Abstract

Rennet-induced aggregation was studied in milk systems containing high-methoxyl pectin (HMP) using ultrasonic and diffusing wave spectroscopy. These two techniques allow for in situ measurements of sol–gel transitions without the need for dilution. At low HMP concentrations, the casein micelles aggregation behavior was similar to that of skim milk, although changes could be noted in the microstructure of the renneted gels. At HMP concentrations between 0.1 and 0.15%, phase-separation kinetics were slower than the rennet-induced aggregation, and different microstructures formed caused by different dynamics of interactions between casein micelles present in HMP-depleted flocs. Higher amounts of HMP failed to create a continuous gel, as phase separation occurred at a faster rate than rennet aggregation. These results highlight the importance of non-invasive techniques in the study of concentration-dependent phase separating and aggregating systems, as only with observations in situ is it possible to determine new ways to control the structuring of protein–polysaccharide mixed systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polysaccharides are often added to food systems as they impart unique and desirable textures and micro-structural properties. Pectin, in particular, is commonly used as a food ingredient because of its unique properties such as water holding capacity, viscosity improvement and gelling properties1. Pectin is often added to milk as it provides stability to acidified milk products against whey separation. Although the mechanism of stabilization of pectin at low pH is well understood1,2, the effect of pectin in milk at neutral pH is much less explored, as at high-enough quantities the polysaccharide can cause phase separation3.

Pectin is an anionic polysaccharide found in plant cell walls and is most widely extracted from citrus peel and apple pomace. It consists of water-soluble, relatively elongated polymeric molecules with carboxyl groups. Its structure is formed by rhamnogalacturonans as well as homopolymeric poly-α-(1 → 4)-d-galacturonic acid with α-(1 → 2)-l-rhamnosyl-α-(1 → 4)-d-galacturonosyl sections containing branch-points with mostly neutral side chains. Some of the carboxyl acid groups in galacturonans can be methyl esterified and the amount that is substituted is referred to as the “degree of esterification”. Pectins with a degree of esterification of 43% or more are classified as high-methoxyl pectins (HMP), whereas those with a lower number of methylesters are called low-methoxyl pectins (LMP)1. HMP is often used in acidified milk since its addition at low pH-values prevents the aggregation of caseins and thus phase and whey separation1,2,4.

Milk is a colloidal suspension composed of protein and fat globules dispersed in a continuous serum phase made up of mainly water with salts, lactose, and whey proteins. The major proteins found in milk are caseins (80% w/w) which are present in an aggregated form, the casein micelle. These particles contain four major proteins, αs1, β, αs2, and κ-casein, with calcium phosphate bridges stabilizing the internal structure. κ-casein is mainly responsible for the stabilization of caseins micelles, since it extends on the surface and provides steric and electrostatic stabilization5. During renneting, the casein micelle is destabilized and aggregation occurs. The mechanism of enzymatic aggregation is well understood. Firstly, chymosin specifically cleaves κ-casein at Phe105-Met106, and only when sufficient hydrolysis has occurred, the casein micelles aggregate, forming a gel network5,6. This is the underlying mechanism behind the formation of cheese-curd.

While the effect of HMP in acid-induced casein aggregation is well understood, very little work has been done on the effect of pectin molecules on milk aggregation caused by chymosin. Tan et al. investigated the addition of HMP to renneted milk, however, the authors limited the concentration of HMP to below the critical value needed for phase separation7. At the native pH of milk, HMP is negatively charged and this causes charge repulsion with the negatively charged casein micelles. At high-enough concentrations, the presence of HMP causes phase separation8.

The possibility of modulating the extent of these segregative interactions during rennet-induced gelation of milk has never been explored. In this work, we investigate the effect of the addition of different HMP concentrations on the stability of skim milk and on the renneting kinetics of casein micelles at pH 6.7. Non-invasive techniques such as diffusing wave spectroscopy (DWS) and ultrasonic spectroscopy (US) were used to closely observe the structure formation during renneting in the presence of HMP. These techniques provide information about particle size and mobility, as well as interparticle interactions that might occur under destabilizing conditions. A better understanding of the extent of the interactions between HMP and casein micelles during renneting could suggest a way to fine-tune texture and microstructure, as well as assist in the development of novel dairy processes.

Materials and Methods

Fresh milk was collected from the dairy research station of the University of Guelph (Elora, ON, Canada). Sodium azide was added at a concentration of 0.02% (w/v). Milk was centrifuged 4,000×g for 20 min at 4 °C using a Beckman J2-21 centrifuge and JA-10 rotor (Beckman Coulter, Mississauga, ON, Canada). To further separate fat globules, milk was then filtered three times through Whatman glass fiber filters (Fisher Scientific, Whitby, ON, Canada) and maintained in the refrigerator at 5 °C until use.

