Abstract

Fungicides based on dithiocarbamates have been used to protect crops from fungal diseases for more than half a century. The purpose of this work was to show the potential impact of improper potato storage on the analysis of mancozeb and other dithiocarbamates. The resulting field samples were divided into two parts. The first part was subjected to sample preparation without violation of storage conditions. Sample preparation of the second part of the sample was carried out after artificially simulated storage violation conditions. The method for the analysis of dithiocarbamates is based on the acid hydrolysis of the sample with the formation of carbon disulphide and its subsequent analysis using GC-FPD. The results of the analysis showed the content in the experimental and control samples of a large amount of carbon disulphide, which is not a product of the hydrolysis of mancozeb. Thus, it is not possible to estimate the correct amount of mancozeb.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

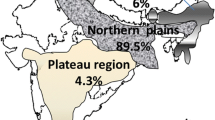

Fungicides rank second in Russia in terms of the volume of use among all plant protection products. The list of approved fungicides for use is growing every year, but over time, some pesticides have established themselves as reliable and effective.

The first dithiocarbamate-based fungicides were developed back in the early 1950s, but they have not lost their relevance to this day. As of 2020, dithiocarbamic acid derivatives account for 12.7% of all fungicide use in Russia, with mancozeb (Ditan, Mancozeb, Penkoceb) and thiram (TMTD, Tyr) being the most common (Mikhaylikova et al. 2020).

Mancozeb fungicide product segment is estimated to be the largest as well as the fastest growing fungicide product in the world (“Fungicides Market (Mancozeb, Chlorothalonil, Metalaxyl, Strobilurin, and Others) for Cereals & Grains, Oilseeds & Pulses, Fruits & Vegetables, and Other Crops—Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2015—2023,” n.d.). In nearly 50 years of commercial use, Mancozeb SP (800 g/kg Mancozeb) has been approved to control 400 fungal diseases on over 70 crops (Nikitin 2012).

Mancozeb is a contact fungicide with a protective effect that prevents infection of crops with false powdery mildew and Pythiaceae (Popov et al. 2003). Because of the high demand for dithiocarbamates, it is necessary to observe the use of the pesticides’ protocols, as well as monitor the maximum residue levels (MRL) of these fungicides and other types of pesticides. There are two approved methods based on acid hydrolysis for determining residual amounts of mancozeb and dithiocarbamates in Russia and USA (“4.1.2997—12. Determination of residual amounts of dithiocarbamates (tiram, mankoceb, metiram and tsineb) in soil and water by gas chromatographic vapor phase,” 2015) (EPA 1993). Its principle is based on measuring the concentration of carbon disulphide in the equilibrium vapour phase by gas chromatography (GC) using a flame photometric detector (FPD) specific for sulphur-containing compounds. Carbon disulphide is formed because of acid hydrolysis of a sample placed in a hermetically sealed vessel at 80–90 °C. The impossibility of direct analysis of dithiocarbamates is related to their insolubility in water and organic solvents (Kakitani et al. 2017). The major advantage of the method is its versatility, since it allows the determination of any compound from the dithiocarbamate class for many crops and environmental objects.

However, this method has several disadvantages. Exogenous CS2 analysis may be inaccurate because of the influence of endogenous carbon disulphide. For example, in the Crucíferae, the level of endogenous carbon disulphide can reach the internationally established limits for the detection of dithiocarbamates by carbon disulphide (Perz et al. 2000). The possibility of a false-positive result may arise.

Endogenous carbon disulphide can be formed in the following way: when plant tissues are damaged, isothiocyanates are released because of the hydrolytic action of an enzyme (myrosinase). This may also explain the endogenous formation of CS2 and other volatile sulphur compounds, such as carbonyl sulphide. The chain of reactions involves the initial cleavage of thioglucoside bonds (glucosinolates) to form d-glucose and unstable thiohydroximate-O-sulfonate, which spontaneously loses sulphate and rearranges into isothiocyanate, thiocyanate, or nitrile (Barba et al. 2016). Isothiocyanates can undergo further degradation, forming CS2 among other products (Fig. 1) (Pecháček et al. 1997).

Glucosinolates are ionic organic compounds with thioglucose bonded to the carbon of a sulphated oxime containing a variable side group (R) and are often the subject of research on cruciferous crops (Hwang et al. 2019a, b; Hwang et al. 2019a, b). Also, glucosinolates can be found in some Solanaceae (Rawani et al. 2014).

