Abstract

This paper reports on preparation and characterization of thin films of a new zinc ion conducting blended polymer electrolyte system containing polyethylene oxide [PEO] and polypropylene glycol [PPG] complexed with zinc triflate [Zn(CF3SO3)2] salt. The room temperature ionic conductivity (σ 298K) data of such PEO-PPG polymer blends prepared by solution casting technique were found to be of the order of 10−5 S cm−1, whereas the optimized composition containing 90:10 wt% ratio of PEO and PPG possessed an appreciably high ionic conductivity of 7.5 × 10−5 S cm−1. Subsequently, six different weight percentages of zinc triflate viz., 2.5, 5, 7.5, 10, 12.5 and 15, respectively, were added into the above polymer blend and resulting polymer-salt complexes were characterized by means of various analytical tools. Interestingly, the best conducting specimen namely 87.5 wt% (PEO:PPG)-12.5 wt% Zn(CF3SO3)2 exhibited an enhanced room temperature ionic conductivity of 6.9 × 10−4 S cm−1 with an activation energy of 0.6 eV for ionic conduction. The present XRD results have indicated the occurrence of characteristic PEO peaks and effects of salt concentration on the observed intensity of these diffraction peaks. Appropriate values of degree of crystallinity for different samples were derived from both XRD and DSC analyses, while an examination of surface morphology of the blended polymer electrolyte system has revealed the formation of homogenous spherulites involving a rough surface and relevant zinc ionic transport number was found to be 0.59 at room temperature for the best conducting polymer electrolyte system thus developed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymer electrolytes have received an immense attention due to their wide range of applications in fuel cells, electrochemical devices and solid state batteries. Furthermore, these polymer electrolytes are well known for certain advantages they possess over conventional liquid electrolytes, some of which include their high flexibility, leak-proof nature, feasibility of miniaturization, lack of corrosion and mechanical strength [1–5]. However, such polymer electrolytes are not practically viable for direct utilization in high-energy power sources due to their low ionic conductivity values noticed at ambient temperatures [6].

In this context, polyethylene oxide (PEO), a semi-crystalline polymer, possessing both amorphous and crystalline phases at room temperature, is one of the extensively studied polymeric ionic conductors due to its capability to solvate elevated concentrations of salts through ion–dipole interactions occurring between metal ions incorporated and ether oxygen atoms existing within the polymeric network structure [7]. Though polyethylene oxide (PEO)-based polymer electrolytes exhibit ionic conduction, they do not yield high ionic conductivity values at ambient conditions due to the retardation of ionic transport imposed mainly by the existence of a highly crystalline phase [8]. The dynamics of polymer chain and local segmental motion prevalent in these electrolytes are in particular crucial for the feasibility of ion conduction mechanism. Therefore, in order to reduce the extent of crystallinity of PEO, a number of techniques such as addition of suitable plasticizers or polar solvents, blends, co-polymers, comb-branch polymers, cross-linked “networks”, etc. are universally preferred [9–11]. Furthermore, incorporation of inorganic fillers into the host polymer electrolyte is also an effective approach so as to improvise the mechanical stability and enhance ionic conductivity [12].

Interestingly, polymer blending is one of the easiest and successful means to reduce the degree of crystallinity of a host polymer and improve its electrical and structural features [13]. Usually, physical properties of such blends are very much dependent on their phase morphology, degree of mixing and type of interfacial interaction existing between two polymeric components [14, 15]. Many polymer blends exhibit properties that are more conducive than that of individual constituent polymers [16]. The addition of a polymer of lower molecular weight as a blend helps in increasing the local chain flexibility and segmental mobility of the host polymer and hence influences the observed ionic conductivity value too. Consequently, an apparent increase in the flexibility of a polymer chain decreases the glass transition temperature T g of a blended electrolyte system which in turn increases its ionic conductivity [17]. Moreover, dielectric constants of polymers also considerably influence the ionic conductivity of blended polymer electrolytes. Low ionic conductivity value is usually ascribed to those polymers with low dielectric constant values whereas polymers of higher dielectric constant with low viscosity and low molecular weight tend to increase the measured ionic conductivity of the system [17].

During the present endeavour, it is planned to blend PEO host polymer (M w = 5,000,000) in conjunction with a liquid-like amorphous polymer namely polypropylene glycol (PPG, M w = 2700). It has been reported earlier that addition of PPG into the crystalline PEO matrix would increase the ionic conductivity of PEO-based electrolytes [18, 19]. The low viscosity of PPG enhances the mobility of carriers and its lower melting temperature (−30 °C) and glass transition temperature (−73 °C) result in an increase in the amorphous content of the blend polymer electrolyte. Furthermore, the higher dielectric constant of PPG (ϵ ̴ 32) as compared to that of PEO (ϵ ̴ 5) helps in the dissociation of ion aggregates eventually increasing the value of effective ionic conductivity of the electrolyte system [17].