Sample Preparation

Skim milk was heated to 60 °C and HMP (powder; 72.8% DE, random, 372 KDa, CpKelco, San Diego, CA) pH 3.6–4.4 (1% solution) was slowly added to skim milk to obtain a final concentration of 0.01%, 0.04%, 0.1%, 0.12%, 0.15%, 0.18%, 0.2%, 0.28%, and 0.3% (w/v). Each sample was stirred for 30 min. The mixtures were then cooled to 30 °C, while stirring, and the pH was adjusted to 6.7 by addition of 0.1 M NaOH. Rennet (0.018 IMCU/ml Chymostar Double Strengh, Rhodia, Cranbury, USA) was added to the milk sample and was immediately measured with DWS and the ultrasound spectrometer.

Viscosity Measurements

The bulk viscosity of HMP solutions (ranging from 0.02 to 0.3% (w/v) was measured using a Cannon-Fenske viscometer for transparent liquids using about 7 ml of sample at 23 °C. Each concentration was measured ten times.

Diffusing Wave Spectroscopy

Measurements were performed using transmission DWS. The light source was a 100 mW, 532 nm solid state diode pumped Nd:YAG laser (Coherent, Santa Clara, CA, USA). The full details of the equipment set-up can be found elsewhere9. A volume of 1.5 ml of sample was placed into a 5-mm thick, flat-faced cuvette (Hellma Canada Limited, Concord, Canada) and kept at a temperature of 30 °C by a circulating thermostatted water bath. Each treatment was measured in triplicate (i.e., three separate milk batches). Each run was carried out for 1 h for samples with no rennet, and for 2 h for renneting experiments; in all cases, the measurement length was 3 min with 1-s intervals. Data were analyzed using Sigma Plot 10.0 (SPSS Inc., Chicago, USA).

DWS measures the properties of scattered light in suspensions where it is known that all photons have been multiple scattered. In transmission DWS, the laser light enters the sample and the scattered light is collected after it has traversed the whole length (L) of the scattering cell. Correlations in the scattered light are characterized by means of the correlation function10

with a characteristic decay time of \( \tau = {\tau_o}{\left( {l*/L} \right)^2} \), where τ o = (Dko 2)−1, D is the particle diffusion coefficient, ko = 2πn/λ is the wave vector of the light, n is the refractive index of the solvent, and λ is the wavelength of the light in vacuum.

The l* parameter is defined as the length scale over which the direction of the scattered light has been completely randomized and it is directly related to the total amount of light scattered by the system in a given period of time. It is function of the scattering form factor F(q) that is related to the size, shape, and refractive index contrast of the scatterers, and the structure factor S(q) that describes the positional correlations between the scatterers11.

For a turbid solution where all photons are multiple scattered, l* can be calculated from the transmission of light, integrated over a given amount of time, in relation to a calibrating latex sphere of well-defined size. As such , it is a “static” experiment measuring the average position of the scatterers at a point in time. An exhaustive analysis of this treatment can be found elsewhere9.

The apparent hydrodynamic radius of the scatterers is derived as the sphere-equivalent size of a particle moving with a given diffusion coefficient. It can be calculated once l* has been determined, using the Stokes–Einstein relation, for a system of non-interacting spheres at infinite dilution:

where, k is the Boltzman constant, T is the temperature, η is the viscosity of the medium and R is the radius of the scatterers.

Ultrasonic Spectroscopy

Changes in the velocity and attenuation of the sound as a function of time were measured using an ultrasonic spectrometer (HR-US102, Ultrasonic Scientific, Dublin, Ireland). The equipment details have been described elsewhere12. Skim milk was heated to 30 °C in a water bath and placed in the reference and sample cells to tune the instrument to selected frequencies between 2 and 12 MHz. Samples (1 ml) containing HMP with or without rennet were loaded into the sample cell and kept at 30 °C by a Haake F8 waterbath (Thermo Haake, Georgetown, ON). Each treatment was measured in triplicate (i.e., three separate milk batches), for 1 h for samples without rennet and for 2 h for samples with rennet. Data reported are from measurements at 7.8 MHz.

Ultrasonic spectroscopy provides information about chemical changes, hydration or compressibility of a system by measuring two parameters: attenuation and velocity of sound. The ultrasonic velocity (phase velocity of the ultrasound wave) is the distance that an ultrasonic wave travels through a material per unit time13. It is related to the compressibility of the medium as well as its density. The velocity (U) of an ultrasonic wave through a material is defined as:

where β and ρ are the compressibility and density of the material, respectively.

