Abstract

Tin oxide (SnO2) with versatile properties is of substantial standing for practical application, and improved features of the material are demonstrated in the current issue through the integration of nanotechnology with bio-resources leading to what is termed as biosynthesis of SnO2 nanoparticles (NPs). This review reveals the recent advances in biosynthesis of SnO2 NPs by chemical precipitation method focused on distinct methodologies, characterization, and reaction mechanism along with a photocatalytic application for dye degradation. According to available literature reviews, numerous bio-based precursors selectively extracted from biological substrates have effectively been applied as capping or reducing agents to achieve the metal oxide NPs. The major precursor obtained from the aqueous extract of root barks of Catunaregam spinosa is found to be 7-hydroxy-6-methoxy-2H-chromen-2-one that has been proposed as a model compound for the reduction of metal ions into nanoparticles due to having highly active functional groups, being abundant in plants (67.475 wt%), easy to extract, and eco benign. In addition, the photocatalytic activity of SnO2 NPs for the degradation of organic dyes, pharmaceuticals, and agricultural contaminants has been discussed in the context of a promising bio-reduction mechanism of the synthesis. The final properties are supposed to depend exclusively upon a number of factors, e.g., particle size (< 50 nm), bandgap (< 3.6 eV), crystal defects, and catalysts dosage. With this contribution, it has been perceived not only to provide an overview of recent advances in the biosynthesis of SnO2 NPs but also to indicate the main issues in need aiming to show vision towards innovative outcomes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanoparticles (NPs) have attracted huge interest from both fundamental science and technological standpoints because their properties exhibit very dramatic differences from higher dimensional counterparts. NPs have immense application in the fields of catalysis, solar cells, sensors, water treatment, and energy storage due to their excellent physical, chemical, electrical, magnetic, optical, and surface properties (Balzani, 2005; Tiwari et al., 2012). Recently, semiconductor NPs have exhibited a broad range of applications in photocatalysis (Chen et al., 2014; Suthakaran et al., 2020), optoelectronics (Nabi et al., 2003), and solar energy conversion (Chappel and Zaban, 2002), owing to their extraordinary features.

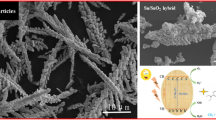

Nanostructured materials are single-phase or multiphase polycrystalline solids and are generally characterized by their size, shape, surface area, and disparity (Shahverdi et al., 2011). The surface area (i.e., surface-to-mass ratio) of nanometric particles is a thousand times higher than that in micrometric levels (Savolainen et al., 2013). Nanoparticles are technologically advanced in improved strength, chemical reactivity, and conductivity associated with attractive research materials, e.g., carbon nanotubes, metal particles, and polymer composites, devoid of nanoscale features of different shapes and sizes (Fig. 1) (Scott, 2005). Various metal oxide NPs (2–100 nm) are characterized by mostly electromagnetic radiation in the UV/visible range.

Tin oxide NPs typically show striking physical and electrical properties and optical transparency in the visible region (300–800 nm) (Finn et al., 2015). SnO2 NPs are of particular interest for a variety of applications such as gas sensors (Kennedy et al., 2002); catalysts (Jeong et al., 2014); anodes in lithium batteries (Chandra Bose et al., 2002); raw materials for transparent films, infra-red mirrors, or optoelectronic devices (Mohan et al., 2015); and improved fuel-cells (Guo, 2011). Further studies showed state-of-the-art catalytic performance of SnO2 NPs with small diameter (~ 2 nm) deposited on a polycrystalline metallic electrode en route for oxidation of methanol or ethanol (Magee et al., 2014). SnO2 NPs are competent to adsorb water molecules after dissociation results in easier production of CO2 from total oxidation of ethanol (Li et al., 2013). The reasons behind huge applications of SnO2 NPs are small particle size as well as the large-specific surface area being essential for high catalytic performances (Zhang and Liu, 1999).

Photocatalytic application of NPs is of current attention in dye degradation because dyes are major toxic chemicals that create environmental pollution (Kostedt et al., 2008; Safavi and Momeni, 2012; Zhang et al., 2009a, 2009b) through discharging effluents and solid wastes all over the world from textiles, cosmetics, foods, drug, and paper industries (Nipa et al., 2019). Complex structures of these dyes are thermodynamically more stable results in difficulties to degrade or eliminate from the effluents. Many physical, chemical, and biological methods were successfully practiced to remove these dyes (Mascolo et al., 2007; Wang et al., 2010a, 2010b). Nanoparticles are stimulated by UV/visible irradiation that generates a redox environment in the system during catalytic degradation (Fatima et al., 2019; Beydoun et al., 1999). In particular, SnO2 NPs show strong photocatalytic activity towards different dyes under many radiation sources reported elsewhere (Bhattacharjee and Ahmaruzzaman, 2015b; Haritha et al., 2016; Tammina and Mandal, 2016). As photodegradation reaction is influenced by photocatalysts (Ajoudanian and Nezamzadeh–Ejhieh, 2015; Derikvandi and Nezamzadeh–Ejhieh, 2017; Ahmad et al., 2016), new strategies are currently demanded to synthesize different nanoparticles with desired properties.

Varied physical and chemical methods are generally employed for synthesizing and fabricating nanostructured materials (Ong et al., 2018). The methods for preparing NPs usually involve either a “top-down” or a “bottom-up” approach (Fig. 2). Size reduction of suitable macro-molecules is starting material for the top-down method; whereas, the bottom-up points out the fabrication of particles from micro-entities. The top-down method suffers drawbacks from surface imperfection structures of the NPs (Thakkar et al., 2010), and the bottom-up mostly counts on chemico–biological methods, where nanostructured building blocks are initially formed and then assembled to obtain the preferred products.

Various methods for preparing nanoparticles (Madkour, 2017)

Synthetic methods of SnO2 NPs, in particular, have been developed in the last few years based on peroxide (Hoffmann et al., 1995) and polymeric precursors (Fu et al., 2011; Yang et al., 2011) such as hydrothermal (Chu et al., 2014), sol–gel (Wang et al., 2015), co-precipitation (Agrahari et al., 2015), microemulsion (Zamand et al., 2014), and chemical precipitation methods (Bhattacharjee et al., 2015) because of their wide range of applications. Temperature is an obviously important factor for the heat treatment method as the precursors are processed at different temperatures and time intervals to achieve materials with a single crystalline phase (Stanulis et al., 2012). Solid-state reactions are the basis of SnO2 synthesis over the peroxide precursor method (Guo et al., 2016). Polymeric precursor–based techniques, in general, are complying with an esterification reaction between metallic citrate and ethylene glycol through chelation of metallic cation designed for polymeric chain formation (Lei et al., 2007).

Among these strategies, the chemical precipitation method is particularly attractive thanks to its fast production period, clean phases, amazing crystal structure formation, and being cost-effective. The synthesis of innovative materials is combined with versatility in process design that offers good chemical homogeneity due to proper mixing at the molecular level (Das, 2001). SnO2 NPs can be prepared by the method using either chemical reagents (Cocco et al., 1987; Kawashima et al., 2012; Naje, 2003) or green biological precursors known as biosynthesis (Elango et al., 2015; Gaber et al., 2013; Viju Kumar and Prem, 2018). Biosynthesis uses biological substrates obtained from the extracts of plants, bacteria, fungus, and algae to substitute commercially available chemical solvents and stabilizers to reduce toxic properties of the process (Kharissova et al., 2013; Król et al., 2017). In the case of SnO2 NPs synthesis, numerous bio-based precursors selectively extracted from biological substrates have effectively been applied as capping or reducing agents to achieve metal oxide NPs. Recently, Matussin et al. (2020) reported green biosynthesis of SnO2 NPs using various plant extracts and demonstrated their effects on the optical and structural properties of the as-prepared SnO2 NPs with possible applications in practical arenas (Matussin et al., 2020). In general, the biosynthesis of SnO2 NPs is a very straightforward process in which tin salts are added to a biological extract for bio-reduction or complex formation, followed by the proper centrifugation and thermal treatment of the precipitate after the reaction, and finally, SnO2 nanopowder is obtained (Celina Selvakumari et al., 2018; Haritha et al., 2016). In fact, the particle size of dispersed phases is a function of temperature, pH, and degree of distribution (Lq et al., n.d.). Elevated temperatures, in contrast, are needed to obtain outstanding crystalline SnO2 NPs with the drawback of the high degree of aggregation during successive drying and calcination processes.

Even though an extensive quantity of research outcomes have been reported in this field, however, there is no comprehensive review article based on the biosynthesis of SnO2 NPs by mostly using the chemical precipitation method. In addition, the reaction mechanism of the nanoparticle formation and photocatalytic degradation of dyes have still to be defined and understood due to the high complexity of the biological extracts besides thermodynamically stable structures of dyes. From this viewpoint, the review summarizes recent advances in the synthetic methods of SnO2 NPs; in particular, the chemical precipitation method focused on distinct methodologies applied, characterization, and bio-reduction mechanism of the synthesis with different biological substrates along with the photocatalytic application for dye degradation.

