Abstract

Barley starch was modified by cross-linking, oxidation and succinylation. Oxidized and succinylated starches were further cross-linked to achieve dual modified starches. Native and modified barley starches were investigated for physicochemical and functional properties. Results revealed that succinylated barley starch showed higher swelling power, solubility, water retention, viscosity and lower tendency to form gels. Higher paste clarity was observed for oxidized barley, oxidized-crosslinked and succinylated-crosslinked barley starches upon storage of 168 h. Delayed retrogradation was observed in case of succinylated, oxidized-crosslinked and succinylated-crosslinked barley starches. Cross-linked starches (single and dual modified) were observed to have reduced swelling power, solubility and water retention. Cold paste viscosity was drastically reduced in case of cross-linked starch. Modifications were further confirmed by crystalline to amorphous phase ratio which was 2.018 for native barley starch determining highly ordered structure as compared to other modified forms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch granules are composed of alpha-glucan chains mainly amylose and amylopectin representing approximately 98–99% of the dry weight. The ratio of amylose and amylopectin varies with the botanical origin of starch [1]. Barley (Hordeum vulgare) is one of the ancient cereal crops. It is the most diverse crop in nature with respect to its growth. About 65–68% of starch is present in barley grains [2]. Normal barley starch may have (20–30%) amylose [3] and (70–80%) amylopectin. Barley endosperm contains two types of starch granules, large lenticular shaped A-granules and small spherical shaped B-granules [4]. Barley cereal is a rich source of dietary fibers (both soluble and insoluble), vitamin E, vitamin B-complex, minerals and phenolic compounds [5]. It is mainly used in animal feed, malt, vinegar and for beer production.

Starch plays a pivotal role in texture, viscosity, gel formation, adhesion, binding, moisture retention, film formation and in homogeneity of food products. Use of starch is common in soups, confectionery, dairy, bakery items, sauces, dips, gravies, snacks, batters, coatings and meat products [6]. However, native starches have some limitations for industrial uses. Native starches easily undergo retrogradation after the cooking process and gelling paste undergoes syneresis which subsequently affects product appearance. Modification of starch is carried out to enhance its use with respect to industrial applications. Modification of starch retards retrogradation, gel formation, and syneresis. Modified starches exhibit improved clarity. Also, depending on type of physical modification, modified starches could also demonstrate shear and pH resistance [7]. The modifications of starches are usually carried out physically, chemically, enzymically and genetically [7,8,9]. Etherification, esterification, oxidation, cross-linking are some methods employed to modify starches chemically. Oxidized starch offers unique functional properties such as low viscosity, high stability, better clarity, film forming, and binding properties. Oxidized starch can be used as a coating and sealing agent in confectionary, as an emulsifier, as a dough conditioner for bread, and as a binding agent in batter applications [10]. Starch succinates or succinylated starches offer a number of desirable properties like high viscosity, better thickener, low gelatinization temperature and good film forming properties. These succinates are used as binders and thickening agents in food industries [11]. As far as, cross-linking is concerned it does not substitute starch molecules but rather stabilizes and strengthens starch granule. The strengthening of starch chain linkages through crosslinking results in lower probability of polymer to break down under high temperature, low acidity and high shear processing conditions [12]. These modifications are also performed in different combinations in order to achieve desirable results as per product specifications.

The aim of the present study was to chemically modify starches isolated from Pakistani barley grains. To this date, not a single study is reported on isolation and chemical modification of Pakistani barley starch. Single chemical modifications performed on barley starch were cross-linking, oxidation and succinylation. The oxidized and succinylated starches were then further cross-linked to prepare dual modified barley starches. These modified starches were then compared in terms of their morphological, thermal, rheological, functional and textural characteristics.

Materials and methods

Barley grains were purchased from local market, fumigated and stored in paper bags at room temperature (± 25 °C). Analytical grade reagents were procured from Merck (Darmstadt, Germany).

