Abstract

Recombined cream (RC, 23 % fat w/w) and standardised commercial cream (CC, 28 % fat w/w) were studied to understand the effects of manipulating fat globule size at the micron-/nano-scale on the stability and rheological properties of cream. All samples were adjusted to a fat: protein ratio of 5:1 and a fat: emulsifier (Tween 80) ratio of 30:1 to stabilize emulsion. For both CC and RC, different emulsions with droplet sizes covering micron- (3.9 μm), sub-micron (0.5 – 0.6 μm) and nano-metric scales (0.13 – 0.29 μm) were obtained using either the homogeniser (7/3 MPa) or the microfluidiser (85 MPa and 42 MPa). Fat globules from both RC and CC had high zeta potential values (-28 to -43 mV) and maintained their reduced size after 1 month of storage at 4 °C, providing evidence of emulsion stability. Droplet size had a significant effect on rheological characteristics of all creams produced. Nano-sized RC tended to have a rigid structure (solid/gel-like form) as compared to micron-sized RC (liquid-like form) as reflected by higher phase angle. Surprisingly, the rheological properties of CC exhibited an opposite tendency to that of RC. This implies that the observed rheological properties of CC and RC could not be fully explained by the discrepancy in droplet size. Differences in interfacial properties between RC and CC might also play a role in the rheological behaviour of the creams. Results indicated the stable high milk fat emulsions could be successfully created by reducing the globule size. These findings would be useful in understanding how micron-/nano-sized emulsions can be utilised in further application or processing of creams.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Emulsions are complex and thermodynamically unstable structures and are given kinetic stability by an absorbed layer of surfactant [1]. In food applications nanoemulsions refer to emulsions of droplet size <0.2 μm [2] and due to the tiny droplet size they exhibit better stability to gravitational separation and droplet aggregation and possess different physical properties when compared with conventional emulsions [3]. Food-grade nanoemulsions are being increasingly employed to encapsulate, protect and deliver functional components such as vitamins and preservatives [4]. Various types of oils/fats have been used to prepare edible nanoemulsions such as triacylglycerols (long/medium chained) and free fatty acids. The aqueous phase in edible nanoemulsions is typically comprised of water with the addition of proteins, carbohydrates and minerals, which can significantly influence its stability and physicochemical characteristics [4]. Nano-sized droplets in oil-in-water emulsion having structure of core-shell type can also be subjected to sedimentation if they are coated by a thick layer of protein, resulting in the overall density being greater than water [5].

To fabricate emulsions, homogenisation is commonly used to mix the two immiscible phases and has been applied extensively within the food, pharmaceutical and biotechnology industries. The intense disruptive forces of homogenisation break down any existing fat globular membrane and allow adsorption of proteins from the continuous phase, thus causing intermixing of the oil and aqueous phase [4]. When applied to food emulsions, homogenisation commonly leads to decreased droplet size and narrow droplet size distribution [6]. The smallest droplet size achieved by a particular device is dependent on a range of variables including; operating conditions, sample composition and temperature [4].

There are a variety of milk based products in the emulsion state (oil-in-water (o/w) or water-in-oil (w/o)) including cream, butter and ice cream. The size of milk fat globules (MFG) plays an important role for many dairy products with the ability to influence their physical properties such as creaming rate, heat stability and crystallisation temperature [7–10]. Previous studies have demonstrated a decrease in the globule size of dairy products led to changes in their rheological, textural and functional properties (e.g., foamability) [11–13]. Recent studies have demonstrated the use of microfluidisation to produce aqueous nanoemulsions of 10 % milk fat (d(0.5) = 0.16 μm) [10] and 50 % milk fat (d(0.5) = 0.12 μm) [14]. However, there is limited information on the physical stability of nano-sized MFG in high fat emulsions, where only limited amounts of surfactant are present to stabilise the increased surface area of the dispersed phase.

Dairy cream is representative of an emulsion with a high fat content (30-40 %) that is typically concentrated from milk by centrifugal separation. Due to the density difference between milk fat and plasma, cream is prone to instability, including creaming and phase inversion via churning. The latter phenomenon is the basis of the industrial process to manufacture butter (w/o emulsion) from dairy cream (o/w emulsion). The volume-weighted diameter of MFG in unhomogenised dairy cream (without coalescence and/or creaming) is approx. 4 μm [10]. Various methods have been applied to obtain native MFG having various size ranges such as gravitational separation [15], microfiltration [16] and ultrasonication [17]. To date the smallest achievable size range (D[3, 4] = 0.9 μm) in native dairy cream was obtained by microfiltration [16]. Given the well-documented effects of droplet size and size distribution on the physical functionality of conventional, micron-size range dairy-based emulsions [9], it is of industrial interest to understand whether these effects are reproduced, strengthened, weakened or completely different at the nano-scale and whether the use of nanoemulsions might give rise to specific effects on stability and rheology, which could then be used to improve the quality and shelf-life of the food.

