attributes besides being able to mask the ‘chemical’ odour. Cold plasma can therefore be used in place of thermal treatment for processing of TCW.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coconut (Cocos nucifera L.) water has physiological health benefits and is helpful for anti-inflammatory property, restoration of electrolytes, oral rehydration, homeostasis, and treatment of conditions like childhood diarrhoea, gastroenteritis and cholera. It also has demand in the sport drinks market for its balanced electrolytes, taste, flavour, available nutrients and functional characteristics. TCW is a refreshing drink in tropical coastal areas but degrades in quality very rapidly. On exposure to air, it’s sensory, nutritional and flavour characteristics are easily lost [1, 2]. Thermal treatment as followed in industrial processing helps to prolong the shelf life but the process causes loss in nutrients and its delicate flavour [1], which adversely affects its acceptability.

Several studies have reported an increase in the shelf life of coconut water on processing while retaining its quality. Campos et al. [3] and Costa et al. [4] used chemical preservative. Studies on the use of two-stage microfiltration technique in sterile atmosphere for preserving the water have been reported [5, 6], but microfiltration in a sterile atmosphere is a tedious and costly technique.

Cold plasma is one of the novel nonthermal techniques being widely studied for microbial decontamination of foods, inactivation of polyphenol peroxidase in fruit juices, enhancement of antioxidant activity and rate of germination of seeds among various other applications [7,8,9,10]. Cold plasma is generated in any neutral gas on the application of high energy. As the energy input is increased beyond a certain level in the gaseous state, the gas molecules are ionised and yields the plasma state [11]. The ionised gas comprises of electrons, ions, radicals and atoms which are both in ground and excited states [12]. The reactive oxygen species and reactive nitrogen species formed in the gas interact with food components and modify them [13]. The synergistic effect of the multiple constituents generated in the plasma have been found to effectively kill or inactivate microorganisms on food surface while maintaining food nutrition [14]. Cold plasma is effective against both pathogenic and spoilage microorganisms [15]. The effect of cold plasma on different foods including dairy products [16], meat [17], bakery products [18], whole fruits like Strawberries [19] and kiwi fruit [20], juices of apple [21] and pomegranate [22] have been reported. The voltage applied for the generation of plasma and the treatment time are important process parameters. Voltage level of 90 kV for 30–120 s was used for orange juice [23], 70 kV for 15–60 s for cashew apple juice [24] and 80 kV for 1–4 min for white grape juice [25].

Blending of juices has been followed to develop refreshing beverage. Chauhan et al. [26] blended lemon with mature coconut water to develop a refreshing beverage with 13.5°Brix and reported that packaged beverage with 2% lemon juice gave shelf stability of 6 months when stored at 5 °C, 25 ± 2 °C and high 37 °C temperatures. A blended beverage using coconut water and clarified cashew apple juice (“cajuina”) was observed to store well for 6 months [27]. Sindumathi and Amutha [28] developed a spice based ready to serve beverage of TCW and had shelf stability of 12 months duration at refrigerated temperature and 10 months duration at room temperature. Effect of cold plasma on the sensory attributes of TCW and development of a blended beverage with orange juice has not been reported.

Sensory evaluation is a scientific tool that measures, analyzes, and interprets sensory attributes perceived by human sensory organs [29]. Without appropriate sensory evaluation, there is a great chance of market failure [30] because it is the primary criteria for acceptability of food [31, 32]. Human perception is always fuzzy and assessors give their opinion in the linguistic form [33]. For analysis of human perception of sensory attributes Fuzzy sets can be used, which give better result as compared to average scores of the attributes [34]. Fuzzy logic is a computing based approach which helps to interpret imprecise and objective interpretations and conclusion are drawn on the acceptability, non acceptability of the product. The developed product can also be ranked on the basis of strong and weak attributes [30]. A comprehensive fuzzy model for ranking of product attributes developed by Zhang and Litchfield [35] has been successfully applied for evaluation of dahi powder [36], gluten-free pasta [37], and mango drinks [38].

In the present investigation, the process condition of cold plasma treatment of TCW was optimized and a blended beverage using cold plasma treated TCW and pasteurized orange juice was developed. Sensory attributes were evaluated by fuzzy logic.

Material and methods

Material

Green tender coconuts between 4 and 7 months of maturation were harvested from coconut trees grown nearby the campus of Tezpur University, Tezpur, Assam during end of August, 2017. Ten plants were selected for harvesting. Harvested nuts were immediately brought to the laboratory. Bruised fruits were discarded. Coconuts were processed on the same day of harvest.

Methods

Preparation and treatment of coconut water

Tender coconuts were washed and sanitized according to Mahnot et al. [6]. Just before processing coconuts were surface dried and cut open at the top. Coconuts were placed on a clean chopping board. A sharp chopper knife was used to cut open the nut at the broader end and the water was collected in a sterilized Borosil glass container in a laminar flow. Any contamination of TCW collected in this manner was unavoidable while obtaining water from the tender coconut for consumption. The collected coconut water was filtered through Whatman paper no 1 in a laminar flow and thereafter kept in freezer at − 20 °C in heavy duty vacuum bottles.

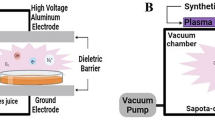

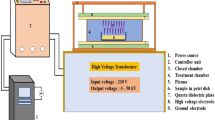

The set up and experimental conditions used for dielectric barrier discharge (DBD) plasma treatment extracted TCW is reported by Chutia et al. [39]. TCW was poured into a Petri plate inside a laminar flow which was then sealed and placed between the two dielectric plates keeping a gap of 15 mm. During DBD plasma treatment voltage, (X1) varied according to the experimental design from 18 to 28 kV and treatment time (X2) varied from 1 to 3 min.

