Abstract

The rheology of potato starch paste (PSP) in an ultrasonic field was studied by an RS600 HAAKE rheometer. The effects of ultrasonic time on the rheological model and on shear thinning of PSP were studied. The thixotropy of PSP in the ultrasonic field and the spatial conformation of the PSP molecular chain were also investigated. From experiments under different ultrasonic times, PSP exhibited pseudoplastic fluid characteristics and conformed to the power law τ = k·γm (where k and m are constants). PSP has the characteristics of a Newtonian fluid after ultrasonic action. At the same shear rate, the apparent viscosity of PSP decreased with increasing ultrasonic time. The degree of shear thinning of PSP was greatly reduced, and the thixotropy of PSP was lower after ultrasonic action.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During food processing, it is important to know the type of fluid flow to be expected and to measure or calculate the rheological parameters of the material. These properties are related to controlling and managing the design and implementation of food processing equipment [1], especially the processes of pipeline transportation, mixing, and heat exchange. The material’s textural stability and the process design are affected by the rheological properties of the material. Therefore, studying PSP rheological properties can provide an understanding of food component properties such as composition, internal structure, and molecular morphology, thus furnishing a convenient basis for processing technology, equipment selection, and quality inspection [2].

The rheology of starch is important for its use, many previous experiments have been conducted to study the rheological properties of starches [3,4,5,6,7,8,9,10,11,12]. Islam et al. [13] studied the intrinsic viscosity and critical concentration of sago starch at different temperatures. The results showed that starch exhibited the characteristics of a pseudoplastic fluid regardless of temperature. As the temperature rose, the intrinsic viscosity of the starch increased, but the critical concentration remained unchanged throughout the experimental temperature range. Mechanical and chemical considerations also have a significant effect on starch rheological properties, which reduces their temperature dependence. Yoo et al. [14] studied the rheological properties of rice starch paste at different sucrose concentrations. The static shear properties of a rice starch paste-sucrose mixture fitted the power law and Carson’s flow model. At 25.0 °C, the starch paste-sucrose mixture exhibited shear-thinning flow behavior (n = 0.25–0.44). Sucrose addition reduced the flow pattern index n of the starch paste and decreased the apparent viscosity and yield. Tarrega et al. [15] studied the effect of milk on the rheology of crosslinked waxy corn and tapioca starch. The results showed that all the samples exhibited sheared olefination. Besun et al. [16] studied the rheological properties of starch and bentonite gels. The power law model can be used to fit the experimental viscosity: \(\eta =k \cdot {\gamma ^{n - 1}}\). The value of n is less than 0.5, and the magnitude of k is proportional to the degree of entanglement and compression of the structure. The trend of the parameters k and n was consistent with the thixotropic index and the shear modulus. Hu et al. [17] investigated the rheological properties of PSP at different concentrations by means of a rheometer. Experimental results showed that starch concentration had a strong influence on viscosity properties. As the starch concentration increased, the maximum hot and cold viscosities both increased, gelation increased, and both hot and cold paste viscosity stabilities remained high. At various concentrations, all starches exhibited pseudoplastic fluid characteristics. Andrea et al. [18] studied the effects of lactic acid and ultraviolet radiation on the rheological properties of cassava and cornstarch. Jee-Yup et al. [19] studied the effect of alkali and borax on pea starch. The experimental results showed that the presence of alkali and borax greatly changed the viscosity peak and the flowability of the starch paste, increased the critical concentration peak and the viscosity of cold starch paste, and weakened starch syneresis.