Isolation of starch

Barley starch was isolated by the method of Yangsheng and Seib [13] with some modifications. Five hundred grams of barley grains were slightly ground to rupture kernels. The ruptured kernels were steeped in 1000 mL of water containing 0.2% (w/v) sodium metabisulphite and 0.5% (w/v) lactic acid overnight at room temperature. The steeping water was decanted and barley kernels were washed extensively with water in order to remove excess chemicals. The kernels were ground with ample amount of water in Braun Multiquick 3 kitchen machine K650 (Braun GmbH, Frankfurter Straβe 145, 61476 Kronberg/Germany) and screened through nylon bolting cloth. The mixture was re-ground in a blender with water and screened again. This step was repeated several times until no more starch could be released. The obtained starch slurry was centrifuged at 1200×g for 5 min. The liquid was decanted carefully and the brown tailing pigment on top was removed. The crude starch was suspended in 0.15% (w/v) NaOH solution and centrifuged again at 1200×g for 5 min. This step was repeated several times until no brown tailings were observed after centrifugation. The obtained starch was washed with water in order to remove excess alkali and was finally screened through 275 mesh sieve. 1 M HCl was added to neutralize starch slurry followed by washing and centrifugation for removal of supernatant. Starch palate obtained was forced air dried in an oven at 40 °C. Dried starch was finely grounded to powder form. The AACC [14] methods were used to determine protein (method 46–13), ash (method 8–01), fat (method 30–25), and crude fiber (method 32–10) in isolated starch. Crude fiber was absent in barley starch. Whereas, protein (nitrogen content × 6.25), fat and ash content was found to be 0.4%, 0.11%, and 0.6%, respectively. The total amylose content was determined using the method of Landers et al. [15] and was found to be 25.60% in native barley starch.

Chemical modifications of barley starch

Single chemical modification

Cross-linking

Barley starch was cross-linked using the method of Woo and Seib [16] with some adjustments. Barley starch 100 g, 10 g Na2SO4, 4 g (STMP and STPP) in the ratio of 99:1 were mixed in 140 mL of distilled water. Fifty millilitres of 1 M NaOH was carefully added to adjust the pH to 11. The reaction was allowed to proceed for 3 h at 45 °C under constant stirring. One molar HCl was added to the starch slurry to bring the pH to 6.5 followed by centrifugation at 770×g for 5 min. The starch was washed several times with distilled water and was then dried in a forced air oven at 45 °C. Dried starch was then ground further into a fine powder.

Oxidation

For the preparation of oxidized barley starches, method of Forssell et al. [17] was used with slight modifications. A 100 g of barley starch was dissolved in 200 mL of distilled water. NaOH (2 M) was used to adjust the pH of the starch slurry to 9.5. After the adjustment of pH, 10 g NaOCl was added drop by drop to the slurry with constant stirring while maintaining pH between 9.0 and 9.5. Sodium hypochlorite (NaOCl) was then allowed to react with starch for 10 min. One molar H2SO4 solution was used to neutralize the pH of the slurry. Starch was then allowed to settle down. The sedimented starch was then washed at least four times with distilled water followed by drying at 45 °C in a forced air oven. After drying, starch was ground to fine powder.

Succinylation

Succinylation was performed using the method of Jyothi et al. [11]. A 100 g of barley starch was suspended in water to make a 40% w/v solution. The slurry was continuously stirred to make uniform slurry. NaOH (3%, w/v) was added dropwise to adjust pH to 9.0–9.5. A weighed quantity of 3% succinic anhydride based on starch weight (dry basis) in small portions was added while maintaining the pH between 9.0 and 9.5. The slurry was continuously stirred for 1 h. NaOH (0.5 M) was added to bring pH to 6.5 after stirring. Afterward, the slurry was centrifuged at 930×g for 5 min. Obtained starch was extensively washed several times with distilled water. Starch was allowed to dry overnight in a forced air oven at 45 °C. Dried starch was then ground to a fine powder before further analysis.

Dual modified starches

Barley starches previously oxidized and succinylated were then further cross-linked using the method of Yangsheng and Seib [13]. For cross-linking STMP and STPP were added in the same quantity and ratio as explained previously in “Cross-linking” section

Swelling power and solubility

Starch (0.6 g) was weighed in a screw-capped centrifuge tubes followed by addition of 30 mL distilled water. The starch suspension was heated in a water bath at 90 °C for 30 min with intermittent mixing. The tube was then centrifuged at 6500×g for 15 min after cooling to room temperature. The formula used to calculate swelling power was

where W2 is the weight of residue after centrifugation (g); W1 is the weight of empty dry centrifuge tube (g) and W is the weight of dried starch before heating. Method of Ali and Hasnain [18] was used to determine starch solubility. Aliquots (5 mL) of the supernatant, obtained after centrifugation was dried at 110 °C and weighed. The weight obtained is the amount of starch that solubilized on heating at 90 °C and was used to calculate solubility (g/g) of starch on a dry basis.