Determination of DPPH (2,2-diphenyl-1-picrylhydrazyl) radical scavenging activity

A modified method of Fonseca et al. [40] was followed. In brief, 0.4 ml of TCW sample was added to a methanolic solution of DPPH (5.6 ml, 0.8 nM) and the solution was mixed vigorously and left undisturbed for 30 min in a dark chamber. TCW sample was replaced with 0.4 ml methanol for use as control and the mixture with no DPPH was used as blank. The developed colour was measured for absorbance at 517 nm in a UV–Vis spectrophotometer (CECIL 7400, 700 series, Aquarius). The inhibitory effects of DPPH radical or antioxidant activity was calculated.

Free fatty acid determination (FFA)

The titration method of Sadasivam and Manickam [41] was followed. Briefly, 5–10 ml of sample was taken in a conical flask to which 50 ml of neutral solvent added, followed by addition of a few drops phenolphthalein. The solution was titrated against 0.1 N KOH while constantly stirring till the development of mild pink colour that persisted for 15 s.

Microbial load analysis

Microorganisms in TCW were determined using Nutrient Agar for aerobic microbial count and HiVeg Coliform Agar for fecal coliform count [5, 6]. Briefly, 100 µL of the samples under study was taken and spread on the plates containing nutrient agar media. The plates were then incubated at 30 °C for 48 h in an incubator for colony enumeration. Total counts were recorded and averaged [5].

Transmittance

The method of Jackson et al. [42] was followed to determine clarity of the sample against distilled water spectrophotometrically (CECIL 7400, 7000 Series, Aquarius) by measuring the transmittance at 610 nm. Hazy sediments in the coconut water were re-suspended by gently rocking the sample holder immediately before measurements were taken.

Experimental design

Response surface methodology (RSM) and face centred central composite design (FCCD) was used to optimize process conditions. Leiviska [43] mentioned that in FCCD only three levels of independent parameters are used (α = ± 1) which require less number of experiments and also it provides relatively high quality predictions over the entire design range. FCCD for two independent variables (input parameters of the plasma treatment) was used to fit a second-order polynomial model. Design-Expert Version 7.1.2 (Stat-Ease, Inc. MN) was used to design the experiment and in all, 13 runs were carried out as per the FCCD. Table 1 gives the real and coded values of the variables used.

Optimization

The variables were optimized on the basis of higher desirability value. Optimization was done by fixing the desired goal of dependent parameters viz maximize, minimize, target, within range, none and putting the exact value of dependent parameters of the possible goal. Then all the dependents parameters were combined into a response called “desirability function” wherein a value can lie between 0 and 1 (0 indicates one or more products are unacceptable and 1 indicates that all products are on target).

A second order polynomial equation, shown in Eq. (1) was used to predict the responses. The dependent parameters (\({Y}_{i}\)) is the function of linear components, quadratic components and interaction components [44].

where Y represents the dependent parameters, βo represents intercept of the graph, βi represents regression coefficients, \({\mathrm{X}}_{\mathrm{i}}^{2}\) is the nonlinear (quadratic) effect of the independent variables and \({\mathrm{X}}_{\mathrm{i}\mathrm{j}}\) represents the interactive effect of two independent variables. Xi represents the independent variables.

After regression analysis, each dependent parameter (yi) was transformed into an individual desirability function \({\mathrm{d}}_{\mathrm{i}}({\mathrm{y}}_{\mathrm{i}})\), a value that lies in the range \({0\le \mathrm{d}}_{\mathrm{i}}({\mathrm{y}}_{\mathrm{i}})\le 1\) and increases with an increase in the desirability of the corresponding output. As FFA and microbial load are not desirable characteristics in TCW, desirability of the dependent parameters of FFA and microbial load was minimized and transmittance and DPPH activity was maximized. Then using geometric mean and combining the individual desirability of all the dependents parameters, overall desirability (D) (Eq. 2) was determined and the process was considered to be optimized [37].

where \({\mathrm{y}}_{1}\), \({\mathrm{y}}_{2}\) and \({\mathrm{y}}_{\mathrm{m}}\) are the dependent parameters and m denotes the number of dependent parameters.

Blending of tender coconut water and orange juice

The optimized conditions for cold plasma treatment of TCW were followed to process coconut water. Orange juice was extracted using a household juicer (Philips juicer). The juice was strained through a muslin cloth and pasteurised at 90 °C for 60 s [45]. The time required to reach 90 °C at the centre was determined and the orange juice was held thereafter at 90 °C for 60 s. The processed water was blended with 0, 1, 2, 3, and 4% of pasteurized orange juice to develop the blended beverage inside a laminar flow, filled in sterilised bottle and tightly capped.

The five beverage samples were coded as S1 (Treated coconut water), S2 (Treated coconut water + 1% orange juice), S3 (Treated coconut water + 2% orange juice), S4 (Treated coconut water + 3% orange juice) and S5 (Treated coconut water + 4% orange juice).

Sensory evaluation

Sensory properties of the blended beverages were evaluated by 27 semi trained panel judges who were trained about the importance of impartial assessment of sensory attributes, definition of quality attributes to be evaluated, the content of the score sheet and the procedure for scoring. The judges rinsed their mouth with normal drinking water before tasting of each sample. Judges were advised to evaluate the quality attributes of the sample and assign a value in the fuzzy scale for each sensory attribute. The judges were told to categorize samples subjectively from ‘Not satisfactory’, ‘Fair’, ‘Medium’, ‘Good’ and ‘Excellent’ [36, 37]. Fuzzy logic was used to analyse all the sets of data noted by the judges.