However, changes in the rheological properties of a food starch paste system in an ultrasound field have not been reported in the literature. Ultrasound consists of sound waves at a frequency that exceeds the human audible threshold. Ultrasound treatment (UT) is a physical method that has shown many advantages over other methods in terms of higher selectivity and quality, reduced use of chemicals and processing time, and environmental friendliness [20]. Ultrasound can affect starch dispersion and damage starch granules [21]. The effects of UT result from acoustic cavitation, which is the fast generation, growth, and finally implosive collapse of bubbles in liquid, generating heat (up to 5000 K) and pressure (up to 20 MPa) in a very short time [22]. During UT, ultrasound energy can be transferred to starch granules through cavitation, which refers to the formation, growth, and rapid collapse of microbubbles [23]. As a result of this treatment, the polymer chains near the collapsing microbubbles are caught in a high-gradient shear field, which leads to breakage of macromolecular C–C bonds and formation of long-chain radicals [24]. High-power ultrasound can reduce the molecular weight of amylose and amylopectin due to breakage of C–C bonds, leading to a decrease in viscosity [25,26,27]. Ultrasound treatment facilitates the disintegration of starch granules and the formation of a homogeneous starch solution [28]. High-frequency vibration-treated maize starch dispersions have improved mechanical properties and lower water–vapor permeability [21].

In this study, the research team investigated the change laws of potato starch rheology in foodstuffs in an ultrasonic field. When ultrasound technology is used in food processing, the rheological properties of food components are affected. For example, ultrasound-assisted filtration reduces the viscosity of liquids and accelerates filtration. Ultrasound-assisted extraction facilitates further refinement of pulp, reduces juice viscosity, enables juice to be easily clarified and filtered, increases juice yield and quality, and reduces mechanical equipment processing load. Ultrasound in the food system can be affected mainly by thermal, mechanical, and cavitation effects. These effects in turn influence the rheological properties of the food components. This study examined the changes in PSP rheological properties in an ultrasonic field, analyzed the structural changes of potato starch in an ultrasonic field, and explored the intrinsic relationship between the two, thus providing fundamental data and a theoretical basis for industrial application of new ultrasonic technology.

In this research, an RS600 HAAKE rheometer was used to study changes in PSP rheological properties in an ultrasonic field. The rheological model of PSP in different ultrasonic fields was studied under different ultrasonic times, intensities, and concentrations. Changes in the apparent viscosity, shear, and thixotropy of PSP under these three factors were also studied.

Materials and methods

Materials

The potato starch used in this experiment was produced by National Starch and Chemical Company, USA (with an excellent grade, containing 14.4% moisture and having 99.5% purity). Congo red was manufactured by Sigma Company, USA. Sodium hydroxide was manufactured by the Guangzhou Chemical Reagent Factory, Guangzhou, China. All these chemicals were of analytical grade.

The electronic balance used in this experiment was produced by the Sartorius Company, Germany. The UP400S ultrasonic equipment was produced by Dr. Hielscher in Germany. The RS600 HAAKE rheometer was manufactured by HAAKE Rheostress, Germany. The HH-2 superheated water bath was manufactured by Jintan Fuhua Electric Company, Jiangsu, China. The DZF-6050X vacuum oven was produced by Shanghai Boxun Industrial Company, Shanghai, China.

Gelatinization of potato starch

Using accurately weighed potato starch samples of 2.000 g, 4.000 g, 8.000 g, 16.000 g, 24.000 g, and 32.000 g, distilled water was used to prepare 400 mL of solution with mass concentrations of 0.5%, 1.0%, 2.0%, 4.0%, 6.0%, and 8.0%, respectively. The starch was stirred to achieve full dispersion and then heated to gelatinization in a boiling water bath for 30.0 min. Then the starch was cooled to room temperature.

Determination of PSP rheological properties

The viscosity and elasticity of the fluid were measured by the rheometer. Viscosity varied with shear rate, temperature and pressure, yield stress, and thixotropy, which were all viscosity measurements. PSP rheological properties were measured by an RS600 rheometer. The apparent viscosity η, shear stress τ, and other parameters were recorded as the shear rate changed. In this way, the rheological model was derived. The hysteresis loop area was calculated by the rheological instrument software. The probe model was PP35Ti, and the plate diameter was 27.83 mm. The sample was placed between the plates, and the gap was set to 1 mm. Excess sample was removed, and a layer of silicone oil was applied to the exposed sample to prevent moisture evaporation.

