Abstract

Residue concentrations of the sprout suppressant chlorpropham (or CIPC) were determined in raw and cooked potatoes and processed potato products, 48 h after CIPC aerosol treatment and after 30 days of subsequent storage at 4 or 12 °C. In the raw (uncooked) tuber, 48 h after CIPC treatment, the CIPC residue in the peel was 4.7 mg kg-1, while in the peeled tuber it was 0.1 mg kg-1. Boiling resulted in a decrease in residue concentration in the peel, but no significant differences in the residue concentration of the peeled tuber were observed. Pressure cooking resulted in a significantly increased residue concentration in the peel, but no significant change in the peeled tuber, whereas microwave cooking also did not increase the residue concentration in the peel significantly compared with that in raw tubers. Also the trend towards increases in residue concentration in microwave-cooked peeled tubers was not significant. The CIPC residue concentration detected in peeled tubers was 0.4–0.7 mg kg-1 after boiling, 0.4–1.5 mg kg-1 after pressure cooking and 0.4–3.8 mg kg-1 after microwave cooking. The highest values were always found for tubers stored for 30 days at 4 °C. Processed products such as crisps, French fries, dehydrated sliced potatoes and starch contained different concentrations of CIPC residue, which was also detected in the cooking water and frying oil. The highest residue concentrations detected were 0.7, 4.7, 1.3 and 0.2 mg kg-1 in crisps, French fries, dehydrated sliced potatoes and starch, respectively. The highest CIPC residue concentration observed in raw potatoes was much lower than the maximum residue level of 10 mg kg-1 prescribed by the European Union.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chlorpropham, or isopropyl-N-(3-chlorophenyl) carbamate (CIPC), has been used in many developed countries as a sprout suppressant on potatoes (Van Vliet and Sparenberg 1970; Boyd et al. 1982). It has been found to be very effective in suppressing sprout growth at a very low concentration of 1–2 g kg-1 tubers. Various formulations of CIPC have been tried for suppressing sprout growth in potatoes and its application in the form of aerosol or fog has been most successful (Anonymous 2002). Considerable work on the effectiveness of CIPC as a sprout suppressant during long-term storage of potatoes has been done and its residues in treated tubers have been determined after storage for different durations. A minimum CIPC concentration of 20 g kg-1 on a peel basis or 1–2 g kg-1 on a whole tuber basis has been found to be necessary for complete sprout inhibition (Corsini et al. 1979; Kleinkopf et al. 1997). A large number of studies have been carried out on the changes in CIPC residues in stored potatoes but only a few studies have been conducted on CIPC residue concentrations in potatoes cooked or processed by various methods (Mondy et al. 1992; Lewis et al. 1996). Considering the health concerns in the light of the report that CIPC has weak toxic activity (WHO/FAO 1964), more work is required on CIPC residue concentrations in cooked potatoes as well as in processed potato products. In India, potatoes have been stored traditionally in cold stores at 2–4 °C and 90–95% relative humidity but these potatoes were found to be unsuitable for processing owing to excessive accumulation of sugars leading to unacceptably high browning in potato crisps (Verma 1991). Therefore, it became necessary to store potatoes at 10–12 °C for processing crops. This storage practice started in 1998, when CIPC was registered for commercial use in India (Ezekiel et al. 2005). Since then several cold stores which were storing potatoes at 2–4 °C without CIPC treatment have started storing potatoes at 10–12 °C with CIPC treatment. But no work has been done in India so far on CIPC residues. The objective of the present study was to determine changes in CIPC residue concentrations in potatoes after cooking by various methods normally used in India, and after processing into different products.

