Abstract

This study aimed to assess the effect of sous vide cooking on the total and resistant starch content, color, and shear force in three potato cultivars (Agria, Agata, and Carrera). Potato strips were also cooked by three common treatments (boiling, frying, and microwaving) to evaluate the differences between the methods. According to principal component analysis (PCA), sous vide-processed cv. Agria and Agata potato strips were grouped with boiled samples, in contrast, cv. Carrera sous vide samples were grouped with microwaved samples. Higher water losses were associated with microwaved potatoes due to the diffusion of water inside the tuber. In addition, a significant decrease in shear force was obtained after microwaving and sous vide cooking (p < 0.05) irrespective of the treatment strength. The three cultivars became less bright, and the intensity of the color decreased; however, variations in the cook value (C 100, min) between treatments did not affect the lightness and hue angle. Regardless of the initial value of resistant starch and the intensity of the cooking process, all of the cultivars reached a final content of less than 5%. From our results, in-pack sterilization may be considered for application in the food industry as a technology that has a similar impact to conventional cooking treatments used on potato products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Some consumers consider ready-to-eat foods as standardized, mass produced, and unappetizing because they believe that they are made with low-quality ingredients, such as overcooked vegetables, and contain excessive amounts of salt, fat, and food additives (Costa and Jongen 2010). Sous vide, or in-pack cooking, is a method that may be suitable for application in the food industry to improve the quality of convenience meals. Sous vide processing consists of cooking foodstuffs (e.g., meat, fish, and vegetables) at product-specific temperatures and times in vacuum pouches, followed by rapid cooling and storage at refrigerator temperatures. This cooking method is widely applied in restaurants and in catering because it improves the texture, color, and flavor of meat and vegetable foodstuffs due to two factors: the absence of oxygen inside the pack and the mild heat treatment applied (Baldwin 2012). The safety of these products has been previously evaluated. Hyytiä-Trees et al. (2000) stated that depending on the food product, the degree of benefit of the sous vide cooking method can be compromised in terms of safety. They concluded that the degree of the pasteurization process must assure the product safety in terms of food-borne pathogens, such as non-proteolytic C. botulinum. In recent years, several studies have focused on the advantages of sous vide cooking in terms of sensorial and nutritional quality. Chiavaro et al. (2012) concluded that depending on the vegetable structure, the benefits of sous vide cooking can differ; however, these authors demonstrated that the nutritional quality of sous vide-processed carrots was enhanced compared to conventional cooking. On the other hand, the loss of texture had to be considered to avoid sensory losses (Lemmens et al. 2013). Studies on sous vide cooking on Kailan-hybrid broccoli showed that the softening obtained (54–58%) was considered to be moderate and pleasant compared to other cooking treatments. Color changes of the Kailan-hybrid broccoli tissues were also the lowest (Martínez-Hernández et al. 2013). Few research studies are available for the sous vide cooking of potato. Recent studies on purple potato “Vitelotte” agreed with the enhancement of the nutritional value of pasteurized sous vide cooking versus vacuum boiling because of the retention of anthocyanin compounds. Moreover, the retention of the color and texture of sous vide cooked potatoes was better (Iborra-Bernad et al. 2014). Lante and Zocca (2010) studied the effect of β-cyclodextrin in pasteurized cultivar (cv.) Agata potatoes under vacuum (75 °C for 40 min) to improve the after-cooking darkening of the potato surface. However, these authors detected growth of aerobic mesophilic bacteria during storage at 4 °C. García-Segovia et al. (2008) evaluated the effect of three cooking methods on the texture of potato cv. Monalisa (texture profile analysis parameters) and found that sous vide cooking was not significantly different to boiling or vacuum cooking under any of the conditions that were assessed (time/temperature); however, significant differences were obtained as the temperature increased.