The main aim of this research was to investigate the effects of emulsion droplet size on the properties of cream and how reducing the fat globule size to nano-scale impacts characteristic properties. Analysis of the physical properties of prepared emulsions included the droplet size and distribution, the droplet surface charge (zeta potential) and rheological properties including viscosity, elastic modulus, viscous modulus, complex modulus and phase angle.

Materials and Methods

Materials

The CC was obtained from a local store. According to the manufacturer, the fat and protein content were 39.9 % w/w and 2.12 % w/w, respectively. This was pure, pasteurised, unhomogenised cream without any other mechanical treatment or addition of other ingredients. To standardise the fat: protein ratio in CC sodium caseinate (NaCN: 92.6 % protein, 0.25 % lactose–casein, 0.7 % fat, 1.2 % sodium) was added, obtained from Murray Goulburn Co-op (Melbourne, Victoria, Australia).

To fabricate RC, anhydrous milk fat (AMF; 99.92 % fat, 0.05 % water) was employed as the oil phase and was obtained from Tatura Milk Industries Limited (Tatura, Victoria, Australia). Dairy ingredients used to prepare the aqueous phase in RC were skim milk powder (SMP) and butter milk powder (BMP) obtained from Tatura Milk Industries Limited (Tatura, Victoria, Australia).

Tween 80 (Tween 80 LR CAS # 9008-65-5; polyoxyethelene sorbitan monooleate C64H124O26; Labtek Pty Ltd., Queensland, Australia) was also employed to investigate the effect of a small molecular weight surfactant on the resultant emulsion size.

Emulsion Preparation

Preliminary work showed that microfluidised CC (without additional protein) tended to coalesce, due to the generation of newly formed surfaces, which could not be wholly covered by the native protein and MFG membrane in the cream. Addition of extraneous dairy protein (i.e., NaCN) was necessary to allow sufficient emulsification of the nano-sized fat globules produced by this method. Preliminary studies found that a fat: protein ratio of 5:1 was optimum in producing the smallest droplet size, with the composition of emulsions being stable against coalescence. At this concentration, the protein was sufficient to maintain emulsion stability.

Since it was impossible to directly add powdered NaCN to the CC without cream churning, a NaCN suspension (15 % dilution) was added to the CC. Standardisation of these samples resulted in the same ratios of fat:protein (5:1), fat:Tween80 (30:1) and water (63 % w/w) but different fat (RC: 23.17 % w/w; CC: 28.68 % w/w), protein (RC: 4.51 % w/w, CC: 5.58 % w/w) and Tween80 (RC: 0.75 %, CC: 0.93 % w/w) contents.

CC emulsion Preparation

Aqueous NaCN was prepared 1 day prior to allow full hydration of the protein and stored overnight at 4 °C. Subsequently the aqueous protein solution was stirred using an overhead mixer at 500 rpm and heated at 45 °C for 20 min. CC was heated at 45 °C to allow the fat crystals to melt. The two phases were then combined with the addition of Tween 80 and potassium sorbate (0.1 % w/w) as the antimicrobial agent and stirred at 200 rpm at 45 °C for 2 h. The samples were then emulsified; using either a 2-valve stage homogeniser (Twin Panda, GEA Niro Soavi, Parma, Italy) operating at 7/3 MPa pressure and 1 cycle or using a microfluidiser (Model M-10 L, Microfluidics, US), operating at different pressures (42 MPa and 85 MPa) and one cycle to obtain a range of emulsion droplet sizes. The microfluidiser interaction chamber was immersed within water at approx. 60 °C to maintain a constant temperature and to prevent clogging of the chamber.

RC emulsion Preparation

BMP and SMP (in a 2:1 ratio), Tween 80 and potassium sorbate (0.1 % w/w) were combined with distilled water and stirred using an overhead mixer for 1 h. Prior to mixing with the aqueous phase, the AMF was melted by heating at 60 °C for 30 min. The two phases were then brought to the same temperature of 45 °C and allowed to equilibrate for 20 min. Coarse emulsions were prepared using a rotor-stator system (Model L2R, Silverson Machines Ltd., UK), combining the phases at 3000 rpm for 2 min at 45 °C, subjecting the phases to high shearing forces and allowing pre-homogenisation of the oil phase into the aqueous phase. The coarse emulsions were then subjected to the homogeniser (7/3 MPa) or a single cycle through the microfluidiser (42 MPa and 85 MPa) to obtain a range of average droplet sizes. Droplet size was measured immediately after the final emulsification step and samples were then stored overnight at 4 °C and subjected to further analysis within 24 h.