Application of fuzzy logic on sensory data

Fuzzy logic uses imprecise and user-dependent data to obtain an output conclusion that helps to determine whether the quality attributes of the food are strong or weak and acceptable or not. It helps to rank foods according to the strength of the attributes. As followed by Jaya and Das [38], Das [31], and Sakre et al. [37], the developed blended beverage samples were ranked using triangular fuzzy membership distribution function. Fuzzy logic modelling follows the following steps for ranking of foods on the basis of sensory data [37, 38].: (1) Formation of triplets from calculated overall sensory data of blended beverages; (2) Fuzzy membership function sensory scores of blended beverages; (3) Normalized fuzzy membership function; (4) Normalized fuzzy membership function matrix on standard fuzzy scale (5) Judgment membership function matrix; (6) Judgment subset; (7) Quality- ranking of blended beverage samples; and (8) Ranking of the blended beverages. Triplets were formed from the obtained sensory scores and similarity values were calculated and on the basis of this, ranking of developed beverage samples was done. Matlab (MATLAB R2012b, The MathWorks) was used to develop a programme for calculating the fuzzy logic steps. A set of three numbers set termed as ‘triplets’ were developed to get the triangular membership distribution pattern of the fuzzy set and 5-point sensory scales comprising of Not satisfactory/Not at all important (0, 0, 25), Fair/Somewhat important (25, 25, 25), Medium/Important (50, 25, 25), Good/Highly important (75, 25, 25) and Excellent/Extremely important (100, 25, 0) were taken [37], as per Fig. 1. The first number of the triplet denotes the value of the abscissa, where the value of membership function was 1. The second and third numbers of the triplet indicate the distance to left and right, respectively, of the first number, where the membership function is 0 [31, 37].

Representation of triangular membership function distribution pattern of the sensory scale [26]

Standard fuzzy scale also termed as the distribution pattern of triangular membership function of 6-point sensory scale is given in Fig. 2, where the sensory scales are represented as F1, F2, F3, F4, F5, and F6. Linguistically, the fuzzy scale for sensory analysis was categorised on a 5 point set as Not satisfactory/Not at all necessary, Fair/Somewhat necessary, Satisfactory/Necessary, Good/ Important, Very good/Highly important and Excellent/ Extremely important, according to Sakre et al. [37]. Each membership function of sensory fuzzy scale follows the triangular distribution structure where 1 is the maximum membership value.

Standard fuzzy scale used for ranking of the blended beverage samples [20]

Figure 3. shows the graphical representation of the overall membership function of sensory score as triplet (a, b, c). The figure represents that when the value of abscissa is a, the value of membership function is 1 while the value is zero when the abscissa is more than (a + c) or less than (a − b) [31, 36].

Graphical view of overall sensory score as triangle ABC and triplet ABC [20]

Results and discussion

Effect of cold plasma on DPPH scavenging activity

The untreated TCW recorded 28.41 ± 9.43% DPPH scavenging activity. As shown in Fig. 4a, after cold plasma treatment, DPPH scavenging activity decreased with increase in voltage and time. Pankaj et al. [25] also reported that both DPPH free radical scavenging activity and total phenolic content of grape juice reduced after high voltage (80 kV) atmospheric cold plasma treatment. This may be attributed to the oxidation of ascorbic acid and phenolic compounds that are the major components of fruit juices by the plasma species [25, 46]. The antioxidant capacity was as such very low in untreated water and was further reduced as the antioxidants reacted with the free radicals generated by the plasma.

Effect of cold plasma on free fatty acid content

Free fatty acid content in untreated coconut water was 5.5 ± 0.54 mg KOH/100 ml. As shown in the Fig. 4b, the content of free fatty acids increased with an increase in the treatment time and voltage applied during cold plasma treatment. This was in agreement with the result reported by Yepez and Keener [47]. Total fat content in TCW varies from 0.01 to 0.2% [48, 49]. Meethawon et al. [50] reported lipase activity of 16 mmol/min/ml in TCW. The increase in free fatty acid can be attributed to increase in the activity of lipase on plasma treatment [51, 52] at the time and voltage combinations used in the present study that hydrolysed the triglycerides in the sample and released free fatty acids. Lipase activity was found to significantly increase with treatment time of helium radio frequency atmospheric pressure glow discharge plasma jet [51]. According to Tolouie et al. [52] time and voltage of plasma treatment are significant factors for lipase inactivation, even though there is no complete inactivation. The authors also observed recovery of lipase activity after plasma treatment of wheat germ.

Effect of cold plasma on microbial load analysis

There was no coliform in the plasma treated coconut water. The aerobic microbial load in TCW before plasma treatment was 150–175 cfu/ml. As shown in the Fig. 4c, with increase in the voltage and time the microbial inactivation was more rapid. Xu et al. [23] reported that the activity on microorganisms continues up to certain period of time after the treatment if the treated sample was held for some time without any processing. 5-log reduction of S. enterica was achieved after 30 s of HVACP treatment of 25-ml orange juice with air and MA65 gas [23]. A sharp increase in membrane permeability of Z. rouxii cells and release of intracellular components observed after cold plasma treatment was attributed to the plasma-induced formation of permeability pores on Z.rouxii cell membrane [53]. The authors suggested cytoplasmic membrane to be the key target for plasma induced inactivation of microorganisms. The short lived reactive species generated in the plasma gas inactivates microbial cells in aqueous environment [54, 55] with ·OH radical being the most potent. Plasma can cause oxidative stress in microbial cells, resulting in damage to DNA, proteins and lipids [56, 57].

