Abstract

Solid polymer blend electrolyte films based on PVP/PVA complexed with KBr were prepared by the solution cast technique. Various experimental techniques such as electrical conductivity and transport number measurement were used to characterize the polymer electrolyte films. Electrochemical cells with the polymer electrolytes (PVP + PVA + KBr) were fabricated in the configuration K / (PVP + PVA + KBr) / (I2 + C + electrode). The discharge characteristics of the cells were studied under a constant load of 100 KΩ. The open-circuit voltage, short-circuit current, and discharge time for the plateau region are measured. Several other cell parameters were evaluated and are reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of portable electronic devices, especially mobile phones and laptops, has been remarkable in the last decade leading to a strong need of high-energy batteries. Indeed, the replacement of common liquid electrolytes by an ionic polymer membrane is an important technological development for the lithium ion technology, as it provides the prospect of a favorable combination of high energy and long life [1] but there is higher risk of fire explosion. In order to overcome this problem, the development of all solid-state batteries using a solid electrolyte may be one solution. A solid polymer is a thin film consisting of ionic salts dissolved in an appropriate polymer which enables ionic conduction at room temperature in the solid state [2]. The electrical and ionic conductivities can be modified by copolymerization, plasticization, blending, addition of ceramic fillers, and addition of ionic salts.

Although some work has been reported on discharge characteristics of doped polymers [3–5], very little work is available on doped polyblend of (PVP + PVA) [6]. PVA is a potential material having a very high dielectric strength, good charge storage capacity, and dopant-dependent electrical properties. As K+ is a fast conducting ion in a number of crystalline and amorphous materials, its incorporation in a polymeric system may be expected to enhance the electric performance of the blend.

Hence, in the present study, the effect of doping with potassium bromide on electrical conduction in PVP/PVA polymer blend electrolyte films has been undertaken.

Experimental

Pure (undoped) and KBr-doped PVP/PVA polymer blend films of thickness 150 μm were prepared by solution cast technique in different weight ratios (50:50), (47.5:47.5:5), (45.0:45.0:10); (42.5:42.5:15), (40:40:20) using triple distilled water as solvent. Appropriate amounts of PVP, PVA, and KBr were dissolved in triple distilled water and the solutions were stirred magnetically for 10–12 h at room temperature to get homogenous solution and then cast onto polypropylene dishes and evaporated slowly at room temperature. All the films were vacuum dried at 45 °C thoroughly under a vacuum of 10−3 Torr to remove residual solvent, if any.

The X-ray diffraction studies were performed by means of SEIFERT X-ray diffractometer. The DC conductivities were measured by using a conductivity cell [7], in the temperature range 300–400 K. The total ionic transport number (t ion) was evaluated by means of Wagner’s polarization technique [8]. In this technique, freshly prepared polymer electrolyte films were polarized in the configuration K/polymer electrolyte/C under a DC bias. The resulting current was monitored as a function of time. Electrochemical cells were fabricated with the configuration K/(PVP + PVA + KBr)/(I2 + C + electrolyte). The discharge characteristics of the cell were monitored under a constant load of 100 KΩ.

Results and discussion

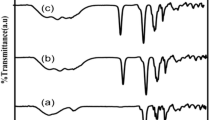

X-ray diffraction studies

XRD studies were made on (PVP + PVA), KBr, and the complexes (Fig. 1) in order to investigate the influence of the concentration of KBr salt. There was a noticeable change in the intensity of XRD peaks of the doped samples in addition to the appearance of additional peaks. Peaks were observed for 2θ values around 23°, 44°, and 51° for pure (PVP + PVA) blend. The intensity of these peaks decreased with increasing salt concentration and got slightly displaced in complexed polymer blend films. The peaks for 2θ values at 27°, 38.6°, 47.7°, 55.8°, pertaining to KBr disappeared in polymer complexes which indicates the complete dissolution of the salt in the polymer matrix. The decrease in the intensities of peaks on doping shows that the addition of KBr salt causes a decrease in the degree of crystallinity and simultaneous increase in the amorphosity of the complexed films. This amorphous nature is responsible for greater ionic diffusivity resulting in high ionic conductivity. This observation confirms that complexation has taken place in the amorphous phase.

Scanning electron microscopy

Figure 2 shows the scanning electron micrographs of pure (PVP + PVA) blend and KBr-doped polymer electrolytes. The morphology was uniform but with different degrees of roughness. The increase in the degree of roughness with increased KBr salt concentration indicates segregation of the dopant in the host matrix. The difference in morphology of the KBr-doped films is consistent with the significant differences in the ionic conductivity of these films.

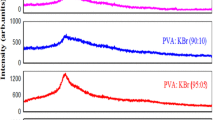

DC conductivity

The variation of DC conductivity (σ), as a function of composition of KBr in (PVP + PVA) for different weight percent ratios of KBr is shown in Fig. 3a in the temperature range of 300–400 K. The variation of conductivity with KBr content at 300 K is shown in Fig. 3b. It continued to increase with increased dopant concentration, although slowly at higher concentrations. The increase in conductivity at lower dopant concentrations of KBr is attributed to the formation of charge transfer complexes or decrease in the crystallinity of the blend [9], while the slow increase at higher dopant concentrations is due to the formation of ionic aggregates. These ionic aggregates impede the conduction process [10] and decrease the conductivity. The conductivity increased with temperature and followed Arrhenius behavior throughout with three regions (regions I, II, and III) having different activation energies. While regions I and III might be due to intrachain and interchain segmental motions, region II may be due to the transition of the polymer from the crystalline to amorphous phase [9, 11].

