Abstract

Novel mixed-matrix electrodialysis heterogeneous ion exchange membranes were fabricated using polyaniline (PANI)-co-graphene oxide (GO) functionalized composite nanoplates. The PANI-co-GO functionalized composite nanoplates were prepared by in situ chemical oxidative polymerization of aniline in the presence of GO nanoplates. The synthesized PANI/GO were characterized by Fourier transform infrared spectroscopy, X-ray diffraction, and scanning electron microscopy. The SEM images demonstrated that utilizing of PANI/GO in membrane matrix led to formation of membranes with a compact structure. Also, more uniform distribution was observed for the incorporated PANI/GO membrane compared to the embedded GO nanoplates ones. The surface hydrophilicity, water content, and ion exchange capacity were enhanced by utilizing PANI/GO composite nanoplates. The membrane potential, transport number, and selectivity were also enhanced in sodium and barium chloride ionic solutions in presence of functionalized nanoplates. The newly prepared membranes showed lower selectivity and transport number for barium ions compared to sodium ions. The sodium and barium flux were enhanced by using PANI/GO. Dialytic rate results showed that modified membranes in this study have good ability in lead ion removal from wastewater. The enhancement in lead flux was more than 50% for the modified membrane containing PANI/GO in comparison with pristine ones.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrodialysis (ED) is an electrically driven membrane technology with many industrial applications including desalination of seawater and brackish water [1, 2], acid/base reclamation from industrial waste water [3, 4], oily wastewater treatment [5], salt production [6, 7], and bromide and bromate removal from natural water [8], as well as manufacturing of chemical products [9]. The high water recovery and low requirements for operating ED, along with the long life time and strong chemical and mechanical stability of typical ion exchange membranes, all make ED a particularly appropriate alternative for application in water recovery and treatment [1]. The electrochemical properties of ion exchange membranes (IEMs) are critical, since they determine the applicability of ED or related processes for a given separation [10,11,12,13]. So, preparing IEMs with suitable physicochemical characteristics may allow for further chemical and waste treatment applications [12, 14,15,16,17]. Besides, demands for superior electrodialysis membranes are enhanced for separation of dangerous soluble pollutants in water, especially heavy metals. Variation of the type and density of functional groups, the selection of different polymeric matrices, polymer blending, alteration of crosslinking density, the use of various additives such as nanoparticles, and surface modification by plasma treatment are important methods to obtain IEMs with special characteristics [18,19,20,21,22,23,24].

Reported studies reveal that composite IEMs may have other enhanced physicochemical and separation properties compared to fully organic polymeric membranes [25, 26].

Nowadays, the use of carbon-based nanomaterials is an interesting option for the modification of polymeric membranes. First of all, carbon-based nanomaterials contain a high amount of functional groups. In addition, specific functional groups may provide novel functions for the substrate membrane. Among this, graphene and chemically modified graphenes (CMGs) as carbon nanomaterials have attracted great attention because of their high specific surface area, compatibility, noticeable electron conductivity, high mechanical strength, flexibility, and superior hydrophilicity [27,28,29,30]. Graphene oxide (GO) nanoplates are a chemically modified graphene type that has emerged as one of the most attractive nanofillers in polymeric membranes because of its potential in enhancing thermal, mechanical, electrical, and separation properties of membrane in different conditions [29, 30]. Furthermore, the use of conducting polymers in modification of nanomaterials combines the electrochemical properties of conducting polymers with superior properties of nanomaterials. Polyaniline (PANI) is a technologically important conducting polymer which has been shown a good affinity with ion-exchange membranes [14, 31,32,33]. It is an efficient approach for improving the stability and selectivity of ion exchange membranes in metal ion removal from wastewater [34,35,36,37,38].

Fabrication of a novel heterogeneous cation-exchange membrane with suitable physicochemical and separation properties for the application in electrodialysis process related to water recovery and treatment was the primary target of the current research. For the purpose, mixed-matrix electrodialysis heterogeneous ion exchange membranes were fabricated using PANI/GO functionalized composite nanoplates by solution casting techniques. The PANI/GO functionalized composite nanoplates were prepared by in situ chemical oxidative polymerization of aniline in the presence of GO nanoplates. No research was found by our literature survey pn the application of PANI/GO functionalized nanoplates into electrodialysis heterogeneous cation-exchange membranes, and the literature is silent on the characteristics and functionality of electrodialysis IEMs prepared using PANI/GO composite nanoplates.