Effect of cold plasma on transmittance

As shown in Fig. 4d, transmittance decreased with increasing treatment time and voltage. Sarangapan,et al. [58], and Lacombe, et al. [59] also reported similar results. Denaturation of protein, oxidation of chemical components and chemical reaction by reactive species [60] may have caused the decrease.

Modeling and validation

All the experimental data obtained from FCCD design were statistically analyzed (Design-Expert 7.0 software, Stat-Ease, Inc.) and fitted to the quadratic model equations. R2 (high regression coefficient) values obtained were 0.95, 0.98, 0.99 and 0.97 for DPPH scavenging activity (\({Y}_{1}\)), FFA content (\({Y}_{2}\)), microbial load (\({Y}_{3}\)) and transmittance \(({Y}_{4}\)) of cold plasma treated coconut water, respectively (Table 2). The linear, quadratic and interaction terms were explained by quadratic model equations.

As seen from Table 3, the lack-of fit for four responses studied were non significant which indicated the validation of models. Analyses of variance (ANOVA) for the models were significant (0.0002, < 0.0001, < 0.0001 and < 0.0001). This implied that the models had strongly fitted with the experimental data. Further, the quadratic model showed a good correlation between dependent and independent variables.

Optimization of responses

The optimum conditions of cold plasma treated TCW were predicted on the basis of maximum desirability [31, 37]. The multiple regression equations were obtained for maximum transmittance, maximum DPPH activity, minimum FFA and targeted microbial load (2 log cycle reduction of the acceptable level of 5000 CFU/ml) as stated by FAO. As seen from Table 3, there are three combinations of the independent variables with desirability ranging from 0.892–0.92. All values of independent parameters were found to be within the experimental range, indicating that the range of variables selected was valid. Thus the optimum cold plasma treatment conditions gave the maximum desirability of 0.920.

Sensory evaluation

The shelf life of TCW was enhanced on cold plasma treatment under optimized conditions by 7 to 10 times as compared to sample without treatment, but there was a negative effect on sensory quality. TCW exhibited ‘chemical’ type odour that was also reported for cold plasma treated apple slices [61]. Sample S1 (cold plasma treated TCW) in Table 4 got higher score for aroma being not satisfactory. So to overcome the undesirable odour, treated coconut water using optimized conditions was blended with pasteurized orange juice at 1–4% levels.

Table 4 presents the sensory scores given by the panel judges for blended beverage of TCW and orange juice. As seen from the Table, more number of panellists found sample S2 (blending with 1% orange juice) to be good for aroma, taste and overall acceptability indicating that addition of orange juice could successfully mask the ‘chemical’ flavour of plasma treated TCW. Beverage with 2–4% orange juice had distinct orange favour and was not liked by panellists. Fuzzy logic optimization for sensory attributes was performed to rank the beverage samples on the basis of sensory attributes. The results of fuzzy logic analysis of sensory attributes of blended TCW beverage that was done according to Sakre et al. [37] and Jaya and Das [38] are discussed in the coming sections.

Triplets for sensory quality of blended beverage samples

Triangular membership function distribution which is a set of three numbers was distributed from 0 to 100 of the sensory scale as described by Sakre et al. [37]. Triplets values were assigned each of the sensory attribute evaluated by the sensory panellists to evaluate the numerical position of the quality attributes on the sensory scale. Sensory quality in triplets of the five samples were determined after taking into consideration (1) sensory scores given by judges added up (Table 4); (2) triplets associated with sensory scales; and (3) total number of panel judges (i.e., 27). The triplet numbers for sensory quality attribute of colour of the blended beverage sample S1 were calculated and the triplets value for colour (S1C) was determined as below.

where 0, 0, 9, 15, 3 at the numerator and denominator represent the number of sensory panellists. The triple values in the matrix denote the distribution function of sensory panellist preference on the sensory scale [37]. Similarly, triplets value for S1 sample quality attributes for taste (S1T), aroma (S1A) and overall acceptability (S1OAA) were obtained as follows:

Similarly, triplets for colour, taste, aroma and overall acceptability were estimated for S2, S3, S4 and S5, as given below:

Determination of important quality attributes based on triplet values

The quality attribute of the blended beverage samples that was perceived by panellists to be the most important on the basis of the sensory scores was identified. Colour, taste, aroma and overall acceptability of the blended beverage samples were the quality attributes judged by the panellists (Table 5). The importance that the judges gave to the quality attributes was determined by (1) sensory scores given by judges added up (Table 4); (2) triplets associated with sensory scales; and (3) total number of panel judges (i.e., 27), according to Sakre et al., [37] and Das [31] and Routran [36];. The importance of quality attribute of colour (QC) was determined as described below.

where 0, 0, 3, 15, 9 at the numerator and denominator represent the number of sensory panellists. Similarly, triplets for sensory panellist’s preference for the importance of taste (QT), aroma (QA) and overall acceptability (QOOA) were obtained as below.

