Abstract

A voltammetric study of norepinephrine (NE) in the presence of paracetamol (PA) was carried out using a poly (rhodamine B)-modified carbon paste electrode (CPE). The poly (rhodamine B) electrode was fabricated by potential cyclic voltammetry using a rhodamine B monomer. The modified electrode exhibited a good affirmative response towards the electrooxidation of NE and PA in physiological pH 7.4 phosphate buffer solution (PBS). The influence of sweep rates and pH (6.2 to 7.8) was studied. The simultaneous electroanalysis of NE and PA and the interference study were investigated by CV and DPV. The modified electrode showed good selectivity and sensitivity with a detection limit of NE of 1.8 μM and PA of 2.2 μM. The real sample analysis of the proposed method is studied by determining the NE in the injection sample and PA in a commercial tablet sample with good recovery results obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrochemical determination of biomolecules has been intensively studied over the past two decades. Among the family of catecholamines, norepinephrine (NE) is a kind of catecholamine neurotransmitter that mediates chemical communication in the central nerves system. It acts as a dual character of neurotransmitter as a stress hormone and fulfils many significant physiological functions. Decrease in the concentration level of NE may lead to the incidence of some neurological disorders such as Parkinson disease, paraganglioma, ganglion neurons, and ganglia neuroblastoma, respectively [1]. Recent reports have indicated that NE enhances adhesion of human immunodeficiency virus-1-infected leukocytes to cardiac microvascular endothelial cells and also accelerates HIV replication via protein kinase [2, 3]. In view of this, it is essential to develop sensitive, fast, and accurate methods for the investigation of trace of NE which is of great importance to diagnostic information for the above mentioned disorder. Generally, the determination of NE is carried out by different methods, including spectrophotometry, capillary electrophoresis, and high-performance liquid chromatography which have been employed to the investigation of NE. Because NE is an electroactive compound, its electrochemical detection has been the focus of research for electroanalytical researchers and neurochemists and some modified electrodes have been used to determine NE [4,5,6,7,8,9,10].

In addition, drug investigation plays an important role in the quality control of drug formulation which has great impact on public health. Paracetamol is a well-known drug and extensively used as a pain reliever (analgesic) and fever reducer (antipyretics) [11, 12]. It is a weak acid with a pKa value of 9.5. Paracetamol quickly gets adsorbed and circulated after oral administration and is easily eliminated in the urine in normal therapeutic dose. However, overdose of PA accumulates toxic metabolites that cause damages to the kidney and liver. In general, paracetamol does not show any harmful side effects on human health [13]. So far, many analytical techniques have been used for the investigation of PA such as spectrophotometry [14], high-performance liquid chromatography [15], electrophoresis [16], and flow injection [17]. The above methods have some drawbacks with several disadvantages like high cast, long analysis time, and requirement of sample preparation. Comparatively, electrochemical techniques are convenient, are reliable, have less time consumption, and are the cheapest [18]. PA administration is known to increase brain serotonin (5-HT) levels as a result of liver tryptophan-2,3-dioxygenase (TDO) inhibition, and 5-HT is known to play a role in NE release in the brain [3, 10]. Therefore, simultaneous determination of NE and PA is very essential. Moreover, oxidation peaks of NE and PA are similar potentials at the bare CPE. This results in overlap and fouling during the investigation of these compounds. Therefore, fabrication of an economically viable electrochemical sensor with simultaneous determination of NE and PA (Scheme 1a) with higher selectivity, stability, and sensitivity is still one of the challenging tasks for electrochemists. However, the shape of the peak and the electrochemical reaction are not good for conventional electrodes. Therefore, to solve this problem, a number of modified electrodes have been used for the investigation of NE and PA [19, 20]. Some forms of carbon and conducting polymers are the most accepted materials that are used as modified electrodes. This is mainly because of their electrochemical stability and relatively high resistance against electrode fouling in physiological environments.

Sensing-based electrochemical methods on conductive polymers are of great importance in the cutting edge field due to their distinctive properties of simple functionality and biocompatibility. In several fields, conducting polymers have emerged as one of the interesting materials and have an expensive potential application for electrochemical sensors which covers biosensors and chemical sensors. Mainly in the area of biosensors, the covalent bond formation with biomolecules is used perfectly to get stable and more sensitive sensor methods. There are few proposed methods using conductive polymers as they contain active groups like –COOH and –NH2 groups to detect various biomolecules, DNA, and heavy metal ions [21,22,23]. Shim et al. and their recent review clearly discussed the importance of some conducting polymers and applications [24,25,26]. By using electropolymerization techniques, the electropolymer films coated with dyes have attracted extensive attention in the investigation of analytes because of their advantages like fast electron transfer, large surface area, high sensitivity, selectivity, good stability, homogeneity, and strong adsorption. Rhodamine B is a triphenylmethane dye and also belongs to a family of fluorone dyes which are used extensively in biotechnology applications such as fluorescence microscopy flow cytometry fluorescence correlation spectroscopy ELISA. Recently, electropolymerization of rhodamine B-based polymer films is reported as redox mediators for developing electrochemical sensors [27,28,29].