Development of polymer electrolytes generally depends on incorporating ionizable salts in a suitable polar polymer host matrix. Interaction of PEO with transition metal triflates is a newly emerging research area due to its copious applications in several fields, such as thin film power devices and sensors [8]. Interestingly, PEO has a high solvating capacity for alkali metal salts and effortlessly forms flexible films. Recently, zinc ion conducting electrolytes have received an increased attention due to their distinct advantages over their lithium equivalence such as non-toxicity, natural abundance, low cost and high specific and volumetric energy density values [20, 21] apart from low power applications [22]. A careful analysis of relevant scientific research has confirmed that no comprehensive analysis or characterization pertaining to the impact of zinc triflate, Zn(CF3SO3)2, incorporation into the PEO:PPG blend polymer electrolyte system has been carried out so far. Therefore, the present work intends to account for the experimental investigation involving preparation, morphological, structural and thermal characterization along with ionic conductivity measurements and cationic transport measurements on a thin film polymer electrolyte system consisting of PEO-PPG blend complexed with different amounts of zinc triflate Zn(CF3SO3)2 salt.

Experimental techniques

Materials

Commercially available starting materials including PEO M w = 5 × 106, PPG M w = 2700 and Zn(CF3SO3)2 M w = 363.53 (which is also chemically known as zinc trifluoromethane sulfonate) were procured from Sigma-Aldrich, USA. Zn(CF3SO3)2 was dried at 100 °C for an hour prior to use in order to eliminate any trace of moisture present within the salt. Analar grade acetonitrile was employed as the common solvent for the preparation of thin film specimens of all the polymer electrolyte systems.

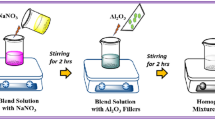

Preparation of blended polymer electrolyte systems

Initially, appropriate amounts of the chosen pair of polymers namely PEO and PPG corresponding to five different wt% ratios of 98:2, 96:4, 94:6, 92:8 and 90:10, respectively, were dissolved in acetonitrile and the solution mixture was continuously stirred for 6 h at 40 °C by means of magnetic stirrer. Subsequently, the solvent was allowed to get evaporated with a constant stirring process performed at room temperature. The homogenous residual solution thus derived was then cast onto glass petri dishes followed by a careful vacuum drying procedure carried out at 40 °C over a period of 24 h. Thin film specimens of PEO-PPG blends thus obtained from solution casting technique were found to be of 80 to 100 μm thickness. All such samples were suitably stored in vacuum desiccators for further analysis.

In order to obtain a variety of thin film specimens of PEO-PPG-Zn(CF3SO3)2 system, preliminary investigations related to room temperature impedance spectroscopic measurements were performed on all the freshly prepared PEO-PPG polymer blends. It was found that the optimized composition namely 90:10 wt% ratio of PEO and PPG would possess an appreciably high ionic conductivity at room temperature. Therefore, this particular polymer blend denoted as (PEO:PPG) in all the following sections was treated as the effective host polymer matrix for subsequent incorporation of the chosen dopant salt namely zinc triflate, Zn(CF3SO3)2. Eventually, six different concentrations involving 2.5, 5, 7.5, 10, 12.5 and 15 weight percentage of zinc triflate salt were dissolved in respective acetonitrile solutions containing (PEO:PPG) polymer blend and the same procedure of solution casting technique as mentioned above was repeated for obtaining a new series of the blended polymer electrolyte system PEO-PPG-Zn(CF3SO3)2. These free-standing thin film samples of approximately 100 micron thickness were subjected to various characterization techniques during the course of the present investigation.

Characterization techniques

Electrochemical impedance spectroscopy

Ionic conductivity measurements on various thin film specimens of PEO-PPG polymer blend and (PEO:PPG)-Zn(CF3SO3)2 blended polymer electrolyte systems were performed by means of impedance spectroscopy using a Hewlett-Packard model HP4284A Precision LCR Meter controlled by a computer. The sample film under test was positioned between a pair of spring-loaded stainless steel disc electrodes. Detailed temperature-dependent ionic conductivity measurements were carried out over the frequency range 1 MHz–20 Hz with an applied excitation voltage of 50 mV in the temperature domain 298–333 K by mounting the sample holder containing the sample inside a temperature-controlled furnace maintained at an accuracy of ±5 K.

Impedance plots have been carefully analysed by means of Boukamp equivalent circuit software package incorporated within the computer. Thus, the values of room temperature ionic conductivity (σ 298K) for all the five different compositions were evaluated using the relation:

where t denotes the thickness of the sample film, A contact area of the film and R b is the bulk resistance value derived from the corresponding Nyquist plot.