In total, two different dairy based emulsions, RC and standardised CC, were each subjected to 3 different homogenising pressures (7/3 MPa: HM, 42 MPa: 42 M and 85 MPa: 85 M), hereafter referred to as RC-HM, RC-42 M, RC 85 M, CC-HM, CC-42 M and CC-85 M. Three replicates of each emulsion were prepared. Unhomogenised, standardised CC (with the addition of aqueous NaCN, tween80 and potassium sorbate) (CC-NON) and unhomogenised, unstandardised CC (CC-ORIG) were also analysed to allow comparison of droplet size, stability and rheological properties.

Analyses

Measurement of Droplet Size

A laser light scattering droplet size analyser (Malvern Mastersizer 2000, Malvern Instruments Ltd., Worcestershire, UK) was employed to measure droplet size and size distribution within the dairy emulsions. Aliquots of sample were added to distilled water until an obscuration rate of 10 % (optimum) was achieved under stirring conditions (2000 rpm). Refractive indices of the milk fat and water were taken as 1.46 and 1.33 respectively, and the absorption coefficient was 0.001. Size distribution was calculated using Malvern software, which uses the Mie theory and assumption of droplet sphericity. The modal diameter, which is a maximum size frequency within the droplet size distribution, was taken as the average droplet size diameter within the sample. Unless specified otherwise, the following results are discussed based on the modal droplet diameter.

Stability Determination

Stability of the emulsions was studied by measuring the droplet size after 1 day, 1 week and 1 month of storage at 4 °C.

Zeta-Potential Measurement

The apparent MFG electrophoretic mobility was measured by electrophoretic light scattering at 25 °C, using a Zetasizer Nano (Zetasizer Nano ZS, Malvern Instruments Ltd., Worcestershire, UK). Samples were prepared by diluting the emulsion 100-fold using distilled water and then introduced into the capillary tube for measurement. Three measurement samples were produced for each emulsion and tested individually to calculate the mean average zeta potential value.

Rheological Properties

Rheological measurements were performed using a TA Rheometer AR1500 (TA Instruments UH Ltd., UK) with a parallel steel plate (40 mm in diameter). The sample was placed on the controlled temperature peltier plate stage, which was pre-set at 4 °C. The measurements were carried out using a gap distance of 1 mm.

Flow Behaviour

A dependence of apparent viscosity and shear stress on the shear rate was measured. The shear rate was linearly increased from 0.5 to 150 s−1 for 486 seconds and 14 data points were collected.

Viscoelastic Properties

Samples were subjected to a frequency sweep from 0.1 to 10.0 Hz in the linear viscoelastic region (data not shown). Both the elastic modulus (G′) and viscous modulus (G″) were recorded as a function of frequency sweep. The complex modulus (G*) and phase angle (δ) were also provided as a result of the oscillatory tests, with reported values taken at a frequency sweep of 1.0 Hz.

Results and Discussion

Droplet Size Distribution

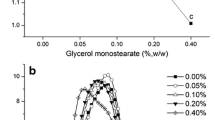

The influence of homogenisation pressure on the modal droplet size and droplet size distribution of RC and CC after 1 day storage at 4 °C is shown in Fig. 1 and Table 1. The average droplet size of the original, unhomogenised CC-ORIG was 4.09 μm, which is in agreement with average MFG sizes reported in literature [8]. Standardisation by mixing with dairy ingredients to obtain a fat: protein ratio of 5:1, without homogenisation (CC-NON) had very little effect on initial droplet size (3.9 μm) but tended to induce partial coalescence after 1 day of storage (14.3 μm) (Table 2). Table 1 shows that for both CC and RC, distinct emulsion droplet size populations covering micron- (3.9 μm), sub-micron (0.5 – 0.6 μm) and nano-metric scales (0.13 – 0.29 μm) were obtained using both the homogeniser and microfluidiser, respectively. Droplet size distribution of creams prepared at low homogenising pressure (CC-HM, RC-HM) tended to be asymmetrical, with a slight shift towards larger droplets, while microfluidisation-generated emulsions showed a narrower, Gaussian-type distribution with a small tail (Fig. 1).