In the present work, the focus is on the poly (rhodamine B) layer that was fabricated on the CPE surface by using cyclic voltammetry. These modified electrodes displayed improved selectivity and sensitivity for the investigation of NE and PA. The poly (rhodamine B)-modified CPE offers several distinct advantages including high electron transfer, rate constant, and low detection limit. The electrocatalytic activities of NE and PA were disscussed in detail. The electrochemical sensing interference exhibits good performance towards the determination of NE and PA,which is of great significance in the chemical and biological fields. The practical application of the current method was confirmed by investigation of the concentration of NE in injection samples and PA in commercial tablets.

Experimental part

Materials and methods

An electrochemical experiment was conducted on a CH660c electrochemical work station (CH Instrument). The cyclic and differential voltammetric measurement was performed in a standard three-electrode cell system. The bare carbon paste electrode or carbon paste electrode was modified with rhodamine B and was used as a working electrode. The platinum wire and saturated calomel electrode were used as counter and reference electrodes, respectively. Oxidation potentials of all the analytes were recorded versus SCE at an ambient temperature of 25 °C.

Chemicals and reagents

Norepinephrine (NE) was purchased from Himedia (molecular weight = 169.2, purity 99%), Paracetamol (PA) was purchased from Himedia (molecular weight = 151.64, purity 99%), and rhodamine B was collected from Sigma-Aldrich (molecular weight = 479.02, 90% dye content). The graphite fine powder (particle size 50 mm) was collected from Lobo Chemie and silicon oil from Himedia, and they were used to prepare the modified electrode. The stock solution of NE (25 × 10−4 M) was prepared in 0.1 M perchloric acid (HClO4), and PA (25 × 10−4 M) and rhodamine B (25 × 10−4 M) were prepared in double-distilled water. Different pH’s of PBS were produced as per literature with 0.2 M NaH2PO4 and 0.2 M Na2HPO4 solution with double-distilled water. The above mentioned chemicals were of analytical grade and no needed further purification. All the experiments were performed at an ambient temperature.

Results and discussion

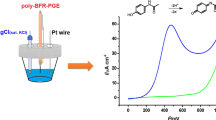

Fabrication of poly (rhodamine B)-modified CPE

The carbon paste electrode was fabricated according to our previous report [30]. The poly (rhodamine B) modified carbon paste electrode (MCPE) was successfully fabricated by electropolymerization of 1 mM aqueous rhodamine B monomer containing 0.1 M NaOH as supporting electrolyte. As shown in Fig. 1 (A), an anodic peak was observed at the first cycle which is corresponding to the oxidation of the rhodamine B monomer. The continuous electrochemical polymerization for the cyclic voltammograms of poly (rhodamine B) in the potential cycles is between − 0.4 and 1.2 V at a sweep rate of 100 mV/s for 20 successive cycles. During the process of multiple cycles, the voltammogram has decreased gradually with further increase in potential cycling. The phenomenon implies that the poly (rhodamine B) membrane was formed and deposited on the surface of the CPE by an electropolymerization process [31]. After completion of the electropolymerization, the obtained modified electrode was dipped in demineralized water to eliminate the physically adsorbed material. The structure of rhodamine B is presented in Scheme 1b.

Based on the above observation, the polymer thickness of the film shows a significant effect on the electrochemical response of poly (rhodamine B)-modified CPE. The film thickness can be effectively controlled by changing the number of cycles (from 5 to 30 multiple cycles) during the polymerization process. The effect of thickness, determined by the number of electropolymerization sweeps, was studied on the response of NE (0.1 mM) in physiological pH (7.4) PBS. The graph of Ipa versus number of cycles was plotted from 5 to 20 cycles; Ipa increased linearly. Hence, at 20 cycles, the current response was maximum and after that it gradually decreases by increasing the number of cycles as shown in the inset in Fig. 1 (B). However, after 20 cycles, the poly (rhodamine B) monomer covers the electrode surface completely and did not show any significant change in the active area as well as the background current of voltammogram that slightly increases [32]. The maximum current signal for poly (rhodamine B) was observed at 20 cycles; thus, the same potential cycles were chosen as the optimum condition to prepare poly (rhodamine B)-modified CPE for subsequent experiments.