Properties of SnO2 NPs

Semiconductor metal oxide nanoparticles, predominantly SnO2 NPs with rutile structure, play a vital role in the conversion of metal ions into nanoparticles, photocatalytic degradation of textile dyes, reduction of heavy metals, etc. because of higher surface area, less toxic effect, more thermal conductivity, and sensitivity (Cao et al., 2006; Kawashima et al., 2012). SnO2 is an amphoteric white- or gray-colored solid that represents high optical transparency and reflectivity in the region of IR radiation. It is one of the n-type (oxygen-deficient) semiconductor materials with a wide bandgap (3.6 eV). Oxygen vacancies are responsible for n-type behavior that corresponds to photoactivation in the UV range of 350 nm, making this material an ideal photocatalyst for the degradation of a variety of organic pollutants and has large excitation binding energy (130 meV) (Liu et al., 2010). Moreover, it works as a chemical sensor that instigates a decrease in the surface barrier properties and leads to a change in conductance through oxidation reaction between chemical species and chemisorbed oxygen (Kar and Patra, 2014). Some physical and crystallographic properties of SnO2 NPs are shown in Table 1 (Houari et al., 2014).

SnO2 NPs are available in the form of faceted high surface area diamagnetic oxide nanostructures. Nanoscale SnO2 is typically 20–40 nm with a specific surface area in the range of 10–80 m2g−1 and is also available in rutile, ultra-high purity, transparent, coated, and dispersed forms.

Tin element is practiced with mostly three oxidation states (+ 2, + 3, and + 4); therefore, it forms three oxides, e.g., SnO, Sn2O3, and SnO2, known as amphoteric oxide of tin, and three Sn states exist in the oxide films that can be labeled as metallic, quasimetallic, and oxidic Sn. The quasimetallic Sn is an intermediate state resulting from oxidized Sn and is still alloyed within other metal surface layers. Tin(II) oxide (SnO, stannous oxide) is a stable blue–black and metastable red form. Tin(IV) oxide (SnO2, stannic oxide) is called cassiterite, and it is the main ore of tin. When SnO is heated in an inert atmosphere, initially disproportionation reaction occurs, producing Sn3O4 that further reacts to generate SnO2 (Wiberg, 2002). In fact, SnO is a thermodynamically unstable phase that leads to the formation of the more stable tetragonal rutile-type SnO2 structure and β-Sn over relatively high temperatures (Cusack, 1998; Giefers et al., 2005; Krishnakumar et al., 2008; Moreno et al., 2001).

The standing of metal substrates in striking structure and crystallographic orientation on oxide films is demonstrated by spectrometric analysis. To evaluate the purity of SnO2 NPs in the form of powder samples, crystal structure and crystallinity are assessed by X-ray diffraction (XRD) analysis (Rahman et al., 2011). Mevada et al. (2020) reported the XRD pattern of commercial SnO2 NPs (Sigma Aldrich Chemie GmbH, Steinheim, Germany) shown in Fig. 3 (Mevada et al., 2020). The diffraction peaks for the SnO2 NPs obtained at 26.20°, 33.9°, 37.96°, 51.80°, 54.78°, 57.80°, 61.90°, 64.74°, 65.98°, 71.32°, and 78.74° corresponding to the planes (110), (101), (200), (211), (220), (002), (310), (112), (301), (202), and (321) (Fig. 3a). It is well known that the sensing features of SnO2 are dominantly controlled by surface properties. In particular, the (110) plane is one of the most thermodynamically stable surfaces among the indexed surfaces (Oviedo and Gillan, 2002, 2001; Wang et al., 2008; Zhang et al., 2011), and it has widely been used to investigate the surface characteristics of SnO2 (Batzill et al., 2003). SnO2 NPs of the tetragonal crystal system with rutile structure were confirmed by the observed peak positions (Batzill et al., 2004; Celina Selvakumari et al., 2018; Letia and Groza, 2009) and compared with standard Bragg positions (Fig. 3a) point out a good agreement with standard database (JCPDS 41–1445) (Begum et al., 2016; Patil et al., 2012). The packing diagram of SnO2 NPs is shown in Fig. 3b (Veerabhadrayya et al., 2018).

SnO2 has space group P42/mnm, and symmetries of optical modes (k = 0), including IR and Raman, are D4h. Its unit cell crystallizes to rutile structure where each Sn atom (blue) is coordinated by six O atoms (red), i.e., the coordination number of Sn 6; whereas, each O atom is coordinated by three Sn atoms, i.e., the coordination number of O3 (Fig. 3b) (Batzill et al., 2004; Chen et al., 2012; Greenwood and Earnshaw (n.d.); Veerabhadrayya et al., 2018). The octahedral structure of SnO2 shares the edges and forms a linear chain along the c-axis, where maximum electron density and high polarization are observed (Celina Selvakumari et al., 2018).

In addition, the crystallite size of nanomaterials is usually calculated by Scherrer’s equation, and the average size of SnO2 NPs was found to be ~ 20 nm for a stronger peak at (110) reported elsewhere (Bhattacharjee et al., 2015, 2014; Bhattacharjee and Ahmaruzzaman, 2015a). The particle size and strain, annealing temperature, and orientation of crystals affect the height and shape of the diffraction peaks across various planes of Miller indices (hkl), as revealed from the XRD patterns (Mevada et al., 2020).

TEM analysis is typically employed to identify the morphology, size, d-spacing, and crystalline nature of SnO2 NPs. Figure 4 shows TEM, particle size distribution, HR-TEM, and SAED pattern of the photocatalyst. The spherical shape of SnO2 NPs with an average radius of 2–3 nm was detected by the TEM image (Fig. 4a) (Bakrania and Wooldridge, 2009). Size distribution of SnO2 NPs is represented by a histogram shown in Fig. 4a (inset), resulting in a mean particle radius of 2.25 nm (Bhattacharjee and Ahmaruzzaman, 2015b).

HR-TEM image of SnO2 NPs clearly demonstrates lattice fringes of the nanomaterials, and inter-planar spacing obtained is d211 = 1.76 Å that corresponds to lattice plane (211) (Fig. 4b). The crystalline nature of SnO2 NPs is perceived in the SAED pattern (Fig. 4b, inset), and the lattice spacing was calculated corresponding to (110), (101), (211), and (301) planes (Celina Selvakumari et al., 2018). The bright field with multiple rings denoted in the SAED pattern revealed polycrystallinity of SnO2 NPs, and Miller indices (hkl) values of the rings verified the rutile crystal structure of the nanoparticles (Bhattacharjee et al., 2014; Bhattacharjee and Ahmaruzzaman, 2015b; Celina Selvakumari et al., 2018).

Moreover, it can be exposed from the TEM analysis that particle size is influenced by the annealing temperature of the precursor materials towards SnO2 NPs synthesis. The crystallinity of the NPs increases with increasing temperature thru reducing the defects owing to the systematic arrangement of the atoms in the unit cell that leads to a rise in particle size. It is interesting to be mentioned that SnO2 NPs can be synthesized with desired size monitoring calcination temperature (Babar et al., 2010; Celina Selvakumari et al., 2018; Tammina et al., 2018). In a nutshell, the electron microscopic results point out that the particle size and lattice plane of the nanoparticles are in well agreement with XRD.

Classification of SnO2 NPs

Diverse nanostructures of SnO2 viz., namely nanocrystals, nanowires, nanotubes, nanodots, and nanobelts, are technologically important due to their size-dependent properties. Additional nanostructures include nanorods, nanohorns, nanowhiskers, nanopyramides, and nanocomposites. The particles are preferentially adsorbed at the surface interface using chemically bound polymeric materials on account of surface-functionalized properties (Nilavazhagan et al., 2014).

Based on dimensions, SnO2 can be divided into one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) nanostructures. They exhibit novel physicochemical characteristics that considerably differ from conventional bulk materials (Park et al., 2007). Figure 5 shows the morphologies of tin oxides having different dimensions. 1D nanostructures have an intense impact on nanoelectronics, nanocomposites, nanodevices, energy resources, and national security (Zhang et al., 2012). 2D structures are exclusively interesting, owing to understanding the basic mechanism of nanoparticle growth besides investigation and application in nanosensors and photocatalysis (Zeng et al., 2009). In addition, 3D nanostructures are frequently employed as catalysts, magnetic materials, and electrodes for batteries (Kim, 2014). In general, 1D includes nanorods (Park et al., 2007), nanowires (Meduri et al., 2009), nanoribbon (Dai et al., 2001), and nanotubes (Dai et al., 2002); whereas, 2D consists of nanosheets, branched structures, nanoprisms, nanoplates, nanowalls, and nanodisks (Parwaz Khan et al., 2016), and 3D comprises flower-type hollow or porous nanostructures (Wang et al., 2010a, 2010b). It can be pointed out that nanostructure materials with low-dimensional, for instance, 1D or 2D, are more competent to withstand volume change during the charge–discharge process (Wang et al., 2010a, 2010b). Momeni et al. (2016a, 2016b) used the atomistic simulation method to reveal the intrinsic structural change of SnO2 that brings down dimensions from 2D nanosheets to 1D nanorods of monolayer materials (Momeni et al., 2016a, 2016b). It is attractive for having a higher surface-area-to-volume ratio and supplies adequate absorption molecules aimed at various nanostructures (1D, 2D, and 3D) involved in a small space (Jung et al., 2008; Chang et al., 2020).