Shear stress determination in PSP

PSP was kept at 25 °C for 60 s at a shear rate of 0.001 s−1. The apparent viscosity and shear stress were measured as the shear rate increased continuously from 1.00 to 1000.00 s−1. The measurement time was 60 s.

Determination of PSP thixotropy

PSP was kept at 25 °C for 60 s at a shear rate of 0.001 s−1. The shear stress was measured as the shear rate increased continuously from 1.00 to 1000.00 s−1. The measurement time was 60 s. The maximum shear rate was maintained for 30 s and then reduced to 1.00 s−1 in 60 s.

Congo red helix-strand structure transition analysis of single starch structure of PSP

An accurately weighed sample of Congo red (0.0862 g) was fully dissolved in 100 mL distilled water. A 1.5 mL of the Congo red solution and 0.5 mL of distilled water were measured, with distilled water as a blank, in the scan test wavelength range of 400–550 nm. The Congo red solution absorption spectrum, λmax was then determined. Distilled water (0.5 mL) was the replaced an equal volume of PSP solution at a concentration of 0.5%, using the same method to obtain the λmax of Congo red-composite potato starch.

Analysis of advanced PSP structure

NaOH concentrations of 0.10 mol/L, 0.20 mol/L, 0.30 mol/L, 0.40 mol/L, 0.50 mol/L, 0.60 mol/L, 0.70 mol/L, 0.80 mol/L, and 0.90 mol/L were made and Congo red was dissolved in each to give a final concentration of 0.38 µmol/L Congo red-NaOH solution. PSP was dissolved in the above NaOH solution to give a final concentration of 10.0 g/L of potato starch-NaOH solution. Then 0.5 mL potato starch-NaOH solution was mixed with different concentrations of Congo-NaOH solution, with the same concentration of NaOH solution for reference, in the 400–550 nm wavelength range to obtain the λmax of the Congo red-potato starch system at different NaOH solution concentrations.

Results and discussion

Effect of ultrasonic time on PSP rheology

Characteristic curves for different fluids have different shapes due to the relationship between shear stress and shear rate difference. Samples with a concentration of 2.0% PSP were placed in an ultrasonic field with an ultrasonic intensity of 75 W/cm2, 150 W/cm2, 225 W/cm2, or 300 W/cm2. Figure 1 shows their shear stress and the shear rate relationship at different ultrasonic times at 25 °C.

According to the relationship between shear stress and shear rate, fluids can be divided into Newtonian and non-Newtonian fluids. A non-Newtonian fluid is characterized by a shear stress that is not proportional to the shear rate. As shown in Fig. 1, the rheological curves of PSP still passed through the origin under the action of the ultrasonic field, but the shear stress curves were convex to varying degrees. These curves can therefore be judged to belong to non-Newtonian fluids [29]. The behavior of PSP in the ultrasonic field can be described by the power law. The shear stress increased with increasing shear rate and had the characteristics of a pseudoplastic fluid. The shear stress decreased with longer time in the ultrasonic field when the shear rate was kept constant. For example, PSP shear stresses were 18.82 Pa, 12.56 Pa, 8.86 Pa, 6.22 Pa, 4.89 Pa, and 2.93 Pa respectively when the ultrasonic sound intensity was 300 W/cm2 and γ = 1000 s−1. The shear stress of the original starch paste was 24.21 Pa, and the times spent in the ultrasonic field were 0.5 min, 1.0 min, 5.0 min, 10.0 min, 30.0 min, and 60.0 min respectively.

According to the shape of the rheological curve, the law of variation of the PSP rheological curve in an ultrasonic field with different parameters can be described by the following power law:

where τ is the shear stress, Pa, and γ is the shear rate, r/min. m is the flow characteristic index, and k is the consistency coefficient, Pa/min. Table 1 shows the k and m values and the correlation coefficients R2 obtained for all samples by univariate nonlinear regression.