Characterization of bare CPE and poly (rhodamine B)-modified CPE

Figure 2 illustrates the electrochemical response from freshly prepared potassium ferrocyanide at unmodified CPE (dashed) and poly (rhodamine B)-modified CPE in 1 M KCL as supporting electrolyte at a sweep rate of 50 mV/s. The redox peaks were observed due to the Fe+2/Fe+3 for bare CPE and poly (rhodamine B)-modified CPE. The peak-to-peak separation (ΔEp) at the developed electrode was significantly condensed to 53 mV than at unmodified CPE (110 mV). The result indicated that the surface property of modified CPE was drastically changed as well as the outcome at poly (rhodamine B)-modified CPE. The total active surface area was calculated by our previous reports [30] and found to be of higher value for poly (rhodamine B)-modified CPE (0.046 cm2) compared with unmodified CPE (0.0291 cm2).

Scanning electron microscope (SEM) images were used to study the electrode surface (Fig. 3). The SEM image of unmodified CPE shows the irregularly shaped micrometer-sized flakes of graphite. However, the poly (rhodamine B) film-coated carbon paste electrode has the typical uniform arrangement of poly (rhodamine B) molecules on the surface of the carbon paste electrode. This confirms that the carbon paste electrode was coated with the poly (rhodamine B) film [33]. The proposed equation (1) was given to estimate the surface coverage concentration [32].

Here, Γ (M/cm2) is the surface coverage concentration, υ is the scan rate, A is the geometric surface area of the electrode, n is the number of electrons involved in the reaction, and R, F, and T have their scientific significance. The surface concentration of poly (rhodamine B) was determined to be 0.073 × 10−10 M/cm2.

Electrochemical analysis of NE and PA at poly (rhodamine B) MCPE

The electrochemical behavior of NE (0.1 mM) in physiological pH (7.4) PBS, with the sweep rate of 50 mV/s at bare CPE and poly (rhodamine B)-modified CPE, is illustrated in Fig. 4a. In bare CPE, NE shows that the oxidation peak current response was less sensible and low in current signal. The oxidation peak potential appeared at 192 mV. At the same time, poly (rhodamine B)-modified CPE showed that the oxidation peak current was significantly enhanced when compared to bare CPE and the oxidation peak potential which appeared at 162 mV. This reduces the overpotential and enhancement in peak currents, which reveals the electrocatalytic activity of poly (rhodamine B)-modified CPE towards the electrochemical oxidation of NE. Figure 4b illustrates the CVs of PA (0.1 mM) in physiological pH (7.4) PBS, with a sweep rate of 50 mV/s using bare CPE and poly (rhodamine B)-modified CPE. On the bare CPE (dashed line), PA shows an irreversible behavior with relatively weak redox peak current and high potential difference. However, poly (rhodamine B)-modified CPE shows strong improvement of the well-defined redox peak current with Epa and Epc at 332 and 222 mV, respectively. This better activity is mainly due to the poly (rhodamine B)-modified CPE that accelerates the electrochemical reaction, and the peak potential difference of PA becomes lower than that on the bare CPE and the oxidation peak shifts slightly towards the negative side. It is clear that this polymer film-coated electrode shows very good electrocatalytic activity by reducing the overpotential and also by improving the current signal.

a CVs of 0.1 mM NE in 0.2 M PBS solution of pH 7.4 at bare CPE (dashed line) and poly (rhodamine B)-modified CPE (solid line) at a sweep rate of 50 mV/s. b CVs of 0.1 mM PA in 0.2 M PBS solution of pH 7.4 at bare CPE (dashed line) and poly (rhodamine B)-modified CPE (solid line) at a sweep rate of 50 mV/s