Water retention capacity

Water retention capacity (WRC) was calculated by the method of Ali and Hasnain [19] with some modifications. Starch (0.5 g, dry basis) was measured in screw-capped pre-weighed centrifuge tubes followed by addition of 10 mL distilled water. The tubes were capped and heated at 90 °C for 15 min. The tubes were cooled to room temperature and then centrifuged at 2350×g for 10 min. The supernatant was discarded. The tubes were re-weighed with the starch cake. The WRC was calculated using the following formula:

Paste clarity

Paste clarity was determined by the method of Lawal [20] with slight modifications. Starch slurry (1%, w/v) was heated in a boiling water bath for 30 min with intermittent mixing followed by cooling to room temperature. Light transmission (%T) was measured at 650 nm against distilled water using UV–Visible Spectrophotomer (Model V670, JASCO Corporation, Tokyo, Japan). The samples were stored at 4 °C and percent transmittance was measured after 24, 72 and 168 h and was then compared to %T measured at 0 h.

Temperature ramp measurements using rheometer

Temperature ramp measurements of native and modified barley starches were analyzed by using HR-1 Hybrid Rheometer (TA Instruments, USA) using the modified method of Li et al. [21]. A cone-plate geometry (40 mm, 2°) was used. The gap was set at 1000 µm. The strain and frequency were set at 1.0% and 10.0 rad/s, respectively. Starch suspensions (10%, w/w) were loaded on the peltier plate and were covered with a thin layer of silicon oil to minimize evaporation losses. The starch samples were subjected to temperature ramp testing from 35 to 95 °C at a rate of 5 °C/min and were then cooled from 95 to 35 °C at the rate of 5 °C/min in order to obtain viscosity profile during heating and cooling. The temperature at which the first rise in viscosity was observed is termed as pasting temperature (PT) while peak viscosity (PV) was the maximum dynamic viscosity observed during the heating ramp. Time to reach peak viscosity (TPV) was also recorded from the graph. Hot paste viscosity was defined as viscosity at 95 °C during heating whereas cold paste or final viscosity was reported at 35 °C i.e. at the end of cooling. The Trios (V.4.1.031739) software was used to find the above-mentioned parameters.

Textural analysis

For gel preparation 10% (w/w) starch solution was used. The starch gels were prepared in temperature controlled water bath at 90 °C with intermittent stirring. These starch gels were then filled in plastic cups having 3.5 cm inner diameter. Two cyclic penetration test was used in order to compress gels to encourage the phenomenon of chewing. A 1 cm diameter cylinder probe was used for compression with a preload speed of 10 mm/min. The speed was changed to 5 mm/s after penetration. (a) Hardness (maximum force observed at the end of first compression cycle, (b) springiness (the distance of the detected height of the product on the second penetration divided by original penetration distance), (c) cohesiveness (ratio between area under the curve during second penetration to the area under curve during first penetration, (d) adhesiveness (area under the curve during first retraction, (e) chewiness (product of hardness, cohesiveness and springiness), (f) gumminess (product of hardness and cohesiveness) were measured using testXpert® II software. These parameters were observed for cooled (room temperature) gels soon after their preparation (0 h) and after 168 h of refrigerated storage.

Differential scanning calorimetery

The gelatinization and retrogradation studies were studied following the method of Ali and Hasnain [22] using a differential scanning calorimeter (DSC Q10, TA Instruments, USA). Starch (2 mg) was placed in Tzero aluminium pans followed by addition of 6µL of distilled water using a microliter syringe. The pans were hermetically sealed using a Tzero hermetic lid and were allowed to rest for 24 h at room temperature for equilibration. The sealed pans were heated from 30 to 110 °C at a heating rate of 10 °C/min. After scanning, the pans were stored at refrigerated temperature (6 °C) and rescanned after 14 days. (a) Onset temperature of gelatinization (To), (b) peak temperature of gelatinization (Tp), (c) conclusion temperature of gelatinization (Tc), (d) enthalpy of gelatinization (∆Hgel), (e) enthalpy of retrogradation (∆Hret), were determined using Universal analysis software (TA Instruments, DE, USA). Percent retrogradation (%R) was calculated using following formula:

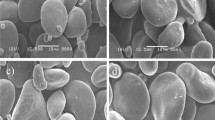

Scanning electron microscopy (SEM)

The shape and surface morphology of native and modified starches was evaluated using a SEM (JSM, 6380A, Jeol Japan). The starch samples were mounted on SEM stub with double-sided adhesive tape and were coated with gold. Starch images were studied at magnifications of × 1500 and × 4000.

