Abstract

Solid fat content (SFC) curve is one the most important physical properties of fats determining their plasticity and melting behavior. It is measured using pulsed nuclear magnetic resonance spectroscope or differential scanning calorimeter. However, the instruments may not be readily available at all laboratories. As a case study, in this research, application of empirical modeling for prediction of the SFC curve of chemically interesterified binary blends of fully hydrogenated soybean (FHSBO) and canola oil (CO) was evaluated. The SFC curve of interesterified fats as a function of temperature (SFC f(T)) or saturated fatty acids (SFA, SFC f(SFA)) were S-shaped and could be described using the sigmoidal Gompertz model. The SFC f(T) models fitted the experimental data with R2s greater than 0.95 and mean absolute errors (MAE) less than 1.61 %. The SFC f(SFA) curves could also be described using the Gompertz model with R2s greater than 0.97 and MAEs less than 1.18 %. Finally, a two-variable Gompertz model considering both temperature and SFA as variables was developed which fitted the experimental data with R2 of 0.98 and MAE of 1.00 %. To validate the final model, the SFC curve of different blends including interesterified FHSBO/CO/sunflower oil, palm olein/CO or palm olein/CO/sunflower oil blends was predicted. The model could predict the SFC of interesterified FHSBO/CO/sunflower oil blends with correlation coefficient of 0.98 and MAE of 1.02 %. When applied for palm olein-based blends, it predicted the SFC curves with correlation coefficient and MAE of 0.87–0.88 and 2.6–3.5 %, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Interesterification has been widely used in the production of various types of trans-free fat products [1–6]. It modifies the physical properties of oils and fats by rearranging the distribution of fatty acids on the glycerol backbone without changing their fatty acid composition [7]. Upon interesterification, physicochemical properties of the product including triacylglycerol (TAG) composition, solid fat content (SFC), melting point and crystallization behavior of the product is changed. Accordingly, the reaction is often monitored by TAG analysis, melting point and SFC determination [7, 8]. The SFC defines the percentage of the solid parts of fats at certain temperatures (generally 10–40 °C) and is measured using pulsed nuclear magnetic resonance spectroscope (pNMR) or differential scanning calorimeter (DSC) [9]. However, the instruments for SFC determination or TAG analysis (high performance liquid chromatography or high temperature gas chromatography) may not be available at all food analysis laboratories. In this context, prediction of SFC of interesterified fats from their fatty acid composition (which is not altered by the reaction, and the instrument for fatty acid composition analysis (gas chromatography) is very common) may obviate the need for advanced instrumentation.

TAG composition is the most important factor determining fat physical properties. Fatty acid distribution within TAGs of naturally occurring oils and fats is rather specific. Accordingly, different blends of natural oils/fats having similar fatty acid compositions may not have similar TAG composition, and consequently, similar physical properties [9]. Upon chemical interesterification, fatty acids are randomly re-distributed within TAGs. The reaction ultimately attains equilibrium when all possible TAGs have been formed [7]. Theoretically, separate interesterification of two different fats having different TAG composition but the same fatty acid composition will lead to a similar TAG composition and consequently similar physical properties. Hence, a model describing the relationship between fatty acid composition and SFC may be helpful in prediction of the consequence of the interesterification.

A few works focusing on modeling of SFC of interesterified fats have been published until now. Augusto et al. [10] reported that the SFC curve of fats (as a function of temperature) could be modeled using sigmoidal functions. Teles dos Santos, Gerbaud and Le Roux [11, 12] used a solid–liquid equilibrium model coupled with an algorithm for direct minimization of the Gibbs free energy function to compute the SFC curve of vegetable oils including interesterified fats. However, models described by by Teles dos Santos, Gerbaud and Le Roux [11, 12] needs many input data such as melting point and melting enthalpy of individual TAGs. Empirical modeling using non-linear regressions can provide a simple mathematical description of the phenomena. Hence, as a case study, the aim of this work was to express the SFC curve of interesterified FHSBO and canola oil (CO) blends in relation to their fatty acid composition and temperature using regression models. Models presented in this work can be used as tools for prediction of SFC of interesterified fats and may be especially useful in development of new fat formulations.