Particle size distribution for the RC and CC fabricated at various homogenising pressures (85 MPa, 42 MPa and 7/3 MPa) in comparison to CC-NON and CC-ORIG after 1 day storage at 4 °C. Symbols: RC-85 M (●), RC-42 M (○), RC-HM (▼), CC-85 M (△), CC-42 M (■), CC-HM (□), CC-NON (♦), CC-ORIG (◊). Vertical reference lines from left to right represent 0.2, 0.5 and 1.0 μm

Figure 1 illustrates the dramatic decrease in droplet size that resulted when both RC and CC were subjected to mechanical shear. Homogenisation using the conventional homogeniser caused reduction of droplet size of CC to sub-micron range (0.59 μm). When CC was microfluidised at 85 MPa, there is a significant down-sizing of emulsion droplet size to the nano-scale range (131-294 nm). This droplet size range is consistent with a previous study subjecting whole milk (fat: 3.5 % w/w) to microfluidisation with pressures ranging from 50-200 MPa (D [2, 3] = 0.24–0.30 μm [18]). Interestingly, CC produced smaller droplet sizes for all three different mechanical treatments in comparison to RC, despite containing a higher percentage of fat (28 > 23 %), perhaps suggesting the contribution of the native MFG membrane (MFGM) in aiding the formation and stability of smaller globules. Moreover, the addition of sodium caseinate has been found to reduce the average droplet size in homogenised whipped cream [19].

It is clear that microfluidisation produced smaller and more uniform globules in comparison to valve homogenisation. Similar patterns have been found previously [18, 20, 21] and explained to be the consequence of the different device geometries. The microfluidiser creates a tight distribution of shearing forces around the maximum force, thus all coarse emulsions entering the chamber experience forces close to this maximum. Whereas within the homogeniser a widespread distribution of forces is dispersed, resulting in the entering of coarse emulsions being subjected to a range of shearing forces, thus creating a broader droplet distribution [21].

As can be seen from Fig. 1, increasing the pressure of homogenisation resulted in decreased droplet size. This is in agreement with previous studies [12, 18, 22] and can be attributed to the increase in the magnitude of the disruptive forces (e.g., shearing, cavitation) generated within the interaction chamber. The modal droplet size did not significantly decrease (0.16 to 0.13 μm) with a pressure increasing from 42 MPa to 85 MPa within the microfluidiser for CC (CC-42 M and CC-85 M); however, the curve representing CC-85 M appears to have a secondary peak in larger size region (0.5 – 1.0 μm). This can be partly explained by the competition between the disruption and formation of fat globules occurred during microfluidisation. The disruption of fat globules results in a fresh interface available for surfactant adsorption, however if the rate of collision and disruption of droplets is higher than the rate of adsorption, this will result in the coalescence of fat globules [6] and consequently larger droplets. Properties including droplet size, lipid concentration and protein load influence the rates of processes (adsorption, deformation and encounter) [23]. Depending on types of protein used, protein aggregation might occur upon high pressure homogenisation. In this study, sodium caseinate was added to stabilise the emulsions. As sodium caseinate has a disordered and flexible structure, thus it is not susceptible to aggregation behaviour due to denaturation [22]. Therefore, the presence of the secondary peak is better explained to be due to fat droplet aggregation upon storage during size measurement.

Stability of the Emulsions

Droplet size was further tested 1 week and 1 month after treatment to examine the physical stability of RC and CC emulsions. As shown in Table 2, no significant changes were found after 1 week and 1 month of storage at 4 °C. According to Stokes law, the rate of creaming is directly proportional to the square of the diameter of the globule [24]. Therefore smaller droplet size tended to have better physical stability against droplet growth from coalescence and gravitational separation [4].

The unhomogenised samples (CC-NON/CC-ORIG), which had relatively larger droplet size (~4.0 μm), were prone to partial coalescence with increasing droplet size upon storage (Table 2). Despite CC-NON containing additional protein and emulsifiers within the aqueous phase, partial coalescence still occurred. This suggests the presence of free surfactants within the aqueous phase does not deter the droplet growth rate, with the generation of an osmotic attraction of micelles formed from non-ionic surfactants (e.g., Tween 80) to oil droplets, consequently promoting flocculation of droplets [25].

Zeta Potential

Table 1 provides the apparent zeta potential values of the prepared emulsions. All the samples possessed negative charges, which is to be expected, due to both sodium caseinate (negatively charged protein) and Tween 80 (non-ionic surfactant) [4] contributing to the formation of the MFGM. In practice a negative charge is often attributed to the ability of the interface to adsorb OH− ions from water [26] with most food-grade ionic surfactants being negatively charged [4].