Biosynthesis of SnO2 NPs

Various physical and chemical methods are, in general, employed to synthesize and fabricate nanostructured materials (Haritha et al., 2016). Researchers are currently exploring biosynthetic methods to improve the production of metal and metal oxide NPs using clean technologies rather than chemical and physical methods commonly used in industry (Kharissova et al., 2013; Król et al., 2017; Muthuvinothini and Stella, 2019; Shah et al., 2015; Zikalala et al., 2018). Recently, the biosynthesis of SnO2 NPs has gained huge attention for its various important applications. Nevertheless, commercially available SnO2 are considered much expensive due to costly precursor materials, difficulties in synthetic technique, complications in separation, etc. This has led to a growing research interest in the production of SnO2 NPs from bio-resources, renewable, widely available, nontoxic, and cost-effective precursors. The chemical precipitation method is now considered as one of the best available processes for the synthesis of SnO2 NPs. The NPs can be synthesized either by using chemical reagents (Cocco et al., 1987; Kawashima et al., 2012; Naje, 2003) or from green biological precursors (Elango et al., 2015; Gaber et al., 2013; Viju Kumar and Prem, 2018); whether the later one is predominant and will be discussed in the current issue.

Reaction procedures

Haritha et al. (2016) showed the green chemical production of SnO2 NPs using SnCl2 solution mixed with Catunaregam spinosa aqueous extract and placed in a water bath at 60℃ for 2 h. Then, the mixture was centrifuged, followed by washing and heating at 450℃ for 2 h to get the NPs (Haritha et al., 2016). A biological method was discussed by Hong et al. (2017). The group placed SnCl2 solution in an incubator, and aqueous extract of the Litsea cubeba fruit was added at room temperature with an agitation of 100 rpm for 10 min. Then, the precipitate was centrifuged in turn washing and drying at 50℃ for 2 h (Hong and Jiang, 2017). Elango et al. (2015) reported an additional biological method using an almost similar procedure. In this case, methanolic extract of P. americana seed was mixed with SnCl2.2H2O at 60℃ for 12 h (Elango et al., 2015). Merlin et al. (2018) proposed a simple method using Stevia rebaudiana extract. Ethanolic extract of S. rebaudiana was mixed with SnO2 aqueous solution and heated at 80℃ (Viju Kumar and Prem, 2018). Bhattacharjee et al. (2015) showed the synthesis method by using amino acid and arginine. SnCl2.2H2O was treated with an equimolar aqueous solution of arginine and irradiated with 300 W shots in a microwave oven (Bhattacharjee and Ahmaruzzaman, 2015c). Tammina and Mandal (2016) exposed the use of amino acid and tyrosine to synthesize SnO2 NPs. SnCl2.2H2O was added with tyrosine solution and stirred at 100℃ for 4 h (Tammina and Mandal, 2016). Gaber et al. (2013) presented the conventional precipitation method by using an ammonia solution. NH3.H2O (30%) was added with SnCl4.5H2O dropwise to control pH 8 at 40℃. After that, it was centrifuged at 3000 rpm for 20 min and obtained white gel precipitation, followed by annealing at a temperature in the range of 300–1050℃ for 2 h (Gaber et al., 2013). Similar methods are also reported elsewhere (Drzymała et al., 2017). Santhi et al. (2016) explored the method of dissolving SnCl2.2H2O in NaOH, and HCl was added dropwise up to pH 5 (Santhi et al., 2016). Another method was studied by Ibarguen et al. (2007) using ammonium hydroxide and diethylamine (Ibarguen et al., 2007). Song and Kang (2000) proposed urea instead of ammonia or ammonium hydroxide. Urea (0.1–1.0 M) was dissolved in SnCl4.5H2O aqueous solution. Then, it was hydrolyzed at 90℃ for 4 h and cooled down to get the final product. Prior to this, the mixture was successfully centrifuged at high speed (8500 rpm for 30 min), dried in an oven at 100℃ for 24 h, and annealed at 600℃ for 2 h (Song and Kang, 2000). Selvi et al. (2018) used urea along with Ni(NO3)2·6H2O for the synthesis of SnO2 NPs (Thamarai Selvi and Meenakshi Sundar, 2018). Shaikh et al. (2018) used SnCl4.5H2O, Sr(NO3)2.6H2O, and liquor ammonia in defined proportion (Shaikh et al., 2018). Deosarkar et al. (2013) exhibited the use of graphene oxide and SnCl2·2H2O under ultrasonic irradiation (Deosarkar et al., 2013). Bhattacharjee et al. (2016) showed the utilization of glycerol with stannic chloride by microwave heating method for green synthesis (Bhattacharjee et al., 2016). The low-temperature situ-precipitation technique was reported by Jia et al. (2014) using Zn(Ac)2·2H2O, Na2HPO4·12H2O, and (CH2)6N4 (Chu et al., 2014). In parallel, Nilavazhagan et al. (2014) used SnCl4.5H2O with some other chemicals like LaCl3.7H2O and CuCl2.2H2O, and the method followed the previous procedures (Nilavazhagan et al., 2014). Metal Sn, HCl, HNO3, and ethanol were used to synthesize SnO2 NPs by Liang et al. (2017). Firstly, Sn was dissolved in HCl/HNO3 mixture, and a fixed amount of HNO3 and ethanol was mixed into it. The solution was then added into deionized water, and pH 3 was controlled at 65℃ by adding polyvinyl alcohol and NH4OH solution. The precipitate was dried at 100℃ and calcined at 350–600℃ for 2 h after filtration and washing with water and ethanol in succession (Liang et al., 2017). Begum and Ahmaruzzaman (2018) showed an additional chemical precipitation method using surfactant (CTAB), anhydrous aspartic acid with SnCl2.2H2O solution following the technique discussed earlier (Begum and Ahmaruzzaman, 2018). From the literature reviews, it can be pointed out that most of the researchers are interested in tin salts (e.g., SnCl2.2H2O and SnCl4.5H2O) as a source of Sn because they are cheap and available worldwide. Of the different capping/reducing agents listed in Table 2, green bio-based chemicals are preferred with reaction conditions, e.g., centrifugation rate 100–5000 rpm at controlled pH, calcination temperature 100–800℃ for ~ 2 h. Table 2 shows varied synthesis methods of SnO2 NPs, capping/reducing agents, crystal structures, and particle size.

In addition, various characterization methods were used to determine the properties of SnO2 NPs: FTIR (Cusack, 1998; Moreno et al., 2001), UV/visible spectroscopy (Giefers et al., 2005; Moreno et al., 2001), XRD (Bhattacharjee and Ahmaruzzaman, 2015b, Bhattacharjee and Ahmaruzzaman, 2015b; Moreno et al., 2001), SEM (Bakrania and Wooldridge, 2009; Krishnakumar et al., 2008), TEM (Bhattacharjee and Ahmaruzzaman, 2015a; Rahman et al., 2011), STEM (Zhang et al., 2011), SPM (Patil et al., 2012), SAED (Bhattacharjee and Ahmaruzzaman, 2015a; Rahman et al., 2011), TGA (Begum et al., 2016; Mevada et al., 2020), DTA (Begum et al., 2016; Mevada et al., 2020), DLS (Oviedo and Gillan, 2001), BET (Greenwood and Earnshaw (n.d.); Patil et al., 2012), DRS (Batzill et al., 2003), XPS (Batzill et al., 2003; Bhattacharjee et al., 2014), PLS (Bhattacharjee et al., 2014; Chen et al., 2012), GC–MS (Moreno et al., 2001), EDX (Bakrania and Wooldridge, 2009; Batzill et al., 2004; Krishnakumar et al., 2008; Moreno et al., 2001; Oviedo and Gillan, 2001; Zhang et al., 2011), VSM (Bhattacharjee and Ahmaruzzaman, 2015d), HR-TEM (Bhattacharjee and Ahmaruzzaman, 2015c; Oviedo and Gillan, 2001), FE-SEM (Batzill et al., 2003; Bhattacharjee and Ahmaruzzaman, 2015b), TG-DSC (Batzill et al., 2004, 2003), UV-DRS (Celina Selvakumari et al., 2018), TEM/EDAX (Moreno et al., 2001), SEM/EDAX (Bhattacharjee and Ahmaruzzaman, 2015c; Giefers et al., 2005), DTA/TGA (N. N. Greenwood, n.d.), etc.

Reaction mechanism

Recently, biosynthesis of nanoparticles has been a more interesting method to reduce metal ions into metal oxide nanoparticles. Bio-based precursors are hydrophilic, biocompatible, nontoxic, and cost-effective in nature and used in diversified fields with exciting morphologies and varied sizes. There are three crucial factors to synthesize and stabilize nanoparticles, i.e., reaction medium, capping, and reducing agents. The reducing agents or complex-forming compounds involved include various water-soluble plant metabolites (e.g., alkaloids, phenolic compounds, terpenoids, flavonoids, saponins, steroids, tannins, and other nutritional compounds), co-enzymes, and bio-waste materials (Batzill et al., 2004). The bio-based resources are comprised of polysaccharides, proteins, and lipids that act as a capping agent that limits the uses of non-biodegradable commercial surfactants. Many researchers showed their interest in the biosynthesis of different metals and metal oxide NPs available in the literature.