During the growing process, all crops are susceptible to diseases caused by bacteria and fungi. For example, common diseases for potatoes are late blight, soft rot, black scab, alternaria blight, and ring rot. Also, the process of decay and maceration of tissues can be triggered by post-harvest rot (Liu et al. 2022). These diseases cause potato rotting and maceration of its tissues.

During the rotting process, thiols can be formed (Roy 2000; Tausz et al. 2003) which might react with isothiocyanates to form dithiocarbamates (Halimehjani et al. 2014; Németh et al. 2019; Ranu et al. 2008; Safa et al. 2014).

It should be noted that thiols can be formed in plants in natural conditions without the influence of external factors (Tausz et al. 2003).

During the decay process, maceration of plant matrix tissues also takes place which can lead to the described above process of endogenous CS2 formation.

There are data in the literature on methods using LC-MS that selectively identify different dithiocarbamate fungicides. However, these methods are mostly derivatization-based, and derivatizing reagents are quite toxic to humans and expose the researcher to additional risks as a result (Kakitani et al. 2017). It is also known that dithiocarbamates can spontaneously decompose to CS2 on contact with plant sap with high acidity (Abakerli et al. 2015). The duration of sample preparation for selective methods using LC-MS is high, which increases the likelihood of acid hydrolysis. Since LC-MS determines directly the concentration of a compound in the matrix under study, and not the hydrolysis product, its potential loss can lead to false-negative results, which is even more dangerous for the end user.

Therefore, the method of acid hydrolysis of dithiocarbamates, although it is not the most perfect and can lead to false-positive results, is still used both in Russia and in Europe (Anastassiadou et al. 2020). For an accurate analysis, control samples are necessary, taken on the same day as the experimental ones, to establish the endogenous content of carbon disulphide.

In 2017, the European Food Safety Authority (EFSA) confirmed the need to develop specific analytical procedures for each active substance in this group of fungicides (European Food Safety Authority (EFSA) 2019).

Besides the natural causes of false positives, which are beyond the researcher’s control, there are also problems associated with improper sample transport and storage. Deviation from the protocol during research and its influence on the result obtained are the actual problems (Ermete 2012; Galuchie et al. 2021; Ghooi et al. 2016; Salerno et al. 1991).

A huge research error can be caused by improper transportation of samples and their storage before laboratory analysis. First, because of the previously mentioned process of decomposition of dithiocarbamates in contact with plant juice with increased acidity, the sample must be whole, not shredded. Second, it is necessary to strictly observe the temperature range during the transportation and storage of plant materials. Violation of storage conditions may increase the likelihood of distorted results.

As the storage temperature rises, several processes occur. The sample may thaw and release a liquid that may be involved in the metabolism of mancozeb. On contact with water, Mancozeb forms ethylene bisisothiocyanate sulphide, which transforms into ethylene bisothiocyanate by UV light (Nikitin 2012) (Fig. 2). Ethylene bisisothiocyanate contains no dithiocarbamate group, so its acid hydrolysis cannot produce CS2. It can also lead to a false-negative result when the official method based on carbon disulphide analysis was used.

As previously shown, in conditions of high humidity after thawing and elevated temperature, the rotting process takes place which can affect on the analysis reliability. Therefore, proper storage conditions ensuring is an important parameter for subsequent analysis. If laboratories working according to GLP standards provide proper storage conditions during the registration process of drugs, then the situation with store-bought potatoes may be the opposite. Also, the process of decay and maceration of tissues can be triggered by post-harvest rot (Liu et al. 2022). All these factors can make the analysis of dithiocarbamates in commercial potatoes difficult.

It should be noted that dithiocarbamates are actively used in potato cultivation. Therefore, the correct analysis of the residual amounts of dithiocarbamates for this culture is especially relevant.

This paper simulates the storage disturbance conditions of potatoes variety “Udacha” treated with Mancozeb SP (800 g/kg) and shows the effect of this factor on the analysis result.

Materials and Methods

Experimental Samples (Pesticides)

Potatoes were treated during the growing season with Mancozeb SP (800 g/kg Mancozeb) at an application rate of 1.6 kg/ha in the experimental field in the Leningrad Region. Samples were taken in 2 h after treatment (day 0) and subsequently after 7, 14, 21, and 28 days and stored frozen at − 18 °C.