Table 1 shows R2 between 0.9453 and 0.9922 when the rheological curve of PSP in the ultrasonic field is described by the power law. This indicates that the power law achieved an accurate fit to PSP rheological properties in the ultrasonic field. Table 1 also shows that the consistency coefficient k decreased and the flow index m increased at longer times in the ultrasonic field. The resulting k and m values for all the samples in Table 1 were plotted (Fig. 2) to obtain the power law consistency coefficient and the flow characteristic index of PSP under the four ultrasonic intensities.

These experimental results show that the effects of an ultrasonic field on PSP rheological properties are positively correlated. The mechanical and cavitation action produced by the ultrasonic field results in high-frequency shear vibration and jet force fields, which fracture part of the starch molecular chain, weakening the interaction between the starch molecules, increasing the free volume of sol, and enhancing diffusion and movement of the macromolecular segments, which is favorable to dissolution of macromolecular chains. These fields also weaken the interaction between molecular chains, strengthen the internal motion of the starch paste system, and enhance interaction between starch and water molecules, whereas larger clusters of starch molecules are destroyed by ultrasound. The intensity of mechanical action and the cavitation produced by the ultrasonic field have a positive correlation with ultrasonic time. The longer the ultrasonic time, the greater is the effect of cavitation on potato starch and the more obvious the effect of stirring and cutting. The reason for this is that as the ultrasonic time becomes longer, energy accumulates. Therefore, the effect of ultrasonic time on the rheological properties of starch paste is positive.

According to rheological theory, the magnitude of the index m indicates the degree of deviation of a fluid from a Newtonian fluid. When m = 1, the fluid is an ideal Newtonian fluid, and the consistency coefficient k is equivalent to the viscosity of a Newtonian fluid. When m > 1, the fluid is denser than a Newtonian fluid and is a plasticized fluid. When m < 1, the fluid is thinner than a Newtonian fluid and is a pseudoplastic fluid [30, 31]. All the samples in Fig. 2 have m less than or equal to 1, indicating that the starch paste is still a pseudoplastic fluid after application of the ultrasonic field. However, as the ultrasonic time becomes longer, the flow characteristic index m increases and tends to 1. At ultrasonic sound intensities of 150 W/cm2, 225 W/cm2, and 300 W/cm2 for 30.0 min, the PSP viscosity coefficient is very small, and the flow characteristic index m = 1.000. With an ultrasound sound intensity of 75 W/cm2 and ultrasound for 60.0 min, the PSP flow characteristic index m = 1.000. This indicates that the mechanical and cavitation effects of the ultrasonic field can make the PSP tend to become a Newtonian rather than a pseudoplastic fluid. The PSP had good flowability after exposure to the ultrasonic field.

Effect of ultrasonic time on PSP shear thinning

Shear thinning is a peculiar phenomenon of a pseudoplastic fluid in which the apparent viscosity of the fluid decreases with increasing shear rate.

Figure 3 shows the apparent viscosity and shear rate of PSP and their relationship with ultrasound intensity. The intensities used were 75 W/cm2, 150 W/cm2, 225 W/cm2, and 300 W/cm2, and all experiments took place at 25 °C.

Figure 3 shows that PSP apparent viscosity decreases with increasing shear rate and that shear-thinning behavior increases at longer ultrasound times. The reason for this is that the molecules tangle with each other when the macromolecular fluid is at rest; the tangles are unwound when the molecules are subjected to shear forces. The molecules or particles are arranged in a line along the flow direction, and the shear stress between the flow layers is reduced, so that the apparent viscosity decreases. An increase in ultrasonic time means that energy accumulates. As the input acoustic energy increases, some starch molecular chains break [9], and the interaction between starch molecules is weakened. This increases the free volume of sol, increases diffusion and movement of macromolecular chains, favors entanglement of macromolecular chains in solution, and weakens the interaction between molecular chains. The apparent viscosity decreased at a faster rate of change than the ultrasonic time. Therefore, the shear-thinning phenomenon increases with ultrasonic time.