Tammina et al. (2018) synthesized SnO2 NPs of different sizes from SnCl2.2H2O and ascorbic acid and reported a plausible mechanism of the redox reaction (Tammina et al., 2018). Haritha et al. (2016) prepared SnO2 NPs using C. spinosa root bark and identified the phytoconstituents of the bark. The major component of the extract (67.475 wt%) was found 7-hydroxy-6-methoxy-2H-chromen-2-one that can act as an active capping agent for the conversion of Sn2+ salts into SnO2 NPs (Elango et al., 2015). Sargassum muticum extract consisted of basic polysaccharides that reduce ferric salts into metal oxide NPs. Protein, as a major component of alga, is responsible for the reduction of nanoparticles and their stabilization (Mevada et al., 2020; Nagarajan and Arumugam Kuppusamy, 2013). The leaf of Delonix regia that consisted of gallic acid is responsible for the biosynthesis of palladium NPs (Dauthal and Mukhopadhyay, 2013). Elango et al. (2015) synthesized SnO2 NPs using the seed of Persia americana to have methanolic extract annealed at 300–500℃ and described the phyto-synthesizing property of transition metals, thanks to biocompatibility, low toxicity, eco-friendly, and green phenomena (Elango et al., 2015). Selvakumari et al. (2018) also investigated eggshell membrane (ESM) and pointed out that the key constituents of the membrane are amino acids and aldehydes having functional groups of amino, carboxyl, and carbonyl on the ESM, which acts as a reducing agent, and its properties are comparable to the published results (Celina Selvakumari et al., 2018).

From the discussion, it can be noted that various bio-based capping, reducing, or complexing agents with almost similar properties are accountable for cationic reduction. The hetero-compound 7-hydroxy-6-methoxy-2H-chromen-2-one obtained from the C. spinosa extract has been proposed as a model complex or adduct forming agent for the transformation of metal ions into NPs because it is bio-based, abundant in a plant, easy to extract, and has highly active functional groups. On the other hand, the bio-precursor having aldehyde functional groups can react with tin salts for the reduction of surface-adsorbed Sn2+ into Sn0. Further conversion of Sn0 into SnO2 NPs is carried out through atmospheric oxidation. The schematic presentation of the chemical precipitation method for the production of SnO2 NPs over the reduction of Sn2+ salt by reducing agents (e.g., aldehyde, amino acid) is shown in Scheme 1.

According to Scheme 1, stannous ion (Sn2+) is reduced to elemental tin that is precipitated out from the first step of the biosynthesis, where bio-based precursors are used as reducing agents. In fact, the biological substrates having hydrophilic and hydrophobic domains contribute to surface adsorption where the hydrophilic end groups absorb Sn2+ ions and hydrophobic parts interact through the formation of H2 bonding (Celina Selvakumari et al., 2018; Devi et al., 2012). In the second step, the elemental tin (Sn) is oxidized to stannic(IV) oxide (SnO2) thru calcination in the presence of air. It is noted that the oxidation of elemental tin in an aqueous medium is usually inactive, and it starts to oxidize at a temperature of over 150℃ (Cho et al., 2005), possibly at 232℃ (mp of Sn) or onward temperature settings. The basic reaction of this conversion is as follows:

Celina Selvakumari et al. (2018) also described a mechanism comparable to Scheme 1, where the eggshell membrane was used as a bio-precursor (Celina Selvakumari et al., 2018). It was reported that the aldehyde group shows reducing properties as well as reduced the surface-adsorbed Sn(II) into Sn(0) prior to annealing at 600℃ in natural air to obtain SnO2 NPs.

The reaction mechanism of SnO2 synthesis by a reducing agent 7-hydroxy-6-methoxy-2H-chromen-2-one (HMC) proposed in the context has been illustrated in Scheme 2. The HMC is a water-soluble polar compound being a source of electrons from the chromenone ring and carbonyl double bonds. In addition, the electrons obtained from the lone pair of hydroxyl groups (OH−) and double bonds take part in the conjugated reaction to form vinyl-based carboxylic compounds prior to the generation of electrons and protons in the system. The p-orbitals of the tin atoms may be occupied by these electrons results in the formation of a complex that controls the nanoparticle growth while annealing the precipitate.

Most of the researchers characterized the final product, SnO2 NPs, rather than the intermediate-precipitated product before calcination. It appraises that the characterization of the intermediate product (colloidal hetero-crystal) may indicate the reaction mechanism involved during the formation of stannic oxide (SnO2) at a certain temperature. Some researchers (Elango et al., 2015; Hong and Jiang, 2017; “Konstantin Stanislavsky – Bella Merlin – Google Books,” n.d.) explained various bio-based precursors as reducing agents and annealed the intermediate product from 50 to 80℃; however, it is incredible to oxidize Sn(0) into SnO2 under the stated conditions. The phenomena behind the concept can be described through Scheme 2, where biological substrates are used as complex-forming agents (or ligands) that may be decomposed easily at lower temperatures producing tin hydroxides and their oxides. Moreover, the as-prepared metal oxide NPs may be coated with a layer of organic ligand molecules at the precipitation stage. These colloidal hetero-nanocrystals are further converted to SnO2 NPs through proper centrifugation and calcination processes. Besides, the bio-based substrates also act as capping agents to provide colloidal stability and prevent agglomeration during the nucleation process. In addition, the effect of intermolecular and intramolecular forces, nonchemical interaction, and electrostatic consequence disposes the biological substrate results in ease of nanoparticle formation and their shape (Zhang et al., 2009a, 2009b). The size and features of the nanoparticles may be affected by the nature and types of functional groups of the reducing agents. Similar phenomena were also reported elsewhere (Drzymała et al., 2017; Sk and Yue, 2014; Tammina et al., 2018; Xiong et al., 2011).

Photocatalytic application

Nanoparticles exhibit favorable photocatalytic properties due to high capacity, selectivity, and specific adsorption en route for various waste products (Coston et al., 1995). Numerous adsorbents of nanosized metallic oxides and selectively oxides of Fe, Mn, Al, Ti, Mg, Ce, Pd, Sn, etc. are typically promising materials to uptake industrial pollutants from liquid systems (Bhattacharjee and Ahmaruzzaman, 2015b; Dauthal and Mukhopadhyay, 2013; Elango et al., 2015; Haritha et al., 2016; Van Benschoten et al., 1994) due to size quantization effect and high catalytic activities (El-Sayed, 2001). The physicochemical properties of SnO2 as photo-anodes are very crucial in dye-sensitized solar cells, which are characterized by recombination resistances, charge transport, and size distributions to a greater extent (Xi and Ye, 2010). Many scientists exposed the catalytic properties of SnO2 NPs intended for photodegradation of organic dyes in different conditions, and pharmaceuticals and agricultural degradation are discussed as follows.

Congo red degradation

Bio-green synthesis of metal oxide NPs, especially, Catunaregam spinosa–mediated nanosized SnO2, was applied for photodegradation of toxic diazo congo red dye studied by Haritha et al. (2016). Heber Multilamp Photoreactor was introduced into the system to degrade the dye at 365 nm. The as-prepared SnO2 NPs were placed in the photoreactor, followed by mixing well with congo red (1 × 10−4 M) and investigating the samples thru UV/visible spectroscopy for 5-min intervals. When SnO2 NPs were introduced into the system, the peaks corresponding to azo dye were started to degrade and completely disappeared within 20 min. The experiment results in the rate constant of dye degradation (92%) to be k = 0.0952 × 10−3 min−1 and kinetic data fitted with pseudo-first-order model in good agreement that relies at a time on increases C/C0 (concentration ratio at any time to initial) decreases (Haritha et al., 2016). Hong et al. (2017) also analyzed the photocatalytic activity of SnO2 NPs formed from the biological source of Litsea cubeba fruit. A glass-made batch reactor of circular shape together with a source of UV light, e.g., mercury vapor lamp, was employed for the degradation system. In general, the NPs were dispersed in congo red dye solution to ameliorate the catalytic effect in a photocatalytic process (Viju Kumar and Prem, 2018). The photodegradation of the dye typically examined by the UV/visible spectra points out that dye absorption peak is a function of annealing temperature and they are inversely proportionated. The reason behind the extensive catalytic activity of SnO2 nanomaterial (annealed at 600℃ during synthesis) might be owing to effective surface area (26.14 m2g−1), and better interaction of the dye molecules on the catalyst surfaces reported elsewhere (Viju Kumar and Prem, 2018).

Phenol red degradation

Elango et al. (2015) showed photodegradation of organic dyes, especially phenolsulfonphthalein (commercially known as phenol red), tarnished by SnO2 NPs prepared from the seed of Persia americana (Elango et al., 2015). Nearly 1 × 10−3 L of phenol red (1 × 10−4 M) in addition to 2.5 × 10−4 g SnO2 NPs was transferred to a UV chamber to carry out the photochemical reaction at 365 nm in the visible light region. The surface plasmon resonance (SPR) of dye degradation was detected evidently at 426 nm, and the SPR band was disappeared within 2 h, proving that catalytic activity of the nanoparticles under UV light irradiation is predominant (Tammina and Mandal, 2016).