In polymer electrolytes, change of conductivity with temperature is due to the segmental motion, which results in an increase in the free volume of the system [12, 13]. This increase in free volume would facilitate the motion of ionic charge [14]. Similar behavior was observed in a number of other films [9, 15–17].

As per Arrhenius relation the dependence of conductivity has the form

where σ 0 is the proportionality constant, E a, the activation energy, and k is the Boltzmann constant

The activation energies were calculated from the slope of these plots, and the values are shown in Table 1. These values are found to decrease with increasing concentration of KBr. This may be due to the fact that the addition of small amounts of dopant forms charge transfer complexes in the host lattice [17]. These charge transfer complexes increase the electrical conductivity by providing additional charges in the lattice. This results in a decrease of activation energy.

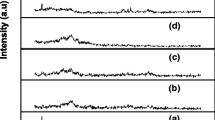

Transference numbers

Electronic and ionic transference number measurements play an important role in explaining the conductivity of polymer electrolyte films. Transference numbers of (PVP + PVA + KBr) electrolyte system were evaluated using Wagner’s polarization technique [8]. In this method, the DC current is monitored as a function of time on application of a fixed DC voltage of 1.5 V across the cell in the configuration K/(polymer blend electrolyte)/C. After polarization, the current versus time plots was drawn (Fig. 4).

The transference numbers were calculated using the relation

where I t is the total current (ionic + electronic) at the start of the time (i.e., when t = 0) and I s is the saturation current (electronic current only). The t ion and t ele values are shown in Table 2. The ionic transference numbers are in the range 0.93–0.96. This suggests that the charge transport in these polymer blend electrolyte films is predominantly ionic with a negligible contribution from electrons.

Cell discharge characteristics

Solid-state electrochemical cells were prepared in the configuration K(anode)/(PVP + PVA + KBr)/(I2 + C + electrolyte)(cathode), and their discharge characteristics at room temperature for a constant load of 100 KΩ are shown in Fig. 5. The sharp initial decrease in voltage may be due to polarization and/or the formation of thin layer of potassium at electrode–electrolyte interface. The cell parameters were calculated and are shown in the Table 3. From the data, it is clear that the short circuit current, discharge time for the plateau region were found to be greater in (PVP + PVA + KBr; 40:40:20) cell compared to the other complexed cells. This may be due to the high ionic conductivity and higher degree of amorphosity of this system when compared to other systems. The parameters of the present electrolyte system are comparable with the earlier work reported on different polymer electrolyte systems [18, 19]. This supports the practical application of the present electrolyte in solid-state battery applications.

Conclusions

The XRD studies showed the amorphous nature of the KBr-doped polymer electrolytes. The conductivity study indicates that the polymer blend can be effectively doped with KBr to improve its conductivity. The increase in conductivity is attributed to the formation of charge transfer complexes. Transference number data shows that the conductivity is predominantly due to ions. The electrolytes showed promising discharge characteristics and may be suitable for fabrication of electrochemical cells.

References

Nishi Y (2001) J Power Sources 100:101–106

Acosta JL, Morales E (1996) J Appl Polym Sci 60:1185

Janaki Rami Reddy T, Achari VBS, Sharma AK, Narasimha Rao VVR (2007) Ionics 13:55–59

Narasimha Rao VVR, Sharma AK, Raja V, Mohan VM (2006) Ionics 12:219–226

Balaji Bhargav P, Madhu Mohan V, Sharma AK, Narasimha Rao VVR (2007) Ionics 13:441–446

Subba Reddy Ch V, Sharma AK, Narasimha Rao VVR (2002) J Power Sources 111:357–360

Lakshminarayana K (1995) Ph.D Thesis, S.V. University

Wagner JB, Wagner C (1957) J Chem Phys 26:1597

Subba Reddy Ch V, Sharma AK, Rao VVRN (2006) Polymer 47:1318

Bruce PG (1991) Synth Met 45:267

Miyamoto T, Shibiyama K (1973) J Appl Phys 44:5372

Druger SD, Nitzam A, Ratner MA (1983) J Chem Phys 79:3133

Druger SD, Ratner MA, Nitzam A (1985) Phys Rev B 31:3939

Park CH, Kiam DW, Prakash J (2003) Solid State Ion 159:111

Reddeppa N, Reddy TJR, Achari VBS, Rao VVRN, Sharma AK (2009) Ionics 15:255

Reddy TJR, Achari VBS, Sharma AK, Rao VVRN (2007) Ionics 13:435

Achari VBS, Reddy TJR, Sharma AK, Rao VVRN (2007) Ionics 13:349

Jaipal Reddy M, Srikanth T, Chandrasekhar M, Subba Rao UV (2000) J Mater Sci 35:2841

Balaji Bhargav P, Madhu Mohan V, Sharma AK, Narasimha Rao VVR (2007) Ionics 13:173–178

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Umadevi, C., Mohan, K.R., Achari, V.B.S. et al. Discharge characteristics of polymer blend (PVP/PVA) electrolyte films doped with potassium bromide. Ionics 16, 751–756 (2010). https://doi.org/10.1007/s11581-010-0459-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-010-0459-5