Materials and methods

Modeling and statistical analyses

The fatty acid composition and SFC data of chemically interesterified binary blends of FHSBO/CO from our previous work was used for modeling study [5]. In addition to the blends reported previously, the physicochemical data of one more blend containing 45 % FHSBO and 55 % CO (which was prepared using the same raw materials and procedures as the other blends) was also included in the study [13] (Table 1). In order to evaluate the correlation between SFC, fatty acid composition and temperature, Pearson bivariate correlation coefficients were calculated using SPSS for Windows (IBM SPSS Statistics Ver. 21, New York, USA). Based on the Pearson bivariate correlation analysis, temperature and saturated fatty acids (SFA) were selected as the most effective independent variables and used for modeling of SFC of chemically interesterified FHSBO/CO blends. SFC as a function of temperature, SFA or both was modeled using sigmoidal Gompertz function by SigmaPlot software ver. 12 (Systat software Inc., USA). Goodness of fit of models including correlation coefficient between experimental and predicted values and mean absolute error of prediction was evaluated using Statistica Ver. 10 (Stat Soft Inc., Tulsa, USA).

Experimental procedures

After description of model, several blends were chemically interesterified and the observed SFC of the blends was compared with that predicted by model. Chemical interesterification was performed as described in our previous works, except that interesterified fats were not washed with ethanol [2, 3, 5]. Briefly, fat blends were interesterified using sodium methoxide (Merck, Darmstadt, Germany, 0.5 % w/w) at 70 °C for 30 min. The catalyst was inactivated by addition of 2 % (w/w) aqueous citric acid (20 % (w/w) concentration) and mixing for an additional 15 min. Finally, 1 % (w/w) filter aid (Celite Hyflo Super Cel filter aid, Fisher Scientific Co., Pittsburgh, PA) was added and the mixture filtered under vacuum through Wattman No. 4 filter paper.

Fatty acid methyl esters were prepared and identified according to the American Oil Chemists’ Society (AOCS) method Ce 2-66 and Ce 1e-91, respectively [14]. A Chrompack CP 9002 gas chromatograph (Middleburg, the Netherlands) equipped with a flame ionization detector and the capillary chromatographic column CP Sil 88 (100 m, 0.25 mm id and 0.2 μm film thickness; Chrompack, Middleburg, the Netherlands) was used to analyze fatty acid methyl esters. The split ratio was 1:100 and the detector and injector temperature was 250 °C. The column was run isothermally at 175 °C, the carrier gas was nitrogen and the column head pressure was 230 kPa.

A minispec mq 20 pulsed nuclear magnetic resonance spectroscope (Bruker Corporation, Hamburg, Germany) was used to measure SFC in samples at 10, 20, 25, 30, 35 and 40 °C according to AOCS Cd 16b-93 direct serial measurement method [14].

Results and discussion

Variable selection

Generally, factors affecting the SFC of fats can be divided into two groups: the temperature at which the fat is held and the chemical composition of fat. Table 1 shows fatty acid composition and SFC of blends at different temperatures. To identify variables having greater correlation with SFC of interesterified fats, Pearson correlation coefficients for binary combinations of SFC with temperature, palmitic, stearic, oleic, linoleic, linolenic, total unsaturated fatty acids (UFA) and total SFA were calculated (Table 2). Pearson correlation coefficient depicts the basic relationship across two variables. The correlation coefficient lies between −1 and +1. If the two variables tend to increase together, the correlation coefficient will be positive. Conversely, if one variable tends to increase as the other decreases, the correlation coefficient will be negative [15]. A negative Pearson correlation coefficient was observed between SFC and temperature (Table 2) i.e., as it is obvious, SFC is lower at higher temperature. This can also be seen in Table 1 and Fig. 1.