Methylene blue degradation

Photocatalytic activity of methylene blue dye was carried out thru the preparation of SnO2 NPs from amino acid arginine reported by Bhattacharjee et al. (2015). After SnO2 addition, the absorption band of the dye degradation decreased with the exposure time of irradiation (Bhattacharjee and Ahmaruzzaman, 2015b). The absorption band was almost disappeared at 663 nm within 4 h, and the dye solution was faded away in succession (Bhattacharjee and Ahmaruzzaman, 2015b). The rate constant of photodegradation of methylene blue was obtained, k = 1.3 × 10−2 min−1. The dye degradation efficiency of methylene blue was found to be 96.4% within 4 h of solar irradiation (Bhattacharjee and Ahmaruzzaman, 2015b).

Violet 4 BSN dye degradation

Tammina and Mandal (2016) exhibited remarkable photocatalytic activity of SnO2 NPs prepared from amino acid tyrosine for Violet 4 BSN dye. The dye, commercially known as V4BSN/Acid Violet 3, was irradiated with UV light (125 W, 254 nm). The quartz tube was operated at constant time intervals in the visible light expanse (554 nm) after being filled it with an aqueous solution of V 4 BSN dye (25 mgL−1) and SnO2 NPs (10 mg) (Drzymała et al., 2017). During photodegradation, it was witnessed to perceive complete reduction of the dye molecules through a change in color over UV exposure for 40 min. Additionally, total organic carbon (TOC) measures the rate of degradation results in 83.30% TOC that was degraded after 80 min of UV irradiation, and finally, the process reached a steady state after 2 h (Drzymała et al., 2017).

Photocatalytic activity of SnO2 NPs for various dyes under different irradiation sources is summarized in Table 3. Particularly, violet 4 BSN dye shows 100% degradation in 40 min under 125 W UV lamp; whereas, methylene blue demonstrates excellent photodegradation for solar irradiation, and the additional results are comparable to them. In fact, photodegradation of dyes is a function of various factors, for example, source and intensity of radiation, exposure time, reaction kinetics, surface properties of the catalysts, and process temperature.

Pharmaceutical degradation

Pharmaceuticals are present in medicines, over-the-counter therapeutic, and veterinary drugs. There are available active natural or synthetic chemicals which can be absorbed into the bloodstream even at low concentrations and persist in the body for full therapeutic effects (Mezzelani et al., 2018). They are classified as (i) antibiotics, e.g., nitrofurantoin, levofloxacin, and chloramphenicol; (ii) antiviral, e.g., Tamiflu and zanamivir; (iii) antidepressant, e.g., alprazolam; (iv) antiepileptic, e.g., felbamate and carbamazepine; (v) analgesic, e.g., acetaminophen, Ibuprofen, and naproxen; and (vi) hormonal, e.g., estriol and 17-β Estradiol (Cuervo Lumbaque et al., 2019). Sources of pharmaceutical contamination to the environment include municipal wastewater, improper disposal of drugs, human excretion, intensive livestock farming, and effluents from hospitals and pharmaceutical industries (Mezzelani et al., 2018; Patel et al., 2019). These contaminants need to be removed from wastewater to protect our environment from the adverse effect of continuous exposure to pharmaceutical drugs in water (Patel et al., 2019).

Much work has been conducted to investigate pharmaceutical degradation which often involves simulation of a real wastewater treatment plant. Current process plants are equipped for the removal of simple organic substances and particulate materials at a macro/micro-scale. A large number of pharmaceutical drugs are, however, very soluble in water and mobile and are easily integrated into the general environment, even at nanoscale levels, making them hard to remove (Majumder et al., 2019).

Advanced oxidation processes (AOPs) rather than conventional methods are becoming attractive alternative techniques because of higher chances of production of harmless byproducts during pharmaceutical degradation. The fundamentals of advanced technology in water treatment for pharmaceutical compounds is the production of highly reactive species that may generate through irradiation by external energy sources like solar, ultraviolet (UV) light, visible light, microwave, or other energy sources like electricity and sound or addition of oxidizing agents. Advanced processes based on UV include photocatalysis (e.g., SnO2/TiO2/UV), sulphate/UV, ozonation/UV, peroxide/UV, Fenton/UV, and UV/ultrasound aimed at degrading and mineralizing organic contaminants (Serpone et al., 2017). Although the new trends of emerging these processes result in more effective degradation of organics, the new trends are rather expensive operationally. Velempini et al. (2021) studied various modified and unmodified photocatalysts in heterogeneous photocatalytic degradation of pharmaceutical drugs (Velempini et al., 2021).

Up to date, a number of reviews have surveyed the treatment of pharmaceuticals using metal oxides (Gautam et al., 2020; Gusain et al., 2019), especially SnO2 (Diallo et al., 2016), TiO2 (Prieto–Rodriguez et al., 2012; Sarkar et al., 2014), doped TiO2 (Varma et al., 2020), metal–organic frameworks (MOFs), and SnO2-based photocatalysts (Mohammad et al., 2021) for photocatalytic oxidation of organic contaminants. Recently, Velempini et al. (2021) have proposed a compound parabolic collector (CPC) that ensures high degradation efficiencies of pharmaceutical drugs through maximizing the harness of solar energy (Velempini et al., 2021). Predominantly, degradation of amoxicillin trihydrate was investigated over parabolic trough collector (PTC) which is a more advanced technological method than CPC (Dixit et al., 2016). In pilot studies, a number of common strategies to improve degradation efficiencies are adopted, i.e., combining different AOPs, dye sensitizations of metal oxides, and the addition of reagents to contaminated wastewater. Oxidative removal of diclofenac, for example, is possible when a dye is used as a photosensitizer to amplify the rate of photon absorption of SnO2 at pilot levels with a capacity of 7.7 L for a single reactor (Diaz-Angulo et al., 2020).

Agricultural degradation

Agricultural degradation, especially soil erosion and water pollution, means a decline in soil and water conditions caused by improper use of chemicals or poor management. The utilization of various chemical fertilizers, herbicides, and insecticides in agricultural fields has led to soil pollution, and the accumulation of such toxic chemicals in water bodies is a serious threat to the aquatic ecosystem and human health (Anju and Sarita, 2010; Singh et al., 2018). Particularly, carbofuran and imidacloprid are the common insecticides utilized on a large scale in agricultural fields. They are neonicotinoid types of insecticides, being the most toxic broad-spectrum and high stability in the aquatic environment (Mishra et al., 2020; Tiˇsler et al., 2009). Prolonged exposure to these hazardous substances, including fertilizers (e.g., urea, TSP, and DAP) and herbicides (e.g., atrazine, cynazine, hexazinone, metribuzin), are detrimental to mammals, birds, fish, wildlife, as well as humans due to their anticholinesterase activity (Otieno et al., 2010; Campbell et al., 2004). They may cause serious reproductive disorders, endocrine disruption, and cytotoxic and genotoxic abnormalities in humans (Mishra et al., 2020). Therefore, the design and development of effective state-of-the-art technologies to eradicate such xenobiotics from soil and water is of utmost significance to the aquatic ecosystem and public health (Bolong et al., 2009).

The addition of nanomaterials in agriculture is to reduce the extent of chemicals, minimize nutrient losses in fertilization, and increase yield through pest and nutrient management. Mahanta and Ahmaruzzaman (2021) demonstrated a cost-effective hydrothermal technique designed for the fabrication of SnO2-based novel nanohybrids, e.g., Fe3O4-SnO2-gC3N4 and Au-SnO2-CdS, with a view to the photodegradation of the toxic chemicals (Mohanta and Ahmaruzzaman, 2021a, 2021b). The heterojunctions showed sound photocatalytic degradation against emerging pollutants like carbofuran and imidacloprid under LED irradiation with a degradation efficiency up to ~ 95%. In fact, superoxide anion radical has been reported to be the major reactive oxygen species. The visible light absorption ability of Fe3O4, Au, CdS, etc., followed by the heterojunction structures of energy levels to hinder charge recombination, facilitates enhanced LED light-induced photocatalytic degradation of the organic pollutants. Prasad et al. (2017) reviewed nanotechnology in sustainable agriculture that includes specific applications like nanofertilizers and nanopesticides to trail levels of products and nutrients to increase the productivity without decontamination of soil, water, and protection against some insect pest and microbial diseases (Prasad et al., 2017).

Mechanism of dye degradation

Organic dye degradation by means of SnO2 NPs is the most common application, and corresponding photodegradation perception is available in the literature. Nonetheless, the mechanism of photocatalytic activity, still an open question, mostly depends upon the free radical generation simultaneously either from the excited dye molecules or/and nanoparticles exposed to UV/visible irradiation.