Chromatographic Analysis

An Agilent 7890B gas chromatograph equipped with a flame photometric detector (FPD) Headspace Sampler (7697A) and fused silica capillary column GS-GAS PRO (30 m × 0.32 mm) was used. The operating conditions were as follows: initial temperature, 70 °C (2 min), increased at 25 °C min−1 to 245 °C for 7 min; N2 carrier gas; column operated in the splitless mode, the split flow was 3.0 mL/min; detector temperature, 220 °C; and injection volume, 1 µL of gas phase. The amounts of mancozeb in the test solution were calculated from the peak areas of CS2. Identification of CS2 was carried out by comparing its retention time on GC/FPD. If the amount corresponding to the peak areas was larger than that of the maximum amount from the standard curve, the test solution needed to be diluted to an appropriate concentration.

Standard Solutions

Working standards were prepared from the stock analytical standard 98.0% mancozeb (LGC).

Sample Preparation

A fresh crushed frozen plant sample (5.0 g) and deionised water (5.0 cm3) were placed in a glass vial (20 cm3). The vial was placed in an ultrasonic bath for 5 min. After that, a 1.5% solution of stannous chloride (5.0 cm3) in 1 M hydrochloric acid was added. The vial was covered with silicone gasket, sealed with aluminium caps, and placed for 1 h in the thermostat of the equilibrium vapour dispenser (90 °C). During temperature control, the vials were placed periodically (after 10–12 min) in an ultrasonic bath for 1–2 min. The gas-vapour phase was dosed into the chromatograph using a special pneumatic dispenser.

Storage disturbance conditions were simulated under laboratory conditions: frozen potatoes were left at room temperature for 1 day until turgor disturbance was evident.

Results and Discussion

The obtained field samples were divided into two parts. The first part was subjected to sample preparation without violation of storage conditions. Sample preparation of the second part of the sample was carried out after artificially simulated storage violation conditions.

Because of simulated storage conditions violation, potatoes became darker in colour; there was maceration of tuber tissues and loss of turgor state. There was a lot of liquid in the individual sample package. Samples of haulm also darkened. The samples were subjected to an identical analysis (Table 1).

According to the method, carbon disulphide formed after acid hydrolysis of the sample is determined in the equilibrium vapour phase. When the calibration characteristic is established, the areas of carbon disulphide peaks are set corresponding to the content of mancozeb in the sample.

In control samples with inviolate storage conditions, mancozeb was not detected. Mancozeb was found in experimental samples: in leaves on “0 day” 2.47 mg/kg. This is a contact fungicide and can only get into tubers upon contact with treated parts.

In all potato samples, which were kept at abnormal conditions, high content of carbon disulphide was observed. Exogenous carbon disulphide appeared even in the control samples. Simulated conditions led to false-positive results. Qualitative and quantitative determination of residual amounts of dithiocarbamates in such potato samples is not possible.

Conclusions

Effects of storage temperature on reduction of pesticides are related to volatilisation, penetration, metabolism of pesticide, moisture content, and microbial growth, if any. In refrigerated or frozen storage, residues are stable or degrade slowly (Holland et al. 1994; Yigit and Velioglu 2020). Storage failure usually leads to false-negative laboratory results.

Incorrect storage of samples containing dithiocarbamates, considering the peculiarities of the analysis method, on the contrary, can lead to false-positive results.

Although the only mancozeb was studied in this work, the results got can also be applied to the other dithiocarbamates, since the formation of exogenous carbon disulphide associated with storage conditions is independent of the active ingredient.

Based on the results obtained, we can conclude that the violation of storage conditions has a significant impact on the qualitative and quantitative analysis and leads to unreliable data in determining the residual amounts of dithiocarbamates in agricultural products.

In order to minimise the effect of storage and transport conditions for samples containing pesticides, national and international guidelines for testing pesticides must be strictly followed.

Availability of Data and Materials

Not applicable.