Triplets for overall sensory scores of the blended beverage samples

In the next step, the overall sensory scores of the blended beverage samples were determined by multiplying the triplets for the sensory quality values with the triplets for important quality parameters as judged by sensory panellists for each sample. The multiplication of triplets (a, b, c) and (p,q,r) was done by the following method

In the above equation, if a and p value are between 0 and 100, multiplication product value a and p (a × p) will be between 0 and 1,000. The first digit value of the overall sensory score will be between 0 and 40,000. So, it is important to bring the first digit value of the overall sensory score between 0 and 100. In order to obtain this, as per Sakre et al. [37], Eq. (6) values were multiplied by the factor 1/\({Q}_{sum}\), where \({Q}_{sum}\) is the summation of the first digit value of the triplets. ‘Relative weightage of the quality attribute’ was expressed for colour as: \({QC}_{rel}\) = QC/\({Q}_{sum}\), taste: \({QT}_{rel}\) = QT/\({Q}_{sum}\), aroma: rel\({QA}_{rel}\) = QA/\({Q}_{sum}\) and for OAA: = \({QOAA}_{rel}\)QOAA/\({Q}_{sum}\)

From the Eq. (6),

In the next step, the relative weightage value for each quality attribute was determined in the form of triplets. The calculation for determining the triplets for relative weightage value for colour is given below.

For colour relative weightage of triplet (\({QC}_{rel}\)) was

Similarly, for the other quality attributes, relative weightage of triplets were determined to be:

Overall sensory score (SO1) for S1 was calculated by using the triplet multiplication method (Eq. 8), as obtained below.

Similarly for others, the overall sensory scores were calculated

Ranking of blended beverage on sensory fuzzy scale

Standard sensory fuzzy scale has been described by Routay and Mishra [36], Sakre et al. [37]. The standard sensory fuzzy scale was categorised on a 6 point set as Not satisfactory/Not at all necessary, Fair/Somewhat necessary, Satisfactory/Necessary, Good/Important, Very good/Highly important and Excellent/Extremely important (Fig. 2), according to Sakre et al. [37]. Each membership function of sensory fuzzy scale follows the triangular distribution structure where 1 is the maximum membership value [31]. In this step, the overall quality score of the blended beverage samples was matched with the standard fuzzy scale. For that, on the basis of overall sensory scores of the blended beverage samples, the overall quality of the samples was measured. The triplet (a, b, c) for overall quality of the blended beverage samples, was expressed by a triangle ABC, as per Fig. 3. The location of the centroid of the triangle ABC, as depicted by the triplet (a, b, c), was used to rank blended beverage samples [36, 37]. It was observed that ABD and BDC are right-angled triangles, so the area covered by ABC, ABD and BDC triangles will be 0.5(b + c), 0.5b and 0.5c, respectively. Thus, if X is the distance of the centroid of triangle ABC, its value is calculated as

From the above X value (Eq. 12), the ranking of overall quality of the developed blended beverage was in the following order:

Ranking of blended beverage on the basis of quality attributes

In this step the developed blended beverage samples were graded on the basis of quality attributes. Here, the triplets values obtained for importance of quality as per the preference given by the sensory panellists were put into Eq. (11). Accordingly, the relative importance of colour, taste, aroma and overall acceptability,\({X}_{QC}\),\({X}_{QT}\), \({X}_{QA}\) and \({X}_{QOAA}\), of the blended beverage were

From the above values of\({X}_{QC}\),\({X}_{QT}\), \({X}_{QA}\) and\({X}_{QOAA}\), blended beverage were graded on the basis of quality attributes in this order: Overall acceptability > Color = Aroma > taste .

Similarity analysis for blended beverage samples on standard fuzzy scale

Distribution pattern of overall sensory score of samples can be represented by similarity analysis in the form of six sensory scales of standard fuzzy scale. It helped to rank and classify sample attributes according to sensory scores in linguistic form. Membership function F1–F6 value of sensory scale expressed by set of 10 numbers [31, 37, 38] was between 0 and 10; between 10 and 20; between 20 and 30; between 30 and 40; between 40 and 50; between 50 and 60; between 60 and 70; between 70 and 80; between 80 and 90; and between 90 and 100.

Following Fig. 2, the membership functions values F1, F2, F3, F4, F5 and F6 can be expressed as [37]:

Membership function of overall sensory scores on standard fuzzy scale

In this step, by using the standard fuzzy scales (values of F1–F6) membership function value of the overall scores for the blended beverage samples were determined. The sensory scores were represented as triplets in Eq. (11). From Fig. 3, for a given abscissa value “ x”, membership function value \({\mathrm{B}}_{\mathrm{X}}\) can be calculated as

Thus, the membership function values of \({\mathrm{B}}_{\mathrm{X}}\) for blended beverage samples at X equal to 0, 10, 20, 30, 40, 50, 60, 70, 80, 90 and 100 were calculated by using Eq. (15), according to Sakre et al. [37] and Das [31]. The membership function value of overall sensory scores of each developed blended sample on standard fuzzy scale was identified by a set of 10 numbers, where the maximum values of \({B}_{X}\) in the 10 intervals from 0 to 100 is in the mentioned range of X. The output products are presented below (Eq. 16):

where B1, B2, B3, B4 and B5 represents the overall sensory scores distribution pattern of S1, S2, S3, S4 and S5 on the standard fuzzy scale.