Transport number measurements

Ionic transport number measurement is one of the vital characterization techniques in the optimization of a polymer electrolyte for battery application and an appreciably high transference number value would indicate a rapid charge-discharge characteristic which is widely desirable [23–25]. Ionic conductivity in the case of an electrolyte is essentially the sum of the contributions of both cations and anions under the application of an external electric field. The corresponding transference number represents the fraction of current carried by either the cation or anion within a polymer electrolyte. Normally, cations and anions have different transference numbers owing to the difference in their ability to move around within the system [26]. The ionic transport number \( \left({t}_{{\mathrm{Zn}}^{2+}}\right) \) of polymeric zinc electrolytes under investigation could be obtained by employing dc polarization technique with the aid of stainless steel blocking electrodes whereas the appropriate cationic transport number may be determined by AC/DC polarization technique with zinc electrodes as non-blocking electrodes [27]. In order to determine the mobility of ionic species in the case of freshly prepared blended polymer electrolyte system, transport number measurements were performed following the procedure proposed by Evans et al. [28] using the relationship,

where ΔV is the constant dc voltage applied to polarize the electrolyte specimen, I 0, initial current, I s, final steady-state current, whereas R 0 and R s denote the total interfacial resistance of the symmetric electrolytic cell before and after polarization. Accordingly, the best conducting composition of the polymer electrolyte system PEO:PPG-Zn(CF3SO3)2 was subjected to an appropriate combination of DC potentiostatic polarization and AC impedance techniques. For this purpose, a cell of contact area 0.5 cm2 was prepared by sandwiching the blended polymer electrolyte specimen between a pair of reversible non-blocking zinc electrodes configured as Zn/sample/Zn. Zinc electrodes (thickness ̴ 0.25 mm) employed in the cell fabrication were earlier procured from Sigma-Aldrich and polished before use. This cell was subjected to DC polarization by applying a voltage (ΔV) of 100 mV by means of Keithley model 6517A electrometer at room temperature and the variation of dc current as a function of time was recorded. The values of resistance of the cell before and after polarization were measured by means of impedance spectroscopy as stated earlier.

Structural analysis

X-ray diffraction (XRD) experiments were performed on all the series of freshly prepared thin films using a Siefert model SF60 X-ray diffraction system with Cu–Kα radiation (wavelength, λ = 1.5406 Å) at room temperature in the scanning angle (2θ) range between 10° and 80°. The average crystallite size (τ) of PEO has been estimated by means of Scherrer formula [29] as given by

where λ is the wavelength of X rays and β is the full width at half maxima of the individual XRD peak. The values of degree of crystallinity (χ c) were obtained for all the samples by deconvoluting the XRD peaks due to amorphous and crystalline phases [30] using peak separation software Origin Pro8 and according to the equation:

where I c represents the total crystalline area and I a represents the amorphous area observed in various diffraction patterns.

Thermal analysis

Thermal analysis in terms of differential scanning calorimetry (DSC) was carried out by means of a NETZSCH model DSC 200F3 system over the temperature range −50 to 150 °C at a heating rate of 10 °C/min. During each DSC measurement, samples weighing 5 to 10 mg were hermetically sealed in aluminium pans whereas an empty aluminium pan was generally employed as the reference pan. Nitrogen (N2) atmosphere has been maintained throughout within the thermal analyser so as to shun the undesirable moisture exposure of the sample and to provide necessary inert environment as well. The degree of crystallinity, χ c, was calculated using the formula,

where ΔH m represents the melting enthalpy of the sample and ΔH omp represents the melting enthalpy of 100 % crystalline PEO = 213.1 J/g [31]. Since PPG is essentially an amorphous polymer, PEO has been considered as a homopolymer.

Surface morphology analysis

The structural and morphological features of (PEO:PPG) polymer blend and best conducting composition of the present blended polymer electrolyte system (PEO:PPG)-Zn(CF3SO3)2 were examined using a Hitachi SU6600 model field emission scanning electron microscope (FESEM) at room temperature with a view to understand their physico-chemical aspects and relevant correlation to the observed ionic conductivity behaviour in a meaningful fashion.

Results and discussion

Ionic conductivity results

Figure 1 depicts the set of Nyquist plots observed for five different thin film specimens of the PEO-PPG polymer blend corresponding to wt% ratios of 98:2, 96:4, 94:6, 92:8 and 90:10, respectively, at room temperature (298 K). The values of bulk resistance (R b) for individual samples could be estimated accurately from the resultant intercept of the semicircular impedance plot obtained on the axis of the real part (Z′) of the relevant Nyquist plot as represented in Fig. 1. It is interesting to note that the room temperature ionic conductivity (σ 298K) data thus evaluated for the series of five different thin film samples of PEO-PPG blend were 3.1 × 10−5, 3.7 × 10−5, 5.3 × 10−5, 6.1 × 10−5 and 7.5 × 10−5 S cm−1, respectively, thereby revealing the fact that an optimized composition viz., 90:10 wt% PEO:PPG would exhibit the maximum ionic conductivity of 7.5 × 10−5 S cm−1 at ambient condition. Hence, the above-optimized composition of the PEO-PPG polymer blend has been designated as (PEO:PPG) and used as the effective host matrix for further doping with the chosen salt namely zinc triflate, Zn(CF3SO3)2, during the current endeavour. In this context, it may be noted that the blend formation in the case of the binary system PEO-PPG was reported to be compatible only over a very limited range [19, 32]. The present work has also suggested that further increase in the content of PPG beyond 10 wt% within the PEO-PPG blend would result in the formation of physically unstable, pasty and liquid-like nature of materials as final products.