The effect of PANI/GO functionalized nanoplates in the casting solution on the physicochemical and separation characteristics of homemade heterogeneous cation-exchange membranes was investigated. Also, sodium chloride (NaCl) and barium chloride (BaCl2) were used for membrane characterization. During the ion removal from solutions, scale formation on the membrane surface is a serious problem which affects the formation of bivalent hydroxide. So, it is beneficial to predict the behavior of the prepared membranes in mono and bivalent ionic solutions. Finally, electrodialysis experiments in a laboratory scale unit were also carried out to evaluate the electrodialytic performance of modified membranes in lead removal from waste water.

Materials and methods

Materials

Polyvinylchloride (PVC, grade S-7054, density 490 g/L, viscosity number 105 Cm3/g) supplied by Bandar Imam Petrochemical company (BIPC), Iran, was employed as a membrane base binder. Tetrahydrofuran (THF, molar mass 72.11 g/mol, density 0.89 g/cm3) was used as the solvent. Graphene oxide nanoplates (GO, nanoplates, 99.5 + %, 2–18 nm with 32 layers) were provided by US Research Nanomaterials, Inc., Houston, USA. A cation-exchange resin (ion exchanger Amberlyst15, strongly acidic cation exchanger, H+ from more than 1.7 meq/l) by Merck Inc., Darmstadt, Germany, was also employed in membrane preparation. Aniline (from Merck, MW = 93.13 g mol−1) and HCl (MW = 36.46 g mol−1 and density = 1.19 kg L−1) manufactured by MOJALLALI, Inc., Iran, and ammonium persulfate (MW = 228.2 g mol−1) from Merck Inc., Darmstadt, Germany, were used for the preparation of polyaniline. All other chemicals were supplied by Merck. Throughout the experiments, distilled water was used. The chemical structure of all employed materials is shown in Table 1.

Preparation and characterization of PANI/GO nanoplates

The PANI/GO nanoplates were prepared by in situ chemical oxidative polymerization of aniline in the presence of GO nanoplates. According to this method, a certain amount of GO nanoplates (mass ratio of GO to aniline monomer was 1:2) was added to 50 ml of 0.1 M HCl solution containing 3 ml of distilled aniline monomer and sonicated for 15 min. For an efficient dispersion of the mixture, it was mechanically stirred. The reaction initiator, ammonium persulfate (APS) (6 g of APS in 50 ml of 0.1 M HCl solution), was added dropwise to the suspension to initiate the polymerization of aniline under constant stirring in an ice bath. After 60 min, the color of the suspension was turned to dark green, indicating the completion of the polymerization reaction. The product was obtained by filtering the solution, followed by washing in deionized water and drying in a vacuum oven for 48 h at 40 °C [36].

The FTIR spectroscopy (Galaxy series 5000, KBr disc, ambient temperature), X-ray diffraction (XRD, model X’Pert Pw 3373, kα = 1.54 A°, Philips, Holland), and scanning electron microscopy (SEM, Philips-X130 and Cambridge SEM) were used to characterize the synthesized PANI/GO functionalized nanoplates.

Fabrication of homemade membranes

Heterogeneous cation-exchange membranes were prepared by solution casting. The steps for membrane preparation and the composition of casting solution are given in Tables 2 and 3, respectively. As mentioned in Table 2 (Step 4), for better dispersion of the particles and breaking up of their aggregates during membrane fabrication, the solution was sonicated for 1 h using an ultrasonic instrument. This improves the relaxation of polymer chains as well as their conformation with particle surfaces and promotes the compatibility of particles and polymer binder [18].

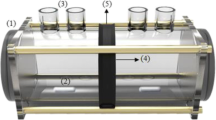

Experimental test cell

A test cell was applied in order to assess the membranes’ electrochemical properties. The cell consists of two cylindrical compartments (each 180 cm3) made of Pyrex glass; the sample membrane disk is fixed between two rubber rings and separates two cylindrical compartments. The ends of each compartment were equipped with Pt electrodes supported by pieces of Teflon. In order to minimize the boundary layer effect and concentration polarization in the vicinity of the membrane during the experiments, both sections were stirred vigorously by magnetic stirrers.

Membrane characterization

Scanning electron microscopy

Because the behavior of the prepared membranes is closely related to their structure, especially the spatial distribution of particles in the membrane matrix [19, 25], the structures of the prepared membranes were examined by scanning electron microscopy (SEM, Philips-X130 and Cambridge SEM).

Fourier transform infrared spectra of prepared membrane

For obtaining information about the chemical structure of the prepared membranes, dried membrane samples were analyzed by utilizing a single-beam Fourier transform infrared spectrometer (Galaxy series 5000). Scans were obtained in the spectral range of 4000–200 cm−1.