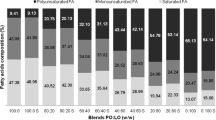

As it can be seen in Table 1, palmitic, stearic, oleic, linoleic and linolenic acids were the main (>97 %) fatty acids found in blends. SFAs (variables palmitic, stearic and total SFA) have high melting points and as it could be expected, a significant positive correlation was observed between individual SFAs or total SFA and SFC (Table 2). Contrary to SFAs, oleic, linoleic, linolenic and total UFA affected the SFC, negatively (Table 2). However, they were strongly correlated (Pearson correlation coefficient = 1.0) with SFAs (Table 2). As the sum of fatty acid percentages of a fat is 100, the increase or decrease in the content of one fatty acid will influence that of the other one. In other word, the statistical distribution of total UFA, oleic, linoleic or linolenic acid is completely dependent to that of total SFA, palmitic or stearic acid. This is especially important in regression analysis, as the distribution of independent variables should not be explained by each other [16]. Accordingly, compositional variables can be selected from either SFAs or UFAs. SFC of fats may be described better by SFAs [17–19]. The main SFA found in blends was stearic acid, which ranged 15–41 % (Table 1). However, interesterified fats also contained about 7–8 % palmitic acid. To take into account the effect of both fatty acids and to simplify model, total SFA (sum of palmitic and stearic acid) was selected as the sole independent compositional variable.

Similar to our results, Davenel et al. [17] found both stearic and palmitic acid to be closely correlated with SFC at 20 °C of pork back fat. They described the SFC of pork fat as a linear function of palmitic and stearic acid. Gläser et al. [18] and Ospina-E et al. [19] identified a high correlation between stearic acid and SFC at the assayed temperatures for pork back fat. However, no report on the effect of fatty acid composition on SFC of interesterified fats was published.

Briefly, temperature and total SFA were selected as independent variables for modeling of SFC of chemically interesterified fats.

Modeling of SFC as a function of temperature

Application of sigmoidal equations for modeling of SFC as a function of temperature (SFC f(T)) has been previously documented by Augosto et al. [10]. They found that the SFC f(T) curve of different fat blends (including one interesterified blend of FHSBO/CO) fitted the sigmoidal models such as Gompertz, Logistic and power decay model but the Gompertz model described it better especially at low and high values of SFC. Although the Gompertz function is a type of mathematical model for a time series, it has been extensively used in different areas, describing a wide number of applications [10]. In this study we evaluated the suitability of Gompertz equation for expression of SFC f(T) curve of chemically interesterified FHSBO/CO blends with varying ratios. As it can be seen from Fig. 1, the SFC f(T) curves of interesterified fats had a sigmoidal shape. At low temperatures, the SFC tends to a maximum asymptotic value, from which melting starts to decay the solid content. At intermediate temperatures, the SFC decays with an inflexion point. Finally, at high temperatures, fat is completely melted, i.e., the SFC tends to a minimum asymptotic value of 0 %, as no more solid fat is observed. Although many sigmoidal functions are known, the Gompertz models (Eq. 1) is one of the most used for mathematical modeling [20]. The effect of temperature on SFC can be mathematically shown using Gompertz model as below:

where, α is the upper asymptote, b sets the ordinate axis displacement and c sets the growth rate (Y scaling).

The coefficients α, b and c for each blend were calculated using Sigmaplot software and are presented in Table 3. The coefficients were generally significant at p < 0.05 and coefficient of determination (R2) of 0.95-1.00 was obtained for models. Models had generally P values less than 0.01 (Table 3). A comparison between experimental and predicted values is shown in Fig. 1. Table 3 shows the correlation coefficient between experimental and predicted SFC f(T) values which were generally more than 0.98. The mean absolute error of models, which is an average of the absolute errors (the difference between experimental and predicted value), ranged 0.14–1.61 % (Table 3). This indicates that the models can predict the SFC with low error. Totally, models described for expression of SFC as a function of temperature showed good fitness with experimental data and can be used for prediction of SFC f(T) of interesterified FHSBO/CO blends.

Modeling of SFC as a function of SFA

Contrary to the effect of temperature, the SFC of fats increases with increase in SFA content. Figure 2 shows SFC curve of interesterified fats as a function of SFA (SFC f(SFA)). The SFC f(SFA) curve of interesterified fats also showed a sigmoidal shape and could be modeled using sigmoidal functions. We used the Gompertz function to model the SFC of interesterified fats as a function of SFA content (Eq 2).