The room temperature Nyquist plots pertaining to six different compositions of (PEO:PPG)-Zn(CF3SO3)2 polymer electrolyte system containing 2.5, 5, 7.5, 10, 12.5 and 15 wt% salt, respectively, are shown in Fig. 2. It is evident from Fig. 2 that each plot is characterized by a high frequency semicircle and a low frequency spike inclined at an angle with the Zʹ axis. The observed semicircle may be ascribed to the bulk relaxation process whereas the spike may correspond to the build-up of charge carriers occurring at the electrode/electrolyte interface [33]. The room temperature ionic conductivity data along with designation of samples and their polymer-salt compositions in the case of PEO:PPG-Zn(CF3SO3)2 system are tabulated in Table 1. With a view to understand the nature and extent of influence of the content of Zn(CF3SO3)2 salt on the polymer blend host, (PEO:PPG) in a systematic manner, Fig. 3 shows the variation of room temperature ionic conductivity (σ 298K) for the PEO:PPG blend as a function of salt concentration. It is seen from Fig. 3 that as the salt concentration increases from 2.5 to 12.5 wt%, ionic conductivity increases in a steady fashion. However, the highest ionic conductivity value of 6.9 × 10−4 S cm−1 exhibited by the typical composition designated as PZ5 may be attributed to the most favourable segmental motion of the polymer chain involving mobile Zn2+ ions provided by the doping of Zn(CF3SO3)2 salt in these compositions wherein the optimized concentration of the salt may correspond to 12.5 wt% loading into the (PEO:PPG) host matrix [21, 22, 34]. On the other hand, when the amount of zinc triflate is increased from 12.5 to 15 wt%, the value of measured ionic conductivity decreases. Such behaviour may be attributed to possible ion aggregation occurring at the loading of 15 wt% zinc triflate thus leading into the predominant effect of a short-range ion-solvent interaction and hence feasible reduction in the effective number of charge carriers available for migration at salt-rich concentrations [35], i.e. beyond 12.5 wt% loading of zinc triflate into the (PEO:PPG) polymer blend. It is also interesting to infer from Fig. 3 that all the chosen compositions of (PEO:PPG)-Zn(CF3SO3)2 blended polymer electrolyte system possess ionic conductivities of the order of 10−4 S cm−1 at room temperature as summarized in Table 1. In other words, it is apparent that incorporation of zinc triflate, Zn(CF3SO3)2, as the dopant salt has effectively enhanced the ionic conductivity of the host matrix namely (PEO:PPG) polymer blend by an order of magnitude from 10−5 to 10−4 S cm−1 at ambient temperature. It is therefore anticipated that further characterization of these new series of blended polymer electrolytes would throw more light on their physico-chemical characteristics and enable analysis of the precise conduction mechanism involved and related electrochemical processes too.

Figure 4 indicates the variation of observed ionic conductivity (σ) over the temperature region 298–333 K in the case of (PEO:PPG)-Zn(CF3SO3)2 polymer electrolyte system having six different concentrations of Zn(CF3SO3)2 viz., 2.5, 5, 7.5, 10, 12.5 and 15 wt%, respectively. It is obvious from these plots that as the temperature increases the value of σ also increases in good agreement with the Arrhenius relationship,

where σ 0 is the pre-exponential factor, E a activation energy for conduction, k Boltzmann constant and T is the absolute temperature [36]. This behaviour may be attributed to the most probable ion-pair dissociation occurring due to the waning of coulombic forces that hold these ion-pairs together, thereby providing more number of ions for ionic conduction at elevated temperatures [21]. The fact that all the observed Arrhenius plots (Fig. 4) exhibit well-defined linear dependency in terms of the variation of σ as a function of inverse absolute temperature undoubtedly suggests the existence of an Arrhenius-type of thermally activated process occurring in these specimens involving the transport of Zn2+ ions. In essence, it is inferred that as the temperature is raised, the blended polymer electrolyte namely (PEO:PPG)-Zn(CF3SO3)2 would expand easily and create free volume within the polymeric framework. As a result, an enhanced polymer segmental motion involving more number of mobile Zn2+ ions as well as solvating molecules may be expected to occur thereby yielding an improved ionic conductivity as well [12, 37]. Further, the values of activation energies (E a) estimated from the slopes of the set of linear fit of Arrhenius plots shown in Fig. 4 are found to be 0.61, 0.67, 0.73, 0.63, 0.6 and 0.62 eV, respectively, corresponding to 2.5, 5, 7.5, 10, 12.5 and 15 wt% Zn(CF3SO3)2 considered during this work. It is interesting to notice that the best conducting blended polymer electrolyte system PZ5 possesses the lowest E a value too.

Cation transport number data

It is essential to determine the mobility of zinc ions by transference number (transport number) measurements in order to substantiate the ionic conductivity data reported in the previous section of this paper. The zinc ionic transport number \( \left({t}_{{\mathrm{Zn}}^{2+}}\right) \) indicating the cationic mobility in the present best conducting (PEO:PPG)-Zn(CF3SO3)2 blended polymer electrolyte system was determined by combining DC potentiostatic polarization and AC impedance techniques as reported by Evans et al. [28]. The initial and steady-state current values were deduced from the polarization current-time plot as shown in Fig. 5. The Zn/PZ5/Zn cell was subjected to AC impedance measurement before the application of the dc potential and after the steady-state was reached in order to extract the values of its initial and final resistance from the respective Nyquist plots.