Membrane surface hydrophilicity/water contact angle

The hydrophobic or hydrophilic nature of a membrane is a determining factor for the interaction between membrane and solutes and between membrane and solvents [39]. In this work, the effect of PANI/GO nanoplates on the surface hydrophilicity of the prepared membranes was determined by contact angle measurements. The measurements were accomplished at ambient temperature using the water drop method on a dry membrane. To minimize the experimental error, the contact angle was measured in five random locations for each sample and then their average was reported.

Water uptake

In the first step, the surface moisture of membrane samples (equilibrated in water at ambient temperature) was mopped using filter papers, then the wet membranes were weighed (OHAUS, Pioneer™, readability 10−4 g, OHAUS Crop., USA). In the second step, the wet membranes were dried in an oven at 70 °C (Behdad Co., Model: O5, Iran) until a constant weight was obtained. Water uptake is calculated by the following eq. [20, 25, 40]:

where Wwet and Wdry represent the weight of the wet and dry membrane, respectively. Measurements were carried out three times for each membrane; the average value was reported in order to minimize the experimental error.

Ion exchange capacity (IEC)

The IEC determination was performed using titration method [40]. For this purpose, the membrane washed with demineralized water is equilibrated in 1.0 M NaCl solution for 24 h at ambient temperature to liberate H+ ions. After that, the concentration of liberated H+ ionic groups was estimated by titration with 0.01 M NaOH using phenolphthalein as indicator. The IEC was calculated from the following eq. [41, 42]:

where a is the milli-equivalent of the ion exchange group in the membrane and Wdry is the weight of the dry membrane (g).

Membrane potential, transport number and permselectivity

The membrane potential is the algebraic sum of Donnan and diffusion potentials determined by the partition of ions into the pores as well as the mobilities of ions within the membrane phase compared with the external phase [20, 42,43,44]. This parameter was evaluated for the equilibrated membrane with unequal concentrations of electrolyte solution (C1 = 0.1 M, C2 = 0.01 M at ambient temperature) on either side of the membrane. During the experiment, vigorous stirring of two sections minimized the effect of boundary layers on the measurement. The diffusion potential across the membrane was measured with two calomel reference electrodes and a voltmeter. The membrane potential (E Measure ) is expressed using the Nernst eq. [41, 43,44,45,46,47] as follows:

where t i m is the transport number of counter ions in membrane phase, R is the universal gas constant, T is the temperature (K), n is electrovalence of counter-ion, and a 1 and a 2 are the solution electrolyte activities in contact with surfaces determined by Debye-Hückel limiting law [48].

The ionic permselectivity of membranes (P s ) is also quantitatively expressed based on the migration of counter-ions through the IEMs [15, 20, 43, 45,46,47].

where t 0 is the transport number of counter ions in solution [49].

Ion permeability and flux

The ionic permeability and flux of ion measurements were carried out using the test cell. A 0.1 M (NaCl/BaCl2) solution was placed on one side of the cell (Anodic section) and a 0.01 M solution on the other side. A DC electrical potential (Dazheng, Dc power supply, Model: PS-302D) with an optimal constant voltage was applied across the cell with stable platinum electrodes. The migration of cations through the membrane to the cathodic section occurs during this experiment. The number of produced hydroxide ions in the cathodic section can be used to estimate the transported cations through the membrane. The permeation of ions through the membrane phase can be calculated based on the pH changes in the cathodic region.

According to Fick’s law, the flux of ions through the membrane can be expressed as follows [41, 46]:

where D is the diffusion coefficient of a given ion, d is the membrane thickness, N is the ionic flux, and C is the cation concentration in the compartments.

where A is the membrane surface area and V 0 is the volume of each compartment in the used test cell.

The diffusion coefficient of cations in the membrane phase is calculated from Eq. (8) considering pH changes (Digital pH-meter, Jenway, Model 3510, UK) in the cathodic region.

Electrodialysis experiments for lead removal from water

To investigate the performance of the prepared membranes in Pb2+ ion separation from water, electrodialysis experiments were carried out in a laboratory-scale unit containing a lab-made cation-exchange membrane and a commercial anion-exchange membrane. A commercial heterogeneous anion-exchange membrane (RALEX® AMH-PES), made by MEGA a.s., Czech Republic, was used in this study. The treated solution was analyzed by atomic emission spectroscopy (ICP-OES simultaneous, VISTA-PRO).