The data reported in the literature mimics the conditions of sous vide cooking used in the catering industry (mainly pasteurization), but for the authors’ knowledge, there are scarce studies on the possibility of applying sous vide processing in the food industry to produce safe ready-to-eat potato products. However, the potato composition, sensory properties, and technological issues (as after-cooking darkening) must be considered in the design of these products. As is well known, starch is the main nutritional component of potato and is responsible for the properties of the cooked product (Camire et al. 2009; Aina et al. 2012). The effect of common cooking methods on potato have been evaluated through weight loss studies and changes of color and instrumental textural properties, such as textural profile analysis (TPA), shear force, and crust hardness (Chiavaro et al. 2006). Texture is an essential factor in the consumer’s perception and has been associated with the starch profile and pectin, dry matter, amylose, sugars, proteins, and total nitrogen contents of the potato tuber (Van Dijk et al. 2002; García-Segovia et al. 2008; Pedreschi et al. 2012). After being heat-treated, the potato became softer and the color of the tuber was negatively affected by a loss of luminosity, chroma, and hue (Pedreschi et al. 2005; Chiavaro et al. 2006). Few studies have reported changes in the resistant starch (RS) of potatoes after being cooked. García-Alonso and Goñi (2000) noted that after being cooked, non-digestible starch became available, but there were remarkable differences between cooking methods (78.18% after boiling, 52.70% after frying), which is in agreement with a previous study by Kingman and Englyst (1994). Additionally, Monro et al. (2009) stated that the RS content of potato after being boiled depended on the potato cultivar.

The main aim of this work was to evaluate the effect of sous vide processing versus common cooking treatments (frying, boiling, and microwaving) on the chemical and physical properties of three potato cultivars. The effect of the treatments on the starch profile of potatoes, focusing on the resistant starch content, and the physical properties (color and texture) of the potato tissues was assessed. Additionally, the properties of three potato cultivars were also studied.

Materials and Methods

Samples

Three European potato cultivars, two defined as multi-purpose (Agata and Carrera) and one as floury (Agria), were selected for this study. Potatoes were supplied by Mercabarna (Mercados de Abastecimientos de Barcelona, S. A).

Experimental Process

Potato tubers, washed and free of defects, were selected according to their weight and size (250 ± 45 g, 10–12 cm in height, and 6–8 cm in diameter, respectively); the samples were stored at 5 ± 2 °C and a relative humidity of 65 ± 4% until use. Three independent experiments were conducted. For each experiment and cultivar, 40 tubers were hand-peeled and cut into rectangular strips (7 × 1.4 × 1.4 cm), and the external strips of the tuber were discarded. Four different cooking treatments were carried out: boiling, frying, microwaving, and sous vide processing. The cooking processes were determined previously according to the palatability of the product.

Boiling

Boiling was carried out in distilled water at a proportion of 2:1 (w/w) at 100.0 °C for 10 min in a stainless steel pot (Fernandes et al. 2005).

Frying

Frying was conducted for 7 min in an electrical fryer (Taurus Professional Compact, Oliana, Spain), in a proportion of 4:1 (w/w) (Gökmen and Palazoğlu 2009). After frying, the fried strips were placed on absorbent paper to remove the excess oil.

Microwaving

For microwaving, potato strips were placed in a lunchbox that was suitable for microwave cooking with a gas outlet and were treated at 700 W for 9 min and 30 s according to Fernandes et al. (2005) in a conventional microwave LG MG-3924 W (LG Corp., Seoul, Korea).

Sous Vide Cooking

The sous vide process was designed in a previous work and the F 0 was 1.0 ± 0.1 min (unpublished results). The potato strips were previously packaged into plastic pouches PA/PEHD (70/150; 220 μm) under vacuum at −98 kPa (ORVED Spa., Musile di Piave, Italy). The dimensions of the pouches were 100 × 250 mm. Sous vide cooking was carried out in a retort (mini STER PE50, ILPRA Systems, Barcelona, Spain). The heat transfer was conducted by steam with continuous agitation. The maximum core temperature was fixed at 117 ± 1 °C. During this process, the temperature was monitored with an internal thermocouple.

For the other three cooking treatments (boiling, frying, and microwaving), the core temperature was monitored using a thermocouple (Testo 926, Testo AG, Lenzkirch, Germany). The cook values (C 100, min) were calculated for each cooking treatment (Eq. 1). The reference cook value of the center of the potato is characterized by zQ = 17.0 °C and T ref = 100 °C (Ling et al. 2015, Pravisani and Calvelo, 1986). After being cooked, the potato strips were cooled.

Chemical and Physical Analysis

Dry Matter Content

Dry matter (DM) was determined by oven drying at 65 °C for 24 h (AOAC 1990); four determinations were performed for each variety and heat treatment. The results are expressed in grams per·kilogram.