Materials and Methods

Tuber Production and Storage

Potatoes of cvs Kufri Jyoti, Kufri Chipsona-1 and Kufri Chipsona-2 grown at the Central Potato Research Institute farm during 2005 were used in this study. Kufri Jyoti, a popular table and processing cultivar, was used in cooking experiments and for preparing dehydrated sliced potatoes and starch. Kufri Chipsona-1, a processing cultivar with oval tubers, was used for preparing French fries and Kufri Chipsona-2, a processing cultivar with round tubers, was used for preparing fresh fried crisps. The crop was raised following the recommended package of practices (Central Potato Research Institute 1999) and the tubers were harvested after full maturity had been reached. Harvested tubers were cured at room temperature for 3 weeks and 1 Mg of potatoes of each cultivar was loaded in a walk-in-chamber. The temperature was brought down by 0.5 °C per day until it reached 12 °C. The relative humidity was maintained at 85–90%. CIPC treatment was given in the form of a fog using a fogger (Dyna-Fog, Curtis Dyna-Fog, Westfield IN, USA). A commercial preparation of CIPC called ‘Oorja’ (United Phosphorus, Mumbai, India) which contains 50% a.i. was applied at 35 ml mg-1 of potatoes, which resulted in a final concentration of 17.5 ppm. After CIPC application, the walk-in-chamber was kept airtight for 48 h, and then ventilated. Tuber samples were taken 48 h after the treatment. Half the quantity of treated tubers (500 kg) was shifted to another walk-in-chamber, wherein the temperature was brought down by 0.5 °C per day until it reached 4 °C. CIPC was also used on tubers stored at 4 °C, in order to see the difference in the loss of CIPC due to volatilization during storage at lower (4 °C) and higher (12 °C) temperatures.

After 30 days of storage at 4 and 12 °C, tuber samples were taken for experiments.

Processing Methods

Tubers weighing 75–125 g were selected and used in cooking and processing experiments. Each replication consisted of ten tubers and there were three replications for each method of cooking and processing. Unwashed tubers were cooked by three methods normally used in India, i.e., boiling, pressure cooking and microwave cooking. Boiling was done by cooking 1 kg of tubers in 2 l of boiling water for 30 min. Pressure cooking was done by cooking 1 kg of tubers in 0.4 l of water under 15 psi for 10 min. Microwave cooking was carried out by cooking 1 kg of tubers without water in a microwave oven for 8 min at 1,350 W. After cooking, tubers were peeled and CIPC residues in peel and peeled tuber were determined. In the case of boiling and pressure cooking, CIPC residue in cooking water was also determined and the values for residues in pressure-cooking water were harmonized to make them comparable with those for the boiled water. CIPC residues were also determined in uncooked (raw) tubers which served as a control.

Tubers were processed into four products. Two fried products (potato crisps and French fries) and two non-fried products (dehydrated sliced potatoes and starch). Potatoes were washed and peeled using a hand peeler. For preparing crisps, the peeled tubers were cut into 1.75-mm-thick slices using a slicer and the slices were kept immersed in water containing 0.5% potassium metabisulphite to avoid browning. The slices were washed in normal water at room temperature to remove surface starch and dried on paper towels. The dried slices were fried in cotton seed oil at 180 °C in a deep fat fryer until the bubbling stopped (frying was done for about 2 min). The fried crisps were drained to remove excess oil and CIPC residue was determined in fried crisps and in oil used for frying. Dehydrated sliced potatoes were prepared as crisps but were dried after slicing by solar drying of slices in the open sun for 6 h and CIPC residue was determined in sun-dried slices. For preparing French fries, sticks of 10-mm cross-section were cut, blanched in water at 60 °C for 2 min and par-fried at 180 °C for 2 min. The par-fried sticks were frozen at -20 °C and CIPC residue was determined in the French fries and in the oil used for frying. For preparation of starch, the tubers were washed thoroughly, peeled and sliced into 2-mm-thick slices and the slices were kept immersed in water containing 0.5% potassium metabisulphite to avoid browning. The slices were ground thoroughly in a laboratory scale grinder (Lumix, Ambala, India) at 12,000 rpm, 450 W, to get a fine slurry. The slurry was filtered through a muslin cloth and the residue on the muslin cloth was washed repeatedly to recover the maximum amount of starch. The filtrate was collected in a tub and left overnight for the starch to settle down. The supernatant liquid was decanted and the starch layer was washed repeatedly (four to five times) with distilled water until the supernatant became transparent. The starch cake was dried in a hot-air oven at 40 °C until it was dry. The dried starch was ground to a fine powder and CIPC residue was determined.