The sweep rate effect on the peak current of NE and PA

The sweep rate effect of NE (0.1 mM) at the surface of poly (rhodamine B)-modified CPE in physiological pH (7.4) PBS was studied in the range of from 50 to 400 mV/s in order to investigate whether the redox behavior of NE on the modified CPE was either adsorption or diffusion controlled. Figure 5 (A) depicts that the CVs of NE at different sweep rates show an increase in the redox peak current with increases in the sweep rate; the plot of Ipa versus sweep rate (υ) (inset, Fig. 5 (B)) and log of Ipa versus log of sweep rate (V/s) (inset, Fig. 5 (C)) exhibit good linearity, and the linear regression equations for both graphs were found to be Ipa (μA) = 0.0149 υ(mV/s) + 1.112 (μA) (R2 = 0.9988) and log Ipa (μA) = 0.626 log υ(V/s) + 1.068 (μA) (R2 = 0.9848). The slope (0.626) obtained from the graph of the log sweep rate (υ) versus the log of the anodic peak current (log Ipa) is closer to the theoretically obtained value of 0.5 for a diffusion-controlled elctrode process [34]. Similarly, the effect of the sweep rate for PA was studied by CV at poly (rhodamine B)-modified CPE. Poly (rhodamine B)-modified CPE showed an increase in the redox peak current with an increase in sweep rates, over the range from 50 to 400 mV/s as shown in Fig. 5 (D). In order to investigate the nature of the electrode process, the plot of Ipa versus the sweep rate (υ) (inset, Fig. 5 (E)) and log of Ipa versus log of sweep rate (V/s) (inset, Fig. 5 (F)) exhibit good linearity, and the linear regression equations for the graphs were found to be as follows: Ipa (μA) = 0.049 υ(mV/s) + 6.993 (μA) (R2 = 0.9961) and log Ipa (μA) = 0.534 log υ(V/s) + 1.617 (μA) (R2 = 0.9989). The slope from the graph of the log sweep rate (υ) versus the log of the anodic peak current (log Ipa) is 0.534 which is closer to the theoretically obtained value of 0.5 for the diffusion-controlled electrode process [34]. From Fig. 5, the obtained ∆Ep values were used to find the heterogeneous rate constant (k°) using Eq. (2) and was a valid approximation of such a curve intended for ∆Ep ˃ 10 mV; the k° values for NE and PA oxidation were obtained and recorded in Table 1 with a range of 50–400 mV/s.

A CVs of 0.1 mM NE in 0.2 M PBS solution of pH 7.4 at poly (rhodamine B)-modified CPE at different sweep rates. (a–h, 50 to 400 mV/s). Inset, B, graph of the anodic peak current versus sweep rate. Inset, C, graph of the log of the anodic peak current versus log of sweep rate. D CVs of 0.1 mM PA in 0.2 M PBS solution of pH 7.4 at poly (rhodamine B)-modified CPE at different sweep rates. (a–h, 50 to 400 mV/s). Inset, E, graph of the anodic peak current versus sweep rate. Inset, F, graph of log of the anodic peak current versus log of sweep rate

Concentration effect of NE and PA at poly (rhodamine B) MCPE

In order to express, the NE detection with the prepared poly (rhodamine B)-modified CPE, the electrochemical response of the modified electrode at different concentrations of NE was examined in physiological pH (7.4) PBS at the sweep rate of 50 mV/s. Figure 6 (A) shows the CVs of various concentrations (20 to 90 μM) of NE at poly (rhodamine B)-modified CPE. From the observation, Ipa and Ipc increase with the addition of NE from 20 to 90 μM. The inset graph in Fig. 6 (B) is the plot of Ipa versus the concentration of NE at poly (rhodamine B)-modified CPE and corresponding linear regression equations Ipa (μA) = 0.0273 (C0, μM/L) + 1.374, and their correlation co-efficient was found to be 0.9991. The limit of detection (LOD) and limit of quantification (LOQ) calculated in the lower concentration range for NE were found to be 1.8 and 6.1 μM, respectively. At the same time, the electrochemical response of poly (rhodamine B)-modified CPE at different concentrations of PA was examined in physiological pH (7.4) at the sweep rate of 50 mV/s. Figure 6 (C) illustrates CVs of various concentrations of PA (20 to 90 μM). There was a dramatic enhancement of Ipa. The graph of Ipa versus concentrations of PA was plotted (inset, Fig. 6 (D)). Ipa was propositional to the concentration of PA, but a better linearity occurred in the range 20 to 90 μM and the linear regression equation can be written as Ipa (μA) = 0.0345 (C0, μM/L) + 1.252 (R2 = 0.9979). The limit of detection for PA in the lower concentration range was 2.2 μM, and the quantification limit was 7.4 μM. The limit of detection (LOD) and limit of quantification (LOQ) was calculated by using Formulas (3) and (4), respectively [30]. Here, M is the slope of the calibration graph and S is the standard deviation. The comparison of the detection limit of poly (Rhodamine B)-modified CPE for NE and PA with other reported modified electrodes are presented in Tables 2 and 3 [35,36,37,38,39,40,41,42,43,44,45,46,47,48].