Therefore, ultrasonic velocity increases with decreasing bulk density and compressibility. Most of the times, compressibility is the dominant effect, since it is extremely sensitive to molecular organization and intermolecular interactions of the propagating medium. Attenuation is a measure of the decrease in amplitude of the ultrasonic wave per unit distance traveled through the material; it is the exponential decay of the amplitude of the ultrasonic wave. It is affected by changes in the composition of the dispersed phase and it increases with the square of frequency14. In colloidal dispersions, the total attenuation of the ultrasonic wave is the contribution of different sources of attenuation and is expressed as a sum of various contributions13,15:

where aI relates to the intrinsic losses, the sound absorption in the continuous and dispersed phases; as is the contribution by scattering and aVI and aT describe viscoinertial and thermal losses respectively. In the long-wavelength regime, the colloidal particles are much smaller than the wavelength of sound, the scattering contribution can be neglected, as is the case in this study15. The intrinsic losses are caused by the interaction of the sound wave with matter, as a wave travels from one medium to another this transition carries an associated energy loss. The viscoinertial losses are caused by density differences between the dispersed particles and the surrounding medium and in milk, they are not as important as the thermal losses, because of the small density differences between the particles and the solvent. Thermal losses dominate in soft-material systems, as particles oscillating in the sound wave generate waves that are damped as they dissipate from the particle14.

Confocal Laser Scanning Microscopy

The microstructure of milk gels was observed using confocal laser scanning microscope (CLSM; Leica TCS SP2). A fluorescent protein dye FITC (fluorescein isothiocyanate isomer I) was dissolved in distilled water to a concentration of 0.5% (w/w) and 40 μl of FITC were added to 10 ml of sample and stirred for 1 min. Subsequently, rennet was added. A few drops of the sample were placed to a cavity slide and a cover slip was placed over it. Each slide was placed in a Petri dish and held in a temperature-controlled water bath for 2 h, at 30 °C to let the enzyme reaction take place. After this, the slides were observed in the CLSM at 494 nm, with an emission value between 510 to 525 nm. The lenses used were ×63 oil immersion objective.

Results

Phase Separation in Milk as a Function of HMP

Figure 1 shows the correlation functions of skim milk plus 0.04% (solid circles) and 0.2% HMP (solid triangles) superimposed with the theoretical fits (empty symbols) obtained using Eq. 1 and measured 3 min after addition of rennet. The goodness of the fits is very good for both samples, the higher amount of pectin presents small deviations from the experimental data, however, it is well within the accepted range. Both correlation functions fully decay to 0 and the goodness of the fits indicates that these samples are fully ergodic. Figure 2 shows the 1/l* and diffusion coefficient values of skim milk plotted as a function of HMP concentration, measured 6 min after the addition of HMP using DWS. Three different stages can be clearly observed with both static (A, 1/l*) and dynamic (B, radius) measurements. Up to 0.1% HMP added, the 1/l* values are constant and comparable to those of control milk (Figure 2a). At intermediate concentrations, from 0.1% to 0.2% HMP, the 1/l* value decreases significantly from 1.7 to 1.1 mm−1. At HMP concentrations above 0.2%, the 1/l* values reach a plateau around 1.00 mm−1 and further addition of polysaccharide does not show further changes in the optical properties of the mixes.

Correlation functions measured 3 min after addition of rennet for SM plus 0.04% (filled circle) and 0.2% (filled inverted triangle) HMP. The open symbols correspond to the fits obtained by applying Equation 1 to the experimental data

In agreement with the static measurements, the diffusion coefficient also shows three different stages related to the particles’ mobility (Figure 2b); however, there is no clear initial plateau. The radius of the particles corresponding to the initial diffusion coefficient was 114 ± 13 nm and could be easily calculated due to the free diffusing nature of the micelles as well as knowledge of the viscosity of milk serum. The monotonic downward trend as a function of pectin concentration suggests that the diffusion of the particles is affected by HMP even at very low concentrations, due to viscosity effects. From concentrations from 0.1% to 0.2% the diffusion of the casein micelles continues to slow down but at a faster rate. At concentrations above 0.2% the diffusion coefficient values level off at around 0.06 m/s, compared to about 1.6 m/s for the initial values.

The HMP addition to milk clearly affects the stability of the suspension. Figure 3 shows the 1/l* value of milk with different amounts of HMP as a function of time. The control (milk without pectin) shows an initial 1/l* value of 1.7 mm−1 and remains constant throughout the length of the experiment. Up to 0.12% pectin, the 1/l* is not significantly different from that of control milk, as shown in Figure 2, and does not change over time. Milk containing >0.18% HMP results in a decrease of the initial 1/l* value (as already seen in Figure 2) with an increase at about 20–30 min for 0.18% and 0.2%. With 0.3% HMP the increase in 1/l* is already apparent right after mixing. These higher concentrations of HMP cause a sudden decrease in 1/l* at 40–60 min. This decrease corresponds to the visible phase separation of the samples and correponds to a change in concentration of scatterers in the scattering volume due to sedimentation of the micelles. Therefore, it renders the physical analysis of the sample no longer possible and the values reported have no physical significance.