Similarity values for blended beverage samples

The membership function (B1, B2, B3, B4, B5) for each of the developed samples S1, S2, S3, S4 and S5 were expressed in Eq. (14). These values were compared with the corresponding membership function value of standard fuzzy scale (F1–F6) from Eq. (14). Similarity value (\({S}_{m}\)) for the samples were calculated as

The calculated similarity values for blended beverages samples are shown in Table 6. The samples were judged by the maximum similarity value. As seen from Table 6, the similarity value and their categories for S1, S2, S3, S4 and S5 were 0.7479 (Satisfactory), 0.8233 (Good), 0.7254 (Satisfactory), 0.7537 (Satisfactory), and 0.8414 (Satisfactory), respectively. Similarity values were used to rank the blended beverages as: S2 (Good) > S5 (Satisfactory) > S4 (Satisfactory) > S1 (Satisfactory) > S3 (Satisfactory). According to fuzzy analysis S2 showed the highest acceptability among these five samples due to its highest similarity value. S2 was a blended beverage of cold plasma treated TCW with 1% orange juice. Fuzzy logic interpretation of sensory data has helped to arrive at a conclusion on the basis of ranking of the blended beverage for its strong attributes.

Conclusion

Desirability approach was followed to optimize process parameters of DBD cold plasma treatment of TCW. The processing parameters of DBD cold plasma were optimized on the basis of DPPH activity, FFA content, microbial load and transmittance. Increase in cold plasma treatment time and voltage reduced antioxidant activity, microbial load and transmittance and increased free fatty acids. Cold plasma treated TCW developed ‘chemical taste’ that reduced its acceptability. TCW treated with the optimized conditions was blended with pasteurized orange juice at different levels (1 to 4%) to mask the ‘chemical taste’. Fuzzy logic was used for evaluating sensory attributes of the blended beverage. Through fuzzy logic, it was found that the sensory panellists judged the sample treated with cold plasma at 18.00 kV voltage for 1.75 min and blended with 1% orange to be more acceptable than the samples with higher concentrations of orange juice. This implied that cold plasma treatment enhances the shelf stability of TCW by reducing microbial load but the disadvantage related to unacceptable sensory attributes can be overcome on adding with 1% orange juice.

References

S. Damar, Unpublished Doctoral thesis, University of Florida, (2006)

M. Das Purkayastha, Unpublished M.Sc thesis, Tezpur University, (2010)

C.F. Campos, P.E. Souza, J.V. Coelho, M.B. Glória, Chemical composition, enzyme activity and effect of enzyme inactivation on flavor quality of green coconut water. J. Food Process. Preserv. 20, 487 (1996)

L.M. Costa, G.A. Maia, J.M. Costa, R.W. Figueiredo, M. Rodrigues, P.H.M. Sousa, A.M. Pinheiro, Qualidade e vida de prateleira da agua de coco obtida pelo processo de enchimento a quente. Rev. Bras. Armaz. 31, 95–102 (2006)

M. Das Purkayastha, D. Kalita, N.K. Mahnot, C.L. Mahanta, M. Mandal, M.K. Chaudhuri, Effect of l-ascorbic acid addition on the quality attributes of micro-filtered coconut water stored at 4 C, Innov. Food Sci. Emerg. Technol. 16:69–79 (2012)

N.K. Mahnot, D. Kalita, C.L. Mahanta, M.K. Chaudhuri, Effect of additives on the quality of TCW processed by nonthermal two stage microfiltration technique. LWT-Food Sci. Technol. 59(2), 1191–1195 (2014)

N.N. Misra, K.M. Keener, P. Bourke, J.P. Mosnier, P.J. Cullen, In-package atmospheric pressure cold plasma treatment of cherry tomatoes. J. Biosci. Bioeng. 118(2), 177–182 (2014)

M. Stoica, P. Alexe, L. Mihalcea, Atmospheric cold plasma as new strategy for foods processing-an overview. Innov. Roman. Food Biotechnol. 1, 15 (2014)

S. Tappi, G. Giorgia, L. Vannini, A. Berardinelli, S. Romani, L. Ragni, P. Rocculi, Cold plasma treatment for fresh-cut melon stabilization. Innov. Food Sci. Emerg. Technol. 33, 225–233 (2016)

S. Pankaj, Z. Wan, K. Keener, Effects of cold plasma on food quality. A review. Foods 7(1), 4 (2018)

Q.Z. Luo, N. D’angelo, R.L. Merlino, Shock formation in a negative ion plasma. Phys. Plasmas 5(8), 2868–2870 (1998)

S. Tappi, A. Berardinelli, L. Ragni, M. Dalla Rosa, A. Guarnieri, P. Rocculi, Atmospheric gas plasma treatment of fresh-cut apples. Innov. Food Sci. Emerg. Technol. 21, 114–122 (2014)

I. Ramazzina, S. Tappi, P. Rocculi, G. Sacchetti, A. Berardinelli, A. Marseglia, F. Rizzi, Effect of cold plasma treatment on the functional properties of fresh-cut apples. J. Agric. Food Chem. 64(42), 8010–8018 (2016)

X. Li, M. Li, N. Ji, P. Jin, J. Zhang, Y. Zheng et al., Cold plasma treatment induces phenolic accumulation and enhances antioxidant activity in fresh-cut pitaya (Hylocereus undatus) fruit. LWT 115, 108447 (2019)

M.J. Rothrock, H. Zhuang, K.C. Lawrence, B.C. Bowker, G.R. Gamble, K.L. Hiett, In-package inactivation of pathogenic and spoilage bacteria associated with poultry using dielectric barrier discharge-cold plasma treatments. Curr. Microbiol. 74(2), 149–158 (2017)

N.M. Coutinho, M.R. Silveira, T.C. Pimentel, M.Q. Freitas, J. Moraes, L.M. Fernandes et al., Chocolate milk drink processed by cold plasma technology: Physical characteristics, thermal behavior and microstructure. LWT 102, 324–329 (2019)