Fourier transform infrared spectroscopy (FTIR)

FTIR spectra of the starch samples were obtained by Tensor II Bruker spectrometer equipped with a deuterated triglycinesulfate (DTGS) detector using attenuated total reflectance (ATR). For each spectrum, 64 scans at 4 cm−1 were recorded. The spectra were baseline corrected and deconvoluted by drawing a straight line between 1500 and 800 cm−1. The absorbance ratio of 1044/1015 cm−1 [R (1044/1015 cm−1)] was obtained from the deconvoluted spectra.

Statistical analysis

All measurements were carried out in triplicates. Software Statistical Package for Social Science (SPSS) software was used for statistical analysis. Analysis of variance (ANOVA) was performed using the Duncan’s multiple range tests to compare treatment means. Significance level was defined at p < 0.05.

Results and discussion

Swelling power and solubility

The results of swelling power and solubility are presented in Table 1. Swelling power and solubility of native starch was 8.21 (g/g) and 0.91 (g/g), respectively. Succinylation caused a remarkable increment in swelling power as compared to native and modified barley starches. A similar increment in swelling power on the addition of succinic groups was also observed by Mehboob et al. and Moin et al. [23, 24] for white sorghum and rice starches, respectively. Succinylation replaces hydroxyl groups with bulky succinyl moieties. These succinyl groups create steric hindrance leading to increment in swelling power allowing more percolation of water into starch granules [11]. Oxidation of barley starch resulted in no significant difference in swelling power and solubility compared to native starch. The single modified cross-linked starch showed a decline in swelling power of starch however, it did not bring about any significant change in solubility. The decrease in swelling could possibly be due to the strengthening of bonds between starch chains which increased its resistance to granular swelling [25]. Dual modified succinylated-crosslinked and oxidized-crosslinked starches showed significant differences as compared to their single modified succinylated and oxidized starches, respectively. Further cross-linking of oxidized and succinylated barley starch resulted in significant decline in swelling power, however, the decline was more pronounced for succinylated-crosslinked (SB + C) starch. Solubility was also reduced by almost 50% for succinylated-crosslinked (SB + C) starch.

Water retention capacity

WRC is the estimation of the hydrophilic tendency of starch granules and measures the availability of water binding sites. WRC of native and modified barely starches is presented in Table 1. WRC of studied starches ranged from 4.72 to 14.83 (g/g). WRC of modified starch followed the order with respect to SB > OB > SB + C ≃ NB > CB > OB + C. Both succinylation and oxidation resulted in higher water retention capacities. Succinylation reaction results in the insertion of succinyl groups which are hydrophilic. Whereas, oxidation not only causes depolymerization [17] but also results in the formation of hydrophilic carboxyl and carbonyl groups which increase WRC. Dual modified oxidized-crosslinked and succinylated-crosslinked starches showed a noticeable decline in WRC as compared to their counterparts. This may be due to the formation of complex linkages among the starch chains which engages water binding site resulting in restricted hydration on the surface of starch granules. Further cross-linking of succinylated and oxidized starches showed almost a 50% decline in WRC.

Paste clarity

The paste clarity of native and modified barley starches is summarized in Table 2. At 0 h, the highest percent transmittance was observed for oxidized starch. The depolymerization after oxidation combined with the presence of carboxyl and carbonyl groups resulted in enhanced transmittance of light. The extent of decline in % transmittance on storage was also observed to be least for oxidized starch after 168 h. The presence of functional groups in starches hinders the re-association starch chains. Further cross-linking of oxidized starch reduced paste clarity observed at 0 h. A similar result was also observed when succinylated starch was dual modified through cross-linking. The formation of diphosphates after cross-linking hinders the pathway of light and thus reduces paste clarity. Cross-linking when performed on native barley starch also reduced paste clarity. Cross-linked starches are said to remain almost intact after heating thus, reducing paste clarity [26]. It could be observed from Table 2 that all chemical modifications reduced the extent of decline in paste clarity compared to native barely starch suggesting the utilization of chemically modified starches in refrigerated food products.

Temperature ramp measurements

Temperature ramp measurements of native and modified starches are presented in Table 3 and their pasting curves are also represented as Fig. 1.