Firstly, the electrons produced from the free radicals of dye molecules are got excited into singlet and triplet states. The electrons were injected into the conduction band (eCB−) of the photocatalyst prior to the formation of cationic dye radicals (dye+) (Nilavazhagan et al., 2014). SnO2 NPs as dye-sensitized photocatalysts react with atmospheric oxygen to form oxidizing species (O2*−, HOO*, and *OH radicals) which are effective towards oxidization of the dye effluents. The probable reaction scheme for the degradation of organic dyes by means of SnO2 NPs was discussed by Bhattacharjee et al. (2016) as follows, and the mechanism is shown in Fig. 6 (Nilavazhagan et al., 2014):

Probable mechanism of dye degradation using dye-sensitized SnO2 photocatalyst under direct sunlight (dye molecules excited first) (Nilavazhagan et al., 2014)

Secondly, SnO2 NPs are exposed to irradiation; electrons get excited and generate holes (h+) spontaneously in the valence band (VB) located below the Fermi energy level (FEL). Electron acceptors, e.g., surface oxygen species (O2), readily capture the as-generated photoelectrons (e−) results in the production of superoxide free radicals (\({O}_{2}^{*-}\)). It is noted that during dye degradation, the number of photoelectrons (e−) is proportional to that of the free radicals (\({O}_{2}^{*-}\)). Consequently, the holes are trapped by electron donors, for instance, surface water or organic effluents, and ultimately reduced. Holes are a strong oxidizing agent that generally influences the oxidizing power of photogenerated holes. As a result, photogenerated electrons (e−) and holes (h+) competitively separate and recombine during the photochemical reaction, finding out the fact that these electrons constrain the recombination of e− and h+ on the surface of the photocatalyst in line for oxygen vacancies or existence of surface defects (Liqiang et al., 2006). An alternative hypothetical mechanism of the photocatalysis system has been illustrated in Fig. 7.

Photocatalytic activity of SnO2 NPs towards photodegradation of hazardous dyes under UV/visible irradiation exclusively depends upon a number of factors, e.g., particle size, bandgap, defects, and dosage of the catalysts. Bandgap plays a vital role in dye degradation. Semiconductor NPs, in general, influence quantum confinement features, i.e., bandgap energy is inversely related to particle size focusing on nanoparticles with lower crystallite size that shows a higher rate of dye degradation or requires time shorter enough (Bhattacharjee and Ahmaruzzaman, 2015b). Besides, particle size is a function of temperature as well as bandgap (Babar et al., 2010; Celina Selvakumari et al., 2018; Tammina et al., 2018). Tammina et al. (2018) investigated the effect of temperature on crystallite size of the SnO2 NPs and calculated corresponding bandgaps from Tauc plots (Fig. 8) (Tammina et al., 2018). The bandgap values obtained to be 2.5 eV, 3.0 eV, and 3.2 eV of the as-prepared samples were calcined to produce crystallite size ~ 2 nm at 170℃, ~ 12 nm at 500℃, and ~ 20 nm at 900℃, respectively. The decrease in bandgap from the standard value of 3.6 eV is attributed to the crystal defects, leading to come-off electronic transitions from VB to FEL (Diallo et al., 2016). These defects create oxygen vacancies as well as generate charge carriers that contribute to reduce the rate of electron–hole recombination on the catalyst surface (Esmaielzadeh Kandjani et al., 2010). In parallel, free radicals may be generated by the charge carriers through the reaction between absorbed O2 and H2O on the surface; the additional reaction may achieve with these free radicals and dye molecules to form azo bonds in the direction of degradation or mineralization of dyes discussed earlier.

Tauc plots of SnO2 NPs of crystallite size 2 nm calcined at 170℃ (bandgap 2.5 eV), 12 nm at 500℃ (bandgap 3.0 eV), and 20 nm at 900℃ (bandgap 3.2 eV) (Tammina et al., 2018)

Furthermore, SnO2 NPs alter the absorption band of the dye molecules, and this band decreases with the exposure time of irradiation over catalyst addition. It has been reported that particle size is an important factor that strongly influences the adsorption of dyes and smaller size NPs enhance interaction between the macro-molecules and free radicals created on the surface (Bhattacharjee and Ahmaruzzaman, 2015b; Jiang et al., 2008; Suttiponparnit et al., 2010). Bhattacharjee et al. (2015) reported that the absorption band of methylene blue almost disappeared within 4 h after the addition of SnO2 NPs at 663 nm of irradiation (Fig. 9) (Bhattacharjee and Ahmaruzzaman, 2015b) results in the reduction of the complex dye structure of chromophore. Haritha et al. (2016) inferred almost similar findings point out that congo red dye showed strong degradation (92%) of a high-intensity peak at 502 nm for 20 min by using the nanoparticles (Haritha et al., 2016). In fact, dye degradation with various nanoparticles is a subject of different conditions, e.g., catalyst/dye ratio, radiation source, synthetic methods, and irradiation time, presented in Table 4.

Photodegradation of methylene blue dye by solar radiation using SnO2 NPs (Bhattacharjee and Ahmaruzzaman, 2015b)

This assessment revealed that SnO2 NPs prepared basically from ascorbic acid exhibited strong photocatalytic activities (Tammina et al., 2018). Besides, various creative findings have been reported in the literature on nanocomposites of SnO2 that enhance remarkable visible-light-induced photodegradation of organic contaminants from wastewater (Mohanta et al., 2018; Mohanta and Ahmaruzzaman, 2021c, 2021b, 2021a). Likewise, heterojunction nanocomposites (Cu/ZnO, Pd/ZnO, etc.) demonstrated better results (⁓100% dye degraded) (Momeni et al., 2016a, 2016b) than the rest reported in Table 4. The reason behind the higher degradation rate of dye molecules with reduced size of SnO2 NPs has been reported that molecules with higher molar absorptivity are more stable and establish surface plasmon resonance (Heger et al., 2005).

Technological challenges

Integration of nanotechnology with bio-resources towards practical application is of current challenges in the field of nanoparticle synthesis and utilization (Chen et al., 2014). The focal point of the biosynthesis of SnO2 NPs is to develop traditional methods as well as create biodegradable materials from available green resources which are nontoxic, cost-effective, and environmentally benign in nature.

To produce SnO2 NPs through the bio-reduction procedure at moderate temperature and pH yields controlled particle size, there should be an improvement in the surface morphology and crystallographic properties. In order to enhance the feasibility of chemical precipitation methods in the future, extensive efforts are needed to overcome some technological challenges.

Firstly, chemical precipitation methods involve the complexity of the process and frequently required high temperature which results in large-grain sizes. At times, this method includes some toxic chemicals a threat to the environment (Chen et al., 2014).

Secondly, an inevitable introduction of byproducts shows the supplementary problem with the methods which require subsequent purification steps. As a result, such processes are time-consuming and entail extra costs (Seabra and Durán, 2015).

Thirdly, in the literature, there are plenty of studies on the removal of organic pollutants; most of them have used dyes as model contaminants for the treatment process. These dyes can simply be removed in comparison to some other organic products, such as pesticides and endocrine-disrupting compounds. However, a deeper understanding is required for a state-of-the-art mechanism of dye degradation and plausible interaction with organic pollutants containing complex molecular structures.

Fourthly, most of the researchers used tin chlorides (SnCl2 or SnCl4) to synthesize SnO2 NPs owing to cost-effective, available, and easy handling properties. Nevertheless, the fact behind the studies is the difficulty to remove chloride ions from the system, and it badly affects the superficial and electrical features of the material (Thamarai Selvi and Meenakshi Sundar, 2018). The chloride tricky can be removed through the usage of organic tin compounds, such as alkoxides, but these reagents are quite expensive which makes their industrial implementation hardly possible.

Fifthly, further improvement is still a current demand in the preparation of nanomaterials. There are three key factors, e.g., reaction medium, capping, and reducing agents, which must be sincerely designed from the green chemistry and economic viewpoints for the synthesis and stabilization of nanoparticles. Additional needs to be investigated the quality and performance of SnO2 NPs based on biological substrates, as the chemicals used are quite costly when chemical precipitation methods are chosen.

Finally, even if the application of metal oxide NPs is increasingly tremendous in various fields, including water treatment, food technology, medicine, and agriculture, but still there are some adverse effects of the NPs on the health of living organisms (Chen et al., 2014; Galdiero et al., 2011). There are various studies on the toxicity of metal oxide NPs, and there is also a rising trend in the cytotoxic potential of these nanoparticles (Carmona–Quiroga et al., 2021; Seabra and Durán, 2015). Recently, Lang et al. (2021) reviewed sustainable smart technology of biosynthesis of nanomaterials to utilize their beneficial effects devoid of posing a threat to living entities. It is a global challenge of preparing ecologically benign SnO2 NPs with better efficiency and minimum toxic effect on humans and to the environment towards sustainability. Therefore, future research must be conducted, suggesting that a series of standard safety evaluations and toxicological risk assessment associated with metal oxide NPs synthesis, characterization, distribution, and environmental emission towards practical application.

