Abstract

It is difficult to describe the taste of Processed Aconite Root (PAR) because it contains toxic compounds, and tasting poses some risk to the examiner. Therefore, there is no description of the taste of PAR in the latest Japanese Pharmacopoeia, although the taste of crude drugs has been regulated as a criterion for judgment. In this study, we revealed the objective taste of PAR by using a taste-sensing system. The PAR samples examined were classified into four types by how the samples were processed: PAR1 processed by autoclaving; PAR2-a processed by autoclaving after rinsing in salt (sodium chloride) solution; PAR2-h processed by heating after rinsing in calcium chloride solution; PAR3 processed by treating with hydrated lime after rinsing in salt solution. The most characteristic taste factor of PAR is an aftertaste of cationic bitterness, which was detected in all PAR sample solutions, even at the concentration of 0.1 mg/ml. In addition, anionic bitterness and saltiness were detected in all sample solutions at 1 mg/ml. Furthermore, umami was detected in the PAR1, PAR2-a, and PAR3 sample solutions at 1 mg/ml. Detailing the analyses of the four taste factors on the four sample types, we found each type has its own characteristic taste pattern. On the basis of these results, we proposed a method for discriminating one PAR type from another by using the system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aconitum plants, such as A. carmichaeli Debeaux (Ranunculaceae), which contain diester-type aconite alkaloids (DAs) in their entire bodies, particularly in their roots, are known as a poisonous herb in Europe. In Asia, however, the tuberous root of Aconitum plants has a long history of use as a poison and also as a crude drug; for example, it is listed in the low-grade item portion of Shen-nong-ben-cao-jing, which is the earliest known book of Chinese materia medica [1].

Depending on their toxicity, crude drugs derived from the tuberous root of Aconitum plants are divided into two types. One is the raw type, which is the dried tuberous root, and the other is the processed type, which is appropriately processed and then dried. The former is highly toxic because of its high content of DAs. Hikino et al. [2] reported that LD50s to mice by oral administration of the raw tuberous root of A. carmichaeli are 1.61 g/kg (collected in Hokkaido, Japan) and 5.49 g/kg (collected in China), although the severity of toxicity in this type varies widely depending on the production region and the time of collection. Thus, prior to medicinal use, the tuberous root of Aconitum plants is generally processed by heating, immersing in salt (sodium chloride) solution, or coating with hydrated lime to attenuate the toxicity and control the medicinal effect. Almost all crude drugs in Japan made from the tuberous root of Aconitum plants are now classified as this processed type. The root is used for its analgesic properties, cardiotonic action, and alleviating coldness of the extremities [3–7] and is blended into many Kampo formulae, such as Hachimijiogan, Maobushisaishinto, Shinbuto, and so on.

In Japan, the second edition of the Japanese National Formulary (Kokumin Iyakuhinshu) adopted the processed type of the tuberous root of Aconitum plants in the monograph of Aconiti Sinensis Tuber in 1955 [8], and the seventh edition of the Japanese Pharmacopoeia (JP7) adopted its contents without modification in 1961 [9]. In 1966, however, the monograph was deleted in the revised version of the JP7, probably because of this crude drug’s ambiguous toxicity [10]. Then a variety of studies were performed on component characteristics and quality evaluation of both the raw and processed types of the crude drugs because of the medicinal importance of the tuberous root as a crude drug [2, 11–20]. Subsequently, in 2004, Processed Aconite Root (PAR) was newly adopted in Supplement II of the JP14, with strict control of the DAs by a purity test [21].

PAR in the JP is subdivided into three categories (PAR1–PAR3) in accordance with how it is processed: PAR1 processed by autoclaving; PAR2 processed by heating or autoclaving after rinsing in sodium chloride, rock salt, or calcium chloride solution; PAR3 processed by treating with hydrated lime (calcium hydroxide) after rinsing sodium chloride solution. The JP set an upper PAR limit for individual and total contents of aconitine, jesaconitine, hypaconitine, and mesaconitine, which are representative DAs, by high-performance liquid chromatography (HPLC) analysis. In addition, the amounts of total alkaloids are controlled by colorimetric titration assay.