References

1.2997—12. Determination of residual amounts of dithiocarbamates (tiram, mankoceba, metiram and tsineb) in soil and water by gas chromatographic vapor phase [WWW Document], 2015. URL https://www.rospotrebnadzor.ru/bitrix/redirect.php?event1=file&event2=download&event3=muk-4.1.2997_12.doc&goto=/upload/iblock/46b/muk-4.1.2997_12.doc. Accessed 6 Feb 2022

Abakerli RB, Sparrapan R, Sawaya ACHF, Eberlin MN, Jara JLP, Rodrigues NR, Fay EF, Luiz AJB, Galvão TDL, Martins DDS, Yamanishi OK, Toledo HHB (2015) Carbon disulfide formation in papaya under conditions of dithiocarbamate residue analysis. Food Chem 188:71–76. https://doi.org/10.1016/j.foodchem.2015.04.059

Anastassiadou M, Bernasconi G, Brancato A, Carrasco Cabrera L, Ferreira L, Greco L, Jarrah S, Kazocina A, Leuschner R, Magrans JO, Miron I, Nave S, Pedersen R, Reich H, Rojas A, Sacchi A, Santos M, Theobald A, Vagenende B, Verani A (2020) Review of the existing maximum residue levels for chlorantraniliprole according to Article 12 of Regulation (EC) No 396/2005. EFSA J 18:6235. https://doi.org/10.2903/J.EFSA.2020.6235

Barba FJ, Nikmaram N, Roohinejad S, Khelfa A, Zhu Z, Koubaa M (2016) Bioavailability of glucosinolates and their breakdown products: impact of processing. Front Nutr 3:24. https://doi.org/10.3389/FNUT.2016.00024/BIBTEX

EPA (1993) Method 630.1: the determination of dithiocarbamates pesticides in municipal and industrial wastewater [WWW Document]. URL https://www.epa.gov/sites/default/files/2015-10/documents/method_630-1_1993.pdf. Accessed 29 Feb 2022

Ermete R (2012) Clinical trials and communicating safely. Clin J Oncol Nurs 16:25–27. https://doi.org/10.1188/12.CJON.25-27

European Food Safety Authority (EFSA) (2019) The 2017 European Union report on pesticide residues in food. EFSA Journal. Eur. Food Saf. Auth. 17, e05743. https://doi.org/10.2903/j.efsa.2019.5743

Fungicides Market (Mancozeb, Chlorothalonil, Metalaxyl, Strobilurin, and Others) for Cereals & Grains, Oilseeds & Pulses, Fruits & Vegetables, and Other Crops - Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2015 - 2023 [WWW Document], n.d. URL https://www.prnewswire.com/news-releases/fungicides-market-mancozeb-chlorothalonil-metalaxyl-strobilurin-and-others-for-cereals--grains-oilseeds--pulses-fruits--vegetables-and-other-crops---global-industry-analysis-size-share-growth-trends-and-forecast-20-300243678.html. Accessed 5.29.22

Galuchie L, Stewart C, Meloni F (2021) Protocol deviations: a holistic approach from defining to reporting. Ther Innov Regul Sci 55:733–742. https://doi.org/10.1007/s43441-021-00269-w

Ghooi R, Bhosale N, Wadhwani R, Divate P, Divate U (2016) Assessment and classification of protocol deviations. Perspect Clin Res 7:132. https://doi.org/10.4103/2229-3485.184817

Halimehjani AZ, Hooshmand SE, Shamiri EV (2014) Synthesis of α-phthalimido-α′-dithiocarbamato propan-2-ols via a one-pot, three-component epoxide ring-opening in water. Tetrahedron Lett 55:5454–5457. https://doi.org/10.1016/j.tetlet.2014.08.017

Holland PT, Hamilton D, Ohlin B, Skidmore M (1994) Pesticides report 31: effects of storage and processing on pesticide residues in plant products (technical report). Pure Appl Chem 66:335–356. https://doi.org/10.1351/pac199466020335

Hwang ES, Bornhorst GM, Oteiza PI, Mitchell AE (2019a) Assessing the fate and bioavailability of glucosinolates in kale (Brassica oleracea) using simulated human digestion and Caco-2 cell uptake models. J Agric Food Chem 67:9492–9500. https://doi.org/10.1021/acs.jafc.9b03329

Hwang IM, Park B, Dang YM, Kim SY, Seo HY (2019b) Simultaneous direct determination of 15 glucosinolates in eight Brassica species by UHPLC-Q-Orbitrap-MS. Food Chem 282:127–133. https://doi.org/10.1016/j.foodchem.2018.12.036