Conclusion

There is a current lacking in a review article on the biosynthesis of SnO2 NPs through the chemical precipitation method; nevertheless, huge studies report the possibility of obtaining SnO2 NPs from bio-resources accompanied by photocatalytic application of the NPs. The method is interesting, thanks to nontoxic, cost-effective, and eco-friendly approaches, but it still remains a challenge due to a number of factors that possess a barrier to the elucidation of the reactions and mechanism of formation. Hence, the review includes a summary of various capping or reducing agents extracted from biological substrates and methodologies applied to the synthesis. The substrate found in abundance from the extract of root bark of Catunaregam spinosa is chromenone compound (C10H8O3) that has been recommended as a model complex-forming agent (or ligand) for the transformation of metal salts into SnO2 NPs, and a promising reaction mechanism has been discussed. Besides, photodegradation of dyes, pharmaceuticals, and agricultural contaminants over SnO2 NPs has been discoursed, and according to the literature review, it has been reported that the photocatalytic activity mainly depends upon the mechanism of free radical generation during UV/visible irradiation. In fact, the bio-reduction mechanism of the nanoparticle formation and photocatalytic degradation features of the metal oxide has still to be defined and understood due to the high complexity of the biological extracts and thermodynamically stable structures of dyes, respectively. With the considerable progress over the last few years and clear goals that emerged from the study, a sensible increase in research on the subject matter and related fields is expected in the near future.

Availability of data and materials

Not applicable.

References

Agrahari V, Mathpal MC, Kumar M, Agarwal A (2015) Investigations of optoelectronic properties in DMS SnO2 nanoparticles. J Alloy Compd 622:48–53. https://doi.org/10.1016/j.jallcom.2014.10.009

Ahmad S, Wijaya K, Trisunayati W S (2016) Journal of. Asian Journal of Chemistry 28, 347–350. https://doi.org/10.1093/jae/ejm029

Ajoudanian N, Nezamzadeh-Ejhieh A (2015) Enhanced photocatalytic activity of nickel oxide supported on clinoptilolite nanoparticles for the photodegradation of aqueous cephalexin. Mater Sci Semicond Process 36:162–169. https://doi.org/10.1016/j.mssp.2015.03.042

Anju TJ, Sarita S (2010) Suitability of Foxtail Millet (Setaria italica) and Barnyard Millet (Echinochloa frumentacea) for development of low glycemic index biscuits. Malays J Nutr 16:361–368

Arularasu MV, Anbarasu M, Poovaragan S, Sundaram R, Kanimozhi K, Magdalane CM, Kaviyarasu K, Thema FT, Letsholathebe D, Mola GT, Maaza M (2017) Structural, optical, morphological and microbial studies on SnO2 nanoparticles prepared by co-precipitation method. J Nanosci Nanotechnol 18:3511–3517. https://doi.org/10.1166/jnn.2018.14658

Ashour NI (2018) Fabrication of SnO2 Q-dot thin films using ultrasonic spray techniques for optoelectronics applications. Int J Appl Eng Res 13:1071–1074. http://www.ripublication.com

Babar AR, Shinde SS, Moholkar AV, Rajpure KY (2010) Electrical and dielectric properties of co-precipitated nanocrystalline tin oxide. J Alloy Compd 505:743–749. https://doi.org/10.1016/j.jallcom.2010.06.131

Bakrania SD, Wooldridge MS (2009) The effects of two thick film deposition methods on tin dioxide gas sensor performance. Sensors 9:6853–6868. https://doi.org/10.3390/s90906853

Balzani V (2005) Nanoscience and nanotechnology: a personal view of a chemist. Small 1:278–283. https://doi.org/10.1002/smll.200400010

Batzill M, Katsiev K, Diebold U (2003) Surface morphologies of SnO2(110). Surf Sci 529:295–311. https://doi.org/10.1016/S0039-6028(03)00357-1

Batzill M, Kim J, Beck DE, Koel BE (2004) Epitaxial growth of tin oxide on Pt(111): structure and properties of wetting layers and crystallites. Phys Rev B 69

Begum S, Ahmaruzzaman M (2018) CTAB and SDS assisted facile fabrication of SnO2 nanoparticles for effective degradation of carbamazepine from aqueous phase: a systematic and comparative study of their degradation performance. Water Res 129:470–485. https://doi.org/10.1016/j.watres.2017.11.031

Begum S, Devi TB, Ahmaruzzaman M (2016) L-lysine monohydrate mediated facile and environment friendly synthesis of SnO2 nanoparticles and their prospective applications as a catalyst for the reduction and photodegradation of aromatic compounds. J Environ Chem Eng 4:2976–2989. https://doi.org/10.1016/j.jece.2016.05.024

Beydoun D, Amal R, Low G, McEvoy S (1999) Role of nanoparticles in photocatalysis. J Nanopart Res 1:439–458. https://doi.org/10.1023/A:1010044830871

Bhattacharjee A, Ahmaruzzaman M (2015a) Facile synthesis of SnO2 quantum dots and its photocatalytic activity in the degradation of eosin Y dye: a green approach. Mater Lett 139:418–421. https://doi.org/10.1016/j.matlet.2014.10.121

Bhattacharjee A, Ahmaruzzaman M (2015b) A green and novel approach for the synthesis of SnO2 nanoparticles and its exploitation as a catalyst in the degradation of methylene blue under solar radiation. Mater Lett 145:74–78. https://doi.org/10.1016/j.matlet.2015.01.029

Bhattacharjee A, Ahmaruzzaman M (2015d) Photocatalytic–degradation and reduction of organic compounds using SnO2 quantum dots (via a green route) under direct sunlight. RSC Adv 5:66122–66133. https://doi.org/10.1039/c5ra07578e

Bhattacharjee A, Ahmaruzzaman M, Sinha T (2014) Surfactant effects on the synthesis of durable tin-oxide nanoparticles and its exploitation as a recyclable catalyst for the elimination of toxic dye: a green and efficient approach for wastewater treatment. RSC Adv 4:51418–51429. https://doi.org/10.1039/C4RA08461F

Bhattacharjee A, Ahmaruzzaman M, Sinha T (2015) A novel approach for the synthesis of SnO2 nanoparticles and its application as a catalyst in the reduction and photodegradation of organic compounds. Spectrochim Acta Part A Mol Biomol Spectrosc 136:751–760. https://doi.org/10.1016/j.saa.2014.09.092

Bhattacharjee A, Ahmaruzzaman M, Devi TB, Nath J (2016) Photodegradation of methyl violet 6B and methylene blue using tin-oxide nanoparticles (synthesized via a green route). J Photochem Photobiol, A 325:116–124. https://doi.org/10.1016/j.jphotochem.2016.03.032

Bolong N, Ismail AF, Salim MR, Matsuura T (2009) A review of the effects of emerging contaminants in wastewater and options for their removal. Desalination 239:229–246. https://doi.org/10.1016/j.desal.2008.03.020

Campbell S, David MD, Woodward LA, Li QX (2004) Persistence of carbofuran in marine sand and water. Chemosphere 54:1155–1161. https://doi.org/10.1016/J.CHEMOSPHERE.2003.09.018

Cao H, Qiu X, Liang Y, Zhang L, Zhao M, Zhu Q (2006) Sol-gel template synthesis and photoluminescence of n- and p-type semiconductor oxide nanowires. Chem Phys Chem 7:497–501. https://doi.org/10.1002/cphc.200500452

Carmona-Quiroga PM, Montes M, Pato E, Fernández-Jiménez A, Blanco-Varela MT (2021) Study on the activation of ternesite in CaO·Al2O3 and 12CaO·7Al2O3 blends with gypsum for the development of low-CO2 binders. J Clean Prod 291:125726. https://doi.org/10.1016/j.jclepro.2020.125726

Celina Selvakumari J, Nishanthi ST, Dhanalakshmi J, Ahila M, Pathinettam Padiyan D (2018) Bio-active synthesis of tin oxide nanoparticles using eggshell membrane for energy storage application. Appl Surf Sci 441:530–537. https://doi.org/10.1016/j.apsusc.2018.02.043

Chandra Bose A, Kalpana D, Thangadurai P, Ramasamy S (2002) Synthesis and characterization of nanocrystalline SnO2 and fabrication of lithium cell using nano-SnO2. J Power Sources 107:138–141. https://doi.org/10.1016/S0378-7753(01)00995-8

Chang JS, Strunk J, Chong MN, Poh PE, Ocon JD (2020) Multi-dimensional zinc oxide (ZnO) nanoarchitectures as efficient photocatalysts: what is the fundamental factor that determines photoactivity in ZnO? J Hazard Mater 381:120958. https://doi.org/10.1016/j.jhazmat.2019.120958

Chappel S, Zaban A (2002) Nanoporous SnO2 electrodes for dye-sensitized solar cells: improved cell performance by the synthesis of 18nm SnO2 colloids. Sol Energy Mater Sol Cells 71:141–152. https://doi.org/10.1016/S0927-0248(01)00050-2

Chen W, Zhou Q, Wan F, Gao T (2012) Gas sensing properties and mechanism of nano-SnO2-based sensor for hydrogen and carbon monoxide. J Nanomater 2012:612420. https://doi.org/10.1155/2012/612420

Chen H, Zhang D, Zhou X, Zhu J, Chen X, Zeng X (2014) Controllable construction of ordered porous SnO2 nanostructures and their application in photocatalysis. Mater Lett 116:127–130. https://doi.org/10.1016/j.matlet.2013.10.111

Cheng B, Russell JM, Shi Zhang L, Samulski ET (2004) Large-scale, solution-phase growth of single-crystalline SnO2 nanorods. Journal of the American Chemical Society 126:5972–5973. https://doi.org/10.1021/ja0493244