In the course of our successive studies for quality control of crude drugs [22–37], we used a taste-sensing system to objectively evaluate the taste of crude drugs and Kampo formulae [38–40], as the taste of crude drugs has been regulated as a criterion for judgment by the JP. In the JP7, for Aconiti Sinensis Tuber, the taste was described as “slightly salty, then prolonged numbing” [9]. However, in modern books on medicinal plants and crude drugs, there are no descriptions of the taste of the tuberous root of Aconitum plants and PAR. In the JP15, the latest JP edition, the taste of PAR is also not described, because tasting poses some risk to the examiner due to the intake of DAs [41].

In the 1990s, a taste-sensing system was developed by Toko et al. [42–44] for objective taste measurement based on the concept of modeling the mechanism of human taste recognition. The system is composed of a sensor unit, which consists of various artificial lipid membrane sensor probes and a personal computer. Taste data are obtained from the change in electrical potential of the artificial lipid membranes when the taste substances interact electrically with, or are absorbed to, the membrane.

In recent years, using the taste-sensing system, we have examined the taste of PAR collected by the official working group for the establishment of the monograph of PAR in the JP14 Supplement II (PAR-WG). The PAR samples provided were previously classified into four types by how they were processed: PAR1, PAR3, and PAR2-a (autoclaving type) and PAR2-h (heating type). In this study, we report the results on taste characteristics of the four types of PAR samples measured by the taste-sensing system. In addition, based on these results, we propose a method for discriminating one PAR type from another using the system.

Materials and methods

Materials

Processed aconite root samples

Forty-seven PAR samples were provided by the PAR-WG. All major companies handling PAR in Japanese markets have participated in the PAR-WG, and the PAR samples were collected by the PAR-WG in 2001 and 2002. Therefore, these samples are thought to be representatives of PAR in the Japanese markets. The number of PAR samples classified by typical processing was as follows: PAR1, 13; PAR2, 23; PAR3, 11. PAR2 samples were further subdivided into PAR2-a (12 samples) and PAR2-h (11 samples) by how the samples were processed: PAR2-a is autoclaved after being rinsed in sodium chloride solution, whereas PAR2-h is heated (steamed) after being rinsed in calcium chloride solution. All samples were stored at the Research Center for Medicinal Plant Resources, National Institute of Biomedical Innovation (NIBIO), Tsukuba, Japan. Brick and cut type PAR samples were pulverized using an electric mill and passed through a no. 50 sieve (300 μm).

Chemicals and reagents

A solution of 30 mM potassium chloride in 0.3 mM tartaric acid was the reference solution in the taste measurement. A 30% ethanol aqueous solution containing 100 mM hydrochloric acid was used as the washing solution for negatively charged artificial lipid membrane sensor probes and a 30% ethanol aqueous solution containing 100 mM potassium chloride and 10 mM potassium hydroxide for positively charged probes. Potassium chloride, tartaric acid, ethanol (99.5 v/v%), and potassium hydroxide were purchased from Wako Pure Chemical Industries, Ltd. (Osaka, Japan). Hydrochloric acid (35–37%) was purchased from Nakalai Tesque, Inc. (Kyoto, Japan). Ultrapure water was obtained by an EQS-10L system (Nihon Millipore K.K., Tokyo, Japan). The internal solution for the artificial lipid membrane sensor probes containing 3.3 M potassium chloride in saturated silver chloride (AgCl) aqueous solution was obtained from Intelligent Sensor Technology, Inc. (Atsugi, Japan).