A CVs of NE in 0.2 M PBS solution of pH 7.4 at poly (rhodamine B)-modified CPE at a sweep rate of 50 mV/s with different concentrations (a–h, 20, 30, 40, 50, 60, 70, 80, and 90 μM). Inset, B, graph of the anodic peak current versus different concentrations of NE. C CVs of PA in 0.2 M PBS solution of pH 7.4 at poly (rhodamine B)-modified CPE at a sweep rate of 50 mV/s with different concentrations (a–h, 20, 30, 40, 50, 60, 70, 80, and 90 μM). Inset, D, graph of the anodic peak current versus different concentrations of PA

Effect of buffer of pH on NE and PA at poly (rhodamine B)-modified CPE

The effect of pH on the oxidation of NE (0.1 mM) at the sweep rate of 50 mV/s in poly (rhodamine B)-modified CPE was examined over a pH range of 6.2 to 7.8 (Fig. 7A). The Fig. 7B shows the graph of Epa versus the pH obtained from the voltammograms of NE recorded at different pH’s of phosphate buffer solution by the CV method. From the graph, the equation can be written as Epa (mV) = 0.625 − 0.061 (mV/pH), for poly (rhodamine B)-modified CPE. The graph illustrated linearity with a slope of 61 mV/pH, and the obtained slope value is almost following the Nernst equation for an equal number of electron and proton transfer reaction [49]. At the same time, the effect of solution of pH on the redox reaction of PA at the poly (rhodamine B)-modified CPE was investigated in the range of pH 6.2–7.8. The CVs of PA (0.1 mM) was recorded at 0.2 M PBS of different pH’s as shown in Fig. 7 (C). The plot of Epa versus pH of the supporting electrolyte (inset, Fig. 7 (D)) has shown that Epa linearly depends on the pH and a linear regression equation can be written as Epa (mV) = 48.50 (mV/pH) + 68.8 (R2 = 0.9911). This shows the uptake of an electron accompanied by an equal number of electron and proton transfer reaction [49].

A CVs of the poly (rhodamine B) MCPE in 0.2 M PBS solution containing 0.1 mM NE at different pH values (a–e, 6.2 to 7.8) at a sweep rate of 50 mV/s. Inset, B, Graph of the anodic peak potential versus different pH’s of NE. C CVs of the poly (rhodamine B) MCPE in 0.2 M PBS solution containing 0.1 mM PA at different pH values (a–e, 6.2 to 7.8) at a sweep rate of 50 mV/s. Inset, D, graph of the anodic peak potential versus different pH’s of PA

Simultaneous electroanalysis of NE and PA

The electrochemical behavior of NE and PA at the bare CPE and poly (rhodamine B)-modified CPE has been investigated. The corresponding CVs of NE and PA in physiological pH (7.4) PBS is shown in Fig. 8 (A). As seen, NE and PA showed a poor oxidation peak at the bare CPE (dashed line) with oxidation peak potentials appeared at 222 and 382 mV, respectively. A poly (rhodamine B)-modified CPE (solid line) shows two well-defined anodic peaks of NE and PA with anodic peak potentials that appeared at 154 and 320 mV, respectively. ∆Ep was found to be 166 mV, and this outcome was sufficient for the simultaneous investigation of NE and PA. The interference method was carried out in the samples containing both NE and PA in DPV experiments. This work was carried out by changing the concentration of NE and PA. The concentration of one species was varied, and the other remained constant. In the first step, the NE concentration was changed from 20 to 70 μM, while the concentration of PA was kept constant at 20 μM (Fig. 8 (B)). There was no change in the peak current and peak potential for PA. Similarly in the second step, the concentration of PA was increased from 20 to 70 μM when 20 μM NE was kept constant (inset, Fig. 8 (C)). However, PA does not have any effect on the peak potential and peak current. This result shows that NE and PA existed independently in their mixture of samples.

A CVs for simultaneous determination of 0.2 mM NE, 0.1 mM PA at bare CPE (dashed line), and poly (rhodamine B)-modified CPE (solid line) at a sweep rate of 50 mV/s. B DPVs of a 20 μM, b 30 μM, c 40 μM, d 50 μM, e 60 μM, and f 70 μM NE in 0.2 M PBS of pH 7.4 in the presence of 20 μM PA at poly (rhodamine B)-modified CPE and (dashed line) blank solution of PBS. Inset, C, DPVs of a 20 μM b 30 μM, c 40 μM, d 50 μM, e 60 μM, and f 70 μM PA in 0.2 M PBS of pH 7.4 in the presence of 20 μM NE at poly (rhodamine B)-modified CPE and (dashed line) blank solution of PBS