Unlike SFC f(T) curve which starts from the upper asymptote and finally reaches to the lower asymptote of zero, the SFC f(SFA) curve starts from the lower asymptote of zero and finally reaches to the upper limit of SFC. The coefficients α, b and c and goodness of fit of Gompertz models of SFC f(SFA) curve was calculated and are shown in Table 3. As it can be seen all models fitted for prediction of SFC f(SFA) had high R2 (>0.97) and were significant at p < 0.01. Coefficients of all models except model describing SFC f(SFA) at 10 °C were generally significant at p < 0.05. The experimental and predicted SFC f(SFA) curve of interesterified fats are compared in Fig. 2. Correlation coefficients of experimental and predicted values were greater than 0.99 and mean absolute error of models was in the range of 0.22–1.18 %.

Davenel et al. [17] reported a linear model for description of the effect of palmitic and stearic acids on SFC at 20 °C of pork back fat. Tough application of linear models for expression of the effect of SFA on SFC may result in good predictions specially in linear region of the SFC f(SFA) curve, this may not be true as a whole. As discussed in this study, the SFC f(SFA) curve is a S-shaped curve and sigmoidal models can properly describe it. On the other hand, linear models may yield negative values specially at low SFCs (at start of the SFC f(SFA) curve or the end of the SFC f(T) curve). Braipson-Danthine and Deroanne [21] described the SFC of binary fat blends as a function of their constituent base stocks using a quadratic model. However, it should be noted that quadratic models, are not suitable for modeling of S-shaped curves. This type of models, though may suitably describe the intermediate part of the curve, cannot fit the two asymptote regions of the curve.

Modeling of SFC as a function of temperature and SFA

Knowing the coefficients presented in Table 3, one may predict the SFC of a fat blend at a given temperature or SFA content. However, none of the models express the combined effect of temperature and SFA on SFC. To include both variables in the model, the coefficients of the one-variable Gompertz model should be expressed as a function of the other variable. Then by substituting the coefficients with the corresponding function, a two-variable Gompertz model will be obtained. Accordingly, the correlation between coefficients of the SFC f(T) models and SFA content or coefficients of SFC f(SFA) models and temperature was evaluated. Figure 3 shows the scatterplot of the coefficients of SFC f(T) models against the corresponding SFA content. Good linear correlations with high R2 were found between coefficients α and c of SFC f(T) models and SFA content (Fig. 3). However, as it can be seen from Fig. 3, linear regression of the coefficients of SFC f(SFA) models and temperature did not yield high R2 values. This means that the coefficients of SFC f(SFA) models could not be good linear functions of temperature.

The correlation between coefficients α and c of SFC f(T) models and SFA content can be mathematically stated as bellow:

By replacing coefficients α and c of Eq. (1) with Eqs. (3) and (4), respectively, the final model expressing SFC as a function of both temperature and SFA will be obtained:

The coefficients of model were obtained by non-linear regression analysis using Sigmaplot and are presented in Eq. (6).

All the coefficients were statistically significant at p < 0.01 and, R2 and standard error of model were 0.98 and 1.405, respectively. These show good power of the model in prediction of SFC of interesterified FHSBO/CO blends. Goodness of fit of model was further evaluated by comparing experimental and predicted values. The results are shown in Fig. 4. The correlation coefficient between experimental and predicted SFC was 0.98. Mean absolute error of the predicted values was 1.00 %. These are indicators of the precision of the model which were very good for Eq. (6).