Changes in PSP thixotropy in an ultrasonic field

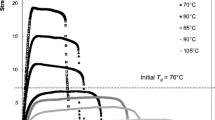

The shear stress of PSP increases with increasing shear rate. Figure 4 shows PSP thixotropy at a concentration of 6.0% at 25 °C.

It is clear from Fig. 4 that when the shear rate reached a predetermined maximum (γmax = 1000 s−1) and then gradually decreased to its starting point, hysteresis occurred between the upstream and downstream shear-stress curves, resulting in a hysteresis loop. Figure 4 shows PSP thixotropy before and after application of the ultrasonic field [32]. The change occurred because the structure of the PSP system was destroyed by external forces (shearing, as measured by the rheometer); the structure was automatically restored after standing. After the structure had been destroyed, the particles needed some period of time to move to an appropriate geometric position to form a new structure. In this way, in the process of increasing the shear rate, the speed of structural recovery always lags behind the speed of disassembly, and therefore PSP has thixotropic properties. From the size of the hysteresis loop, the thixotropy of PSP at a concentration of 6.0% decreases with increasing ultrasound time at 25 °C. When PSP was sonicated for 30.0 min, the shear stress of the upstream and downstream curve hysteresis loop was very small. The shear stresses of the upward and downward curves substantially coincided when the PSP was sonicated for 60.0 min.

Using an RS600 HAAKE rheometer system software to calculate the thixotropic hysteresis loop areas for PSP treated for different ultrasonic times, the changes in PSP thixotropy at different concentrations were described and are shown in Fig. 5.

As shown in Fig. 5b, c, the thixotropic hysteresis loop area of the original PSP at 4.0% concentration was 1.155 × 104 Pa s−1, and the thixotropic hysteresis loop area decreased as the ultrasonic time became longer. After 30.0 min of ultrasonic time, the thixotropic ring area was 985 Pa s−1, and after 60.0 min ultrasound time, it was 506 Pa s−1. The original PSP at 6.0% concentration had a thixotropic hysteresis loop area of 2.461 × 105 Pa s−1. After 1.0 min of ultrasound time, the area of the thixotropic hysteresis loop was 5.479 × 104 Pa s−1, but after 60.0 min of ultrasound time, the loop area was 2.602 × 103 Pa s−1. Therefore, the thixotropic ring area of PSP was significantly reduced by the action of the ultrasound field.

PSP concentrations vary, and in the ultrasound field, the extent of their thixotropic decline also varies. Concentrations of 2.0% and 8.0% PSP and their thixotropic hysteresis loop areas as a function of sonication time are shown in Fig. 5a, d. The thixotropic hysteresis loop areas of the original PSP at concentrations of 2.0% and 8.0% were 5355 Pa s−1 and 3.693 × 105 Pa s−1, respectively. With longer ultrasonic time, the thixotropic ring area continued to decrease. When the ultrasound time was 60.0 min, the thixotropic hysteresis loop areas were 494.1 Pa s−1 and 1.078 × 104 Pa s−1, respectively. Concentrations of 0.5% and 1% PSP were not studied because these concentrations were so low that the rheometer could not detect changes in thixotropy.