Analysis of real samples

The poly (rhodamine B)-modified CPE was used for the investigation of NE and PA in noradrenaline bitartrate injection and paracetamol tablets, respectively. The NE injection sample was purchased from Troikaa Pharmaceuticals Ltd., with the specified amount of NE, i.e., 2.0 mg/mL, and the injection sample was used after suitable dilution in 0.2 M PBS [50]. The obtained results are presented in Table 4. From the experimental results, the recovery result was obtained which was between 95.06 and 98.97%. This method shows promising results for NE in injection samples. Furthermore, a commercial tablet (Dolo 500, Micro Labs Limited [specified content of PA is 500 mg]) was used for the investigation of paracetamol. The obtained results are shown in Table 4. The recovery results showing the proposed methods could be efficiently used for the detection of PA in the commercial tablet with recovery in the range between 101.21 and 108.91%. All the experiments were carried out for three times using poly (rhodamine B)-modified CPE.

Conclusion

In the present work, the modified poly (rhodamine B) was used for the determination of NE and PA. The higher oxidation and reduction peak currents were observed at poly (rhodamine B)-modified CPE. The modified carbon paste electrode showed good sensitivity, selectivity, and electrocatalytic activity towards the oxidation of NE in the presence of PA. The detection limits of NE and PA were found to be 1.8 and 2.2 μM, respectively. The potential difference between NE and PA was 160 mV, and it was large enough to determine the NE and PA simultaneously. From these observations, poly (rhodamine B)-modified CPE could be used as a promising sensor probe for the simultaneous detection of NE and PA in various medically important samples.

References

Voet D, Voet JG (1995) Biochemistry, 2nd edn. Wiley, New York

Cole SW, Korin YD, Fahey JL, Zack JA (1998) Norepinephrine accelerates HIV replication via protein kinase A-dependent effects on cytokine production. J Immunol 161:610–616

Beitollahia H, Sheikhshoaie I (2011) Selective voltammetric determination of norepinephrine in the presence of acetaminophen and folic acid at a modified carbon nanotube paste electrode. J Electroanal Chem 661:336–342

Mazloum-Ardakani M, Ganjipour B, Beitollahi H, Amini MK, Mirkhalaf F, Naeimif H, Nejati-Barzokif M (2011) Simultaneous determination of levodopa, carbidopa and tryptophan using nanostructured electrochemical sensor based on novel hydroquinone and carbon nanotubes: application to the analysis of some real samples. Electrochim Acta 56:9113–9120

Beitollahi H, Tajik S, Biparva P (2014) Electrochemical determination of sulfite and phenol using a carbon paste electrode modified with ionic liquids and graphene nanosheets: application to determination of sulfite and phenol in real samples. Measurement 56:170–177

Beitollahi H, Taher MA, Ahmadipour M, Hosseinzadeh R (2014) Electrocatalytic determination of captopril using a modified carbon nanotube paste electrode: application to determination of captopril in pharmaceutical and biological samples. Measurement 47:770–776

Zahra T, Mohammad MA, Hossein N, Hadi Beitollahi MN, Hamid RZ (2008) Electrochemical behavior of ascorbic acid at a 2,2¢-[3,6-dioxa1,8 octanediylbis (nitriloethylidyne)]-bis-hydroquinone carbon paste electrode. Anal Sci 24:1039–1044

Karimi-Maleh H, Ensafi AA, Beitollahi H, Nasiri V, Khalilzadeh MA, Biparva P (2012) Electrocatalytic determination of sulfite using a modified carbon nanotubes paste electrode: application for determination of sulfite in real samples. Ionics 18:687–694

Beitollahi H, Gholami A, RezaGanjali M (2015) Preparation, characterization and electrochemical application of Ag–ZnO nanoplates for voltammetric determination of glutathione and tryptophan using modified carbon paste electrode. Mater Sci Eng C 57:107–112

Akhgar MR, Beitollahi H, Salari M, Karimi-Maleh H, Zamani H (2012) Fabrication of a sensor for simultaneous determination of norepinephrine, acetaminophen and tryptophan using a modified carbon nanotube paste electrode. Anal Methods 4:259–264

De Carvalho RM, Freire RS, Rath S, Kubota LT (2004) Effects of EDTA on signal stability during electrochemical detection of acetaminophen. J Pharm Biomed Anal 34:871–878

Parojcic J, Karljikovic-Rajic K, Ðuric Z, Jovanovic M, Ibric S (2003) Development of the second-order derivative UV spectrophotometric method for direct determination of paracetamol in urine intended for biopharmaceutical characterisation of drug products. Biopharm Drug Dispos 24:309–314

Yesilada A, Erdogan H, Ertan M (1991) Second derivative spectrophotometric determination of p-aminophenol in the presence of paracetamol. Anal Lett 24:129–138