With the addition of sodium caseinate and Tween 80 the measured zeta-potential for CC (-85 M/-42 M/-HM) maintained a similar value to CC-ORIG (ξ = -41.18 mV), with the values increasing with decreased modal droplet size, highlighting a potential influence of droplet size on the measured zeta potential value. Zeta potential of the MFGM has been found to increase in a non-linear way with respect to the surface coverage of casein micelles on the membrane as a result of homogenisation [27]. Moreover, CC-NON resulted in the highest zeta-potential value (ξ = -50.49 ± 1.13 mV; d (0.5) = 14.31 μm). The difference in zeta-potential values between unhomogenised and homogenised CC could be due to existing casein micelles and added emulsifiers formed emulsified layers surrounding newly generated fat globules in processed CC.

RC had lower measured zeta potential values (-27.98 to -37.19 mV) than processed CC emulsions (-41.92 to -43.07 mV) and did not possess a trend in regards to droplet size. It is important to note the structural integrity of the surface membrane for RC differs from CC, with no original MFGM material present, hence will impact the overall surface charge of the membrane. Differences in the zeta potential value between buffalo and cow milk samples was explained to be due to variances in the mineral composition of the aqueous phase or the composition of the globular membrane [28]. Furthermore, zeta potential values have been found to be influenced by a range of factors including droplet size, surfactant type, protein concentration, ionic salts and pH [4, 29, 30].

Previous studies have proposed that zeta potential value is a good indicator of emulsion stability. For instance, a zeta potential above (±) 30 mV is said to indicate a stable emulsion [31, 32] and represent mutual repulsion hence prevention of droplet coalescence. Thus the majority of the prepared samples exhibited high stability in regards to the measured zeta-potential value. This tendency agreed with corresponding droplet size measurements up to 1 month of storage (Table 2).

Rheological Properties

Flow Behaviour

Figure 2 displays the apparent viscosity curves for both manipulated CC and RC under different homogenising pressures tested after being stored 4 °C for 1 day. Both shear rate dependency and shear thinning behaviour (non-Newtonian fluid) was displayed by all samples, agreeing with previous studies on dairy based protein stabilised emulsions [12], raw milks and creams [33]. At low temperatures, cold agglutination of globules occurs resulting in flocculation of globules [10]. This clusters of fat globules along with trapped interstitial plasma induced high effective volume fraction at low shear rate. An increase in shear rate produced higher shearing forces, facilitating either formation of irregular shape of aggregates or disruption of aggregates. Consequently, the apparent viscosity was decreased with increasing shear rate [33]. This impact on apparent viscosity became less effective when shearing forces surpassed the attractive forces binding fat droplets/globules together. Hence at high shear rates samples provided converging low viscosity values as shown in Fig. 2.

The effect of homogenisation pressure on the apparent viscosity of RC and CC after 1 day storage at 4 °C. Symbols: RC-85 M (●), RC-42 M (○), RC-HM (▼), CC-85 M (△), CC-42 M (■), CC-HM (□), CC-NON (♦), CC-ORIG (◊). Insert box represents the apparent viscosity of emulsions produced at shear rate of 5 s−1; these values for CC-NON and CC-ORIG were 2.55 ± 0.10 and 0.25 ± 0.03, respectively

The shear rate dependence of the viscosity for oil-in-water emulsions can be attributed to droplet size [34], droplet charge and colloidal interactions [35]. With regards to nanoemulsions the volume fraction of the dispersed phase and the importance of surfactant type/concentration have also been found to influence rheological properties [36, 37].

Mechanically treated (HM/M) RC displayed increased viscosity values (0.026 Pa.s to 3.14 Pa.s) with decreased average droplet size (0.59 μm to 0.24 μm) respectively, at a shear rate of 5 s−1(Fig. 2) which is in agreement with a previous study on recombined whipped cream stabilised by sodium caseinate and whey protein isolate [12]. Smaller droplet size with increasing viscosity has been explained to be caused by reduced inter-droplet distance, therefore increasing inter-droplet resistance between droplets and consequently increasing the apparent viscosity [12].

CC did not follow the established viscosity trend in regards to droplet size as performed on RC (Fig. 2). It is speculated that the discrepancy in tendencies between RC and CC could be attributed to the difference in structural elements and their changes during homogenisation. As illustrated in Fig. 2, the apparent viscosities of CC at shear rate of 5 s−1 were unchanged regardless of droplet size in range of d[0.5] 0.13 – 0.59 μm. This indicates the binding forces between structural elements in CC were prominent that any increased resistance due to droplet size effect was negligible. The components of MFGM lose their original structure upon destabilisation (i.e., mechanical homogenisation) and tend to produce larger binding forces among fragmented membrane material as compared to the surface of fat globule [11]. Darling and Butcher [38] also reported that the binding forces between fat and caseins became greater after homogenising cream (32 % fat) at 20 MPa and 60 °C. Further research will need to be conducted into this behaviour.