1/l* as a function of time for milk containing 0% (empty circle); 0.04% (filled circle); 0.1% (filled diamond); 0.12% (empty upright triangle); 0.18% (filled upright triangle); 0.2% (empty square); 0.3% (filled inverted triangle) HMP. Lines are drawn to guide the eye. Values are average of three replicate experiments

The diffusion coefficient measurements also show a change as a function of time for milk with high concentrations of HMP (Figure 4). The control presents a diffusion coefficient of 1.8 μm2/s, and this value remains constant for the duration of the experiment. Up to 0.12% HMP, the diffusion coefficients decrease (see also Figure 2b) but remain constant for the whole duration of the experiment. Higher concentrations cause the diffusion coefficients to decrease after 20–30 min. These changes correlate well with the changes in 1/l* value seen in Figure 3. At about 40–60 min, the diffusion coefficients can no longer be measured with confidence (there is too much error in the fit of the correlation function as reported for the 1/l* values). At these concentrations, after 40–60 min visible separation occurs.

Diffusion coefficient as a function of time for milk containing 0% (empty circle); 0.04% (filled circle); 0.1% (filled diamond); 0.12% (empty upright triangle); 0.18% (filled upright triangle); 0.2% (empty square); 0.3% (filled inverted triangle) HMP. Values are average of three replicate experiments. Error bars denote standard deviations

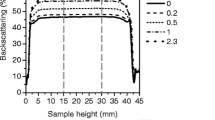

Figure 5 illustrates the change in the parameters measured on the same samples using ultrasonic spectroscopy. Skim milk control shows a constant value of ultrasonic attenuation of 10 m−1 throughout the experiment and indicates a stable system (Figure 5a). No differences are noted with milk containing <0.12% HMP. These results are in full agreement with the DWS measurements of 1/l* (Figure 3). With an addition of 0.18%, 0.2% and 0.3% pectin, the ultrasonic attenuation remains constant for the first 10 min after mixing, but later increases significantly. Interestingly, this increase does not show a statistically significant time dependence with concentration, as in the case of the 1/l* measurements (Figure 3). In milk containing >0.18%, the ultrasound wave attenuation continues to increase to values four to five times higher than the initial value of attenuation.

Ultrasonic attenuation (a) and velocity (b) as a function of time for milk containing 0% (empty circle); 0.04% (filled circle); 0.1% (filled diamond); 0.12% (empty upright triangle); 0.18% (filled upright triangle); 0.2% (empty square); 0.3% (filled inverted triangle) HMP. Curves are representative runs

Changes in ultrasonic velocity also indicate that concentrations of HMP < 0.12% do not show instability (Figure 5b). The velocity of the sound wave propagating through control milk shows a constant velocity of 1,537 m/s over time. With the addition of HMP (<0.12%) the value of the ultrasonic velocity increases with each increasing amount of pectin, however, within each sample, the value of the velocity remains unchanged throughout the 60-min duration of the measurement, indicating stability of the system. This behavior is similar to that shown with attenuation, 1/l* and diffusion coefficient measurements. Higher amounts of HMP (>0.18%) cause a significant decrease in the velocity of sound with a continuous decrease in value since the start of the experiment. This decrease in velocity indicates an increase in the overall compressibility due to the rearrangement of mass caused by the phase separation of the system. As pectin-enriched pockets are formed, the compressibilty of the previously, mainly water areas is increased by the presence of these “impurities”. Furthermore, the density of the casein micelles is not changed by this rearrangement effect and the overall density of the system is increased, at most, by 0.3% at the highest pectin amount. All these points confirm that the changes in velocity are driven by compressibility variations. After between 35 and 50 min from mixing, depending on amount of pectin, the velocity value reaches a plateau.