Dalmasso PR, Pedano ML, Rivas GA (2012) Electrochemical determination of ascorbic acid and paracetamol in pharmaceutical formulations using a glassy carbon electrode modified with multi-wall carbon nanotubes dispersed in polyhistidine. Sens Actuators B: Chem 173:732–736

Özcan A, Sahin Y (2011) A novel approach for the determination of paracetamol based on the reduction of N-acetyl-p-benzoquinoneimine formed on the electrochemically treated pencil graphite electrode. Anal Chim Acta 685:9–14

Sirajuddin KAR, Shah A, Bhanger MI, Niaz A, Mahesar S (2007) Simpler spectrophotometric assay of paracetamol in tablets and urine samples. Spectrochim. Acta Part A 68:747–751

Guo JH, Harcum WW, Skinner GW, Dluzneski PR, Trumbull DE (2000) Validation of tablet dissolution method by high performance liquid chromatography. Drug Dev Ind Pharm 26:337–342

Jain AK, Gupta VK, Singh LP, Raisoni JR (2006) A comparative study of Pb 2+ selective sensors based on derivatized tetrapyrazole and calix [4] arene receptors. Electrochim Acta 51:2547–2553

Beitollahi H, Karimi-Maleh H, Khabazzadeh H (2008) Nanomolar and selective determination of epinephrine in the presence of norepinephrine using carbon paste electrode modified with carbon nanotubes and novel 2-(4-oxo-3-phenyl-3,4-dihydro-quinazolinyl)-N'-phenyl-hydrazinecarbothioamide. Anal Chem 80:9848–9851

Taheri AR, Mohadesi A, Afzali D, Karimi-Maleh H, Mahmoudi-Moghaddam H, Zamani H, Rezayati-Zad Z (2011) Simultaneous voltammetric determination of norepinephrine and folic acid at the surface of modified carbon nanotube paste electrode. Int J Electrochem Sci 6:171–180

Lee TY, Shim YB (2001) Direct DNA hybridization detection based on the oligonucleotide-functionalized conductive polymer. Anal Chem 73:5629–5632

Rahman MA, Won MS, Shim YB (2003) Characterization of an EDTA bonded conducting polymer modified electrode: its application for the simultaneous determination of heavy metal ions. Anal Chem 75:1123–1129

Won MS, Rahman MA, Kwon NH, Shankaran DR, Shim YB (2005) Square-wave voltammetric detection of dopamine at a copper-(3-mercaptopropyl) trimethoxy silane complex modified electrode. Electroanalysis17:2231–2238

Gurudatt NG, Naveen MH, Ban C, Shim YB (2016) Enhanced electrochemical sensing of leukemia cells using drug/lipid co-immobilized on the conducting polymer layer. Biosens Bioelectron 86:33–40

Naveen MH, Gurudatt NG, Noh HB, Shim YB (2016) De alloyed Au Ni dendrite anchored on a functionalized conducting polymer for improved catalytic oxygen reduction and hydrogen peroxide sensing in living cells. Adv Funct Mater 26:1590–1601

Naveen MH, Gurudatt NG, Shim YB (2017) Applications of conducting polymer composites to electrochemical sensors: a review. Appl. Mater. Today 9:419–433

Thomas T, Mascarenhas RJ, Kumara Swamy BE (2012) Poly (rhodamine B) modified carbon paste electrode for the selective detection of dopamine. J Mol Liq 174:70–75

Hayati F, Asiye AA, Sevda A, Reşat A (2015) Poly (rhodamine B) and MWCNTs composite film for the separation and simultaneous voltammetric quantification of tryptophan, paracetamol, uric acid, dopamine and ascorbic acid, Current Analytical Chemistry11: 87–95

Wang W, Leng J, Yu Y, Lu L, Bai L, Qiu X (2014) An electropolymerized rhodamine B sensing film-based electrochemical sensor for nitrite with high sensitivity and selectivity. Int J Electrochem Sci 9:921–930

Kuskur CM, Kumara Swamy BE, Jayadevappa H (2017) Poly (naphthol green B) modified carbon paste electrode sensor for catechol and hydroquinone. J Electro anal Chem 804:99–106

Hong Y, Yuanyuan S, Xinhua L, Yuhai T, Liying H (2007) Electrochemical characterization of poly (Erichrome Black T) modified glassy carbon electrode and its application to simultaneous determination of dopamine, ascorbic acid and uric acid. Electrochim Acta 52:6165–6167

Chitravathi S, Kumara Swamy BE, Mamatha GP, Sherigara BS (2011) Simultaneous electrochemical determination of dopamine and ascorbic acid using poly (L-serine) modified carbon paste electrode. J Mol Liq 160:193–199