CIPC Residue Analysis

The extraction of CIPC from the tuber samples was done by a method earlier standardized in the laboratory (Singh and Kaul 1999). CIPC residue was determined in peels (consisting of the skin and approximately 2 mm of the flesh) and peeled tubers (entire tuber without the peel) in composite samples made from ten randomly selected tubers per replication. The samples were diced and mixed thoroughly. Representative samples of 10 g were taken into 50-ml culture tubes and n-hexane (analytical reagent grade, E. Merck India, Mumbai, India) was added for proper immersion of the samples. The extraction was done using n-hexane and 10 g each of anhydrous sodium sulphate (E. Merck India, Mumbai, India) and Kieselguhr (HiMedia Lab, Mumbai, India) were added to the mixture. The grinding was done with the help of a pestle and mortar and the final cleanup was done by passing the extract through Celite (HiMedia Lab, Mumbai, India). The extract was filtered (through Whatman no. 1A paper, UK) and reduced to near dryness in 30-ml glass vials below 30 °C to avoid CIPC loss due to volatilization. These vials were sealed before further analysis by high-performance liquid chromatography (HPLC). All the solvents used for analysis of CIPC residues by HPLC were of HPLC grade (E. Merck India). Water used in the mobile phase was of Milli-Q grade (Millipore, USA) having a resistivity of more than 14 Ω. The CIPC standard used was obtained from Sigma (USA).

A modified procedure developed by Wilson et al. (1981) for HPLC analysis was standardized and the residues were analysed using the conditions described as follows: injector, Rheodyne injector with starter switch; pump, Lachrom L-7100 isocratic (Merck-Hitachi, Darmstadt, Germany); column, 250 mm × 4 mm Purospher RP-18e column; oven, Lachrom L-7350 (Merck-Hitachi); detector, Lachrom L-7420 UV–vis detector (Merck-Hitachi); mobile phase, methanol–acetonitrile–water in 35:35:30 ratio; flow rate, 1 ml min-1; column temperature, 35 °C; injection volume, 20 μl; detector wavelength and absorbance, 236 nm set at 0.04 absorbance units full scale; retention time, 7 min from injection.

The concentrated extract was dissolved in 200 μl of HPLC-grade methanol and 20 μl of this sample (equivalent to 1 g tuber sample) was injected into the system for quantification. The residues in tuber samples were quantified by comparing the peak area with that of a standard curve, since the peak area versus the CIPC concentration was linear within the range of concentrations (0.16–16 ppm) used in the investigations. CIPC residue in crisps, French fries and oil was estimated following the procedure described by Ritchie et al. (1983) and in water was estimated by the method of Mondy et al. (1992).

Statistical Analysis

A completely randomized design was followed with each treatment having three replications. The data were analysed using MSTAT 4.0C software and the means were separated using Tukey’s honestly significant difference test.