Rennet-Induced Aggregation of Skim Milk in the Presence of HMP

To determine the effect of HMP on the aggregation of caseins in milk during renneting, four levels of HMP were chosen: 0.04%, 0.12%, 0.15%, and 0.18% (see Figures 2, 3, 4 and 5). Figure 6a shows the 1/l* value for milk during renneting as a function of time. The control (skim milk) presents an initial 1/l* value around 1.65 mm−1 and remains constant until 20 min from the addition of rennet, when it starts and continues to increase through the remainder of the experiment. This change of 1/l* behavior has been observed before and it is related to the development and later formation of a gel16. When 0.04% HMP is added to milk, the behavior of 1/l* is similar to that of the control, with an initial plateau and an increase at about 20 min. This indicates that this amount of HMP does not affect the average space-distribution of the caseins in solution, the point of aggregation or the initial structure development of the casein matrix. At a concentration of 0.12% pectin, the initial value of 1/l* is again similar to that of the control; however, for this pectin concentration, the value of 1/l* remains constant up to 40 min (instead of 20 min for the control), before showing a marked decrease (instead of an increase, as in the case of skim milk). The decrease in the 1/l* value occurs earlier in milk samples with a higher concentration of HMP. It is important to note that the drop in 1/l* is not as pronounced at HMP > 0.15% compared to that observed in milk containing 0.12% HMP. However, the estimates of 1/l* for these last two systems after 30 min carry significant error. It is worth noting that these samples (HMP > 0.15%) do not form a continuous gel, but are visibly phase separated after renneting.

Figure 6b shows the diffusion coefficient of the casein micelles as a function of time during renneting for milk containing different amounts of HMP. As shown in Figure 2b, the diffusion coefficient decreases with the addition of pectin. The diffusion coefficient of casein micelles in skim milk remains constant at 1.7 μm2/s until 40 min from rennet addition, when it starts to decrease indicating the rennet-induced aggregation of the casein micelles. This delay on the onset of aggregation (at 40 min) of the diffusion coefficient as compared to the onset shown in the 1/l* values (where the changes appear earlier; see Table 1) is related to the high sensitivity of l* to changes in particle interactions, even before macroscopic changes (such as aggregation) are observed. At long times (above approximately 75 min), the diffusion coefficient becomes constant and this corresponds to the entrapment of the casein micelles in a gel network. With the addition of 0.04% HMP, the aggregation point (when the diffusion starts to decrease) also corresponds to that of milk control; however, the changes following are more pronounced with the diffusion coefficient dropping much faster than that of the control and to a lower value, indicating an earlier change in the mobility of the casein micelles and an effect of HMP, even at the low concentrations, on the renneting behavior of skim milk. The segregation behavior caused by the presence of the polysaccharide increases the extent of decrease in the movement of the casein micelles. This is even more pronounced at the higher amounts of HMP. With the increase in pectin concentration (0.12% to 0.18%), a similar behavior can be observed but with a shift in the decay times: each addition of pectin causes a shift in time of about 10 min reaching a lower plateau value for the diffusion coefficient. However, it is important to point out that very low diffusion coefficients (below 0.1 μm2/s) are related to large errors in the determination of its value. In all cases, when the diffusion coefficent reaches a plateau, the system is fully arrested and the decay times are much longer than the time scales of the instrumental set-up.

The attenuation measured for the sound wave propagating through the samples during renneting is summarized in Figure 7. During renneting of control milk or milk containing 0.04% HMP, the attenuation of sound is nearly constant, with a slight monotonic increase after 60 min from rennet addition. In aggrement with previously published data17, the change in attenuation when caseins aggregate in rennet gels is very small. The small increase shown in the value of attenuation occurs at 60 min when there is also a significant decrease in the mobility of the caseins. Milk containing 0.12% HMP shows a behavior similar to that of control milk at the beginning stages, with a significant increase in attenuation after 60 min. This indicates a much larger increase in the thermal losses compared to the control milk after casein aggregation. The drastic increase in attenuation might also be due to the rather large casein-rich domains, percieved as extensive aggregation due to possible correlation in their time-dependent displacements. This will result in scattering effects which will also contribute to further attenuation of the sound. A different behavior was shown for milk containing higher amounts of HMP (0.15% and 0.18%): both systems show an increase in the ultrasonic attenuation after 20 and 30 min, to a smaller extent for 0.15% compared to 0.18% HMP. This increase in attenuation corresponds to the increase observed in Figure 5a for milk containing HMP measured under quiescent conditions (with no rennet). It is important to note that this increase is much smaller than that of non-renneted systems: for example, for 0.18% HMP, the attenuation increases less than twofold. In both systems, after 60 min from the addition of rennet, the attenuation shows an increase again, most likely because of an increase in the interactions between caseins due to rennet-induced aggregation.

To confirm the formation of phase separated domains of caseins and HMP in renneted milk samples, CLSM was carried out. Samples containing various amounts of HMP are shown in Figure 8. Although DWS and ultrasound spectroscopy suggest similarities between the control milk and milk containing 0.04% HMP, even low concentrations of HMP affect the rennet-induced aggregation: with 0.04% HMP (Figure 8b), the caseins form a more open network compared with that formed with skim milk (Figure 8a). With further addition of HMP (0.12%, 0.15%; Figure 8c,d,e) casein micelles start to form clusters which become denser, with more open areas with increasing HMP concentration, inhibiting to different extents the formation of a three-dimensional network.