CC-NON displayed a gel like consistency and exhibited the highest apparent viscosity value at low shear rates (Fig. 2). As the protein was not integrated into the globular membrane, it is likely that the dispersed casein micelles and fat globule droplets both contributed to the viscosity behaviour.

Frequency Sweep and Modulus

The viscoelastic properties of the emulsions were measured through a frequency sweep test of elastic modulus (G′) and viscous modulus (G″) after storing the samples at 4 °C for 1 day. All samples displayed frequency dependency (Fig. 3a and b), with values of both moduli (G′ and G″) increasing with increasing frequency sweep. The G′ value was higher than G″ value in the majority of samples, indicating a greater contribution of elastic properties, and consequently demonstrating solid like systems which exhibit limited transitional movement upon shear stress due to the fat-crystal complex. It has been claimed that emulsions with a high gelation ability are characterised by a mean droplet diameter ranging 0.3-0.7 μm and a narrow droplet size distribution [39]. The values obtained for G″ of the samples produced similar values and trends of generally increasing and then plateauing, whereas values obtained for elastic modulus (G′) all differed between each sample.

RC displayed increased G′ and G″ with decreasing droplet size (RC-85 M > RC-42 M > RCHM). This tendency is in line with a previous study on recombined whipped cream [12]. However, CC displayed the opposing pattern of modulus values decreasing with respect to decreasing droplet size (CCHM > RC-42 M > CC85M), correlating with the opposing trends found from the viscosity results. Rheological properties of dairy based emulsions have been found to be dependent on the nature of coating on the surface membrane of the fat globule with respect to both protein and emulsifier type [40]. During homogenisation the fat globules become coated with casein micelles, which interact with the casein gel matrix and increase the rigidity of the milk gel [39]. Thus the opposing trend of rheological properties can be attributed to the difference in coating layers between RC (mainly dairy proteins added) and CC (mainly MFGM) as previously discussed.

CC-NON displayed significantly different viscous and elastic properties. Exceeding both the viscous and elastic properties than all other sample tested, G′ values in the range 70 and 320 Pa, have been explained to possess characteristics of a weak gel [41]. Thus CC-NON displays the characteristic onset of a weak gel at higher frequency sweeps (>7.5Hz), and this could suggest the influence of the non-integrated aqueous sodium caseinate on the rheological properties, hence more resistance against deformation and strain at higher shear rates.

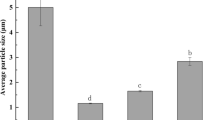

Phase Angle and Complex Modulus

The phase angle (δ) refers to the inverse tangent of the ratio of G″ to G′. δ gives an indication of a samples rheological characteristics, with a phase angle 0° and 90° demonstrating behaviour of a purely elastic solid and viscous fluid, respectively [42]. Material exhibits viscoelastic behaviour if the phase angle is between 0° and 90° [43]. A small value of phase angle (i.e., 20°) indicates pronounced elastic (gel) characteristics of material (a large value of G′ in comparison with G″). Figure 4a illustrates the increased phase angle values of RC (21 – 66°) with increasing droplet size. The trend illustrates the transition of a gel-like form, at reduced droplet size, due to electrostatic repulsion between the fat globules in close proximity, to a liquid-like form with increasing globular droplet size [5] achieving a phase angle close to 65° for modal droplet size 0.59 μm, indicating behaviour of a viscous fluid. As shown in Fig. 4a, phase angle of 45° (critical gel point when the equilibrium elastic modulus is zero) was obtained at droplet size of 0.29 μm. This means RC behaves as a liquid once the droplet size is above 0.29 μm but RC is solid-like when the droplet size is in nano-sized range (below 0.29 μm). The complex modulus (G*), sum of the viscous and elastic moduli, was also found to decrease with increasing droplet size. Similar trends have been reported for oil-in-water nanoemulsions (0.075 μm - 0.1 μm) containing 25 % w/w hydrocarbon oil [42].

In comparison, CC (Fig. 4b) displayed the inverse trends, with respect to phase angle and complex modulus. Minimal phase angle change (59.3° to 52.5°) is displayed with increasing droplet size (0.13 μm to 0.59 μm) and the complex modulus demonstrates decreasing behaviour with decreasing droplet size. This is perhaps due to the presence of extra protein added that partly modify both the structural integrity of the fat globules and aqueous phase being comparatively different to RC. Further investigations are needed to elucidate the role of extraneous proteins on rheological properties in CC systems.