Changes in the spatial conformation of potato starch molecular chains in the ultrasound field

Experiments were performed to verify the spatial conformation changes of potato starch molecular chains in the ultrasound field, with the intention of researching the root cause of the decrease in PSP viscosity. According to the theory of transition analysis of the Congo red helix-coil structure established by Ogawa et al., Congo red can form stable complexes with dextran that have a helical structure [33] (mainly single-helix structures). The maximum absorption wavelength (λmax) of the Congo red solution moves towards higher values when each Congo red molecule binds to six dextrans in the glucan chain. Therefore, 0.5% concentration PSP was selected to study spatial conformation changes in potato starch molecular chains and to deduce whether potato starch has a single-helix structure. Assuming that the potato starch molecular chain is sufficiently dissolved in the solution, the maximum absorption wavelengths (λmax) of Congo red and starch-Congo red complex were obtained and compared (Fig. 6). The maximum absorption wavelength of Congo red was 491 nm, and that of the starch-Congo red complex was 508 nm. The maximum absorption wavelength of the starch-Congo red complex moved towards higher values. From this point, it could be inferred that PSP was present in the solution, at least in part as a single-helix structure.

According to the relevant theory of polysaccharide solutions, polysaccharides are destroyed under certain alkali concentrations, resulting in the disintegration of their advanced spiral structure. To maintain its high-level spiral hydrogen bond structure, the polysaccharide molecule then forms a single-helix structure. Therefore, sodium hydroxide treatment is a common method for polysaccharide conformation analysis and for inducing conformational transformation [34]. To deduce the change in the advanced spiral structure of PSP in sodium hydroxide solution, sodium hydroxide treatment and Congo red helix coil structure transition analysis were combined. First, the change in the maximum light wavelength absorbed by PSP at different sodium hydroxide solution concentrations was determined. This suggested that conformational changes were occurring in the PSP. The results are shown in Fig. 7.

Congo red is a dye that can form a complex with multi-stranded conical polysaccharides. The maximum absorption wavelength of the complex is shifted relative to Congo red. As shown in Fig. 7, with increasing sodium hydroxide concentration, the maximum absorption wavelength of the Congo red complex decreased linearly, and the maximum absorption wavelength of the Congo red-starch complex decreased gradually, but differently from the Congo red complex. According to experimental results, the complex formed by starch and Congo red has the following λmax characteristic change in the range of 0.0–0.9 mol/L NaOH solution. The redshift of the maximum absorption wavelength of the Congo red complex indicates that PSP undergoes a conformational transition under alkaline conditions. Under conditions of strong alkali disintegration as a single strand of a random group, starch cannot form a complex with Congo red, and λmax drops sharply to the same value as pure Congo red.

According to these studies, not only does PSP have a single-helix structure, but it also exhibits some advanced spiral structures. These advanced spiral structures are formed by many single-helix structures that are stabilized by hydrogen bonds in the molecule. The solution viscosity is reduced after the advanced structures are destroyed.

Generally, intermolecular hydrogen bonds are destroyed without causing alkali degradation of polysaccharide chains in NaOH solutions with concentrations of 0.1–0.4 mol/L. Therefore, in this study, 0.5% PSP and 0.2 mol/L NaOH treatment were selected to examine the variation of potato starch behavior in an ultrasonic field by Congo red helix-to-linear structure transition analysis. The results are shown in Fig. 8.

From Fig. 8, the maximum absorption wavelength of the Congo red complex decreased as time in the ultrasonic field increases. PSP underwent a conformational change in the ultrasonic field and existed only in certain advanced helical structures. Macromolecules are present in solution in three conformations: triple-helix structures, single-helix structures, and random coil structures [35]. These various conformations are transformed from one to another because of differences in the environment, so that a polymer solution may contain a variety of conformational morphologies coexisting in a mixed system. The solution viscosity with different polymer conformations is different, and viscosity often increases when the polymer is constrained by a random coil to a regular helical conformation or by transformation of a single-stranded spiral structure into a triple-stranded spiral structure [36]. In the ultrasonic field, disintegration of the PSP spiral structure reduces solution viscosity. The sound intensity of the input was very low in this study, and the PSP was not degraded. Therefore, it is proposed that the decrease in PSP viscosity was caused by changes in conformation.