J. Lee, K. Jo, Y. Lim, H.J. Jeon, J.H. Choe, C. Jo, S. Jung, The use of atmospheric pressure plasma as a curing process for canned ground ham. Food Chem. 240, 430–436 (2018)

N. Bahrami, D. Bayliss, G. Chope, S. Penson, T. Perehinec, I.D. Fisk, Cold plasma: a new technology to modify wheat flour functionality. Food Chem. 202, 247–253 (2016)

R. Ma, G. Wang, Y. Tian, K. Wang, J. Zhang, J. Fang, Non-thermal plasma-activated water inactivation of food-borne pathogen on fresh produce. J. Hazard. Mater. 300, 643–651 (2015)

I. Ramazzina, A. Berardinelli, F. Rizzi, S. Tappi, L. Ragni, G. Sacchetti, P. Rocculi, Effect of cold plasma treatment on physico-chemical parameters and antioxidant activity of minimally processed kiwifruit. Postharvest Biol. Technol. 107, 55–65 (2015)

X. Liao, J. Li, A.I. Muhammad, Y. Suo, S. Chen, X. Ye et al., Application of a dielectric barrier discharge atmospheric cold plasma (Dbd-Acp) for Eshcerichia Coli inactivation in apple juice. J. Food Sci. 83(2), 401–408 (2018)

P. Putnik, Z. Kresoja, T. Bosiljkov, A.R. Jambrak, F.J. Barba, J.M. Lorenzo et al., Comparing the effects of thermal and non-thermal technologies on pomegranate juice quality: a review. Food Chem. 279, 150–161 (2019)

L. Xu, A.L. Garner, B. Tao, K.M. Keener, Microbial inactivation and quality changes in orange juice treated by high voltage atmospheric cold plasma. Food Bioprocess Technol. 10(10), 1778–1791 (2017)

O. Rodríguez, W.F. Gomes, S. Rodrigues, F.A. Fernandes, Effect of indirect cold plasma treatment on cashew apple juice (Anacardium occidentale L). LWT 84, 457–463 (2017)

S.K. Pankaj, Z. Wan, W. Colonna, K.M. Keener, Effect of high voltage atmospheric cold plasma on white grape juice quality. J. Sci. Food Agric. 97(12), 4016–4021 (2017)

O.P. Chauhan, B.S. Archana, A. Singh, P.S. Raju, A.S. Bawa, A refreshing beverage from mature coconut water blended with lemon juice. J. Food Sci. Technol. 51(11), 3355–3361 (2014)

J.M. De Carvalho, G.A. Maia, R.W. De Figueiredo, E.S. De Brito, S. Rodrigues, Development of a blended nonalcoholic beverage composed of coconut water and cashew apple juice containing caffeine. J. Food Qual. 30(5), 664–681 (2007 Oct)

G. Sindumathi, and S. Amutha, Development of Spiced TCW Ready to Serve Beverage, Int. J. Sci. Res. 2319–7064 (2013)

H. Stone, J.L. Sidel, Discrimination Testing, Sensory Evaluation Practices, 3rd edn. (Elsevier, London, 2004), p. 177

K.P. Singh, A. Mishra, H.N. Mishra, Fuzzy analysis of sensory attributes of bread prepared from millet-based composite flours. LWT Food Sci. Technol. 48(2), 276–282 (2012)

H. Das, Food Processing Operations Analysis (Asian Books Private Limited, New Delhi, 2005)

B.Y. Imm, J.H. Lee, S.H. Lee, Sensory quality index (SQI) for commercial food products. Food Qual. Pref. 22(8), 748–752 (2011)

C. Debjani, S. Das, H. Das, Aggregation of sensory data using fuzzy logic for sensory quality evaluation of food. J. Food Sci. Technol. 50(6), 1088–1096 (2013)

H.L. Westenberg, S. Jong, D.A. Meel, J.F. Quadt, E. Backer, R.P. Duin, Fuzzy set theory applied to product classification by a sensory panel. J. Sens. Stud. 4(1), 55–72 (1989)

Q. Zhang, J.B. Litchfield, An optimization of intermittent corn drying in a laboratory scale thin layer dryer. Drying Technol. 9(2), 383–395 (1991)

W. Routray, H.N. Mishra, Sensory evaluation of different drinks formulated from dahi (indian yogurt) powder using fuzzy logic. J. Food Process. Preserv. 36(1), 1 (2012)

N. Sakre, A.B. Das, P.P. Srivastav, Fuzzy Logic Approach for Process Optimization of Gluten-Free Pasta. J. Food Process. Preserv. 40(5), 840–849 (2016)

S. Jaya, H. Das, Sensory evaluation of mango drinks using fuzzy logic. J. Sens. Stud. 18(2), 163–176 (2003)

H. Chutia, D. Kalita, C.L. Mahanta, N. Ojah, A.J. Choudhury, Kinetics of inactivation of peroxidase and polyphenol oxidase in TCW by dielectric barrier discharge plasma. LWT Food Sci. Technol. 1(101), 625–629 (2019)

A.M. Fonseca, A. Bizerra, J.S. Souza, F.J. Monte, M.D. Oliveira, M.C. Mattos, G.A. Cordell, R. Braz-Filho, T.L. Lemos, Constituents and antioxidant activity of two varieties of coconut water (Cocos nucifera L.). Rev. Bras. Farm. 19(1B), 193–198 (2009)