Total and Resistant Starch

The total starch (TS) was assessed following the AOAC 996.11-2005 method (K-TSTA, Megazyme International Ireland Ltd., Wicklow, Ireland). The sample was dispersed in aqueous ethanol (80%) and re-suspended in 2 M KOH. Hydrolysis was performed with α-amylase and amyloglucosidase (AMG) at 50 °C for 30 min with intermittent mixing in 1.2 M sodium acetate buffer (pH 3.8) and was quantified by a colorimetric reaction at an absorbance of λ = 510 nm using a spectrophotometer (Nicolet Evolution 300, Thermo Electron Corporation, Waltham, USA). The RS was assessed following AOAC 2002.02-2005 procedure (K-RSTAR, Megazyme International Ireland Ltd., Wicklow, Ireland). The samples diluted with α-amylase and AMG were incubated at 37 °C with continuous agitation for 16 h. The supernatant was discarded, and the residue was dispersed in ethanol using vortex agitation. The sample was centrifuged, and the residue containing the resistant starch was re-suspended in 2 M KOH. The subsequent hydrolysis and the colorimetric quantification was the same as the total starch determination. Six replicates for each treatment and variety were made for the determination of the total and resistant starch. The samples were previously dried at 35 ± 5 °C for 48 h and sieved to a particle size less than 500 μm. The results are expressed in grams of starch·per kilogram of dry matter. Soluble starch was calculated as the difference between the total and resistant starch content (García-Alonso and Goñi 2000). The ratio between the resistant starch and total starch (RS/TS) was also calculated.

Shear Force

Shear force was measured using a texture analyzer TA. XT Plus (Stable Micro Systems Ltd., Surrey, UK). A Warner-Blatzer blade set was used to evaluate the shear force of the samples. The test speed was 1 mm·s−1, and the penetration distance was 30 mm, with a 30-kg load cell. Force-distance curves were obtained, and the shear force is expressed as the maximum shear force (N). The degree of cooking of the potato was calculated as the ratio between the thermal shear force of the potato (F 02) and the original shear force (F 01) according to Alvarez and Canet (2009). For each variety and heat treatment, 60 independent measurements were performed.

Color

The color of the surface of raw and cooked potato strips was determined using a colorimeter Minolta Chromo Meter CR-400 (Minolta Camera Co. Ltd., Osaka, Japan) in the CIELab space (Illuminant D65, 10° viewing angle). The L* (lightness), a* (greenness [−] to redness [+]), and b* (blueness [−] to yellowness [+]) values were measured. For each cultivar and heat treatment, 30 measurements were performed. The chroma (C*) and hue angle (H*) parameters were also calculated according to Eqs. 2 and 3, respectively.

Cell Microstructure

The cell structural changes were studied by optical microscopy in the various types of potatoes. For observation, histological cuts were made using a scalpel in raw and heat-treated potato strips. The cuts were examined using a light microscope (Nikon Trinocular Microscope Alphaphot 2 s2, Tokyo, Japan), and micrographs were taken at different magnifications (×100 and ×400) to observe the changes in the cellular wall structure and starch grains.

Statistical Analysis

Data is the mean of three independent experiments. The effect of the cooking treatments on the variables studied was analyzed by one-way analysis of variance (ANOVA) using Minitab17 Statistical Software (Minitab Inc. State College, USA). Differences between the mean values were evaluated using the HSD Tukey’s test with a 95% confidence interval. Principal component analysis (PCA) was performed to understand the relationship between the cultivars, the cooking treatments, and the parameters studied.

Results and Discussion

Starch Profile, Physical Properties, and Cell Microstructure of Fresh Potatoes

The three potato cultivars (Agria, Agata, and Carrera) varied significantly across the majority of the parameters studied (dry matter, total starch content, color, and shear force) (p < 0.05) (Table 1). The dry matter content of the Agria cultivar was 35% higher than the other two cultivars. However, the resistant starch content of the Carrera cultivar is significantly lower than Agria and Agata. In addition, the starch profile of the three cultivars varied significantly (p < 0.05). Agria contained the highest total starch content, but had a similar RS/TS ratio to Agata. For these three varieties, the resistant starch accounted for 50.21–60.70% of the dry matter. Previous researchers reported that fresh potato contains 48.20–76.42% RS (García-Alonso and Goñi 2000; Lante and Zocca, 2010; Yang et al. 2015).