Conclusions

Shear stress increases with increasing shear rate and makes a starch solution exhibit the characteristics of a pseudoplastic fluid. Shear stress decreases with increasing ultrasonic time when the shear rate is kept constant. At the same shear rate, the apparent PSP viscosity decreased with increasing ultrasonic time. The effects of ultrasonic time on PSP rheological properties were positively correlated, indicating that ultrasonic sound intensity and ultrasonic time have some equivalent effects. With increasing PSP concentration, the viscosity coefficient k of PSP increased, but the increase in k was slowed down as ultrasonic time was increased. The shear-thinning behavior of PSP increased with increasing ultrasonic time, and the degree of shear thinning increased with increasing potato starch molecular weight. PSP remained thixotropic in ultrasound fields. As the ultrasonic time became longer, the area of the thixotropic hysteresis loop decreased, and the degree of thixotropy of PSP was reduced. Moreover, PSP thixotropy in an ultrasonic field was related to its concentration. PSP underwent conformational changes in the ultrasound field, but only part of the higher-order helical structure was destroyed. Macromolecules converted each other into various conformations in solution.

References

S.Y. Chun, B. Yoo, Steady and dynamic shear rheological properties of sweet potato flour dispersions. Eur. Food Res. Technol. 223, 313–319 (2006)

C.S. Raina, S. Singh, A.S. Bawa, et al, Rheological properties of chemically modified rice starch model solu. J. Food Process Eng. 29, 134–148 (2006)

G. Zurima, P.B. Elevina, Effect of acetylation on some properties of rice starch. Starch. 54, 90–94 (2002)

B.A. David, G.C. Elodia, C.H. Eduardo et al., Chemical modification of jack bean (Canavalia ensiformis). Starch. 54, 540–546 (2002)

J.L. Willett, I.K. Jasbern, C.L. Swanson, Rheology of thermo-plastic starch: effects of temperature, moisture content, and additives on melt viscosity. Polym. Eng. Sci. 35, 202–210 (1995)

A. Walter, P. IIansGerhard, R. Stuttnart, Rheological characterization of theimplastic starch materials. Starch-Starke. 50, 77–83 (1998)

R.C. Eerlingen, H. Jacobs, K. Block, et al, Effects of hydrothermal treatments on the rheological properties of potato starch. Carbohydr. Res. 297, 347–356 (1997)

R. Hoover, T. Vasanthan, The flow properties of native, heat-moisture treated, and annealed starches from wheat, oat, potato and lentil. Food Biochem. 18, 67–82 (1994)

L. Chen, Y.S. Pang, X.X. Li et al., Effect of ball milling on the crystalline structure and paste rheological properties of mung bean starch. Food Sci. 26, 126–130 (2005)

C.S. Raina, S. Singh, A.S. Bawa et al., Rheological properties of chemically modified rice starch model solutions. J. Food Process Eng. 29, 134–148 (2006)

K. Morikawa, K. Nishinari, Effects of granule size and size distribution on rheological behavior of chemically modified potato starch. J. Food Sci. 67, 1388–1392 (2002)

E. Merica, M. Lungu, Natural polymers as rheological additives. Cellul. Chem. Technol. 37, 371–383 (2003)

M.N. Islam, M.D. Abdul. M. AzemiBin et al., Effect of temperature and starch concentration on the intrinsic viscosity and critical concentration of Sago starch. Starch. 53, 90–94 (2001)

D. Yoo, B.T. Yoo, Rheology of rice starch-sucrose composites. Starch-Starke. 57, 254–261 (2005)

A. Tarrega, E. Costell, M.A. Rao, Vane yield stress of native and cross-linked starch dispersions in skimmed milk: effect of starch concentration and lambda-carrageenan addition. Food Sci. Technol. Int. 12, 253–260 (2006)

N. Besun, B. Ozguclu, S. Peker, Shear-dependent rheological properties of starch/bentonite composite gels. Colloid Polym. Sci. 275, 567–579 (1997)

F. Hu, L. Chen, L. Li et al., Study on the rheological characteristics of micronized potato starch (a). J. Chin. Cereals Oils Assoc. 18, 61–63 (2003)