Discussion

The presence of HMP in milk at neutral pH clearly causes phase separation by a depletion mechanism, as previously reported2,18. Up to a critical concentration of 0.1% pectin, there is no change (within the error) in the 1/l*, attenuation of sound and velocity, and a very small decrease in diffusion coefficient when measuring milk under quiescent conditions.

At low levels of HMP, the unadsorbed polysaccharide increases the viscosity of the mobile phase, but there are no measurable changes in the thermal losses and the overall compressibility of the milk sample during the propagation of the ultrasonic wave. It is then possible to explain why, at these concentrations of HMP, there is very little change in the renneting behavior of the caseins. The mobility of the caseins decreases slightly earlier in the presence of 0.04% HMP (Figure 6b, Table 1) suggesting an earlier formation of aggregates.Differences can be noted in the microstructure of the rennet gels as shown by confocal images (Figure 8a,b). On the other hand, skim milk with 0.04% HMP attenuation and velocity of sound as well as 1/l* values are fully comparable to control milk. These results may suggest that even if there is no signature of phase separation, small amounts of HMP can be employed to fine-tune the structuring of rennet gels.

The increase in background viscosity due to the presence of 0.1% HMP should correspond to a diffusion coefficient of 0.75 μm2/s for the milk mixture. Figure 2b shows that the experimental diffusivity is 1.3 μm2/s, a much higher value than the calculated value of 0.75 μm2/s. This discrepancy can only be explained by depletion effects. The micelles are starting to be segregated to pectin-depleted domains. These domains have a local net viscosity slightly lower than that measured in the bulk, for the simple reason that the net concentration of pectin inside them is less. The casein micelles, therefore, are somewhat slowed down dynamically, as shown by the decrease in the diffusion coefficient, but are otherwise structurally free in space, as detected by the relative invariance of the other parameters.

The change in 1/l* (Figure 2a) can also be used to obtain quantitative information of the depleted state of the milk mixtures. A depleted system can be described as a heterogeneous system with certain parts of the volume (1 − x) consisting of voids larger than the typical interparticle distance between the caseins and other parts (x) with particle clusters. The transport mean free path of a system is a non-linear function of volume fraction. This means that changes in the distribution of mass which can form large heterogeneities, will modify the optical properties of a system, albeit keeping the same total volume fraction. If we know the dependence of 1/l* on the concentration of casein micelles in milk, we can determine, to good approximation, the total volume fraction occupied by the voids (serum only). By applying the fact that in a non-interacting, multi-component system, the final 1/l* is the sum of the 1/l* of each individual component9, and by assuming that the clusters (x) formed by depletion will have a higher particle density, ϕ o/x, where ϕ o is the initial volume fraction of the particles in milk, discrete numerical calculations18 can determine the value of x by making use of the known dependency of 1/l* on casein micelle concentration in fresh skim milk19. If we use ϕ o = 0.10 and the total optical density of the sample, 1/l* = 1 mm−1 (for milk containing 0.3% HMP, Figure 2a), the value of (x) for the depleted sample is 36%. The voids (larger than the typical intermicelle distance at 10% volume fraction) after depletion with 0.3% HMP account for approximately 64% of the total volume. Though this is a calculation based on a concentration-only effect on the changes in 1/l*, but it is a sound assumption and gives us a good and quantifiable indication of the state of depletion.

Milk containing 0.12% HMP shows some structural signs of depletion effects, as seen by the changes in the DWS and ultrasonic spectroscopy parameters compared to the control (Figures 2, 3, 4 and 5). Changes in the values of 1/l*, diffusion coefficient, velocity and attenuation of sound are noted right after mixing and are constant throughout the experiment, indicating that at these concentrations the system is depleted but still in a pre-flocculated state, where the assumption of monodispersity is still relatively valid and the decrease in the value of 1/l* can be easily explained as an apparent increase in particle size due to the correlated motion of the individual caseins “trapped” in distinct, pectin-depleted domains. Other researchers19,20 have observed a similar behavior in model suspensions of polystyrene spheres in the presence of different molecular weight (polyethylene glycol); in addition, Asakura and Oosawa21 predict increasing ordering of colloidal bodies with increasing polymer content in solution leading to changes in the fluid structure.