To validate the model (Eq 6), it was used to predict the SFC curve of several interesterified blends including ternary blends of FHSBO/CO/sunflower oil, binary blends of palm olein/CO, and ternary blends of palm olein/CO/sunflower oil. The predicted curves were then compared with the experimental ones (Fig. 5) and evaluated for goodness of fit. For blends composed of FHSBO, CO and sunflower oil (Fig. 5a), the coefficients of the model fitted the experimental data very well. The model was able to predict the SFC of ternary blends with 1.02 % mean absolute error. High correlation coefficient (0.98) was also found between experimental and predicted values. For interesterified binary or ternary palm olein-based blends, mean absolute error of the model was 3.5 and 2.6 %, respectively, which were significantly higher than that obtained for FHSBO-based blends. The correlation coefficient between experimental and predicted values was also lower for binary (0.87) and ternary (0.88) palm olein-based blends. The ability of the model in good prediction of the SFC curve of the FHSBO-based ternary blends may be due to the compositional similarity between ternary blends and binary blends that were used to fit the model. As it can be seen from Table 4, similar to binary FHSBO blends, ternary FHSBO blends had stearic acid as main SFA. Fatty acid composition of palm olein-containing blends was more different than FHSBO-containing blends. Contrary to blends containing FHSBO, the main SFA in blends composed of palm olein was palmitic acid which has different melting point from stearic acid. Hence the difference in SFA composition may explain the higher mean absolute error of the model in prediction of the SFC curve of palm olein-based blends.

Predicted versus experimental solid fat contents (SFC) of chemically interesterified blends; a ternary blends of fully hydrogenated soybean/canola/sunflower oils; b binary blends of palm olein/canola oil; c ternary blends of palm olein/canola oil/sunflower oil. Markers and solid lines represent experimental and predicted SFC values, respectively. E experimental values; P predicted values

Ospina-E et al. [19] presented a quadratic model using temperature and stearic acid content as independent variables for expression of the SFC of pork back fat. However, as described above and by Augosto et al. [10], quadratic models may not suitably describe the SFC curve as the SFC curve is a sigmoidal curve. Teles dos Santos, Gerbaud and Le Roux [11, 12], modeled and simulated the melting curves and chemical interesterification of vegetable oils using a solid–liquid equilibrium model coupled with an algorithm for direct minimization of the Gibbs free energy function. The methodology was able to predict the SFC curve of different chemically interesterified fats including binary blends of fully hydrogenated palm stearin/CO, palm stearin/CO, palm stearin/cottonseed oil, milk fat/corn oil with a mean absolute error of 4.13 % [11]. For interesterified ternary blends of palm oil/sunflower oil/palm kernel olein they reported a mean absolute error of 4.2 % in SFC prediction [12]. However, the need for a lot of input data such as melting point and melting enthalpy of TAGs may limit its application. On the other hand the mean absolute error of their model was more than that obtained in this study (4.13–4.20 vs. 1.00–3.50 %).

Conclusions

In summary, based on the results of the current study it could be concluded that the SFC f(T) and SFC f(SFA) curves of chemically interesterified blends of FHSBO and CO can be modeled using the sigmoidal Gompertz function. By some substitutions in Gompertz model it was possible to describe a two-variable sigmoidal function for expression of SFC as a function of both temperature and SFA content. As discussed in this paper the model had high power in prediction of the SFC of chemically interesterified binary blends of FHSBO and CO or chemically interesterified FHSBO/CO/sunflower oil blends. However, for palm olein-based interesterified fats, predictions were with higher errors. Another model may be needed to be fitted for prediction of SFC curve of these kinds of blends. The results of this study may be especially helpful in preliminary selection of the desired fat formulation before performing any experiment.

References

S. Khatoon, S.R.Y. Reddy, Plastic fats with zero trans fatty acids by interesterification of mango, mahua and palm oils. Eur. J. Lipid Sci. Technol. 107(11), 786–791 (2005)

J. Farmani, M. Hamedi, M. Safari, A. Madadlou, Trans-free Iranian vanaspati through enzymatic and chemical transesterification of triple blends of fully hydrogenated soybean, rapeseed and sunflower oils. Food Chem. 102(3), 827–833 (2007)

J. Farmani, M. Hamedi, M. Safari, Production of zero trans Iranian vanaspati using chemical transesterification and blending techniques from palm olein, rapeseed and sunflower oil. Int. J. Food Sci. Technol. 43(3), 393–399 (2008)

A.P.B. Ribeiro, R.C. Basso, R. Grimaldi, L.A. Gioielli, L.A.G. Gonçalves, Effect of chemical interesterification on physicochemical properties and industrial applications of canola oil and fully hydrogenated cottonseed oil blends. J. Food Lipids 16(3), 362–381 (2009)