Preparation of sample solutions for taste measurement

A pulverized and sieved PAR sample was weighed and suspended in ultrapure water at concentrations of 1 or 0.1 mg/ml and then extracted by sonication for 10 min at 25°C. After centrifuging at 1,710×g for 10 min at 25°C, the supernatant was filtered with cotton. Potassium chloride and tartaric acid were added to the filtrate at concentrations of 10 mM and 0.1 mM, respectively. This solution was applied to the taste-sensing system for taste measurement. Aqueous solution containing 10 mM potassium chloride and 0.1 mM tartaric acid was used as a blank control.

Taste measurement

The objective tastes of the PAR samples were measured fundamentally according to our previous report [38] using the taste-sensing system SA402B (Intelligent Sensor Technology, Inc.) equipped with a sensor unit, which consists of artificial lipid membrane sensor probes of anionic bitterness, astringency, saltiness, umami, and catatonic bitterness (C00, AE1, CT0, AAE, and AN0, respectively) (Table 1).

The artificial lipid membrane sensor probe is composed of silver-wire electrode, the surface of which is coated with Ag/AgCl, with a sensor body made of polypropylene, and artificial lipid membranes made by mixing lipids (which play an important role in taste sensing) with a polymer. The internal cavity of the artificial lipid membrane sensor probe is filled with the internal solution. The reference solution was measured by the sensor unit for 30 s, and the electric potential at the endpoint of measurement (Vr) was recorded. Then, the sample solution was measured by the sensor unit in the same manner (Vs). After measuring the sample solution, the sensor unit was briefly rinsed in the reference solution, then the reference solution is measured again by the sensor unit for 30 s (Vr′). Finally, the sensor unit was washed by the washing solution and then rinsed by the reference solution for the next measurement. All measurement procedures were carried out at the room temperature. Electrical potential changes between the sample solution and the reference solution, which occurs before the sample solution measurement (Vs − Vr) is called the relative potential and used to calculate the initial tastes. The change in electric potentials of the reference solution between before and after sample solution measurement (Vr′ − Vr) is called the change of membrane potential caused by adsorption (CPA) value and used to calculate the aftertaste [45].

This system detects two types of taste: the initial taste and aftertaste. The initial taste means the taste a person senses when food and/or drink is in the mouth, whereas aftertaste means the taste a person senses after swallowing food and/or drink. Estimate of taste intensity from the outputs of the artificial lipid membrane sensor probes is based on the Weber–Fechner’s law that the intensity of the perception is proportional to the logarithm of stimulus intensity. For taste, it is said that humans normally recognize a change of taste if the concentration of the taste substance is changed by 20% [46, 47], and this 20% change was defined as one unit of taste intensity [44].

In this study, relative potentials (Vs − Vr) obtained from the C00, AE1, AAE, and CT0 sensor probes were used to measure selective initial taste. CPA values (Vr′ − Vr) obtained from C00, AE1, and AN0 sensor probes were used to measure selective aftertastes.

Statistical analysis

Values are shown as mean ± standard deviation (SD). Mann–Whitney U test was applied to test the difference between two independent groups. Kruskal–Wallis test was applied to test the difference among four independent groups, and when significance was noted, Mann–Whitney U test was applied to each independent groups. For each test, a value of P < 0.01 was considered to be significant.

Results

Taste patterns of PAR obtained by the taste-sensing system

Seven taste factors were measured by the artificial lipid membrane sensor probes used in this study. Anionic bitterness, astringency, umami, and saltiness were measured as taste factors of the initial taste, whereas the aftertastes of anionic bitterness, astringency, and cationic bitterness were measured as taste factors of the aftertaste (Table 1). Figure 1 and Table 2 show the taste patterns of water extract from the PAR samples and the taste intensities of each taste factor in each type of PAR sample. The aftertaste of cationic bitterness was detected in all PAR sample solutions, even at a concentration of 0.1 mg/ml. In addition, anionic bitterness and saltiness were detected in all PAR sample solutions at 1 mg/ml. Furthermore, umami was detected in PAR1, PAR2-a, and PAR3 sample solutions at 1 mg/ml. In contrast, astringency and the aftertastes of anionic bitterness and astringency were not detected in most of PAR sample solutions.