Results and Discussion

Cooking Methods

In the raw (uncooked) tuber, after 48 h of CIPC aerosol treatment, the CIPC residue in the peel was 4.7 mg kg-1, while in the peeled tuber it was 0.1 mg kg-1 (Table 1). Large variations have been reported in the residues determined in peels and peeled tubers, and CIPC residues in peels have been found to be 10 times higher than those in peeled tubers (Corsini et al. 1979; Conte et al. 1995). The CIPC residue concentrations in peel and peeled raw (uncooked) tuber were higher after 30 days of storage at 4 and 12 °C than that at 48 h after treatment, but the increase was significant only at 4 °C (Table 1). Although the increase is not expected as no additional CIPC was applied, this could be due to the uneven distribution of CIPC aerosol. As a result, the sample tubers collected 48 h after treatment might have had a lower deposition of CIPC on them, and the sample tubers collected after 30 days of storage might have had a higher deposition of CIPC on them. Uneven distribution of CIPC aerosol within the store has been observed by other researchers as well (Corsini et al. 1979; Kleinkopf et al. 1997). Conte et al. (1995) reported that CIPC residues can vary significantly as a function of sampling point in the storage cell. CIPC residue concentrations were higher in peels of tubers stored at 4 °C than in those stored at 12 °C. Since CIPC is volatile, greater volatilization can be expected at 12 °C than at 4 °C. Mondy et al. (1992) also observed higher volatilization of CIPC in tubers stored at 20 °C than in those stored at 5 °C. The method of cooking affected the CIPC residue concentrations in the peel and the peeled tuber (Table 1). When the potatoes were boiled, the mean CIPC residue in the peel of boiled tubers was significantly lower (4 mg kg-1) than that in the peel of raw (uncooked) tubers (9.3 mg kg-1), but in the flesh of the peeled tubers, there were no significant differences between boiled and raw tubers. Mondy et al. (1992) also observed significant reduction in the CIPC residue of the peel by boiling. The CIPC residue concentration in the boiling water was higher than that in the boiled and peeled tuber. The higher concentration of CIPC in the boiling water could be due to the leaching of CIPC residues from the peel into the water, during boiling. Lentza-Rizos and Balokas (2001) also observed CIPC residue in the boiling water, although the concentration in boiling water reported by them (0.2 mg kg-1) is lower than the concentration reported by us (1 mg kg-1). When the potatoes were pressure-cooked, the mean CIPC residue in the peel increased significantly (15 mg kg-1), compared with that in raw (uncooked) peel (9.3 mg kg-1). The mean CIPC concentration in pressure-cooked peeled tuber (0.8 mg kg-1) was higher than that in boiled peeled tuber (0.6 mg kg-1), but the difference was statistically non-significant. Mondy et al. (1992) reported that pressure cooking caused an increase in CIPC concentration in the cortex and they concluded that high pressure could have forced some of the residue from the periderm into the cortex. Koniger and Wallnofer (1998) also reported that pressure cooking resulted in the penetration of CIPC into the inner tissues. The mean CIPC concentration in the pressure-cooking water was higher (1.8 mg l-1) than that in boiled water (1 mg l-1), but the difference was statistically non-significant. When the potatoes were cooked in a microwave oven, the CIPC residue levels in the peel and in the peeled tuber were higher than those in the raw (uncooked) peel and raw (uncooked) peeled tuber, respectively, but the differences were statistically non-significant. The higher values of CIPC residue in microwave-cooked tubers could be due to the concentration effect caused by water loss. When the three cooking methods were compared, the CIPC residue concentration in the peel was significantly lower after boiling than after microwave and pressure cooking. However, the mean CIPC residue concentration in the peeled tuber flesh was not significantly affected by the cooking method.

Processing Methods

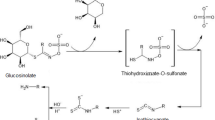

When they were prepared 48 h after CIPC treatment, potato crisps had a lower CIPC residue concentration (0.3 mg kg-1) than raw peeled tubers (0.4 mg kg-1), but the difference was non-significant (Fig. 1a). When they were prepared after 30 days of storage at 4 and 12 °C, crisps had CIPC residue concentrations that were significantly lower by 87 and 41%, respectively. This could be due to losses in CIPC residues during slicing and keeping the slices immersed in water (to prevent enzymatic browning) before frying. The CIPC concentration in the frying oil (0.5 mg kg-1) was higher than that in the fried crisps (0.3 mg kg-1) when crisps were prepared 48 h after CIPC treatment, but the differences were not significant. CIPC residues have been reported in potato crisps (Nagami 1997). In addition, Dalziel and Duncan (1980) reported tecnazene residues in potato crisps prepared from tubers treated with tecnazene.