J. Farmani, M. Safari, M. Hamedi, Trans-free fats through interesterification of canola oil/palm olein or fully hydrogenated soybean oil blends. Eur. J. Lipid Sci. Technol. 111(12), 1212–1220 (2009)

Z. Meng, Y. Liu, L. Shan, Q. Jin, X. Wang, Reduction of graininess formation in beef tallow-based plastic fats by chemical interesterification of beef tallow and canola oil. J. Am. Oil Chem. Soc. 87(12), 1435–1442 (2010)

D. Rousseau, A.G. Marangoni, Chemical interesterification of food lipids: theory and practice, in Food Lipids: Chemistry, Nutrition, and Biotechnology, ed. by C.C. Akoh, D.B. Min (CRC Press, Boca Raton, 2008), p. 267

H. Zhang, L.S. Pedersen, D. Kristensen, J. Adler-Nissen, H.C. Holm, Modification of margarine fats by enzymatic interesterification: evaluation of a solid-fat-content-based exponential model with two groups of oil blends. J. Am. Oil Chem. Soc. 81(7), 653–658 (2004)

H.D. Belitz, W. Grosch, P. Schieberle, Food Chemistry, 4th edn. (Springer, Heidelberg, 2009)

P.E.D. Augusto, B.M.C. Soares, M.C. Chiu, L.A.G. Gonçalves, Modeling the effect of temperature on lipid solid fat content (SFC). Food Res. Int. 45(1), 132–135 (2012)

M. Teles dos Santos, V. Gerbaud, G.A.C. Le Roux, Modeling and simulation of melting curves and chemical interesterification of binary blends of vegetable oils. Chem. Eng. Sci. 87(14), 14–22 (2013)

M. Teles dos Santos, V. Gerbaud, G.A.C. Le Roux, Solid Fat Content of vegetable oils and simulation of interesterification reaction: predictions from thermodynamic approach. J. Food Eng. 126, 198–205 (2014)

J.Farmani, Improving quality of solid shortening through enzymatic interesterification. MSc thesis, University of Tehran, Iran (2005)

AOCS, Official Methods and Recommended Practices of the American Oil Chemists’ Society, 4th edn., 3rd printing, (American Oil Chemists’ Society Press, Champaign, 1996)

N.P. Bali, Comprehensive Engineering Mathematics (Laxmi Publications, New Dehli, 1997)

S. Chatterjee, Regression Analysis by Example (Wiley, New Jersey, 2006)

A. Davenel, A. Riaublanc, P. Marchal, G. Gandemer, Quality of pig adipose tissue: relationship between solid fat content and lipid composition. Meat Sci. 51(1), 73–79 (1999)

K.R. Gläser, C. Wenk, M.R.L. Scheeder, Evaluation of pork backfat firmness and lard consistency using several different physicochemical methods. J. Sci. Food Agric. 84(8), 853–862 (2004)

J.C. Ospina-E, A. Cruz-S, J.A. Pérez-Álvarez, J. Fernández-López, Development of combinations of chemically modified vegetable oils as pork backfat substitutes in sausages formulation. Meat Sci. 84(3), 491–497 (2010)

D. Kaplan, L. Glass, Understanding Nonlinear Dynamics (Springer, New York, 1995)

S. Braipson-Danthine, C. Deroanne, Determination of solid fat content (SFC) of binary fat blends and use of these data to predict SFC of selected ternary fat blends containing low-erucic rapeseed oil. J. Am. Oil Chem. Soc. 83(7), 571–581 (2006)

Acknowledgments

This research was financially supported by Sari Agricultural and Natural Resources University (Project no. 02-1392-08). Special thanks to Mr Ahmad Motaharri (the chief manager of the Faravard edible oil Co., Fariman, Iran) for his supports during this study. Dr. Rahmat Abbasi of the Sari Agricultural and Natural Resources University is thanked for his assistance in model construction.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farmani, J. Modeling of solid fat content of chemically interesterified fully hydrogenated soybean oil and canola oil blends as a function of temperature and saturated fatty acids. Food Measure 9, 281–289 (2015). https://doi.org/10.1007/s11694-015-9233-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-015-9233-8