In the present investigation, the value of zinc ionic transport number was found to be 0.59 at room temperature (298 K) which indicates the mobility of zinc cations in good agreement with earlier reports [34, 35]. Initially when the dc potential is applied, both Zn2+ cations and CF3SO3 - anions would move towards zinc electrodes contributing the initial current (I 0), and after a sufficiently long time when the steady state is reached, the value of current (I s) is due to zinc ions solely [35]. This transference number value may be attributed to the ease of dissociation of Zn2+ cations from the coordinating ether oxygen of PEO polymer and due to local segmental relaxation [38] also and hence it could be inferred that charge transport within the chosen blended polymer electrolyte is mainly due to cationic motion. The ionic transport within a polymeric matrix requires free volume and rearrangement of polymer segments. Polymers with flexible back-bone like PEO and PPG are expected to exhibit efficient packing, and therefore ion transport is strongly associated with local segmental relaxation of the polymer. Hence, the enhanced value of ionic conductivity of the order 10−4 S cm−1 as reported in this paper has been confirmed by the realization of a significant transport number value which in turn throws more light on the relevant charge transport mechanism as well.

X-ray diffraction (XRD) data

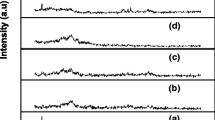

The room temperature XRD patterns observed for the various compositions of (PEO:PPG)-Zn(CF3SO3)2 blended polymer electrolyte system are shown in Fig. 6. The appearance of well defined and sharp XRD peaks tends to indicate the presence of crystalline phase of PEO. All the six different samples exhibit two distinct crystalline peaks corresponding to PEO, while a maximum intensity peak is noticed at 2θ = 19.3° and another diffraction peak is seen at 23.5°. It is observed from Fig. 5 that the relative intensity of these peaks decreases whereas the amorphous nature of the host polymer blend increases with an increase in the amount of zinc triflate, Zn(CF3SO3)2, from 2.5 to 12.5 wt%. The correlation between the observed intensity of peak and degree of crystallinity was reported by Hodge et al [39]. It was suggested that the intensity of an XRD pattern decreases as the amorphous nature increases with the addition of a dopant. Such an amorphous nature in turn results in a better ionic diffusivity and hence elevated ionic conductivity, which could be observed in the case of amorphous polymers and certain semi-crystalline polymers having flexible back-bone structures. The halo noticed in the XRD pattern further establishes the presence of an amorphous PPG in various specimens. The fact that no peaks corresponding to pure Zn(CF3SO3)2 are observed in the freshly prepared thin film samples of the present polymer blend electrolyte tends to signify the complete dissolution of the chosen salt into the (PEO:PPG) polymer blend matrix.

The calculated crystallite size (τ) of PEO is found to vary from 3 to 10 nm for all the different compositions of the system. The values of degree of crystallinity (χ c) obtained for all the samples by deconvoluting those XRD peaks due to amorphous and crystalline phases are presented in Table 2. As reported in Table 2, the degree of crystallinity of the electrolyte is found to decline from 57.9 to 36.4 % with the addition of zinc triflate salt from 2.5 to 12.5 wt%. Interestingly, the minimum crystallinity realized at 12.5 wt% loading of salt may be attributed to the realization of a higher amorphous content in the case of PZ5 owing to the most probable disturbance along the PEO side chain existing as a result of interaction of Zn2+ ions in terms of Lewis acid/base reactions [40]. This feature as inferred from the detailed XRD analysis is found to be in good agreement with the present ionic conductivity measurements since the value of ionic conductivity is by and large enhanced by the amorphous phase of a polymer electrolyte system [19, 21]. Table 2 tends to suggest that the degree of crystallinity (χ c) becomes large at 15 wt% loading of Zn(CF3SO3)2 salt (PZ6) in consistent with the trend noticed from the following section dealing with present DSC results.

Differential scanning calorimetric (DSC) results

The series of DSC thermograms recorded during the present DSC measurements for six different compositions of the blended polymer electrolyte system (PEO:PPG)-Zn(CF3SO3)2 containing 2.5, 5, 7.5, 10, 12.5 and 15 wt% Zn(CF3SO3)2 are compared in Fig. 7 and their respective values of glass transition temperature (T g) and melting temperature (T m) along with degree of crystallinity (χ c) are summarized in Table 2. The typical DSC trace obtained for (PEO/PPG) polymer blend has also been included in the same figure for the sake of comparison.