S. Sadasivam, A. Manickam, Biochemical methods (New age international (P) Limited, New Delhi., 2008)

J.C. Jackson, A. Gordon, G. Wizzard, K. McCook, R. Rolle, Changes in chemical composition of coconut (Cocos nucifera) water during maturation of the fruit. J. Sci. Food Agric. 84(9), 1049–1052 (2004 Jul)

K. Leiviskä, Introduction to experiment design. University of Oulu, Control Engineering Laboratory. 5 (2013)

S. Şahin, R. Şamlı, Optimization of olive leaf extract obtained by ultrasound-assisted extraction with response surface methodology. Ultrason. Sonochem. 20(1), 595–602 (2013)

J. Sadecka, M. Polovka, E. Kolek, E. Belajova, B. Tobolkova, L. Daško, J.A.N. Durec, Orange juice with pulp: impact of pasteurization and storage on flavour, polyphenols, ascorbic acid and antioxidant activity. J. Food Nutr. Res. 53(4), 371–388 (2014)

F.D. Almeida, R.S. Cavalcante, P.J. Cullen, J.M. Frias, P. Bourke, F.A. Fernandes, S. Rodrigues, Effects of atmospheric cold plasma and ozone on prebiotic orange juice. Innov. Food Sci. Emerg. Technol. 1(32), 127–135 (2015 Dec)

X.V. Yepez, K.M. Keener, High-voltage atmospheric cold plasma (HVACP) hydrogenation of soybean oil without trans-fatty acids. Innov. Food Sci. Emerg. Technol. 1(38), 169–174 (2016 Dec)

U. Santoso, K. Kubo, T. Ota, T. Tadokoro, A. Maekawa, Nutrient composition of kopyor coconuts (Cocos nucifera L.). Food Chem. 57(2), 299–304 (1996)

M.N. Shubhashree, G. Venkateshwarlu, S.H. Doddamani, Therapeutic and nutritional values of Narikelodaka (TCW) – a review. Res. J. Pharm. Phytochem. 6(4), 195–201 (2014 Oct)

Meethaworn K, Siriphanich J (2014) Volatiles and enzymes involved in off-flavor development in trimmed young coconut water during low temperature storage. In XXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014): 1178 (pp. 105–110)

H.P. Li, L.Y. Wang, G. Li, L.H. Jin, P.S. Le, H.X. Zhao et al., Manipulation of lipase activity by the helium radio-frequency, atmospheric-pressure glow discharge plasma jet. Plasma Proc. Polym. 8(3), 224–229 (2011)

H. Tolouie, M.A. Mohammadifar, H. Ghomi, A.S. Yaghoubi, M. Hashemi, The impact of atmospheric cold plasma treatment on inactivation of lipase and lipoxygenase of wheat germs. Innov. Food Sci. Emerg. Technol. 47, 346–352 (2018)

Q. Xiang, X. Liu, J. Li, S. Liu, H. Zhang, Y. Bai, Effects of dielectric barrier discharge plasma on the inactivation of Zygosaccharomyces rouxii and quality of apple juice. Food Chem. 254, 201–207 (2018)

Y. Gorbanev, A. Privat-Maldonado, A. Bogaerts, Analysis of short-lived reactive species in plasma–air–water systems: the dos and the do nots. Anal. Chem. 90, 13151–13158 (2018)

H.A. Aboubakr, U. Gangal, M.M. Youssef, S.M. Goyal, P.J. Bruggeman, Inactivation of virus in solution by cold atmospheric pressure plasma: identification of chemical inactivation pathways. J. Phys. D 49(20), 204001 (2016)

L. Han, S. Patil, D. Boehm, V. Milosavljević, P.J. Cullen, P. Bourke, Mechanisms of inactivation by high-voltage atmospheric cold plasma differ for Escherichia coli and Staphylococcus aureus. Appl. Environ. Microbiol. 82(2), 450–458 (2015)

O. Lunov, V. Zablotskii, O. Churpita, A. Jäger, L. Polívka, L. Syková et al., The interplay between biological and physical scenarios of bacterial death induced by non-thermal plasma. Biomaterials 82, 71–83 (2016)

C. Sarangapani, G. O'Toole, P.J. Cullen, P. Bourke, Atmospheric cold plasma dissipation efficiency of agrochemicals on blueberries. Innov. Food Sci. Emerg. Technol. 1(44), 235–241 (2017)

A. Lacombe, B.A. Niemira, J.B. Gurtler, X. Fan, J. Sites, G. Boyd, H. Chen, Atmospheric cold plasma inactivation of aerobic microorganisms on blueberries and effects on quality attributes. Food Microbiol. 1(46), 479–484 (2015)

D. Bermúdez-Aguirre, E. Wemlinger, P. Pedrow, G. Barbosa-Cánovas, M. Garcia-Perez, Effect of atmospheric pressure cold plasma (APCP) on the inactivation of Escherichia coli in fresh produce. Food Control 34(1), 149–157 (2013)

U. Schnabel, R. Niquet, O. Schlüter, H. Gniffke, J. Ehlbeck, Decontamination and sensory properties of microbiologically contaminated fresh fruits and vegetables by microwave plasma processed air (PPA). J. Food Process. Preserv. 39(6), 653–662 (2015)

Acknowledgements

Authors are grateful to Tezpur University, Assam, India, for facilities and AICTE for GATE Fellowship (Student ID: 1-3139726178) to first author.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chutia, H., Mahanta, C.L., Ojah, N. et al. Fuzzy logic approach for optimization of blended beverage of cold plasma treated TCW and orange juice. Food Measure 14, 1926–1938 (2020). https://doi.org/10.1007/s11694-020-00440-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00440-1