Pasting is defined as the change that occurs in starch after gelatinization when heated/cooked in excess amount of water [27]. The PT of native barley starch was found to be 61.67 °C which is quite similar to that reported for W.B. Merlin barley starch [28]. Succinylation of barely starch significantly reduced PT indicating weakening of granules. However, no significant difference was observed between oxidized, succinylated-crosslinked barley starches as compared to its native counterparts. Cross-linked and succinylated-crosslinked barley starches showed an increment in PT as compared to native barley starch. Succinylated and succinylated-crosslinked starch showed an increment in PV it could be possibly due to the attachment of hydrophilic succinyl moieties in the starch chains [29]. However, further cross-linking of succinylated and oxidized starches reduced PV. No significant difference was observed between native, cross-linked, oxidized and oxidized-crosslinked starches. Cross-linked barley starch and dual modified starches with cross-linking showed higher values for TPV as compared to their counterparts. It could be due to addition of covalently bonded inter and intramolecular bridges between the starch chains as a result of cross-linking. The distarch phosphates restricted swelling and thus more time was required to attain PV. A significant decline was observed in TPV for succinylated barely starch confirming the weakening of granules due to the accumulation of hydrophilic groups. Similar results were observed by Moin et al. [24] for Pakistani basmati and irri rice. Hot paste viscosity is the indicator of the shear stability of starch at high temperatures. No significant differences were observed between native and modified barley starches with the exception of oxidized barley starch. Oxidized barley starch showed exceptionally lower hot paste viscosity perhaps due to depolymerization. Cold paste viscosity indicates the extent of gelation tendency that occurs during the cooling phase. When hot pastes are cooled, the extent of increase in viscosity is governed by the re-association tendency of starch [30]. Except succinylated, succinylated-crosslinked (SB + C), all modified starches demonstrated lower cold paste viscosity (CPV) values, whereas succinylated starch showed an insignificant difference compared to native starch. These results suggested that gelation tendency on quick cooling was reduced for cross-linked (CB), oxidized (OB) and oxidized-crosslinked (OB + C) barley starches.

Textural analysis

Starch texture analysis is a very important tool to speculate product’s behaviour. Textural properties of fresh and 7 days refrigerated starch gels are presented in Table 4a, b. It could be observed that hardness of starch gels reduced significantly upon single chemical modification. Whereas, cross-linking of modified starches led to a further decline in hardness of gels. Crosslinking of oxidized starches resulted in loss of gelation tendency. This result corroborates with the low CPV value of oxidized-crosslinked starches. Oxidized-crosslinked barley starch failed to develop a gel-like structure even after 7 days of storage. Other starch gels showed significant increase in hardness after refrigerated storage. However, the hardest gel was formed by native starch, suggesting strong retrogradation. In case of dual modified succinylated-crosslinked starch, hardness markedly increased with storage. Succinylated barley starch forms the hardest gel upon storage among single modified starches. However, succinylated barley starch showed a significant decline in hardness as compared to its native counterpart as self-association of amylose chains substituted with functional groups was more restricted [29]. Springiness is the indicator of the breakdown in starch chain structure as a result of initial compression. Succinylated and succinylated-crosslinked starches demonstrated slight increment in springiness on storage. Whereas, decline in springiness was observed for crosslinked and oxidized barley starches. Modified starches showed a significant decline in cohesiveness exception of oxidized barley starch which showed same cohesiveness as native starch. Upon storage, cross-linked and succinylated-crosslinked starches increased their cohesive character which could be attributed to aggregation of starch chains. Adhesiveness is an interfacial property and is a measure of force holding dissimilar particles/surfaces together that is the strength of a particulate system [31]. No significant difference was observed between native and oxidized starches in terms of adhesiveness. However, adhesive forces became stronger with storage. A drastic decline was observed in the adhesiveness of succinylated and succinylated-crosslinked starch. Adhesive characteristic is particularly useful in coatings and batters. Oxidized barley starches could, therefore, be used in batters because of its higher adhesiveness. Chewiness is the quantity to simulate the energy required for masticating a semi-solid sample to a steady state of swallowing [32]. Succinylated barley starches formed more chewy gels (both fresh and stored). Succinylated-crosslinked starch gel was the least chewy. In general, storage increased chewiness of native and modified starch gels but was still significantly lower than chewiness of native starch gel after 7 days storage. Succinylated barley starch produced most gummy gels whereas, succinylated-crosslinked gels were least gummy. This suggests that cross-linking of starch reduces gumminess making it suitable for use in dips and sauces.