Taste patterns of each type of Processed Aconite Root (PAR). Data were obtained by the taste-sensing system SA402B. Aqueous solution containing 10 mM potassium chloride and 0.1 mM tartaric acid was measured as the blank control. Taste values of aftertaste of cationic bitterness were obtained from 0.1 mg/ml sample solutions and the others from 1 mg/ml. Details of each taste value in a radar chart are described in Table 2

Differences in taste intensities among four PAR types

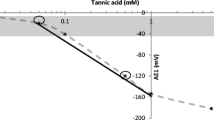

Next, we investigated the detailed characteristics of the four taste factors detected in the water extracts of four types of PAR samples, namely, the aftertaste of cationic bitterness, umami, anionic bitterness and saltiness. As shown in Fig. 2, at 0.1 mg/ml concentration, PAR2-h and PAR3, both the nonautoclaved type, had higher intensity of aftertaste of cationic bitterness than PAR1 and PAR2-a, both autoclaved types (Fig. 2a). In addition, the taste intensity of the aftertaste of cationic bitterness was significantly higher for PAR1 than for PAR2-a, even at 0.1 mg/ml concentration. The tendency was more clearly at the 1 mg/ml concentration (Fig. 2b). As for umami, PAR2-h showed negative taste intensity, meaning that the taste value was lower than that of the blank control, whereas the other PAR types showed positive taste intensity at 1 mg/ml (Fig. 3). For anionic bitterness and saltiness, PAR3 showed the highest taste intensity (Fig. 4a, b). These data clearly suggested that each PAR type has specific taste features.

Taste intensities of aftertaste of cationic bitterness in each type of Processed Aconite Root (PAR). Data were obtained by the taste-sensing system SA402B. Sample solution concentrations were 0.1 mg/ml (a) and 1 mg/ml (b). Each value represents the mean ± standard deviation (SD). Details of each value are described in Table 2. *P < 0.01 compared with PAR1, † P < 0.01 compared with PAR2-a, and § P < 0.01 compared with PAR2-h

Taste intensities of umami in each type of Processed Aconite Root (PAR). Data were obtained by the taste-sensing system SA402B. Sample solution concentration was 1 mg/ml. Each value represents mean ± standard deviation (SD). Details of each value are described in Table 2. *P < 0.01 compared with PAR1, † P < 0.01 compared with PAR2-a, and § P < 0.01 compared with PAR2-h

Taste intensities of anionic bitterness (a) and saltiness (b) in each type of Processed Aconite Root (PAR). Data were obtained by the taste-sensing system SA402B. Sample solution was 1 mg/ml. Each value represents mean ± standard deviation (SD). Details of each value are described in Table 2. *P < 0.01 compared with PAR1, † P < 0.01 compared with PAR2-a, and § P < 0.01 compared with PAR2-h

Discussion

Taste of PAR obtained by the taste-sensing system

In the measurements by the taste-sensing system, the aftertaste of cationic bitterness was detected in all four PAR types, whereas umami, anionic bitterness, and saltiness were detected in some PAR types. In contrast, astringency and the aftertastes of anionic bitterness and astringency were not detected in any PAR sample solutions (Fig. 1; Table 2).

Considering PAR components, we thought that the high intensity of the aftertaste of cationic bitterness may derive from alkaloids. It is of interest to analyze the contents of alkaloids in the tested PAR samples and to deduce the correlation between their contents and the taste intensities of the aftertaste of cationic bitterness. Results of the related experiments will be reported elsewhere.