As is shown in Table 1, the higher the dry matter content, the higher the shear force obtained. Thus, the Agria cultivar was the hardest, and Carrera was the softest. These observations coincide with the total starch content. It is known that there is a strong correlation between the dry matter and texture of potatoes. However, we obtained a linear non-significant Pearson correlation (0.992; p = 0.079). The water content and starch profile can further explain the relationship between the dry matter and potato texture. Figure 1 shows the contour diagrams of the shear force with dry matter and RS (Fig. 1a) or TS (Fig. 1b). Shear force was also dependent on the amount of total or resistant starch. Potatoes with similar dry matter can be classified into three types: waxy, general purpose, and floury (Monro et al. 2009). The starch profile and water content are responsible for the final texture of potatoes. In addition, light micrographs showed a qualitative difference in the microstructure of the parenchyma and in the size and shape of the cell between cultivars (Fig. 2). Agria cv. contained a remarkable amount of starch granules inside the cell, followed by Agata and Carrera. These results are in agreement with the differences obtained in the total starch content.

Agria exhibited the most intense yellow color (H* = 82.81 ± 058), the highest luminosity (L* = 70.69 ± 1.88), and chroma (C* = 34.46 ± 2.34) of the three cultivars assessed. Agata and Carrera cultivars showed duller white colors Lu et al. (2001) positively correlated the yellow color of potato flesh with the carotenoid content. For Agria, the carotenoid content was in the range of 4.5 to 8.5 mg·kg−1 DM (Hejtmánková et al. 2013). To the best of our knowledge, no carotenoid content has been reported elsewhere for Agata and Carrera cultivars.

Effect of the Cooking Treatments

Temperatures up to 50 °C promote the absorption of water by starch granules and their swelling. Then, between 64 and 71 °C, the gelatinization of starch begins, together with the separation between the potato cellules, which become rounded (Alvarez and Canet 2009). The average increase in the core temperature of the potato strips during the four thermal treatments is shown in Fig. 3. Frying and boiling achieved a core temperature of 71 °C in less than 1 and 2.5 min, respectively; whereas, microwave and sous vide processing required 3.5 and 8 min, respectively. However, the highest core temperature was obtained in sous vide processing (117.3 ± 2.0 °C), as expected. The other treatments did not exceed 100 °C (93.3 ± 2.0 °C for boiling, 96.1 ± 2.0 °C for frying, or 98.6 ± 2.0 °C for microwaving). The heat treatment intensity was compared with the cook value (C 100), which relates the quality loss during a high-temperature thermal process to an equivalent cooking process at 100 °C. The level of intensity was remarkably higher for sous vide cooking (22.02 min) compared to the other culinary treatments of boiling (2.31 min), microwaving (2.71 min), and frying (2.41 min).

Dry Matter

The dry matter content of potatoes after processing is presented in Table 2. Significant differences between treatments were found for the three cultivars assessed (p < 0.05). However, frying was not included in the reported statistical analysis because part of the remarkable increase in dry matter was due to the absorption of oil during the treatment. The absorption of oil is related to the potato/oil ratio (w/w) during frying; a lower ratio may cause a large absorption (De Wilde et al. 2006). From our results, the differences in the dry matter content between the fresh potatoes did not explain the dry matter content obtained after frying at the same potato/oil ratio. The ratio between the dry matter after frying and the original dry matter of the potato was 10% less for the Carrera cultivar.

For boiling and sous vide cooking, cv. Carrera showed a different behavior than cv. Agria and Agata. Sous vide-processed Agria and Agata potatoes had a slightly relative increment of dry matter (0.2–3.2%, respectively), while it was 15% for cv. Carrera. Boiling exhibited a similar variation for cv. Agata and Agria (less than 11%), while it was only a 3.6% for Carrera. During sous vide processing, the tubers are cooked inside the package under vacuum; the higher water content and lower total starch content of Carrera may play a role in the exuded formation. In contrast, microwave cooking caused a relative increase of 39.0 to 46.4% of dry matter. Microwaving produced higher water losses than boiling and sous vide treatments due to the diffusion of water inside the tuber. Our results are in agreement with Błaszczak et al. (2004). These authors studied the mechanical properties and microstructure of potatoes after they were cooked and concluded that the microstructure of microwaved potatoes differs notably from boiled potatoes. Moreover, the higher weight loss (19–23%) was due to the less hydrated and swollen starch granules, which promote the evaporation of cellular water during microwave cooking.