Differential scanning calorimeter

Gelatinization temperatures, enthalpy of gelatinization and percent retrogradation of native and chemically modified barley starches are reported in Table 5. As compared to transition temperatures of native barley starch all modified starches showed higher values except for succinylated barley starch which showed reduced To, Tp and Tc values. Similar results were obtained by Mehboob et al. [23] on succinylation of sorghum starches. This could be possibly due to the hydrophilic nature of succinic groups that ease penetration of water. This reduces thermal energy and transition temperature owing to changes in crystalline structure required for gelatinization by changing coupling forces between amorphous and crystalline regions of starch granules. All chemical modifications significantly reduced enthalpy for gelatinization. Succinylation of starches markedly reduced percent retrogradation followed by dual modified succinylated and cross-linked starch. Bulky succinic groups delay re-association of amylopectin chains due to steric hindrance. Oxidized starch showed a significant increment in transition temperatures as compared to their native counterparts. Oxidation weakens starch granules from partially degrading starch molecules in crystalline lamella consequently decreasing enthalpy value. As a result, less energy was needed to gelatinize starch [33]. Results are inconsistent with the findings of Forssell et al. [17]. However, percent retrogradation was found to be higher for oxidized starches compared to native starch. An increase in retrogradation of oxidized starch might be due to depolymerization which causes degradation of a long chain of amylopectin or amylose molecules producing dextrins with an appropriate length for retrogradation [34]. A slight increase in retrogradation was also observed by Kuakpetoon and Wang [35]. A significant increment in gelatinization temperatures and enthalpy of gelatinization was also observed in case of cross-linked modified starch. These results contribute to the fact that the introduction of phosphate groups into starch strengthened the molecular organization/bond between starch granules. These results are in consistent with the findings of Sukhija et al. [36] for elephant foot yam starch. The amount of energy required to melt and disrupt the inner and intra hydrogen bonds of double helices which have developed during cold storage of gelatinized starch gel is known as enthalpy of retrogradation. No significant difference was observed between the retrogradation enthalpies of succinylated, oxidized-crosslinked and succinylated-crosslinked barley starches. However, the enthalpies are much lower than native barley starch. Succinylated barley starch showed a significant decline in the retrogradation enthalpy possibly due to the association of bulky succinyl groups to outer branches of amylopectin, thereby reducing the re-association of amylopectin chains [29]. Oxidized barley starch showed a significant increase in retrogradation enthalpy as compared to native barley starch. Oxidation of starch could either increase or decrease retrogradation. The degradation of long-chain amylopectin or amylose molecules in the amorphous phase could produce dextrins with an appropriate length for re-association which facilitates starch retrogradation [37]. Retrogradation enthalpy of native and cross-linked starches is insignificantly different from each other however, a slight difference can be observed among the values. A higher degree of retrogradation in cross-linked starch is due to the highly ordered structure [38]. Cross-linking of oxidized starches resulted in significantly higher percent retrogradation as compared to other starches. However, for succinylated-crosslinked starch the increase was insignificant.

Fourier transform infrared spectroscopy (FTIR)

The molecular changes attributed by chemical modifications were further studied by FTIR and are represented in Fig. 2. FTIR spectra for native and modified barley starches were recorded from 500 to 4000 cm−1. The band between 3500 and 3700 cm−1 corresponds to O–H vibrations [39]. The band around 2920 cm−1 [40] and 1644 cm−1 [41] was due to C–H stretching vibrations and tightly bound water, respectively. However, spectra characteristics of the starch and modified starch were similar in the fingerprint region of 800–1500 cm−1. The cross-linked starch spectrum did not show any inherent peaks for P–O (phosphorus oxide) and P–O–C (phosphorus esters). This could be possible due to a low degree of cross-linking. Similar results were also observed by Gao et al. [42]. However, a new peak was observed at 1451.33 cm−1 which are possibly due to CH2 bending and C–O–C stretch [43]. The similar peaks at 1415.47 cm−1 and 1414.81 cm−1 were also observed for oxidized-crosslinked and succinylated-crosslinked starches, respectively. These additional peaks confirmed successful alteration in molecular structure by dual modification. No difference among the spectra of native and oxidized barley starches was detected. These findings are inconsistence with the results of El Halal et al. [44]. Compared to native barley starch some new peaks were observed in the spectra at 1715.56 cm−1, 1567.57 cm−1 for succinylated barley starch and 1566.92 cm−1 for succinylated-crosslinked starch. The peaks at 1567.57 cm−1 and 1566.92 cm−1 belong to asymmetric stretch vibrations of carboxyl group. However, a new peak at 1715.56 cm−1 represented C=O stretching vibration of an ester group [45]. This could be possibly due to the fact that during ionization, the formation of COO− gives resonance effect between two C–O bonds. As a result, carbonyl absorption brought about a new peak in the range of between 1550 and 1610 cm−1 in the succinylated starches [39].