As far as we know, there is no description for umami in the JP, probably because the Pharmacopoeia is not the standard for food. Therefore, our data suggest that the taste of PAR could be described as “strongly bitter with saltiness” if a description of taste is needed in the JP. As mentioned above, the taste of Aconiti Sinensis Tuber was described in the JP7 as “slightly salty, then prolonged numbing” [9]. It is of interest that numbing is not a taste and could not be measured by the taste-sensing system. Although the way of processing by which Aconiti Sinensis Tuber in the JP7 was prepared seemed to be different from those of the PAR examined, some taste factors, such as bitterness in Aconiti Sinensis Tuber, might be masked in the sensory test by its strong numbing qualities.

The AAE sensor probe used for umami detection responds to amino acids. PAR includes higenamine (demethyl coclaurine), a benzylisoquinoline-type alkaloid, as well as various terpenoid-type alkaloids, such as aconitine [3, 48]. This means that amino acids such as tyrosine, a precursor of higenamine, could exist in PAR. In addition, Matsui et al. [49] reported that Kako-Bushi-Matsu originating from A. japonicum contained many kinds of amino acids. Thus, it is plausible that PAR also contains substantial amounts of amino acids and shows some intensities of umami, although the original plant of most tested PAR samples is A. carmichaeli.

It is interesting that PAR2-h showed negative taste intensity in umami (Fig. 3). All PAR2-h samples in this study were processed by steaming after rinsing with calcium chloride solution. Therefore, PAR2-h probably contains calcium salt. The artificial lipid membrane sensor probes of the taste-sensing system were designed by emulating the biological membrane, and the sensor probe for umami detection includes phospholipid as a component of the sensor membrane. Furthermore, it is known that phospholipids in the biological lipid bilayer membrane respond to calcium ion [50]. Considering these facts, we thought that an excess amount of residual calcium ion in PAR2-h might affect sensor output and result in the negative taste intensity for umami. In the early processing stage, PAR3 was coated with hydrated lime (calcium hydroxide). However, it is known that calcium hydroxide is removed in subsequent processes, and we think this is the reason PAR3 showed the positive intensity of umami.

PAR1, PAR2-a, and PAR2-h are produced after a heating process, whereas PAR3 is not. This may contribute to the difference in anionic bitterness taste intensity between the former three types and that of PAR3 (Fig. 4a).

For saltiness (Fig. 4b), it is logical that PAR1 showed significantly lower taste intensity than any other PAR types, because PAR1 was not treated with any salts during the processing. The differences of the taste intensities of saltiness among PAR2-a, PAR2-h, and PAR3 may be attributed to variety in the salt treatment procedure, including the amounts and treating time of salts. Unfortunately, we could not obtain detailed information to clarify this point.

Discrimination among four types of PAR by taste characteristics

It is possible to discriminate each type of PAR from the others by their appearance when PAR exists as a whole crude drug. However, it is very difficult to know how the PAR was processed when PAR exists as small cuts or powders. As mentioned above, we found that the taste intensities of each type of PAR measured by the taste-sensing system showed specific features. Therefore, we propose a procedure for discriminating these four types of PAR by using water extract of PAR and the taste-sensing system. The scheme is shown in Fig. 5. First, sample extracts at the concentration of 0.1 mg/ml (solution A) and 1 mg/ml (solution B) are prepared. Then, the taste intensity of the aftertaste of cationic bitterness of solution A is measured. When the taste intensity is less than +1, the measurement is repeated with the solution B. If the taste intensity of this measurement is not less than +4, the tested PAR is identifiable as PAR1, while if the intensity is less than +4, it is identifiable as PAR2-a. When the taste intensity of the aftertaste of the cationic bitterness of solution A is not less than +1, the taste intensity of umami of solution B is measured. If the taste intensity of umami is observed as a negative value, the tested PAR is identifiable as PAR2-h, while if the taste intensity is observed as a positive value, this PAR is identifiable as PAR3. Discrimination of PAR2-h from PAR3 is also possible by comparing the taste intensity of anionic bitterness or saltiness.

It was found that PAR2-a and PAR2-h have characteristic taste patterns, even though they are classified as being in the same category in the JP15 monograph. This suggests the possibility that these two types of PAR have different composition patterns. Further studies are needed to separate PAR2 into two different categories in future JP monographs.