Chlorpropham (CIPC) residues in a potato crisps of cv. Kufri Chipsona-2 and b French fries of cv. Kufri Chipsona-1, prepared 48 h after CIPC treatment and after 30 days of storage at 4 and 12 °C, and c dehydrated sliced potatoes and starch of cv. Kufri Jyoti, prepared 48 h after CIPC treatment. f wt fresh weight, LSD 0.05 least significant difference at the 5% significance level, NS not significant

When they were prepared 48 h after treatment or 30 days after storage at 4 °C, French fries had higher CIPC residue levels than raw (uncooked) peeled tubers, but in both cases the differences were non-significant. An increase in CIPC concentration in French fries could be due to the effect of water loss during frying. Also, losses in CIPC residues during the preparation of French fries could be expected to be less than those occurring during the preparation of crisps as more surface area is exposed in crisps. Up to 0.3 mg l-1 CIPC concentration was found in the frying oil during the frying of French fries. During the frying of both crisps and French fries, CIPC moved into the frying oil, indicating that the frying oil becomes contaminated with CIPC when CIPC-treated tubers are processed, and this will contaminate even the crisps and French fries prepared from untreated tubers during frying.

Dehydrated sliced potatoes and starch were prepared only 48 h after CIPC treatment and were not prepared after 30 days of storage. When compared with that in raw, peeled tubers (0.4 mg kg-1), the CIPC residue concentration was higher in dehydrated sliced potatoes (1.3 mg kg-1) but the difference was non-significant (Fig. 1c). The higher CIPC concentration in dehydrated sliced potatoes could be attributed to water loss during sun-drying. The CIPC residue concentration in dehydrated sliced potatoes was 4 times higher than that in fresh fried crisps. This was because loss of CIPC occurred while keeping the slices immersed in water and during frying of fresh crisps, whereas no such loss of CIPC occurred during the preparation of dehydrated sliced potatoes, as the slices were spread for drying, without keeping them in water. During the preparation of starch from CIPC-treated tubers, if the CIPC concentration in the peeled tubers was taken as the initial amount, then 56% of the residues were lost during the preparation of starch and only 44% remained in the starch (Fig. 1c). If the CIPC residue in the peel was also considered as the initial amount, then about 1% of the residue remained in starch and the rest was lost during washing and peeling. Hasegawa et al. (1992) processed CIPC-treated potatoes stored for 6 weeks at 5 °C into starch and found the amount of residue in starch to be less than 1% of the initial residue in unpeeled potatoes. They further observed that major losses in CIPC occurred during washing and a considerable portion remained in the refuse which contained the peel.

The mean CIPC concentration detected in raw (uncooked) peel was 9.3 mg kg-1, and in raw (uncooked) peeled tuber it was 0.7 mg kg-1. This shows that the CIPC concentration in whole tuber would be much lower than that in peel and, therefore, within the maximum residue level (MRL) of 10 mg kg-1 prescribed by the European Union (Anonymous 2002; Kleinkopf et al. 2003) and 30 mg kg-1 prescribed by the US Environmental Protection Agency (EPA 1996). Although the MRL applies only to raw (uncooked) potatoes, it may be said that the increase in CIPC concentration caused by different methods was also within the limit, as the highest CIPC concentration observed in peeled tuber was 3.8 mg kg-1 in microwave-cooked tubers after 30 days of storage at 4 °C. The CIPC concentration in cooked peel was considerable, with the highest values for all cooking methods being attained after 30 days of storage at 4 °C. Anyway, this CIPC would be removed during peeling.

Abbreviations

- CIPC:

-

Isopropyl N-(3-chlorophenyl) carbamate

- HPLC:

-

High-performance liquid chromatography

- MRL:

-

Maximum residue level

References

Anonymous (2002) CIPC suppliers prepared for residue limit. Potato Rev (Nov): 20–23

Boyd IMG, Dalziel J, Duncan HJ (1982) Studies on potato sprout suppressants. 5. The effect of chlorpropham contamination on the performance of seed potatoes. Potato Res 25:51–57

Central Potato Research Institute (1999) Package of practices for ware and seed potato production in north-western hills. Extension Bulletin 15. Central Potato Research Institute, Shimla