An interesting feature noticeable in these DSC curves is the fact that the single melting endotherm around 70 °C is observed in all the samples which is characteristic of PEO-based polymer electrolytes [41], and that no other transition is evident up to 150 °C. The undoped (PEO:PPG) polymer blend records a glass transition temperature of −51 °C and melting temperature of 69.1 °C. As the concentration of zinc triflate salt is increased from 2.5 to 15 wt%, it is seen that an increase in T g from −40.1 to −26.6 °C occurs until 12.5 wt% salt content but further increase in the salt concentration tends to decrease the T g value to −28.7 °C. The melting endotherm corresponding to undoped (PEO:PPG) polymer blend shifts with an addition of zinc triflate salt from 69.1 to 64.1 °C. This drop has been observed even for the typical sample PZ6 which is higher than that of the best conducting sample. This type of behaviour noticed in the case of the sample containing 15 wt% zinc salt strongly suggests that the amorphous phase content is increasing even beyond 12.5 wt% (best conducting PZ5), but a decrease in both the observed ionic conductivity and its T g value has been realized. The blocking of ion movement in the conducting path by higher degrees of ionic aggregates could be responsible for the drop in the ionic conductivity at 15 wt% zinc triflate loading [42]. In other words, the fact that a noticeable decrease in T g value occurs when the zinc triflate content goes above 12.5 wt% is an affirmation of this kind of mechanism. Another prominent feature involves the decrease in the area under the curve for the melting endotherm which has been related to changes occurring in the degree of crystallinity of various specimens under consideration. The trend of correlation between glass transition temperature and ionic conductivity is an obvious indication that the observed enhancement in ionic conductivity may possibly be attributed as due to an improved segmental mobility mechanism witnessed in the polymer chains of the chosen polymer blend electrolyte system.

The fact that degree of crystallinity (χ c) considerably decreases from 54 to 34.1 % due to the increasing incorporation of zinc triflate salt has also been confirmed from the detailed results of thermal analysis presented in Table 2. The observed minimum degree of crystallinity is attributed to the typical sample PZ5 which exhibits the highest ionic conductivity at ambient condition. It is witnessed that the values of degree of crystallinity as calculated from the present DSC data are in good agreement with those obtained from XRD analysis thus confirming the fact that introduction of zinc triflate salt effectively increases the amorphous nature of the chosen blend polymer electrolyte system.

Surface morphological features

Specific efforts have been made during the course of the present investigation towards evaluation of surface morphology in respect of the chosen blended polymer electrolyte system based on FESEM. Figure 8a, b depicts the set of FESEM images observed for thin film specimens of undoped (PEO:PPG) polymer blend and best conducting polymer electrolyte designated as PZ5, respectively. In the case of PEO-based polymer electrolytes, reduction in crystallinity phase of PEO is generally associated with its smooth and even surface morphology [43, 44]. During the present consideration, the observed surface morphology of the above film has been found to be uniformly patterned, though characterized with different degrees of roughness consisting of spherulites of an almost identical size as shown in the image similar to earlier reports [15, 40, 45]. The surface roughness is frequently associated with a high surface free energy which may aid the attachment of particles to the nucleus and in that way would contribute towards more rapid kinetics of nucleation [46]. The higher value of ionic conductivity observed in the case of the particular blend polymer electrolyte is therefore understood to result from the existence of a lower degree of crystallinity and uniform morphology, as confirmed from XRD and DSC studies.

Conclusions

The combined effects of incorporation of PPG and Zn(CF3SO3)2 on the morphological, structural, thermal and electrochemical properties of PEO polymeric matrix have been investigated by means of FESEM, XRD, DSC and impedance spectroscopy methodologies. The typical composition PZ5 viz., 87.5 wt% (PEO:PPG)-12.5 wt% Zn(CF3SO3)2 records the highest ionic conductivity of 6.9 × 10−4 S cm−1 at 298 K and lowest activation energy of 0.6 eV. Arrhenius-type of thermally activated process was identified over a wide range of compositions of the blended polymer electrolyte system and found to be responsible for the transport of zinc and triflate ions. The variation of glass transition temperature, T g, and melting temperature, T m, in the case of various compositions was evaluated through DSC analysis, whereas the relevant XRD data tend to confirm the fact that addition of zinc triflate salt considerably decreases the crystallinity of the chosen polymer matrix which also explains the behaviour of ionic conductivity in these blended polymer electrolytes in a satisfactory fashion.

References

Mohapatra SR, Thakur AK, Choudhary RNP (2009) Effect of nanoscopic confinement on improvement in ion conduction and stability properties of an intercalated polymer nanocomposite electrolyte for energy storage applications. J Power Sources 191:601–613. doi:10.1016/j.jpowsour.2009.01.100

Sengwa RJ, Dhatarwal P, Choudhary S (2014) Role of preparation methods on the structural and dielectric properties of plasticized polymer blend electrolytes: correlation between ionic conductivity and dielectric parameters. Electrochim Acta 142:359–370. doi:10.1016/j.electacta.2014.07.120

Agrawal RC, Pandey GP (2008) Solid polymer electrolytes: material designing and all-solid-state battery applications: an overview. J Phys D Appl Phys 41:223001. doi:10.1088/0022-3727/41/22/223001

Syzdek J, Armand M, Marcinek M, Zalewska A, ˙Zukowska G, Wieczorek W (2010) Detailed studies on the fillers modification and their influence on composite, poly(oxyethylene)-based polymeric electrolytes. Electrochim Acta 55:1314–1322. doi:10.1016/j.electacta.2009.04.025

Choudhary S, Sengwa RJ (2013) Effects of preparation methods on structure, ionic conductivity and dielectric relaxation of solid polymeric electrolytes. Mater Chem Phys 142:172–181. doi:10.1016/j.matchemphys.2013.06.053