In this study, we investigated the objective taste of four PAR types collected by PAR-WG by using the taste-sensing system. These PAR samples are thought to be representative of PAR in Japanese markets, and we found PAR taste was undoubtedly affected by its own processing method.

References

Matsumoto K (ed) (1984) Shinkoku-koho Shinnohonzokyo. Shobundo, Tokyo, pp 185–186

Hikino H, Yamada C, Nakamura K, Sato H, Ohizumi Y, Endo K (1977) Change of alkaloid composition and acute toxicity of Aconitum roots during processing. Yakugaku Zasshi 97:359–366

Kosuge T, Yokota M (1976) Studies on cardiac principle of aconite root. Chem Pharm Bull 24:176–178

Higashi K (1996) A case of postherpetic neuralgia successfuly controlled with 3 Kampo medicines which Bushi commonly. Jpn J Orient Med 47:267–270

Toriizuka K (ed) (2003) Monographs of pharmacological research on traditional herbal medicines. Ishiyaku Publishers, Inc., Tokyo, pp 401–413

Nakae H (2009) Efficacy of aconite tuber powder in patients with arthralgia and somatic pain. Kampo Med 60:81–85

Chino A, Ishida A, Sekiya N, Ohno K, Hirasaki Y, Kasahara Y, Namiki T, Miyazaki M, Terasawa K (2010) A case of multiple intractable skin ulcers of bilateral legs due to arteriovenous fistula successfully treated with Kampo medicines. Kampo Med 61:325–330

The Ministry of Health and Welfare Notification No. 65, March 15, 1955

The Ministry of Health and Welfare Notification No. 76, April 1, 1961

The Ministry of Health and Welfare Notification No. 163, April 1, 1966

Hikino H, Shiota S, Takahashi M, Murakami M (1983) Seasonal dynamics of the accumulation of aconite alkaloids in Aconitum carmichaeli roots. Jpn J Pharmacog 37:68–72

Kitagawa I, Chen ZL, Yoshihara M, Yoshikawa M (1984) Chemical studies on crude drug processing. IV. Aconiti Tuber (3), Quantitative determination of aconitine alkaloids in aconiti tuber by means of high performance liquid chromatography. Yakugaku Zasshi 104:867–872

Mori T, Murayama M, Bando H, Kawahara N (1991) Studies on the constituents of Aconitum species. XII. Syntheses of Jesaconitine derivatives and their analgestic and toxic activities. Chem Pharm Bull 39:379–383

Taki M, Omiya Y, Suzuki Y, Ikeda Y, Noguchi M, Matuba T, Kubo M, Niitu K, Komatsu Y, Okada M (1998) Quality and pharmacological investigation of processed aconiti tuber (TJ-3022). Nat Med 52:343–352

Nose M, Arai T, Zhao CH, Kojima K, Ogihara Y, Sekita S, Satake M (2001) Quantitative determination of aconitine alkaloids in aconiti tuber and Kampo prescription containing aconiti tuber commercially available. Nat Med 55:124–133

Taki M, Terabayashi S, Matsuba T, Sasaki H, Fukuchi M, Okada M (2002) Quality investigation of aconiti tuber in China and Japan. Nat Med 56:163–172

Okada K, Kawaguchi K (2004) The effect of tuberous root size on growth and alkaloid content of aconite (Aconitum subcuneatum). Nat Med 58:49–54

Taki M, Matsuba T, Fukuchi M, Aburada M, Okada M (2004) Comparison of seasonal variations on growth of Aconitum carmichaeli DEBX. and constituents of root tubers cultivated in Hokkaido and Ibaraki prefecture. Nat Med 58:55–63

Okada K, Kawaguchi K (2005) Change in chemical component characters within and among years of aconite. Nat Med 59:36–41