Shear Force

As expected, all of the treatments strongly reduced the shear force of the tuber (90–95%), indicating the softening of the product (Table 2). The softness of the cooked potato is attributable to the dissolution of the calcium-pectin gel in the wall matrix and in the middle lamella (Chiavaro et al. 2006). In general, fried samples obtained the highest shear force due to the crust formed on the surface of the sample during the frying process. In contrast, the microwave and sous vide treatments achieved the largest softness for the three cultivars studied (p < 0.05). However, there was no relationship between the cook values of the treatments and the degree of cooking (F 02/F 01). In our study, Agria cultivar showed the highest shear force for all of the thermal treatments but the degrees of cooking were similar to Agata. According to Kozempel (1988), the potato cultivar or batch did not affect the rate of change of this value. In contrast, Carrera showed a lower degree of cooking than the other two cultivars assessed. Garcia-Segovia et al. (2008) reported that the texture of cooked potatoes is directly associated with the dry matter content. From our results, highly significant Pearson correlation coefficients were found between dry matter and shear force for Agria and Agata (0.838, 0.842, respectively; p < 0.001) and were lower for Carrera (0.697; p < 0.01).

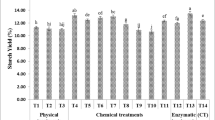

Starch Profile

The treatments resulted in a new starch profile in all of the cultivars. In general, the application of heat resulted in a remarkable reduction in the resistant starch (RS) content and an increase in the soluble starch content (Fig. 4). The RS losses were 63.4–81.7%, and the total starch (TS) losses were 1.6–16.8%, depending on the treatment and cultivar assessed. According to our results, both factors have an influence on the final RS and TS content. The less densely packed microstructure and higher degree of gelatinization involved lesser RS in the potato cells. The RS content of cv. Agria was reduced more significantly by frying, whereas sous vide processing and boiling exerted the highest change to cv. Agata and Carrera, respectively (p < 0.05). The differences obtained between cultivars may be due to the differences in the potato cell microstructure, starch granule morphology, and available water during the cooking process. The final core temperature and intensity of the treatment (cook values, C 100) do not appear to have a clear effect, as all of the treatments exceeded the gelatinization temperature (71 °C). Mulinacci et al. (2008) noted that microwave cooking tended to reduce the starch availability versus traditional boiling due to the water evaporation. From our results, this effect was found in cv. Agria, but was not as clearly exhibited by cv. Agata and Carrera, although the corresponding water loss was observed. The cell microstructure of cv. Agria is showed in Fig. 5. Microwaving tends to promote the crystallization of potato starch; while boiling induces the breaking of the starch crystals. After being cooked, potato cells showed a disruption of the starch granules due to gelatinization. Frying and microwaving treatments may promote similar changes inside the parenchyma whereas sous vide may affect the cellular turgidity. Water removal from the cells during the first steps in the cooking process and the distribution of starch granules might explain the differences found in this study. Nevertheless, after being treated, the RS content was lower than 8 g·100 g−1 DW in the three cultivars assessed. In addition, the RS/TS ratios also varied depending on the cultivar and culinary treatment (5.36% for boiled cv. Carrera to 10.43% for boiled cv. Agria). It must be highlighted that sous vide-processed potatoes obtained similar RS/TS ratios for the three cultivars assessed.

Color

All of the culinary treatments had an effect on the color parameters, with losses in lightness (L*), hue, and chroma for all of the cultivars (Fig. 6). It is known that the chroma increases if the pigment concentration increases and then decreases when the sample becomes darker. Chroma was the color parameter most affected, depending on the cultivar and culinary treatment. The loss of color of cv. Agata and Carrera was remarkable compared with cv. Agria. This yellow cultivar retained its lightness and hue better. Therefore, the color of white cultivars was more sensitive to all of the cooking processes. Surprisingly, the intensity of the treatment did not impact the color loss proportionately. Boiling, sous vide processing, and microwave cooking involved higher losses in color than frying for all of the cultivars. Moreover, the microwaved samples retained their color (C*, and hue) better than boiled or sous vide-processed potatoes. A non-enzymatic reaction, where a colored chlorogenic acid-ferric iron complex is formed, may be responsible for the after-cooking darkening of potatoes (Adams and Brown, 2007). The lightness (L*) measured on the surface of the potato may be useful to determine that phenomenon (Lante and Zocca 2010). The authors proposed that the difference between the final and initial values of L* (∆L*) can be compared between samples to avoid the possible variation between cultivars. From our results, after-cooking browning was more evident for cv. Carrera for all of the cooking treatments, followed by cv. Agata. These results are in agreement with the changes obtained in chroma, suggesting that the losses in both parameters explain the darkening of the samples. Boiling and sous vide cooking promoted similar changes in the three cultivars studied.