Further, changes in the structure of starch were determined by the ratio between the crystalline and amorphous region of starch. IR absorbance bands at 1035–1048 cm−1 and 1022–1055 cm−1 represents crystallinity and amorphous regions, respectively [42]. Native and modified barley starches were deconvoluted for better resolution of overlapping peaks. The ratio 1044/1015 cm−1 was calculated to determine the amount of crystalline to amorphous phase in native and modified barley starches. The ratios are represented in Table 6. The ratio for native barley starch was 2.018 whereas, modified starches showed significantly lower ratios. This suggested that the structure of native barley starch granules is more organized than its modified forms [46].

Scanning electron microscopy

Scanning electron micrographs of native and chemically modified barley starches under × 1500 and × 4000 magnification are represented in Fig. 3a, b, respectively. Barley starch granules are smooth-surfaced, oval, irregular or slightly cuboidal in shape [47]. The size of starch granules ranged between 6.96 and 25.1 µm. Native starch granules were mostly smooth however, some grooves were seen when observed under × 4000 magnification. Cross-linked barley starches showed rough surface and some dents under × 4000 magnification. Indentations and some roughness was also observed for oxidized and succinylated starches. On higher magnification a clear groove on oxidized barley starch was observed while succinylated barley starch did not illustrate much difference as compared to native starch. In case of dual modified starches a clear distortion in granular structure was observed. Surface roughness was obvious on granules of oxidized-crosslinked barley starch. While succinylated-crosslinked starches showed signs of depression on their surface. However, none of the chemical modifications affected granular integrity of starches.

Conclusion

Food grade starches are chemically modified to achieve several properties like improved consistency, smoothness, clarity, freeze thaw and cold storage stability. Cross-linked barley starch showed resistance against swelling, higher temperature tolerance and high viscosity which makes it suitable for use in soups, gravies, sauces etc. Oxidation of barley starch improved paste clarity and adhesiveness making it suitable for use as batters and breadings for coating purposes and in confectionary. Succinylation favoured lower gelatinization temperature and retrogradation and lower tendency to form gels. This type of starch is suitable for use in refrigerated and frozen products. Dual modified barley starches exhibited delayed retrogradation during storage and higher stability towards thermal degradation making it appropriate for use in canned, refrigerated and frozen foods, salad dressings, puddings and gravies. Hence, it could be concluded that chemical modifications (both single and dual) offset undesirable properties of native barley starch.

References

R.F. Tester, J. Karkalas, X. Qi, J. Cereal Sci. 39(2), 151–165 (2004)

B.-K. Baik, S.E. Ullrich, J. Cereal Sci. 48(2), 233–242 (2008)

P. Sullivan, E. Arendt, E. Gallagher, Trends Food Sci. Technol. 29(2), 124–134 (2013)

A. Andersson, R. Andersson, P. Åman, Cereal Chem. 78(5), 507–513 (2001)

M. Izydorczyk, J. Dexter, Food Res. Int. 41(9), 850–868 (2008)

B. Kaur, F. Ariffin, R. Bhat, A.A. Karim, Food Hydrocoll. 26(2), 398–404 (2012)

J.N. Bemiller, Starch-Stärke 49(4), 127–131 (1997)

S. Jobling, Curr. Opin. Plant Biol. 7(2), 210–218 (2004)

R.N. Tharanathan, Crit. Rev. Food Sci. Nutr. 45(5), 371–384 (2005)

M. Sánchez-Rivera, F. García-Suárez, M.V.Del Valle, F. Gutierrez-Meraz, L. Bello-Pérez, Carbohydr. Polym. 62(1), 50–56 (2005)

A.N. Jyothi, K.N. Rajasekharan, S.N. Moorthy, J. Sreekumar, Starch-Stärke 57(7), 319–324 (2005)

A.N. Jyothi, S.N. Moorthy, K.N. Rajasekharan, Starch-Stärke 58(6), 292–299(2006)

W. Yangsheng, P.A. Seib, Cereal Chem. 67(2), 202–208 (1990)

A. A. o. C. C. A. M. Committee, Approved Methods of the American Association of Cereal Chemists (American Association of Cereal Chemists, St. Paul, 2000)