Nakamura Y, Yomura K, Kammoto T, Ishimatsu M, Kikuchi Y, Niitsu K, Terabayashi S, Takeda S, Sasaki H, Arimoto K, Okada M, Sekita S, Satake M, Goda Y (2006) Physicochemical quality evaluation of natural compounds isolated from crude drugs. Standard compounds for the official specification and testing method of “Processed Aconite Root” and “Powdered Processed Aconite Root” in the Japanese Pharmacopoeia. J Nat Med 60:285–294. doi:10.1007/s11418-006-0005-y

The Ministry of Health, Labour and Welfare Ministerial Notification No. 461, December 28, 2004. http://jpdb.nihs.go.jp/jp14supp2/YAK2T.pdf

Sato M, Anetai M, Goda Y (2005) Analysis of organophosphorus pesticide residues in crude drugs. Pharm Regul Sci 36:83–97

Yamamoto K, Yamamoto T, Kondo S, Tamura M, Shibata Y, Umeda K, Akiba S, Kawakami T, Saito F, Sugimoto T, Isomi Y, Nakada T, Takao M, Nakashima K, Tahara M, Hayashi K, Sudo M, Nakanishi K, Isozaki O, Kawahara N, Goda Y (2005) Assay of ginsenoside Rg1 and ginsenoside Rb1 in ginseng and red ginseng by high-performance liquid chromatography. Pharm Regul Sci 36:211–222

Kawahara N, Kim IH, Goda Y (2006) Content of sulfur dioxides in herbal materials obtained form the Japanese market. Jpn J Food Chem 13:105–108

Sato M, Anetai M, Goda Y (2006) Organophosphorus pesticide residues in decoctions of crude drugs. Pharm Regul Sci 37:245–250

Kawahara N, Anjiki N, Kim IH, Mikage M, Goda Y (2007) Studies on the relationship between color and content of sulfur dioxides in crude drugs obtained from the Japanese market. Jpn J Food Chem 14:140–144

Maruyama T, Sugimoto N, Kuroyanagi M, Kim IH, Kamakura H, Kawasaki T, Fujita M, Shimada H, Yamamoto Y, Tada A, Yamazaki T, Goda Y (2007) Authentication and chemical study of Isodonis Herba and Isodonis extracts. Chem Pharm Bull 55:1626–1630

Maruyama T, Kamakura H, Miyai M, Komatsu K, Kawasaki T, Fujita M, Shimada H, Yamamoto Y, Goda Y (2008) Authentication of the traditional medicinal plant Eleutherococcus senticosus by DNA and chemical analyses. Planta Med 74:787–789. doi:10.1055/s-2008-1074537

Sato M, Anetai M, Kamakura H, Goda Y (2008) Analysis of organophosphorus pesticide residues in crude drugs (Part 2). Pharm Regul Sci 39:203–222

Tokumoto H, Shimomura Y, Katsuki S, Goda Y (2008) Morphological discrimination of Curcuma longa L. and Curcuma aromatica Salisb. Jpn J Pharmacog 62:54–65

Goda Y, Kawahara N, Kiuchi F, Hirakura K, Kikuchi Y, Nishimura H, Marumoto M, Kitazaki H (2009) A guanidine derivative from seeds of Plantago asiatica. J Nat Med 63:58–60. doi:10.1007/s11418-008-0275-7

Kawahara N, Anjiki N, Hosoe J, Kim IH, Ikezaki H, Mikage M, Goda Y (2009) Studies on relationship between taste and content of sulfur dioxide in crude drugs obtained from the Japanese market. Pharm Regul Sci 40:129–135

Kondo K, Shiba M, Yotsuyanagi Y, Nishimura N, Maruyama T, Goda Y (2009) Discrimination between Atractylodes Rhizome (Byaku-jutsu) and Atractylodes lancea Rhizome (So-jutsu) by the PCR-RFLP analysis of ITS region on nrDNA. J Jpn Bot 84:356–359