Conte E, Imbroglini G, Bertolini P, Camoni I (1995) Presence of sprout inhibitor residues in potatoes in relation to application techniques. J Agric Food Chem 43:2985–2987

Corsini D, Stalknecht G, Sparks W (1979) Changes in chlorpropham residues in stored potatoes. Am Potato J 56:43–50

Dalziel J, Duncan HJ (1980) Studies on potato sprout suppressants. 4: The distribution of tecnazene in potato tubers and the effect of processing on residue levels. Potato Res 23:405–411

EPA (1996) Registration eligibility decision. Environmental Protection Agency (EPA)-738-R-96–023

Ezekiel R, Mehta A, Singh B, Kumar D, Kumar NR, Paul V, Das M (2005) CIPC (isopropyl N-(3-chlorophenyl) carbamate) for sprout suppression in potatoes during storage. Technical Bulletin 69. Central Potato Research Institute, Shimla

Hasegawa Y, Tonogai Y, Nakamura Y, Ito Y (1992) Residue concentrations of dichlorvos, chlorpropham and pyrethrins in post harvest-treated potatoes during storage or processing into starch. J Agric Food Chem 40:1240–1244

Kleinkopf GE, Brandt TL, Frazier MJ, Moller G (1997) CIPC residues on stored Russet Burbank potatoes: 1. Maximum label application. Am Potato J 74:107–117

Kleinkopf GE, Oberg NA, Olsen NL (2003) Sprout inhibition in storage: current status, new chemistries and natural compounds. Am Potato J 80:317–327

Koniger M, Wallnofer PR (1998) Behaviour of growth inhibitors propham (IPC) and chlorpropham (CIPC) in potatoes after different cooking methods. Dtsch Lebensm Rundsch 94:229–231

Lentza-Rizos C, Balokas A (2001) Residue concentrations of chlorpropham in individual tubers and composite samples of post harvest-treated potatoes. J Agric Food Chem 49:710–714

Lewis DJ, Thorpe SA, Reynolds SL (1996) The carry-through of residues of thiabendazole, tecnazene and chlorpropham from potatoes following manufacture into potato crisps and jacket potato crisps. Food Addit Contam 13:221–229

Mondy NI, Sharada D, Munshi CB, Wurm CM (1992) Effect of storage time, temperature and cooking on isopropyl N-(3-chlorophenyl) carbamate concentrations in potatoes. J Agric Food Chem 40:197–199

Nagami H (1997) Residues of maleic hydrazide and chlorpropham in potato chips. Bull Environ Contam Toxicol 58:764–768

Ritchie W, Boyd IMG, Duncan HJ (1983) A method for the determination of chlorpropham residues in crisps and crisp frying oil. Potato Res 26:73–77

Singh B, Kaul HN (1999) Analysis of chlorpropham (CIPC) residues in stored potato tubers by gas chromatography. Indian J Plant Physiol 4:121–124

Van Vliet WF, Sparenberg H (1970) The treatment of potato tubers with sprout inhibitors. Potato Res 13:223–227

Verma SC (1991) Potato processing in India. Technical Bulletin 34. Central Potato Research Institute, Shimla

WHO/FAO (1964) Evaluation of the toxicity of pesticide residues in foods; report of the joint meeting of the FAO committee on pesticides in agriculture and the WHO expert committee on pesticide residues. FAO meeting report PL/1963/13: WHO Food Add./23. FAO, Rome

Wilson AM, Bushway AA, Bushway RJ (1981) Residue analysis of isopropyl N-(3-chlorophenyl) carbamate in fruits and vegetables using high-performance liquid chromatography. J Agric Food Chem 29:746–749

Acknowledgements

The authors are grateful to the Director, Central Potato Research Institute, Shimla for facilities and to Suresh Kumar for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ezekiel, R., Singh, B. Effect of Cooking and Processing on CIPC Residue Concentrations in Potatoes and Processed Potato Products. Potato Res. 50, 175–184 (2007). https://doi.org/10.1007/s11540-008-9043-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11540-008-9043-z