C. Andrea, Bertolini, rheological properties of acidified and UV-irradiated starch. Starch. 52, 340–344 (2000)

H. Jee-yup, T.T. Robert, Characterization of pea starches in the presence of alkali and borax. Starch. 55, 457–463 (2003)

A.M. Amini, S.M.A. Razavi, S.A. Mortazavi, Morphological, physicochemical, and viscoelastic properties of sonicated corn starch. Carbohydr. Polym. 122, 282–292 (2015)

W. Cheng, J. Chen, D. Liu, X. Ye, F. Ke, Impact of ultrasonic treatment on properties of starch film-forming dispersion and the resulting films. Carbohydr. Polym. 81, 707–711 (2010)

S. Mallakpour, L. Khodadadzadeh, Ultrasonic-assisted fabrication of starch/MWCNT glucose nanocomposites for drug delivery. Ultrason. Sonochem. 40, 402–409 (2018)

H.Y. Kim, J.A. Han, D.K. Kweon, J.D. Park et al., Effect of ultrasonic treatments on nanoparticle preparation of acid-hydrolyzed waxy maize starch. Carbohydr. Polym. 93, 582–588 (2013)

S. Manchun, J. Nunthanid, S. Limmatvapirat, P. Sriamornsak, Effect of ultrasonic treatment on physical properties of tapioca starch. Adv. Mater. Res. 506, 294–297 (2012)

G.L. Peres, D.C. Leite, N. Pesce, Ultrasound effect on molecular weight reduction of amylopectin. 67, 407–414 (2015)

S.S. Wong, S. Kasapis, D. Huang, Molecular weight and crystallinity alteration of cellulose via prolonged ultrasound fragmentation. Food Hydrocolloids. 26, 365–369 (2012)

Y. Iida, T. Tuziuti, K. Yasui, A. Towata, T. Kozuka, Control of viscosity in starch and polysaccharide solutions with ultrasound after gelatinization. Innov. Food Sci. Emerg. Technol. 9, 140–146 (2008)

A.R. Jambrak, Z. Herceg, D. Šubarić, J. Babić, M. Brnčić et al., Ultrasound effect on physical properties of corn starch. Carbohydr. Polym. 79, 91–100 (2010)

K.F. Chen, Food Rheology and Measurement (Light Industry Press, Beijing, 1989)

L.T. Li, F. Physics, Beijing: China Agricultural Press. (2001)

Y.F. Li, Y.G. Yin, W.H. Jin, Food Properties, Beijing: China Light Industry Press. (2005)

Y.Z. Xu, P.S. Rheology, Chengdu: Sichuan Education Publishing House. (1988)

Z.M. Wang, Preparation of anticoagulant microcrystalline cellulose sulphate and its structure-activity relationship, Guangzhou: South China University of Technology (PhD thesis). (2003)

S. Alban, J. Kraus, G. Franz, Synthesis of laminarin sulfates with anticoagulant activity. Drug Res. 42, 1005–1008 (1992)

M. Wang, X.L. Ding, Some properties of modified yeast glucan-CMG and its conformational behavior in solution. Chin. J. Biochem. Mol. Biol. 14, 636–640 (1998)

Z.Y. Liang, Y.S.C.Y. Zhang, Miao et al., Studies on the conformational behavior in the glycosaminoglycans CF2a solution. Biochem. Biophys. 26, 411–415 (1994)

Acknowledgements

This study was supported by Grants from the National Natural Science Foundation (Nos. 20864001 and 31160326), a Grant from the Key Project of the Guangdong Natural Science Foundation (No. 04105934), and the Collaborative Innovation Center for Guangxi Sugar Industry, Guangxi, Nanning 530004, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, YF., Li, JB., Zhang, ZY. et al. Rheological law of change and conformation of potato starch paste in an ultrasound field. Food Measure 13, 1695–1704 (2019). https://doi.org/10.1007/s11694-019-00086-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00086-8