Terabayashi S, Sakai E, Yamaji H, Kondo K, Kawahara N, Goda Y (2009) Authentication and standardization of botanical origin and morphology of Coix Fruit in the Japanese Pharmacopoeia. J Jpn Bot 84:77–84

Maruyama T, Miyai M, Kamakura H, Nakajima I, Kawasaki T, Komatsu K, Fujita M, Yamamoto Y, Shibata T, Goda Y (2010) The authentication and the purity test of Eleutherococcus Senticosus Rhizome based on the genetic approach. Jpn J Pharmacog 64:15–20

Sato M, Anetai M, Kamakura H, Goda Y (2010) Analysis of organophosphorus pesticide residues in crude drugs (Part 3). Pharm Med Dev Regul Sci 41:324–337

Maruyama T, Kondo K, Yotsuyanagi Y, Yamamoto Y, Kawasaki T, Shiba M, Terasaka K, Yamane M, Zhu S, Sakata K, Fujita M, Akiyama H, Nishimura N, Komatsu K, Mizukami H, Goda Y (2010) The inter-laboratory validation study for the purity test of crude drugs based on a PCR-RFLP. Jpn J Pharmacog 64:96–101

Anjiki N, Kawahara N, Goda Y (2005) Evaluation of the taste of Kampo formulae by taste-sensing system (1). Nat Med 59:164–170

Anjiki N, Suzuki A, Kawahara N, Goda Y (2006) Evaluation of the taste of a Kampo formula by a taste-sensing system (2), taste of Kakkonto. Jpn J Pharmacog 60:21–27

Anjiki N, Yoshino C, Kawahara N, Goda Y (2007) Evaluation of the taste of a Kampo formula by a taste-sensing system (3), the taste of Ryokeijutsukanto. Jpn J Pharmacog 61:6–13

The Ministry of Health, Labour and Welfare Ministerial Notification No. 285, March 31, 2006. http://jpdb.nihs.go.jp/jp15/YAKKYOKUHOU15.pdf

Toko K (2000) Biomimetic sensor technology. The Press Syndicate of The University of Cambridge, Cambridge

Toko K, Uchida T (2007) Taste modification technology of food and medicine. CMC Publishing Co., Ltd., Tokyo, pp 219–252

Habara M, Toko K (2009) Biomimetic membrane for taste sensing, Chap. 6. In: Ariga K, Nalwa HS (eds) Bottom-up nanofabrication, vol 6. American Scientific Publishers, Los Angeles, pp 91–109

Ikezaki H, Taniguchi A, Toko K (1998) Increase in information by improvement of measuring method in a multichannel taste sensor. TIEE Japan 118-E:506–512

Pfaffmann C (1959) Neurophysiology. In: Field J (ed) Handbook of physiology, vol 1. American Physiological Society, Washington, DC, pp 507–534

Schutz HG, Pilgrim ES (1957) Differential sensitivity in gustation. J Exp Psychol 54:41–48

Bai G, Yang Y, Shi Q, Liu Z, Zhang Q, Zhu YY (2008) Identification of higenamine in radix aconiti Lateralis Preparata as a beta2-adrenergic receptor agonist. Acta Pharmacol Sin 29:1187–1194

Matsui M, Bando H, Murayama M, Miura T (1999) Constituent of “KAKO-BUSHI-MATSU” II Components of amino acid and sugars. Nat Med 53:313–315

Ohnishi S (1975) A spin-label study of biological membranes with special emphasis on calcium-induced lateral phase separation. Adv Biophys 8:35–82

Acknowledgements

The authors are grateful to members of PAR-WG for kindly providing PAR samples and information for aconite processing. This work was supported in part by a Health and Labour Sciences Research Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anjiki, N., Hosoe, J., Fuchino, H. et al. Evaluation of the taste of crude drug and Kampo formula by a taste-sensing system (4): taste of Processed Aconite Root. J Nat Med 65, 293–300 (2011). https://doi.org/10.1007/s11418-010-0489-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11418-010-0489-3