Results and discussion

Characterization of PANI/GO functionalized composite nanoplates

FTIR analysis, X-ray diffraction, and SEM were utilized to prove the formation of PANI on GO nanoplates. The FTIR analysis of GO and PANI/GO composite nanoplates are shown in Fig. 1a. The FTIR spectrum analysis indicates that the PANI polymerization occurred decisively in composite nanoplate science strong peaks at 1494 (N-B-N), 1580 (N-Q-N), 1300 (QBB, QBQ), and 1145, 1260 cm−1 (C-N) were presented which are assigned to PANI formation. This is not visible for GO nanoplates. Moreover, the FTIR results for unmodified membrane and modified ones containing PANI/GO (Fig. 1b) confirms the incorporation of PANI/GO in the matrix of homemade membrane decisively [36].

The XRD patterns of PANI/GO functionalized composite nanoplates are given in Fig. 2. In this diffraction pattern, the sharp peaks at 2Ө = 20.43 and 2Ө = 22.82 are shown which are assigned to PANI. Also, the peak at 2Ө = 10.16 is referred to as GO nanoplates [50]. The results indicate a crystalline structure for the prepared composite nanoparticles.

The SEM images of the synthesized PANI/GO functionalized composite nanoplates are exhibited in Fig. 3. The PANI and GO nanoplates are clearly seen in the images. Also, images show a uniform distribution of PANI on the surface of GO nanoplates relatively. The homogeneity and uniform distribution of PANI on the surface of GO provide more conducting regions for the composite nanoparticles which improves the electrochemical properties of them.

Characterization of homemade membranes

Morphological study

The SEM images of the unmodified/pristine membrane and modified membrane containing PANI/GO composite nanoplates are shown in Fig. 4. The polymer binder, resin particles, and PANI/GO composite nanoplates are seen in the images. As shown in SEM images, the use of PANI/GO in the membrane matrix caused the formation of a more compact structure for the modified membrane. In addition, the distribution pattern of the mixed-matrix membrane containing GO nanoplates and the modified membrane containing the PANI/GO composite nanoplates were compared using surface SEM and scanning optical microscopy images; Fig. 5 shows that the membrane containing PANI/GO composite nanoplates has a more uniform distribution compared to the GO-embedded ones. This is assigned to PANI formation on the surface of GO nanoplates which decrease the possibility of agglomeration of nanoplates by their exclusion.

Physicochemical and electrochemical properties

The obtained results (Table 4) showed that increase of PANI/GO concentration in the membrane matrix caused to decrease the water contact angle for the prepared membranes. This may be attributed to the hydrophilic nature of PANI/GO nanoplates which produces a more hydrophilic surface for the modified membranes. Moreover, migration of PANI/GO composite nanoplates to the surface of the membrane due to their low density during the fabrication process could be another reason for the decrease of contact angle by declining in surface roughness.

The increase of PANI/GO composite nanoplate loading ratio up to 4 wt% in the membrane matrix initially led to the increase of water content for the homemade membranes (Fig. 6). This may be due to the hydrophilic property of functionalized nanoplates which enhances the amount of water absorption in the prepared membrane. Furthermore, the increase of membrane heterogeneity by increase of PANI/GO concentration causes the creation of more voids and cavities in the membrane matrix which enhance the possibility of water molecule accommodation in the membrane body. The membrane water content was declined again by more increase of additive concentration from 4 to 16 wt%. This may be assigned to the pore-filling phenomenon at high additive concentration which produces a compact structure for the membrane and decreases the amount of water content.

The obtained results (Fig. 6) also revealed that increase of PANI/GO composite nanoplate concentration up to 4 wt% in the membrane matrix caused the improvement of the membrane ion exchange capacity from 1.2 to 1.35 meq/g. This is assigned to the adsorption property of PANI/GO functionalized nanoplates; the presence of a partial negative charge of N in polyaniline due to the lone pair of electrons and unreacted carboxylic groups of GO nanoplates which strengthen the ion exchange possibility between the solution and the membrane phase. The pore-filling phenomenon and the compact structure created by PANI/GO nanoplates at high additive loading ratios restrict the resin particles and cause the decrease of the membrane IEC again.

The membrane potential, transport number, and membrane permselectivity (Fig. 7a–c) all were improved initially by utilizing PANI/GO up to 4 wt% in the casting solution in sodium chloride and barium chloride ionic solutions. This may be affected by a variety of factors including (i) the presence of partial negative charge of nitrogen in polyaniline due to the lone pair of electrons and (ii) the high surface area to volume ratio of composite nanoplates, which is favorable for the diffusion of counter-ions from the solution onto the active sites on the surface of composite nanoplates in the membrane matrix, with superior interaction between the ions and the membrane surface. The membrane potential, transport number, and permselectivity were declined again by a further increase of the additive concentration. Some parts of the produced polymer are probably protonated; this positive charge of the charged polymer units (Q = NH+-B or B-NH+ -B) and resin particle isolation by additive nanoplates results in a decrease of membrane potential, transport number, and permselectivity.