Chandra U, Kumara Swamy BE, Gilbert O, Sherigara BS (2010) Voltammetric resolution of dopamine in the presence of ascorbic acid anduric acid at poly (calmagite) film coated carbon paste electrode. Electrochim Acta 55:7166–7174

Mahanthesha KR, Kumara Swamy BE, Pai KV (2014) Poly (alizarin) modified glassy carbon electrode for the electrochemical investigation of omeprazole: a voltammetric study. Anal. Bioanal. Electrochem 6:234–244

Beitollahi H, Mohadesi A, Mahani SK, Karimi-Maleh H, Akbari A (2012) New voltammetric strategy for simultaneous determination of norepinephrine, acetaminophen, and folic acid using a 5-amino-3′,4′-dimethoxy-biphenyl-2-ol/carbon nanotube paste electrode. Ionics 18:703–710

Zhang XH, Wang SF (2003) Voltammetric behavior of noradrenaline at 2-mercaptoethanol self-assembled monolayer modified gold electrode and its analytical application. Sensors 3:61–68

Wang Q, Li N (2001) Electrocatalytic response of norepinephrine at a thiolactic acid self-assembled gold electrode. Talanta 55:1219–1225

Chandrashekar BN, KumaraSwamy BE (2012) Simultaneous cyclic voltammetric determination of norepinephrine, ascorbic acid and uric acid using TX-100 modified carbon paste electrode. Anal Methods 4: 849–854

Wang J, Li M, Shi Z, Li N, Gu Z (2002) Electrocatalytic oxidation of norepinephrine at a glassy carbon electrode modified with single wall carbon nanotubes. Electroanalysis 14:225–230

Wei M, Li M, Li N, Gu Z, Duan X (2002) Electrocatalytic oxidation of norepinephrine at a reduced C60-[dimethyl-(β-cyclodextrin)]2 and Nafion chemically modified electrode. Electrochim Acta 47:2673–2678

Zhao H, Zhang Y, Yuan Z (2002) Electrochemical behavior of norepinephrine at poly (2,4,6-trimethylpyridine) modified glassy carbon electrode. Electroanalysis 14:445–448

Goyal RN, Singh SP (2006) Voltammetric determination of paracetamol at C-60-modified glassy carbon electrode. Electrochim Acta 51:3008–3012

Ensafi AA, Karimi-Maleh H, Mallakpour S, Hatami M (2011) Determination of N-acetylcysteine and acetaminophen by voltammetric method using N-(3, 4- dihydroxyphenethyl)-3, 5-dinitrobenzamide modified multiwall carbon nanotube paste electrode. Sensors Actuators B Chem 155:464–472

Pournaghi-Azar MH, Saadatirada A (2010) Determination of paracetamol, ascorbic acid and codeine by differential pulse voltammetry on the aluminum electrode modified by thin layer of palladium. Electroanalysis 22:1592–1598

Rodriguez MC, Rivas GA (2002) Glassy carbon paste electrodes modified with polyphenol oxidase analytical applications. Anal. Chim. Acta 459:43–51

Boopathi M, Won MS, Shim YB (2004) A sensor for acetaminophen in a blood medium using a Cu (II)-conducting polymer complex modified electrode. Anal Chim Acta 512:191–197

Kachoosangi RT, Wildgoose GG, Compton RG (2008) Sensitive adsorptive stripping voltammetric determination of paracetamol at multiwalled carbon nanotube modified basal plane pyrolytic graphite electrode. Anal Chim Acta 618:54–60

Wangfuengkanagul N, Chailapakul O (2002) Electrochemical analysis of acetaminophen using a boron-doped diamond thin film electrode applied to flow injection system. J Pharm Biomed Anal 28:841–847

Chandrashaker BN, Kumar Swamy BE, Pandurangachar M, Sathisha TV, Sherigara BS (2011) Electropolymerisation of l-arginine at carbon paste electrode and its application to the detection of dopamine, ascorbic and uric acid. Colloids Surf B 88:413–418

Mahanthesha KR, Kumara Swamy BE (2013) Pre-treated/carbon paste electrode based voltammetric sensors for the detection of dopamine in presence of ascorbic acid and uric acid. J Electroanal Chem 703:1–8

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuskur, C.M., Kumara Swamy, B.E., Jayadevappa, H. et al. Poly (rhodamine B) sensor for norepinephrine and paracetamol: a voltammetric study. Ionics 24, 3631–3640 (2018). https://doi.org/10.1007/s11581-018-2483-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-018-2483-9