The color changes from frying were due to the increase in the parameter a*, as a result of non-enzymatic browning reactions on the surface of the potato, which are highly dependent on temperature and the reducing sugar content (Pedreschi et al. 2005). Krokida et al. (2001) suggested that the b* value increased with frying time, resulting in more yellow products, which are more desirable for fried products. In agreement with previous reports, the cv. Agata and Carrera a* value increased (−3.77 to −3.59 and −4.59 to 3.83), but the b* values decreased (18.98 to 13.48 and 26.06 to 18.54), resulting in darker potatoes. However, after frying, the yellow color of cv. Agria improved (a* −4.31 to −6.32, b* 34.19 to 35.55). The different behavior of the cultivars after frying may be due to their reducing sugar content.

Principal Component Analysis

Principal component analysis was performed to visualize the response patterns in the feature space of the principal components (PCs). The cooking treatments are displayed in the score plot (Fig. 7a), while the loading plot shows the chemical and physical parameters studied (Fig. 7b). PC1 and PC2 account for 80.40% of the data variance and explain the difference between cultivars and treatments. PC1 was determined by the color parameters, dry matter content, and texture; whereas, the TS and RS accounts for PC2. A clear separation of the cooking treatments and cultivars was obtained in the score plot. Frying was distributed in the positive area of both components, as these samples contained the highest dry matter, hue, and shear force. Moreover, cv. Agria was clearly separated from the other two cultivars according to the cultivar properties that define PC1. It should be noted that the boiled cv. Agata and Carrera were clearly separated due to PC2, which is in agreement with their TS content after being processed. For cv. Agria and Agata, sous vide processing is grouped close to the boiled samples; whereas, it is grouped close to the microwaved sample for cv. Carrera. PCA analysis confirms our findings in this work; the potato cultivar properties may determine primarily the repercussions of the cooking treatment on the potato tissue.

Principal component analysis of the cooking treatments. a

Agata-Boiling.

Agata-Boiling.  Agata-Frying.

Agata-Frying.  Agata-Microwaving.

Agata-Microwaving.  Agata Sous vide.

Agata Sous vide.  Agria-Boiling.

Agria-Boiling.  Agria-Frying.

Agria-Frying.  Agria-Microwaving.

Agria-Microwaving.  Agria Sous vide. ּ Carrera-Boiling.

Agria Sous vide. ּ Carrera-Boiling.  Carrera-Frying.

Carrera-Frying.  Carrera-Microwaving.

Carrera-Microwaving.  Carrera-Sous vide. b RS resistant starch, TS total starch, SS soluble starch

Carrera-Sous vide. b RS resistant starch, TS total starch, SS soluble starch

Conclusions

The effects of the cooking treatment on the properties of potato are highly dependent of the initial characteristics of the potato cultivar studied. Potatoes classified as floury (cv. Agria) may be less affected than multi-purpose (cv. Agata) potatoes after being cooked.

The cooking treatments had an effect on the physical properties of potatoes (shear force and color) together with changes in the main components of the potatoes. The solubilization of RS during the cooking process is the main outcome, but how the process affects the microstructure of the cells determines the impact of the treatment. The results obtained indicate that sous vide processing has a similar effect on the cultivars assessed and that the consequences of the treatment are comparable to boiling and microwaving, although differences were observed and were dependent on the intensity between the three treatments. Therefore, sous vide processing is a valid alternative to common cooking treatments.

It should be noted that sous vide processing have some advantages over the other treatments studied, which the present work was not designed to investigate. In-pack processing avoids recontamination of the product after being processed, so a longer shelf-life is expected. Additionally, cold storage during the shelf-life of sous vide potato products promotes the retrogradation of starch, thus the RS content would increase over time.

In conclusion, sous vide processing may be applied as an industrial alternative to common cooking treatments. However, further research is needed to evaluate the effect of cold storage on the nutritional and sensorial properties of these products during their shelf-life.

References

Adams, J. B., & Brown, M. (2007). Discoloration in raw and processed fruits and vegetables. Critical Reviews in Food Science and Nutrition, 47(3), 319–333.

Aina, A. J., Falade, K. O., Akingbala, J. O., & Titus, P. (2012). Physicochemical properties of caribbean sweet potato (Ipomoea batatas (L) Lam) starches. Food Bioprocess Technology, 5(2), 576–583.