P. Landers, E. Gbur, R. Sharp, Cereal Chem. 68(5), 545–548 (1991)

K. Woo, P. Seib, Cereal Chem. 79(6), 819 (2002)

P. Forssell, A. Hamunen, K. Autio, P. Suortti, K. Poutanen, Starch-Stärke 47(10), 371–377 (1995)

T.M. Ali, A. Hasnain, Int. J. Polym. Anal. Charact. 16(3), 187–198 (2011)

T.M. Ali, A. Hasnain, Int. J. Food Prop. 17(3), 523–535 (2014)

O.S. Lawal, Carbohydr. Res. 339(16), 2673–2682 (2004)

Y. Li, C.F. Shoemaker, J. Ma, X. Shen, F. Zhong, Food Chem. 109(3), 616–623 (2008)

T.M. Ali, A. Hasnain, Int. J. Polym. Anal. Charact. 17(3), 227–234 (2012)

S. Mehboob, T.M. Ali, F. Alam, A. Hasnain, LWT-Food Sci. Technol. 64(1), 459–467 (2015)

A. Moin, T.M. Ali, A. Hasnain, Food Chem. 191, 52–58 (2016)

J. Singh, L. Kaur, O. McCarthy, Food Hydrocoll. 21(1), 1–22 (2007)

S.H. Koo, K.Y. Lee, H.G. Lee, Food Hydrocoll. 24(6), 619–625 (2010)

S.C. Alcázar-Alay, M.A.A. Meireles, Food Sci Technol. (Campinas) 35(2), 215–236 (2015)

Y. Song, J. Jane, Carbohydr. Polym. 41(4), 365–377 (2000)

M. Shaikh, T.M. Ali, A. Hasnain, J. Cereal Sci. 63, 57–63 (2015)

A. Hagenimana, X. Ding, T. Fang, J. Cereal Sci. 43(1), 38–46 (2006)

B. Adhikari, T. Howes, B. Bhandari, V. Truong, Int. J. Food Prop. 4(1), 1–33 (2001)

K.S. Sandhu, N. Singh, Food Chem. 101(4), 1499–1507 (2007)

C.E. Chávez-Murillo, Y.J. Wang, L.A. Bello-Pérez, Starch-Stärke 60(11), 634–645 (2008)

K. Sangseethong, S. Lertphanich, K. Sriroth, Starch-Stärke 61(2), 92–100 (2009)

D. Kuakpetoon, Y.-J. Wang, Carbohydr. Res. 341(11), 1896–1915 (2006)

S. Sukhija, S. Singh, C.S. Riar, Food Hydrocoll. 55, 56–64 (2016)

K. Sangseethong, N. Termvejsayanon, K. Sriroth, Carbohydr. Polym. 82(2), 446–453 (2010)

H.-X. Xiao, Q.-L. Lin, G.-Q. Liu, F.-X. Yu, Molecules 17(9), 10946–10957 (2012)

G.L. Arueya, T.M. Oyewale, Food Chem. 177, 258–266 (2015)

V. Pushpamalar, S. Langford, M. Ahmad, Y. Lim, Carbohydr. Polym. 64(2), 312–318 (2006)

F. Luo, Q. Huang, X. Fu, L.-x. Zhang, S.-j. Yu, Food Chem. 115(2), 563–568 (2009)

F. Gao, D. Li, C.-h. Bi, Z.-h. Mao, B. Adhikari, Carbohydr. Polym. 103, 310–318 (2014)

R. Kizil, J. Irudayaraj, K. Seetharaman, J. Agric. Food Chem. 50(14), 3912–3918 (2002)

S.L.M. El Halal, R. Colussi, V.Z. Pinto et al., Food Chem. 168, 247–256 (2015)

N.Z. Abiddin, A. Yusoff, N. Ahmad, Food Hydrocoll. 75, 138–146 (2018)

H.-J. Chung, Q. Liu, R. Hoover, Food Res. Int. 43(2), 501–508 (2010)

M. Gupta, A.S. Bawa, A.D. Semwal, Int. J. Food Prop. 12(3), 587–604 (2009)

Acknowledgements

We would like to thank Dean Faculty of Science, University of Karachi for funding this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehfooz, T., Ali, T.M. & Hasnain, A. Effect of cross-linking on characteristics of succinylated and oxidized barley starch. Food Measure 13, 1058–1069 (2019). https://doi.org/10.1007/s11694-018-00021-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-00021-3