Conclusions

To conclude, in this study milk fat globules having micron- to nano-sized range (0.13 – 14.3 μm) were successfully produced in RC and CC. Fabrication of the high fat emulsions (23 – 28 % fat) involved usage of a low amount of surfactants, without the addition of external additives. All mechanically processed creams were stable and resistant against creaming after storing for 1 month. The surface droplet charge was found to differ between CC and RC, thus implying the influence of intact/adsorbed membrane layers surrounding oil droplets and additional factors (including components in the aqueous phase) influencing the overall surface charge.

In regards to rheological properties, all samples displayed shear rate dependency, shear thinning behaviour and solid like systems (G′ > G″). It is apparent that droplet size had a significant impact of rheological characteristics of all creams produced. Nano-sized RC cream had a rigid structure as compared to micron-sized RC cream. Despite having a similar size range to RC, CC exhibited opposing trends in rheological properties. This highlights the effect of compositional difference, particularly coating layers between mainly native MFGM in CC and emulsified dairy proteins in RC.

Taken together, the differentiated physical properties of nano-sized RC and CC creams might be particularly important in the development of innovated dairy cream-based products. Our previous studies have confirmed the influence of nano-sized fat globules in dairy-based nanoemulsions on crystallisation properties [8] and foamability [13]. We are further investigating the effects of nano-sized dairy creams on the overall properties of dairy based products.

References

J. Palanuwech, J.N. Coupland, Effect of surfactant type on the stability of oil-in-water emulsions to dispersed phase crystallization. Colloids Surf. A Physicochem. Eng. Asp. 223(1), 251–262 (2003)

C. Solans et al., Nano-emulsions. Curr. Opin. Colloid Interface Sci. 10(3), 102–110 (2005)

T. Tadros et al., Formation and stability of nano-emulsions. Adv. Colloid Interf. Sci. 108, 303–318 (2004)

D.J. McClements, J. Rao, Food-grade nanoemulsions: formulation, fabrication, properties, performance, biological fate, and potential toxicity. Crit. Rev. Food Sci. Nutr. 51(4), 285–330 (2011)

D.J. McClements, Edible nanoemulsions: fabrication, properties, and functional performance. Soft Matter 7(6), 2297–2316 (2011)

S.M. Jafari et al., Re-coalescence of emulsion droplets during high-energy emulsification. Food Hydrocoll. 22(7), 1191–1202 (2008)

P. Juliano et al., Enhanced creaming of milk fat globules in milk emulsions by the application of ultrasound and detection by means of optical methods. Ultrasonics - Sonochem. 18(5), 963–973 (2011)

T. Truong et al., Effects of emulsion droplet sizes on the crystallisation of milk fat. Food Chem. 145, 725–735 (2014)

T. Truong et al., SpringerBriefs in Food, Health, and Nutrition, in Effect of Milk Fat Globule Size on the Physical Functionality of Dairy Products, ed. by R.W. Hartel (Springer, New York, 2016), p. 70

P. Walstra, J.T.M. Wouters, T.J. Geurts, Dairy science and technology (CRC Press/Taylor & Francis, Boca Raton, 2005)

H.-G. Kessler, Food and bio process engineering: dairy technology (Verlag A. Kessler, München, 2002)

Z. Long et al., Effect of homogenisation and storage time on surface and rheology properties of whipping cream. Food Chem. 131(3), 748–753 (2012)

T. Truong, N. Bansal, B. Bhandari, Effect of emulsion droplet size on foaming properties of milk fat emulsions. Food Bioprocess Technol. 7(12), 3416–3428 (2014)

L. Bai, D.J. McClements, Development of microfluidization methods for efficient production of concentrated nanoemulsions: Comparison of single- and dual-channel microfluidizers. J. Colloid Interface Sci. 466, 206–212 (2016)

Olsson, A. and A. Mamic, Method Development for Fractionation of Milk Fat Globules-For improvement of cream functionality. 2015.

M.C. Michalski et al., Microfiltration of raw whole milk to select fractions with different fat globule size distributions: process optimization and analysis. J. Dairy Sci. 89(10), 3778–3790 (2006)

T. Leong et al., Ultrasonically enhanced fractionation of milk fat in a litre-scale prototype vessel. Ultrason. Sonochem. 28, 118–129 (2016)

D.W. Olson, C.H. White, R.L. Richter, Effect of pressure and fat content on particle sizes in microfluidized milk. J. Dairy Sci. 87(10), 3217–3223 (2004)

Q. Zhao et al., Effects of sodium caseinate and whey proteins an whipping properties and texture characteristics of whipped cream. J. Food Process Eng. 31(5), 671–683 (2008)