Alvarez, M. D., & Canet, W. (2009). Thermal processing and quality optimization. In J. Singh & L. Kaur (Eds.), Advances in potato chemistry and technology. MA: Academic Press. Elsevier Burlington.

AOAC (1990). AOAC Official Methods of Analysis. (15th ed., Vol. 2, p. 614). Arlington, VA, USA.

AOAC 2002.02-2005. Resistant starch in starch and plant materials. Enzymatic digestion. AOAC Official Methods of Analysis. (19th Ed.). Arlington, VA, USA.

AOAC 996.11-2005. Starch (total) in cereal products. Amyloglucosidase-α-amylase method. AOAC Official Methods of Analysis. (19th Ed.). Arlington, VA, USA.

Baldwin, D. E. (2012). Sous vide cooking: a review. International Journal of Gastronomy and Food Science, 1(1), 15–30.

Błaszczak, W., Sadowska, J., Fornal, J., Vacek, J., Flis, B., & Zagórski-Ostoja, W. (2004). Influence of cooking and microwave heating on microstructure and mechanical properties of transgenic potatoes. Nahrung/Food, 48(3), 169–176.

Camire, M. E., Kubow, S., & Donnelly, D. J. (2009). Potatoes and human health. Critical Reviews in Food Science and Nutrition, 49(10), 823–840.

Chiavaro, E., Barbanti, D., Vittadini, E., & Massini, R. (2006). The effect of different cooking methods on the instrumental quality of potatoes (cv. Agata). Journal of Food Engineering, 77(1), 169–178.

Chiavaro, E., Mazzeo, T., Visconti, A., Manzi, C., Fogliano, V., & Pellegrini, N. (2012). Nutritional quality of sous vide cooked carrots and Brussels sprouts. Journal of Agricultural and Food Chemistry, 60(23), 6019–6025.

Costa, A. I. A., & Jongen, W. M. F. (2010). Designing new meals for an ageing population. Critical Reviews in Food Science and Nutrition, 50(6), 489–502.

De Wilde, T., De Meulenaer, B., Mestdagh, F., Govaert, Y., Ooghe, W., Fraselle, S., Demeulemeester, K., Van Peteghem, C., Calus, A., Degroodt, J.-M., & Verhé, R. (2006). Selection criteria for potato tubers to minimize acrylamide formation during frying. Journal of Agricultural and Food Chemistry, 54(6), 2199–2205.

Fernandes, G., Velangi, A., & Wolever, T. (2005). Glycemic index of potatoes commonly consumed in North America. Journal of the American Dietetic Association, 105(4), 557–562.

García-Alonso, A., & Goñi, I. (2000). Effect of processing on potato starch: in vitro availability and glycaemic index. Starch - Stärke, 52(2–3), 81–84.

García-Segovia, P., Andrés-Bello, A., & Martínez-Monzó, J. (2008). Textural properties of potatoes (Solanum tuberosum L. cv. Monalisa) as affected by different cooking processes. Journal of Food Engineering, 88(1), 28–35.

Gökmen, V., & Palazoğlu, T. K. (2009). Measurement of evaporated acrylamide during frying of potatoes: effect of frying conditions and surface area-to-volume ratio. Journal of Food Engineering, 93, 172–176.

Hejtmánková, K., Kotíková, Z., Hamouz, K., Pivec, V., Vacek, J., & Lachman, J. (2013). Influence of flesh colour, year and growing area on carotenoid and anthocyanin content in potato tubers. Journal of Food Composition and Analysis, 32(1), 20–27.

Hyytiä-Trees, E., Skyttä, E., Mokkila, M., Kinnunen, A., Lindström, M., Lähteenmäki, L., Ahvenaiben, R., & Korkeala, H. (2000). Safety evaluation of sous-vide-processed products with respect to nonproteolytic Clostridium botulinum by use of challenge studies and predictive microbiological models. Applied and Environmental Microbiology, 66(1), 223–229.

Iborra-Bernad, C., García-Segovia, P., & Martínez-Monzó, J. (2014). Effect of vacuum cooking treatment on physicochemical and structural characteristics of purple-flesh potato. International Journal of Food Science and Technology, 49(4), 943–951.

Kingman, S. M., & Englyst, H. N. (1994). The influence of food preparation methods on the in-vitro digestibility of starch in potatoes. Food Chemistry, 49(2), 181–186.

Kozempel, M. F. (1988). Modeling the kinetics of cooking and precooking potatoes. Journal of Food Science, 53(3), 753–755.