It can be speculated, that these intermediate concentrations (i.e., 0.12% HMP) strongly affect the structure formation of rennet gels. The casein micelles can still be considered as individual entities albeit in a depleted state. This “in-between” situation places the system in an easily perturbed energetic condition. During renneting, there is a distinct change in behavior from milk containing less HMP. The 1/l* and attenuation of sound are quite similar to the control during the initial stages of the reaction, confirming that the system is stable and structurally somewhat unaffected. However, after 40 min, 1/l* shows a marked decrease, compared to the control samples where the 1/l* values increase (Figure 6). This indicates that the aggregation of the micelles is now occurring in pectin-depleted pockets. This is clearly confirmed by confocal images where phase separation after renneting is now evident (Figure 8c). Figure 6b shows a drop in the diffusion coefficient at an earlier time (40 min) compared to control samples and a plateau at about 60 min, when the attenuation of sound shows a dramatic increase. This indicates that aggregation of the casein micelles occurs earlier (in the depleted pockets), and the ultrasound wave becomes attenuated only when mobility of the caseins has decreased significantly. At this concentration, the casein micelles are slightly altered by the presence of HMP but still free enough to move around and caught in depleted zones where microphase separation has already started. This metastable region is fragile enough that any further destabilization by rennet forces an abrupt change in the system. It is important to note that in milk with 0.12% HMP, the rennet-induced aggregation still did not affect the overall compressibility of the system, as the velocity of sound remains constant throughout the renneting reaction as for control milk.

Above 0.15% HMP, there is enough polysaccharide to destabilize the caseins even under quiescent conditions, without any rennet addition. At these concentrations, HMP molecules trigger casein micelle rearrangement and the micelles are now in a flocculated state immediately after addition of HMP20. Depletion attraction is considerable and the individual micelles now exist in clusters of different sizes and shapes with a substantial arrest in movement. The micelles are now in close proximity and the decrease in diffusion coefficient corresponds to the presence of like-charged sterically stabilized particles constrained in space. There is a clear indication of the rerrangement caused by the polymer.

The milk containing HMP shows an increase in the attenuation of the sound wave within a few minutes after mixing (Figure 5a). There are possibly two effects taking place. Firstly, scattering losses due to the apparent size increase of the individual caseins in close proximity, inside the pectin-depleted zones. Secondly, an increase in the viscous layers surrounding the particles will cause an increase in the decay of the shear and thermal waves generated by the oscillations. The boundary layers between the casein micelles are still sufficiently separated that no particle–particle interactions are noted. On the other hand, the drop in sound attenuation corresponds to the closer approach of the casein micelles, with a corresponding appearance of scattering effects as well as an overlap of the thermal and viscous boundary layer14. When rennet is added, the attenuation of sound still shows an increase similar to the samples without rennet, however, the extent of the increase in the attenuation is much lower (compare Figure 5a with Figure 7). This is most likely due to the decrease in steric-stabilization caused by renneting, allowing for a closer approach of the casein micelles sooner than for non-renneted samples. This ultimately results in a decrease in the extent of the attenuation peak are shown in Figure 7.

The velocity of sound also shows a decrease that reaches a plateau after about 30 min (Figure 5b), indicating a gradual increase in the compressibility of the system. These parameters indicate a larger extent of interactions between the sterically stabilized micelles and an increase in the compressibility of the milk due to the formation of casein-depleted pockets. Between 20 and 30 min after mixing, the time being inversely proportional to the amount of pectin added, there is a substantial increase in value of 1/l* and a drop in the diffusion coefficient and ultrasound attenuation (Figures 2, 3 and 4). The increase in turbidity is caused by an increase in the particle–particle interactions (and increase in S(Q), with very little change in the size) caused by the close proximity of like-particles with stabilizing hairy layers. It is important to note that an increase in size of scatterers should result in a decrease in 1/l* (as already seen for the intermediate HMP concentrations). The sudden drop in the 1/l* at long times (about 40 min; Figure 3) is an indication that the system has reached another stable arrangement, one of macro-phase separation. This is confirmed by visual observations. There are two clear populations, one micelle-rich and the other one pectin-rich and no further development in structure or dynamics happens with time.

Since the rennet concentrations used in this study take around 60 min to coagulate skim milk, concentrations larger than 0.18% would result in fully phase separated by this time. When rennet was added to milk containing 0.15% and 0.18% HMP, the formation of a self-supporting gel was inhibited, as confirmed by confocal micrographs (Figure 8d, e). One possible explanation is that once the casein micelles are segregated and clustered enough, the rennet action can only coagulate the caseins within the domains. The small difference between initial and final values of 1/l* in the milk with high HMP (Figure 6) points to a somewhat similar bulk structure before and after renneting, thereby indicating the possible aggregation of micelles inside domains. The diffusion coefficient shows an earlier decrease (Figure 6b), in agreement with studies of renneting in concentrated milk systems, where casein micelles aggregation occurs at lower levels of hydrolysis of κ-casein22,23. It is interesting to note that the extent of change in attenuation is similar between 0.12%, 0.15%, and 0.18% of HMP between 60 and 120 min. After 60 min, the caseins have very restricted mobility due to their state of arrest in the polymer-depleted zones as well as their state of aggregation due to rennet effects. It is very likely that this highly immobile condition would restrict the possibility of large reorganizations occuring within the pockets which would, in turn, impede large variations in ultrasonic attenuation.