Reddeppa N, Sharma AK, Rao VVRN, Chen W (2014) AC conduction mechanism and battery discharge characteristics of (PVC/PEO) polyblend films complexed with potassium chloride. Measurement 47:33–41. doi:10.1016/j.measurement.2013.08.047

Sim LH, Gan SN, Chan CH, Yahya R (2010) ATR-FTIR studies on ion interaction of lithium perchlorate in polyacrylate/poly(ethylene oxide) blends. Spectrochim Acta A 76:287–292. doi:10.1016/j.saa.2009.09.031

Caramia V, Bayer SI, Anyfantis GC, Ruffilli R, Ayadi F, Martiradonna L, Cingolani R, Athanassiou A (2013) Tailoring the morphology of poly(ethylene oxide)/silver triflate blends: from crystalline to self-assembled nanofibrillar structures. Nanotechnology 24:055602. doi:10.1088/0957-4484/24/5/055602

Borkowska R, Laskowski J, Plocharski J, Przyluski J, Wieczorek W (1993) Performance of acrylate-poly(ethylene oxide) polymer electrolytes in lithium batteries. J Appl Electrochem 23:991

Wieczorek W, Stevens JR (1997) Impedance spectroscopy and phase structure of polyether-poly(methyl methacrylate)-LiCF3SO3 blend-based electrolytes. J Phys Chem B 101:1529–1534. doi:10.1021/jp962517w

Song JY, Wang YY, Wan CC (1999) Review of gel-type polymer electrolytes for lithium-ion batteries. J Power Sources 77:183–197. doi:10.1016/S0378-7753(98)00193-1

Johan MR, Shy OH, Ibrahim S, Yassin SMM, Hui TY (2011) Effects of Al2O3 nanofiller and EC plasticizer on the ionic conductivity enhancement of solid PEO–LiCF3SO3 solid polymer electrolyte. Solid State Ionics 196:41–47. doi:10.1016/j.ssi.2011.06.001

Jacob MME, Prabaharan SRS, Radhakrishna S (1997) Effect of PEO addition on the electrolytic and thermal properties of PVDFLiClO4 polymer electrolytes. Solid State Ionics 104:267–276

Radhakrishnan S, Venkatachalapathy PD (1996) Effect of casting solvent on the crystallization in PEO/PMMA blends. Polymer 37:3749–3752. doi:10.1016/0032-3861(96)00192-9

Sekhar PC, Kumar PN, Sharma AK (2012) Effect of plasticizer on conductivity and cell parameters of (PMMA + NaClO4) polymer electrolyte system. J Appl Phys 2:01–06. doi:10.9790/4861-0240106

Rand DAJ (1979) Battery systems for electric vehicles—a state-of-the-art review. J Power Sources 4:101–143. doi:10.1016/0378-7753(79)85001-6

Kumar M, Sekhon SS (2002) Role of plasticizer’s dielectric constant on conductivity modification of PEO–NH4F polymer electrolytes. Eur Polym J 38:1297–1304. doi:10.1016/S0014-3057(01)00310-X

Kang MS, Kim JH, Kim YJ, Won J, Park NG, Kang YS (2004) Dye-sensitized solar cells based on composite solid polymer electrolytes. Chem Commun 889-891. doi: 10.1039/B412129P

Paulmer RDA, Kulkarni AR (1994) Synthesis and conductivity behavior of ternary PEO-PPG-NaClO4 amorphous blends. Solid State Ionics 68:243–247. doi:10.1016/0167-2738(94)90182-1

Kumar GG, Sampath S (2004) Spectroscopic characterization of a gel polymer electrolyte of zinc triflate and polyacrylonitrile. Polymer 45:2889–2895. doi:10.1016/j.polymer.2004.02.053

Sownthari K, Suthanthiraraj SA (2014) Preparation and properties of a gel polymer electrolyte system based on poly-ε-caprolactonecontaining1-ethyl-3-methylimidazolium bis (trifluoromethylsulfonyl)imide. J Phys Chem Solids 75:746–751. doi:10.1016/j.jpcs.2014.02.003

Narayanan NSV, Ashokraj BV, Sampath S (2010) Ambient temperature, zinc ion-conducting, binary molten electrolyte based on acetamide and zinc perchlorate: application in rechargeable zinc batteries. J Colloid Interface Sci 342:505–512. doi:10.1016/j.jcis.2009.10.034

Tao R, Zhao Y, Fujinami T (2007) Lithium borate–PEO polymer electrolytes characterized with high lithium ion transference numbers. Mater Sci Eng B 137:69–73. doi:10.1016/j.mseb.2006.10.010

Watanabe M, Tokuda H, Muto S (2001) Anionic effect on ion transport properties in network polyether electrolytes. Electrochim Acta 46:1487–1491. doi:10.1016/S0013-4686(00)00743-X

Ciosek M, Sannier L, Siekierski M, Golodnitsky D, Peled E, Scrosati B, Głowinkowski S, Wieczorek W (2007) Ion transport phenomena in polymeric electrolytes. Electrochim Acta 53:1409–1416. doi:10.1016/j.electacta.2007.03.037