C.I.E. Ciron et al., Comparison of the effects of high-pressure microfluidization and conventional homogenization of milk on particle size, water retention and texture of non-fat and low-fat yoghurts. Int. Dairy J. 20(5), 314–320 (2010)

L. Lee, I.T. Norton, Comparing droplet breakup for a high-pressure valve homogeniser and a Microfluidizer for the potential production of food-grade nanoemulsions. J. Food Eng. 114(2), 158–163 (2013)

C. Qian, D.J. McClements, Formation of nanoemulsions stabilized by model food-grade emulsifiers using high-pressure homogenization: Factors affecting particle size. Food Hydrocoll. 25(5), 1000–1008 (2011)

P. Walstra, Dairy technology : principles of milk properties and processes. Food science and technology (Marcel Dekker, New York, 1999), p. 90. xvii, 727

H. Mulder, P. Walstra, The milk fat globule : emulsion science as applied to milk products and comparable foods (Pudoc, Wageningen, 1974), p. 292

D.J. McClements, Ultrasonic determination of depletion flocculation in oil-in-water emulsions containing a non-ionic surfactant. Colloids Surf. A Physicochem. Eng. Asp. 90(1), 25–35 (1994)

S. Mun, E.A. Decker, D.J. McClements, Influence of droplet characteristics on the formation of oil-in-water emulsions stabilized by surfactant-chitosan layers. Langmuir 21(14), 6228–6234 (2005)

M.C. Michalski et al., Native vs. damaged milk fat globules: membrane properties affect the viscoelasticity of milk gels. J. Dairy Sci. 85(10), 2451–2461 (2002)

O. Ménard et al., Buffalo vs. cow milk fat globules: Size distribution, zeta-potential, compositions in total fatty acids and in polar lipids from the milk fat globule membrane. Food Chem. 120(2), 544–551 (2010)

J.I. Acedo-Carrillo et al., Zeta potential and drop growth of oil in water emulsions stabilized with mesquite gum. Carbohydr. Polym. 65(3), 327–336 (2006)

Q. Gan et al., Modulation of surface charge, particle size and morphological properties of chitosan–TPP nanoparticles intended for gene delivery. Colloids Surf. B: Biointerfaces 44(2–3), 65–73 (2005)

P. Calvo, J.L. Vila-Jato, M.J. Alonso, Comparative in vitro evaluation of several colloidal systems, nanoparticles, nanocapsules, and nanoemulsions, as ocular drug carriers. J. Pharm. Sci. 85(5), 530–536 (1996)

J.M. de Morais et al., Characterization and evaluation of electrolyte influence on canola oil/water nano-emulsion. J. Dispers. Sci. Technol. 27(7), 1009–1014 (2006)

P. Walstra, R. Jenness, Dairy Chemistry and Physics (John Wiley, New York, 1984)

E.A. Collins, D.J. Hoffmann, P.L. Soni, Rheology of PVC dispersions. I. Effect of particle size and particle size distribution. J. Colloid Interface Sci. 71(1), 21–29 (1979)

D.J. McClements, Food emulsions: principles, practice, and techniques (CRC Press, Boca Raton, 1999)

S.R. Derkach, Rheology of emulsions. Adv. Colloid Interf. Sci. 151(1), 1–23 (2009)

Y. Otsubo, R.K. Prud’homme, Rheology of oil-in-water emulsions. Rheol. Acta 33(1), 29–37 (1994)

D.F. Darling, D.W. Butcher, Milk-fat globule membrane in homogenized cream. J. Dairy Res. 45(2), 197 (1978)

I. Heertje, Structure and function of food products: a review. Food Struct. 1(1), 3–23 (2014)

D.W. Everett, N.F. Olson, Dynamic rheology of renneted milk gels containing fat globules stabilized with different surfactants. J. Dairy Sci. 83(6), 1203–1209 (2000)

F. Speroni et al., Gelation of soybean proteins induced by sequential high-pressure and thermal treatments. Food Hydrocoll. 23(5), 1433–1442 (2009)

J. Weiss, D.J. McClements, Influence of ostwald ripening on rheology of oil-in-water emulsions containing electrostatically stabilized droplets. Langmuir 16(5), 2145–2150 (2000)

Steffe, J.F., Rheological methods in food process engineering. 1996: Freeman press.

Acknowledgments

The authors would like to thank ARC Dairy Innovation Hub for the financial support during this research. We thank Dr. Martin Palmer for his advice during the course of this research and in the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hussain, H., Truong, T., Bansal, N. et al. The Effect of Manipulating Fat Globule Size on the Stability and Rheological Properties of Dairy Creams. Food Biophysics 12, 1–10 (2017). https://doi.org/10.1007/s11483-016-9457-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-016-9457-0