Conclusions

In conclusion, by controlling the mechanisms of destabilization of milk by rennet in the presence of HMP it is possible to modify the formation of structure. At very low pectin concentrations, the physical and dynamic characteristics of gel formation are very similar to those of the control milk without HMP, however, some differences can be noted in the formation of the structure. At intermediate HMP concentrations (0.1–0.12%), the destabilization by depletion flocculation is much slower than the rennet action, and this suggest an interesting concentration regime to explore for the development of new textures, as networks with structural and dynamic characteristics extremely different from control milk can be created. Higher amounts of pectin failed to create a continuous gel after rennet addition, as destabilization by depletion occurs at a faster rate than renneting, however, interesting textures could also developed in this area by fine-tuning the aggregation kinetics and the mobile phase viscosity. This study highlights the potential and versatility of milk/polysaccharide systems in the creation of novel foods. It also affirms the value of non-invasive techniques, such as diffusing wave spectroscopy and ultrasound to the study of concentration-dependent behaviors.

References

G.B. Seymour, J.P. Knox, Pectins and their manipulation (Blackwell, Oxford, UK, 2002)

A. Syrbe, W.J. Bauer, H. Klostermeyer, International Dairy Journal 8(3), 179–193 (1998)

E. Dickinson, M.G. Semenova, A.S. Antipova, E.G. Pelan, Food Hydrocolloids 12(4), 425–432 (1998)

W.G.T. Willats, J.P. Knox, J.D. Mikkelsen, Trends in Food Science & Technology 17(3), 97–104 (2006)

P.F. Fox, P.L.H. McSweeney, Advanced dairy chemistry (Kluwer, New York, 2003)

D.G. Dalgleish, J Dairy Res 47, 231–235 (1980)

A.Y.Y.L. Tan, H. Singh, Y. Hemar, Journal of Texture Studies 38, 404–422 (2007)

E. Dickinson, Trends in Food Science & Technology 9(10), 347–354 (1998)

M. Alexander, D.G. Dalgleish, Colloids and Surfaces B: Biointerfaces 38(1–2), 83–90 (2004)

D.A. Weitz, D.J. Pine, Dynamic light scattering: The method and some applications (Oxford University Press, Oxford, UK, 1993)

M. Alexander, M. Corredig, D.G. Dalgleish, Food Hydrocolloids 20(2–3), 325–331 (2006)

V. Buckin, C. Smyth, Seminars in Food Analysis 4, 113 (1999)

D.J. McClements, Langmuir 12, 3454–3461 (1996)

A.S. Dukhin, P.J. Goetz, B. Travers, J Dairy Sci 88(4), 1320–1334 (2005)

F. Babick, F. Hinze, S. Ripperger, Colloids and Surfaces A: Physicochemical and Engineering Aspects 172(1-3), 33–46 (2000)

S. Sandra, M. Alexander, D.G. Dalgleish, J Colloid Interf Sci 308(2), 364–373 (2007)

M. Corredig, M. Alexander, D.G. Dalgleish, Food Res Int 37(6), 557–565 (2004)

A. Maroziene, C.G. de Kruif, Food Hydrocolloids 14(4), 391–394 (2000)

R. Shinde, G. Balgi, S. Richter et al., Appl Optics 38(1), 197–204 (1999)

S. Banerjee, R. Shinde, E.M. Sevick-Muraca, J Colloid Interf Sci 209(1), 142–153 (1999)

S. Asakura, F. Oosawa, J Chem Phys 22, 1255–1256 (1954)

S. K. Sharma, G. S. Mittal and A. R. Hill, Milchwissenschaft 48(9), (1993)

S. K. Sharma, G. S. Mittal and A. R. Hill, Milchwissenschaft 49(8), (1994)

Acknowledgments

The authors would like to acknowledge funding support from the Natural Sciences and Engineering Research Council of Canada, and CpKelco (San Diego, CA, USA) for providing research-grade pectin. The assistance of Ms. Edita Verespej with the ultrasonic experiments is also recognized.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lopez, A.A., Corredig, M. & Alexander, M. Diffusing Wave and Ultrasonic Spectroscopy of Rennet-Induced Gelation of Milk in the Presence of High-Methoxyl Pectin. Food Biophysics 4, 249–259 (2009). https://doi.org/10.1007/s11483-009-9122-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-009-9122-y