Fan F (2015) Ion transport in polymer electrolytes. PhD dissertation, University of Tennessee

Zainol NH, Samin SM, Othman L, Isa KBM, Chong WG, Osman Z (2013) Magnesium ion-based gel polymer electrolytes: ionic conduction and infrared spectroscopy studies. Int J Electrochem Sci 8:3602–3614

Evans J, Colin VA, Bruce PG (1987) Electrochemical measurement of transference numbers in polymer electrolytes. Polymer 28:2324–2328. doi:10.1016/0032-3861(87)90394-6

Guinier A (1994) X-ray diffraction in crystals, imperfect crystals and amorphous bodies. Dover Publications, New York

Hyun J (2001) A new approach to characterize crystallinity by observing the mobility of plasma treated polymer surfaces. Polymer 42:6473–6477. doi:10.1016/S0032-3861(01)00116-1

Dey A, Karan S, De SK (2010) Molecular interaction and ionic conductivity of polyethylene oxide–LiClO4 nanocomposites. J Phys Chem Solids 71:329–335

Booth C, Pickles CJ (1973) Phase separation in mixtures of poly(ethylene oxide) and poly(propylene oxide). J Polym Sci B Polym Phys 11:595. doi:10.1002/pol.1973.180110316

Sownthari K, Suthanthiraraj SA (2015) Preparation and properties of biodegradable polymer-layered silicate nanocomposite electrolytes for zinc based batteries. Electrochim Acta 174:885–892. doi:10.1016/j.electacta.2015.06.049

Guisao JPT, Romero AJF (2015) Interaction between Zn2+ cations and n-methyl-2-pyrrolidone in ionic liquid-based gel polymer electrolytes for Zn batteries. Electrochim Acta 176:1447–1453. doi:10.1016/j.electacta.2015.07.132

Prasanna CMS, Suthanthiraraj SA (2015) Electrical, structural, and morphological studies of honeycomb-like microporous zinc-ion conducting poly (vinyl chloride)/poly (ethyl methacrylate) blend-based polymer electrolytes. Ionics. doi:10.1007/s11581-015-1546-4

Armand MB, Chabagno JM, Duclot MJ, Vashista P, Mundy JN, Shenoy GK (1979) Fast ion transport in solids, North Holland, p. 131

Souquet JL, Lévy M, Duclot M (1994) A single microscopic approach for ionic transport in glassy and polymer electrolytes. Solid State Ionics 70/71:337. doi:10.1016/0167-2738(94)90333-6

Fan F, Wang Y, Sokolov AP (2013) Ionic transport, micro-phase separation, and polymer relaxation in poly(propylene glycol) and lithium perchlorate mixtures. Macromolecules 46:9380–9389. doi:10.1021/ma401238k

Hodge RM, Edward GH, Simon GP (1996) Water absorption and states of water in semi crystalline poly(vinyl alcohol) films. Polymer 37:1371–1376. doi:10.1016/0032-3861(96)81134-7

Amudha S, Suthanthiraraj SA (2015) Silver ion conducting characteristics of a polyethylene oxide-based composite polymer electrolyte and application in solid state batteries. Adv Mater Lett 6(10):874–882. doi:10.5185/amlett.2015.5831

Akhtar MS, Kim UY, Choi DJ, Yang OB (2010) Effect of electron beam irradiation on the properties of polyethylene oxide–TiO2 composite electrolyte for dye sensitized solar cells. Mater Sci Forum 658:161–164. doi:10.4028/www.scientific.net/MSF.658.161

Vignarooban K, Dissanayake MAKL, Albinsson I, Mellander BE (2015) Ionic conductivity enhancement in PEO:CuSCN solid polymer electrolyte by the incorporation of nickel-chloride. Solid State Ionics 278:177–180. doi:10.1016/j.ssi.2015.06.014

Ulaganathan M, Nithya R, Rajendran S, in: Viacheslav Kazmiruk (Ed.), (2012) Scanning electron microscopy, ISBN: 978-953-51-0092-8, InTech 671-694

Chu PP, Reddy MJ, Kao HM (2003) Novel composite polymer electrolyte comprising mesoporous structured SiO2 and PEO/Li. Solid State Ionics 156:141. doi:10.1016/S0167-2738(02)00582-9

Suthanthiraraj SA, Vadivel MK (2012) Effect of propylene carbonate as a plasticizer on (PEO)50AgCF3SO3:SnO2 nanocomposite polymer electrolyte. Appl Nanosci 2:239. doi:10.1007/s13204-012-0099-3

Yap YL, You AH, Teo LL, Hanapei H (2013) Inorganic filler sizes effect on ionic conductivity in polyethylene oxide (PEO) composite polymer electrolyte. Int J Electrochem Sci 8:2154–2163

Acknowledgments

We acknowledge the characterization facility provided for FESEM analysis by the National Centre for Nanoscience and Nanotechnology, University of Madras.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nancy, A.C., Suthanthiraraj, S.A. Preparation and characterization of a new PEO-PPG blend polymer electrolyte system. Ionics 22, 2399–2408 (2016). https://doi.org/10.1007/s11581-016-1767-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-016-1767-1