Also, the prepared membranes exhibited lower potential, selectivity, and transport number for the bivalent ions in comparison with the monovalent ones. These lower electrochemical properties of membranes for bivalent ions compared to monovalent type can be explained by the stronger bonds of bivalent cations with ionic functional groups which decrease the functional group activity [19].

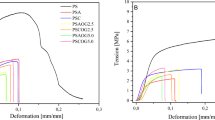

According to the observations, the increase of the PANI/GO nanoplate loading ratio up to 4%wt in the membrane matrix is associated with a higher sodium permeability and flux (Fig. 8a) in the prepared membranes. The enhanced sodium flux in the presence of PANI/GO may be ascribed to various factors including sodium adsorption on PANI/GO composite nanoplates, increase of membrane water content, and enhancement of IEC in the modified membranes. The abundance of functional groups of PANI/GO nanoplates reinforces the interaction of cations with the membrane surface and increment the ion transportation. In addition, the facilitation of ion transport between the solution and the membrane phase occurs as a result of the change in the hydrophilicity/wettability of the membrane surface in the presence of PANI/GO nanoplates, reducing the distance between the solution bulk and membrane surface. Moreover, the use of polyaniline as a conducting polymer in the prepared membranes leads to an enhancement of conducting regions in membranes, which in turn facilitates the ion transport. The pore-filling phenomenon and the compact structure created by the PANI/GO functionalized composite nanoplates at 8 wt% loading ratio cause a decrease of the sodium permeability/flux. The evident increase of sodium permeability/flux at high PANI/GO concentration (16 wt%) is assigned to the superior adsorptive behavior of the membrane at high PANI/GO content ratio which can be prevailed upon the negative effect of pore filling and the compact structure of the membrane and enhances the sodium flux/permeability.

Also, Fig. 8b shows that utilizing of PANI/GO composite nanoplates in the membrane matrix increases the barium permeability/flux, which is assigned to the unique adsorption capacity of PANI/GO functionalized composite nanoplates in bivalent ion adsorption. The electrostatic interaction of barium ions with PANI chains also enhances the ionic flux. This behavior indicates more affinity of PANI/GO functionalized composite nanoplates for barium ions (bivalent type) compared to sodium ions (monovalent type), which leads to an improvement of the barium permeability/flux compared to sodium ions.

Table 5 compares the electrochemical properties of the modified membrane containing 4%wt PANI/GO (superior membrane) with that of modified membrane containing 4%wt GO, pristine membrane, and some earlier reported studies. Results showed appropriate performance for the modified sample in this study containing 4%wt PANI/GO compared to others.

Table 6 also shows a comparison between the electrochemical properties of the prepared membranes in this study and some commercial membranes. The IEC, transport number, and selectivity results indicate that membranes in this study are comparable with commercial types.

The electrodialysis experiment was also utilized to study the ability of modified membranes in Pb2+ ion removal from waste water. The dialytic rate for the prepared membranes (sample 1: unmodified membrane and sample 5, sample 7: modified membranes) was investigated. The obtained results (Table 7) show that utilizing PANI/GO functionalized composite nanoplates in the membrane matrix causes an increase of dialytic rate for lead ion separation from the solution. This confirms that modified membranes have a high capacity for lead removal from water. This can be explained by the strong affinity of functionalized nanoplates for Pb2+ ions. Also, the current efficiency (C.E.) in lead ion removal from water was calculated using the following eq. [23, 24]:

where F is Faraday constant, Z i is the valance of ion, Δn is the transferred ion, I is the current intensity, and t is the time of experiment. Obtained results (Table 7) revealed that utilizing of PANI/GO composite nanoplates in membrane matrix caused to increase current efficiency.

Moreover, in order to study the reproducibility of the performance of mixed-matrix membranes, the used membranes were removed from the cell and washed by ultrasonic cleaner and kept in distilled water for 5 h. Consequently, their performance was estimated to evaluate the membrane reusability. Obtained results showed small decrease of the performance for the modified membranes containing PANI/GO (less than 4%). However, this slight decrease in flux shows the potential and strong adsorptive affinity of composite nanoplates toward bivalent ion attraction which makes difficult the release of lead ions presumably. Also, Table 8 shows the enhancement of flux (%) in Pb removal from water for the modified membranes in this study and some reported modified ones.