Kakitani A, Yoshioka T, Nagatomi Y, Harayama K (2017) A rapid and sensitive analysis of dithiocarbamate fungicides using modified QuEChERS method and liquid chromatography-tandem mass spectrometry. J Pestic Sci 42:145–150. https://doi.org/10.1584/JPESTICS.D17-025

Liu J, Sun Z, Zou Y, Li W, He F, Huang X, Lin C, Cai Q, Wisniewski M, Wu X (2022) Pre- and postharvest measures used to control decay and mycotoxigenic fungi in potato (Solanum tuberosum L.) during storage. Crit Rev Food Sci Nutr 62:415–428. https://doi.org/10.1080/10408398.2020.1818688

Mikhaylikova VV, Strebkova NS, Pustovalova EA (2020) Active substances – the basis of chemical plant protection. Agrochemistry 44–46. https://doi.org/10.31857/S0002188120050105

Musita CN, Okoth MW, Abong’ GO (2019) Postharvest handling practices and perception of potato safety among potato traders in Nairobi, Kenya. Int J Food Sci 2019, 2342619. https://doi.org/10.1155/2019/2342619

Németh AG, Keserű GM, Ábrányi-Balogh P (2019) A novel three-component reaction between isocyanides, alcohols or thiols and elemental sulfur: a mild, catalyst-free approach towards O -thiocarbamates and dithiocarbamates. Beilstein J Org Chem 15:1523–1533. https://doi.org/10.3762/bjoc.15.155

Nikitin A (2012) Mancozeb [WWW Document]. Newsp. Artic. Plant Prot. URL https://www.agroxxi.ru/gazeta-zaschita-rastenii/zrast/mankoceb.html. Accessed 6 May 2022

Pecháček R, Velísek J, Hrabcová H (1997) Decomposition products of allyl isothiocyanate in aqueous solutions. J Agric Food Chem 45:4584–4588. https://doi.org/10.1021/jf970316z

Perz RC, Van Lishaut H, Schwack W (2000) CS2 blinds in Brassica crops: false positive results in the dithiocarbamate residue analysis by the acid digestion method. J Agric Food Chem 48:792–796. https://doi.org/10.1021/jf9905323

Popov S, Dorozhkina LA, Kalinin VA (2003) Fundamentals of chemical plant protection. Art-Lion, Moscow

Ranu BC, Saha A, Banerjee S (2008) Catalysis by ionic liquids: significant rate acceleration with the use of [pmIm]Br in the three-component synthesis of dithiocarbamates. Eur J Org Chem 2008:519–523. https://doi.org/10.1002/ejoc.200700842

Rawani A, Ghosh A, Laskar S, Chandra G (2014) Glucosinolate from leaf of Solanum nigrum L. (Solanaceae) as a new mosquito larvicide. Parasitol Res 113:4423–4430. https://doi.org/10.1007/s00436-014-4120-5

Roy K-M (2000) Thiols and organic sulfides. In: Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany. https://doi.org/10.1002/14356007.a26_767

Safa KD, Tavakkoli Osgoei S, Alyari M (2014) Synthesis of novel dithiocarbamyl-containing organosilicon compounds. J Sulfur Chem 35:683–690. https://doi.org/10.1080/17415993.2014.953163

Salerno SM, Wrenn KD, Slovis CM (1991) Monitoring EMS protocol deviations: a useful quality assurance tool. Ann Emerg Med 20:1319–1324. https://doi.org/10.1016/s0196-0644(05)81074-1

Tausz M, Gullner G, Kömives T, Grill D (2003) The role of thiols in plant adaptation to environmental stress. In: Sulphur in plants. Springer, Netherlands, pp 221–244. https://doi.org/10.1007/978-94-017-0289-8_12

Yigit N, Velioglu YS (2020) Effects of processing and storage on pesticide residues in foods. Crit Rev Food Sci Nutr 60:3622–3641. https://doi.org/10.1080/10408398.2019.1702501

Author information

Authors and Affiliations

Contributions

EA: concept, technical research work, chromatographic studies, data analysis, and writing and AK: field work, sampling, chromatographic studies, data analysis, and writing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alekseev, E., Komarova, A. Effect of Potato Storage Conditions on the Quality of Dithiocarbamate Analysis. Potato Res. 67, 749–757 (2024). https://doi.org/10.1007/s11540-023-09666-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11540-023-09666-0