Krokida, M. K., Oreopoulou, V., Maroulis, Z. B., & Marinos-Kouris, D. (2001). Colour changes during deep fat frying. Journal of Food Engineering, 48(3), 219–225.

Lante, A., & Zocca, F. (2010). Effect of β-cyclodextrin addition on quality of precooked vacuum packed potatoes. LWT-Food Science and Technology, 43(3), 409–414.

Lemmens, L., Colle, I., Knockaert, G., Van Buggenhout, S., Van Loey, A., & Hendrickx, M. (2013). Influence of pilot scale in pack pasteurization ad sterilization treatments on nutritional and textural characteristics of carrot pieces. Food Research International, 50(2), 526–533.

Ling, B., Tang, J., Kong, F., Mitcham, E. J., & Wang, S. (2015). Kinetics of food quality changes during thermal processing: a review. Food Bioprocess Technology, 8(2), 343–358.

Lu, W., Haynes, K., Wiley, E., & Clevidence, B. (2001). Carotenoid content and color in diploid potatoes. Journal of the American Society for Horticultural Science, 126(6), 722–726.

Martínez-Hernández, G. B., Artés-Hernández, F., Colares-Souza, F., Gómez, P. A., García-Gómez, P., & Artés, F. (2013). Innovative cooking techniques for improving the overall quality of a Kailan-hybrid broccoli. Food Bioprocess Technology, 6(8), 2135–2149.

Monro, J., Mishra, S., Blandford, E., Anderson, J., & Genet, R. (2009). Potato genotype differences in nutritionally distinct starch fractions after cooking and cooking plus storing cool. Journal of Food Composition and Analysis, 22(6), 539–545.

Mulinacci, N., Ieri, F., Giaccherini, C., Innocenti, M., Andrenelli, L., Canova, G., Saracchi, M., & Casiraghi, M. C. (2008). Effect of cooking on the anthocyanins, phenolic acids, glycoalkaloids, and resistant starch content in two pigmented cultivars of Solanum tuberosum L. Journal of Agricultural and Food Chemistry, 56(24), 11830–11837.

Pedreschi, F., Moyano, P., Kaack, K., & Granby, K. (2005). Colour changes and acrylamide formation in fried potato slices. Food Research International, 38(1), 1–9.

Pedreschi, F., Bunger, A., Skurtys, O., Allen, P., & Rojas, X. (2012). Grading of potato chips according to their sensory quality determined by color. Food Bioprocess Technology, 5(6), 2401–2408.

Pravisani, C. I., & Calvelo, A. (1986). Minimum cooking time for potato strip frying. Journal of Food Science, 51(3), 614–617.

Van Dijk, C., Fischer, M., Holm, J., Beekhuizen, J. G., Stolle-Smits, T., & Boeriu, C. (2002). Texture of cooked potatoes (Solanum tuberosum). 1. Relationships between dry matter content, sensory-perceived texture, and near-infrared spectroscopy. Journal of Agricultural and Food Chemistry, 50(18), 5082–5088.

Yang, Y., Achaerandio, I., & Pujolà, M. (2015). Classification of potato cultivars to establish their processing aptitude. Journal of the Science Food and Agriculture. doi:10.1002/jsfa.7104.

AOAC (1990). AOAC Official Methods of Analysis (15th ed., Vol. 2, p. 614). Arlington, VA, USA.

Acknowledgements

This work was carried out with the support of Torribas SA (Barcelona Spain). Author Yali Yang thanks the China Scholarship Council (File number. 201206990014) for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muñoz, S., Achaerandio, I., Yang, Y. et al. Sous Vide Processing as an Alternative to Common Cooking Treatments: Impact on the Starch Profile, Color, and Shear Force of Potato (Solanum tuberosum L.). Food Bioprocess Technol 10, 759–769 (2017). https://doi.org/10.1007/s11947-016-1857-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1857-0

Frying.

Frying.  Boiling.

Boiling.  Microwave.

Microwave.  Sous vide

Sous vide

:SS.

:SS.  :RS. Values are the average + standard deviation (n = 12). Different letters indicate statically different groups (p < 0.05). Lower-case letters (RS), capital-case letters (TS)

:RS. Values are the average + standard deviation (n = 12). Different letters indicate statically different groups (p < 0.05). Lower-case letters (RS), capital-case letters (TS)

: Agria

: Agria  : Agata

: Agata  : Carrera

: Carrera