Conclusion

SEM images revealed that utilizing PANI/GO composite nanoplates in modification of membranes caused a more compact structure for the lab-made membranes. Moreover, PANI/GO nanoplates showed a more uniform distribution in comparison to GO nanoplates in the membrane matrix. The membrane IEC and membrane surface hydrophilicity were improved by using PANI/GO functionalized composite nanoplates in the membrane matrix. The increase of the concentration of PANI/GO nanoplates in the casting solution led to an increase of the water content in the membrane. In addition, in the presence of PANI/GO nanoplates, the membrane potential, transport number, and selectivity showed an increasing trend in sodium chloride and barium chloride solutions, while the membrane had a lower potential, selectivity, and transport number for bivalent ions in comparison with monovalent ions. Generally, the sodium and barium permeability/flux were improved by using PANI/GO composite nanoplates. Obtained results also show that utilizing of PANI/GO functionalized composite nanoplates in membrane matrix causes to increase of dialytic rate. The modified membranes containing PANI/GO functionalized composite nanoplates showed a good ability in removal of lead ions from wastewater.

References

Malek P, Ortiz JM, Schulte-Herbruggen HMA (2016) Decentralized desalination of brackish water using an electrodialysis system directly powered by wind energy. Desalination 377:54–64

Allioux F, He L, She F, Hodgson P, Kong L, Dumee L (2015) Investigation of hybrid ion-exchange membranes reinforced with non-woven metal meshes for electro-dialysis applications. Separation and Purification Technology 147:353–363

Bialek R, Mitko K, Dydo P, Turek M (2014) Electrodialytic separation of boric and hydrochloric acids. Desalination 342:29–34

Tran ATK, Mondal P, Lin J, Meesschaert B, Pinoy L, Van der Bruggen B (2015) Simultaneous regeneration of inorganic acid and base form a metal washing step wastewater by bipolar membrane electrodialysis after pretreatment by crystallization in a fluidized pellet reactor. J Membr Sci 473:118–127

Guo H, You F, Yu S, Li L, Zhao D (2015) Mechanisms of chemical cleaning of ion exchange membranes: a case study of plant-scale electrodialysis for oily wastewater treatment. J Membr Sci 496:310–317

Strathmann H (2004) Ion-exchange membrane separation processes. Elsevier

Xu T, Huang C (2008) Electrodialysis-based separation technologies: a critical review. AlChE Journal 54:3147–3159

Wisniewski JA, Kabsch-Korbutowicz M, Lakomska S (2014) Ion-exchange membrane processes for Br- and Bro3-ion removal from water and for recovery of salt from waste solution. Desalination 342:175–182

Strathmann H (2010) Electrodialysis, a mature technology with a multitude of new applications. Desalination 264:268–288

Mikhaylin S, Bazinet L (2016) Fouling on ion-exchange membranes: classification. Characterization and strategies of prevention and control, Advances in Colloid and Interface Science 229:34–56

Dlugolecki P, Anet B, Metz SJ, Nijmeijer K, Wessling M (2010) Transport limitations in ion exchange membranes at low salt concentrations. J Membr Sci 364:163–171

Elattar A, Elmidaoui A, Pismenskaia N, Gavach C, Pourcelly G (1998) Comparison of transport properties of monovalent anions through anion-exchange membranes. J Membr Sci 143:249–261

Shahi VK, Trivedi G, Thampy S, Rangarajan R (2003) Studies on the electrochemical and permeation characteristics of the asymmetric charged porous membranes. J Colloid Interface Sci 262:566–573

Nagarale RK, Gohil GS, Shahi VK, Trivedi GS, Rangarajan R (2004) Preparation and electrochemical characterization of cation- and anion- exchange/polyaniline composite membranes. J Colloid Interface Sci 277:162–171

Schauer J, Brozova L (2005) Heterogeneous ion-exchange membranes based on sulfonated poly (1,4-phenylene sulfide) and linear polyethylene: preparation, oxidation stability, methanol permeability and electrochemical properties. J Membr Sci 250:151–157

Baker RW (2004) Membrane technology and applications, 2nd edn. Wiley, England

Marder L, Navarro EMO, Herranz VP, Bernardes AM, Ferreira JZ (2006) Evaluation of transition metals transport properties through a cation-exchange membrane by chronopotentiometry. J Membr Sci 284:267–275

Hosseini SM, Gholami A, Koranian P, Nemati M, Madaeni SS, Moghadassi AR (2014) Electrochemical characterization of mixed matrix heterogeneous cation exchange membrane modified by aluminum oxide nanoparticles: mono/bivalent ionic transportation. J Taiwan Inst Chem Eng 45:1241–1248

Hosseini SM, Nemati M, Jeddi F, Salehi E, Khodabakhshi AR, Madaeni SS (2015) Fabrication of mixed matrix heterogeneous cation exchange membrane modified by titanium dioxide nanoparticle: mono/bivalent ionic transport property in desalination. Desalination 359:167–175

Hosseini SM, Madaeni SS, Khodabakhshi AR (2011) Preparation and characterization of heterogeneous cation exchange membranes based on S-polyvinylchloride and polycarbonate. Sep Sci Technol 46:794–808

Vatanpour V, Madaeni SS, Khataee AR, Salehi E, Zinadini S, Ahmadi Monfared H (2012) TiO2 embedded mixed matrix PES nanocomposite membranes: influence of different sizes and types of nanoparticles on antifouling and performance. Desalination 292:19–29

Hosseini SM, Madaeni SS, Khodabakhshi AR, Zendehnam A (2010) Preparation and surface modification of PVC/SBR heterogeneous cation exchange membrane with silver nanoparticles by plasma treatment. J Membr Sci 365:438–446

Hosseini SM, Madaeni SS, Khodabakhshi AR (2010) Preparation and characterization of ABS/HIPS heterogeneous cation exchange membranes with various blend ratios of polymer binder. J Membr Sci 351:178–188

Maximous N, Nakhla G, Wong K, Wan W (2010) Optimization of Al2O3/PES membranes for wastewater filtration. Sep Purif Technol 73:294–301

Hosseini SM, Madaeni S, Khodabakhshi A (2010) Preparation and characterization of PC/SBR heterogeneous cation exchange membrane filled with carbon nano-tube. J Membr Sci 362:550–559

Parvizian F, Hosseini SM, Hamidi AR, Madaeni SS, Moghadassi AR (2014) Electrochemical characterization of mixed matrix nanocomposite ion exchange membrane modified by ZnO nanoparticles at different electrolyte conditions pH/concentration. J Taiwan Inst Chem Eng 45:2878–2887

Safarpour M, Khataee A, Vatanpour V (2015) Thin film nanocomposite reverse osmosis membrane modified by reduced graphene oxide/TiO2 with improved desalination performance. J Membr Sci 489:43–54

Fan Z, Wang Z, Duan M, Wang J, Wang S (2008) Preparation and characterization of polyaniline/polysulfone nanocomposite ultrafiltration membrane. J Membr Sci 310:402–408

Xu W, Peng L, Li B, Xie Z, Tong C, Liu B (2016) Areal time S1 assay at neutral pH based on graphene oxide quenched fluorescence probe. Sensing and Bio-Sensing Research 7:42–47

Zinadini S, Zinatizadeh AA, Rahimi M, Vatanpour V, Zangeneh H (2014) Preparation of a novel antifouling mixed matrix PES membrane by embedding graphene oxide nanoplates. J Membr Sci 453:292–301

Amado FDR, Gondran E, Ferreira JZ, Rodrigues MAS, Ferreira CA (2004) Synthesis and characterization of high impact polystyrene/polyaniline composite membranes for electrodialysis. J Membr Sci 234:139–145

Scherer R, Bemardes AM, C-Forte MM, Ferreira JZ, Ferreira CA (2001) Preparation and physical characterization of a sulfonated poly(styrene-co-divinylbenzene) and polypyrrole composite membrane. Mater Chem Phys 71:131–138

Partridge AC, Milestone CB, Too CO, Wallace GG (1999) Polypyrrole based cation transport. J Membr Sci 152:61–68

Kumar M, Ali Khan M, AlOthman ZA, Siddiqui MR (2013) Polyaniline modified organic-inorganic hybrid cation-exchange membranes for the separation of monovalent and multivalent ions. Desalination 325:95–103

Mansour MS, Ossman ME, Farag HA (2011) Removal of Cd(II) ion from waste water by adsorption onto polyaniline coated on sawdust. Desalination 272:301–305

Daraei P, Madaeni SS, Ghaemi N, Salehi E, Khadivi MA, Moradian R, Astinchap B (2012) Novel polyethersulfone nanocomposite membrane prepared by PANI/Fe3O4 nanoparticles with enhanced performance for Cu(II) removal from water. J Membr Sci 415:250–259

Ai L, Jiang J (2011) Ultrasonic-assisted synthesis of polyaniline nanosticks, and heavy metal uptake performance. Material Letters 65:1215–1217

Khan AA, Paquiza L (2011) Characterization and ion-exchange behavior of thermally stable nano-composite polyaniline zirconium titanium phosphate: its analytical application in separation of toxic metals. Desalination 265:242–254

Suwal S, Doyen A, Bazinet L (2015) Characterization of protein, peptide and amino acid fouling on ion-exchange and filtration membranes: review of current and recently developed method. J Membr Sci 496:267–283

Hwang GJ, Ohya H, Nagai T (1999) Ion exchange membrane based on block copolymer, Part III: Preparation of cation exchange membrane. J Membr Sci 156:61–65

Li X, Wang Z, Lu H, Zhao C, Na H, Zhao C (2005) Electrochemical properties of sulphonated PEEK used for ion exchange membranes. J Membr Sci 254:147–155

Nagarale RK, Shahi VK, Schubert R, Rangarajan R, Mehnert R (2004) Development of urethane acrylate composite ion-exchange membranes and their electrochemical characterization. J Colloid Interface Sci 270:446–454

Nagarale RK, Shahi VK, Thampy SK, Rangarajan R (2004) Studies on electrochemical characterization of polycarbonate and polysulfone based heterogeneous cation exchange membranes. React Funct Polym 61:131–138

Barragaan VM, Bauza CR (1999) Membrane potentials and electrolyte permeation in a cation-exchange membrane. J Membr Sci 154:261–272

Gohil GS, Binsu VV, Shahi VK (2006) Preparation and characterization of monovalent ion selective polypyrrole composite ion-exchange membranes. J Membr Sci 280:210–218

Kerres J, Cui W, Disson R, Neubrand W (1998) Development and characterization of crosslinked ionomer membranes based upon sulfinated and sulfonated PSU crosslinked PSU blend membranes by disproportionation of sulfinic acid groups. J Membr Sci 139:211–225

Nagarale RK, Shahi VK, Rangarajan R (2005) Preparation of polyvinylalcohol-silica hybrid heterogeneous anion-exchange membranes by sol-gel method and their characterization. J Membr Sci 248:37–44

Hunter RJ (1966) Calculation of activity coefficient from Deby-Huckel theory. J Chem Educ 43:550–558

Lide DR (2006-2007) CRC handbook of chemistry and physics, 87th ed. CRC Press

Srinivas CH, Srinivasu D, Kavitha B, Narsimlu N, Sivakumar K (2012) Synthesis and characterization of nano size conducting polyaniline. J Appl Phys 1:12–15

Hosseini SM, Jashni E, Habibi M, Nemati M, Vander der Bruggen B (2017) Evaluating the ion transport characteristics of novel graphene oxide nanoplates entrapped mixed matrix cation exchange membranes in water deionization. J Membr Sci 541:641–652

Nemati M, Hosseini SM, Shabanian M (2017) Novel electrodialysis cation exchange membrane prepared by 2-acrylamido-2-methylpropane sulfonic acid; heavy metal ions removal. J Hazard Mater 337:90–104

Hosseini SM, Ahmadi Z, Nemati M, Parvizian F, Madaeni SS (2016) Electrodialysis heterogeneous ion exchange membranes modified by SiO2 nanoparticles: fabrication and electrochemical characterization. Water Science and Technology 73/9:2074–2084

Nemati M, Hosseini SM (2016) Fabrication and electrochemical property modification of mixed matrix heterogeneous cation exchange membranes filled with Fe3O4/PAA core-shell nanoparticles. Ionics 22:899–909

Hosseini SM, Rafiei S, Hamidi AR, Moghadassi AR, Madaeni SS (2014) Preparation and electrochemical characterization of mixed matrix heterogeneous cation exchange membranes filled with zeolite nanoparticles: ionic transport property in desalination. Desalination 351:138–144

Hosseini SM, Seidypoor A, Nemati M, Madaeni SS, Parvizian F, Salehi E (2016) Mixed matrix heterogeneous cation exchange membrane filled with clay nanoparticles: membranes’ fabrication and characterization in desalination process. Journal of Water Reuse and Desalination 6(2):290–300

Długołęcki P, Nymeijer K, Metz S, Wessling M (2008) Current status of ion exchange membranes for power generation from salinity gradients. J Membr Sci 319:214–222

Nagarale R, Gohil G, Shahi VK (2006) Recent developments on ion-exchange membranes and electro-membrane processes. Adv Colloid Interf Sci 119:97–130

Xu T (2005) Ion exchange membranes: state of their development and perspective. J Membr Sci 263:1–29

Hosseini SM, Askari M, Koranian P, Madaeni SS, Moghadassi AR (2014) Fabrication and electrochemical characterization of PVC based electrodialysis heterogeneous cation exchange membranes filled with Fe3O4 nanoparticles. J Ind Eng Chem 20:2510–2520

Acknowledgments

The authors gratefully acknowledge Arak University for the financial support during this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseini, S.M., Jashni, E., Habibi, M. et al. Fabrication of novel electrodialysis heterogeneous ion exchange membranes by incorporating PANI/GO functionalized composite nanoplates. Ionics 24, 1789–1801 (2018). https://doi.org/10.1007/s11581-017-2319-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2319-z