Cho S, Yu J, Kang SK, Shih D-Y (2005) Oxidation study of pure tin and its alloys via electrochemical reduction analysis. Journal of Electronic Materials 34:635–642. https://doi.org/10.1007/s11664-005-0077-6

Chu G, Zeng Q, Shen Z, Zou H, Chen J (2014) Preparation of SnO2 nanoparticles using a helical tube reactor via continuous hydrothermal route. Chem Eng J 253:78–83. https://doi.org/10.1016/j.cej.2014.05.016

Cocco G, Enzo S, Carturan G, Orsini PG, Scardi P (1987) Synthesis and thermal behavior of gel-derived SnO2-Sb2O5 semiconducting glaze. Mater Chem Phys 17:541–551. https://doi.org/10.1016/0254-0584(87)90013-7

Coston JA, Fuller CC, Davis JA (1995) Pb2+ and Zn2+ adsorption by a natural aluminum- and iron-bearing surface coating on an aquifer sand. Geochim Cosmochim Acta 59:3535–3547. https://doi.org/10.1016/0016-7037(95)00231-N

Cuervo Lumbaque E, Lopes Tiburtius ER, Barreto-Rodrigues M, Sirtori C (2019) Current trends in the use of zero-valent iron (Fe0) for degradation of pharmaceuticals present in different water matrices. Trends in Environmental Analytical Chemistry 24:e00069. https://doi.org/10.1016/j.teac.2019.e00069

Cusack, P.A., 1998. Book Review: Chemistry of Tin, 2nd edition, P.J. Smith (ed). Blackie Academic & Professional, London, 1997. 578 pages. ISBN 0–7514–0385–7. Applied Organometallic Chemistry 12, 520. https://doi.org/10.1002/(SICI)1099-0739(199807)12:7<520::AID-AOC747>3.0.CO;2-T

Dai ZR, Pan ZW, Wang ZL (2001) Ultra-long single crystalline nanoribbons of tin oxide. Solid State Commun 118:351–354. https://doi.org/10.1016/S0038-1098(01)00122-3

Dai ZR, Gole JL, Stout JD, Wang ZL (2002) Tin oxide nanowires, nanoribbons, and nanotubes. J Phys Chem B 106:1274–1279. https://doi.org/10.1021/jp013214r

Das RN (2001) Chemical processing of nanostructured materials. MRS Proc 676(Y3):10. https://doi.org/10.1557/PROC-676-Y3.10

Dauthal P, Mukhopadhyay M (2013) Biosynthesis of palladium nanoparticles using Delonix regia leaf extract and its catalytic activity for nitro-aromatics hydrogenation. Ind Eng Chem Res 52:18131–18139. https://doi.org/10.1021/ie403410z

Deosarkar MP, Pawar SM, Sonawane SH, Bhanvase BA (2013) Process intensification of uniform loading of SnO2 nanoparticles on graphene oxide nanosheets using a novel ultrasound assisted in situ chemical precipitation method. Chem Eng Process 70:48–54. https://doi.org/10.1016/j.cep.2013.05.008

Derikvandi H, Nezamzadeh-Ejhieh A (2017) Increased photocatalytic activity of NiO and ZnO in photodegradation of a model drug aqueous solution: effect of coupling, supporting, particles size and calcination temperature. J Hazard Mater 321:629–638. https://doi.org/10.1016/j.jhazmat.2016.09.056

Devi P, Banerjee S, Chowdhury S, Suresh Kumar G (2012) Eggshell membrane: a natural biotemplate to synthesize fluorescent gold nanoparticles. RSC Adv 2:11578–11585. https://doi.org/10.1039/C2RA21053C

Diallo A, Manikandan E, Rajendran V, Maaza M (2016) Physical & enhanced photocatalytic properties of green synthesized SnO2 nanoparticles via Aspalathus linearis. J Alloy Compd 681:561–570. https://doi.org/10.1016/j.jallcom.2016.04.200

Diaz-Angulo J, Lara-Ramos J, Mueses M, Hernández-Ramírez A, Li Puma G, Machuca–Martínez, F., (2020) Enhancement of the oxidative removal of diclofenac and of the TiO2 rate of photon absorption in dye-sensitized solar pilot scale CPC photocatalytic reactors. Chem Eng J 381:122520. https://doi.org/10.1016/j.cej.2019.122520

Dixit D, Verma A, Gupta S, Bansal P (2016) Assessment of solar photocatalytic degradation and mineralization of amoxicillin trihydrate (AMT) using slurry and fixed-bed batch reactor: efficacy of parabolic trough collector. RSC Adv 6:36109–36117. https://doi.org/10.1039/C6RA03414D

Drzymała E, Gruzeł G, Depciuch J, Budziak A, Kowal A, Parlinska-Wojtan M (2017) Structural, chemical and optical properties of SnO2 NPs obtained by three different synthesis routes. J Phys Chem Solids 107:100–107. https://doi.org/10.1016/j.jpcs.2017.03.026

Elango G, Kumaran SM, Kumar SS, Muthuraja S, Roopan SM (2015) Green synthesis of SnO2 nanoparticles and its photocatalytic activity of phenolsulfonphthalein dye. Spectrochim Acta Part A Mol Biomol Spectrosc 145:176–180. https://doi.org/10.1016/j.saa.2015.03.033

El-Sayed MA (2001) Some interesting properties of metals confined in time and nanometer space of different shapes. Acc Chem Res 34:257–264. https://doi.org/10.1021/ar960016n

Esmaielzadeh Kandjani A, Farzalipour Tabriz M, Arefian NA, Vaezi MR, Halek F, Sadrnezhaad SK (2010) Photocatalytic decoloration of Acid Red 27 in presence of SnO2 nanoparticles. Water Sci Technol 62:1256–1264. https://doi.org/10.2166/wst.2010.156

Fatima R, Afridi MN, Kumar V, Lee J, Ali I, Kim K-H, Kim J–O (2019) Photocatalytic degradation performance of various types of modified TiO2 against nitrophenols in aqueous systems. Journal of Cleaner Production 231:899–912. https://doi.org/10.1016/j.jclepro.2019.05.292

Finn RD, Coggill P, Eberhardt RY, Eddy SR, Mistry J, Mitchell AL, Potter SC, Punta M, Qureshi M, Sangrador-Vegas A, Salazar GA, Tate J, Bateman A (2015) The Pfam protein families database: towards a more sustainable future. Nucleic Acids Res 44:D279–D285. https://doi.org/10.1093/nar/gkv1344

Fu Z, Yang HK, Moon BK, Choi BC, Jeong JH (2011) Hydrothermal synthesis and optical properties of Eu 3+-doped CaSnO3 nanocrystals. J Nanosci Nanotechnol 11:1629–1631. https://doi.org/10.1166/jnn.2011.3384

Gaber A, Abdel-Latief AY, Abdel-Rahim MA, Abdel-Salam MN (2013) Thermally induced structural changes and optical properties of tin dioxide nanoparticles synthesized by a conventional precipitation method. Mater Sci Semicond Process 16:1784–1790. https://doi.org/10.1016/j.mssp.2013.06.026

Galdiero S, Falanga A, Vitiello M, Cantisani M, Marra V, Galdiero M (2011) Silver nanoparticles as potential antiviral agents. Molecules 16:8894–8918. https://doi.org/10.3390/molecules16108894

Gautam S, Agrawal H, Thakur M, Akbari A, Sharda H, Kaur R, Amini M (2020) Metal oxides and metal organic frameworks for the photocatalytic degradation: a review. J Environ Chem Eng 8:103726. https://doi.org/10.1016/j.jece.2020.103726

Giefers H, Porsch F, Wortmann G (2005) Kinetics of the disproportionation of SnO. Solid State Ionics 176:199–207. https://doi.org/10.1016/j.ssi.2004.06.006

Greenwood, N.N., Earnshaw, A., n.d. Chemistry of the Elements, 2nd Edition

Guo D-J (2011) Electrooxidation of ethanol on novel multi-walled carbon nanotube supported platinum-antimony tin oxide nanoparticle catalysts. J Power Sources 196:679–682. https://doi.org/10.1016/j.jpowsour.2010.07.075

Guo H, Wang Y, Li G, Liu J, Li Y (2016) The persistent energy transfer of Eu2+ and Dy3+ and luminescence properties of a new cyan afterglow phosphor α–Ca3(PO4)2:Eu2+, Dy3+. RSC Adv 6:101731–101736. https://doi.org/10.1039/C6RA19386B

Gusain R, Gupta K, Joshi P, Khatri OP (2019) Adsorptive removal and photocatalytic degradation of organic pollutants using metal oxides and their composites: a comprehensive review. Adv Coll Interface Sci 272:102009. https://doi.org/10.1016/j.cis.2019.102009

Haritha E, Roopan SM, Madhavi G, Elango G, Al-Dhabi NA, Arasu MV (2016) Green chemical approach towards the synthesis of SnO2 NPs in argument with photocatalytic degradation of diazo dye and its kinetic studies. Journal of Photochemistry and Photobiology B: Biology 162:441–447. https://doi.org/10.1016/j.jphotobiol.2016.07.010

Heger D, Jirkovsk J, Kln P (2005) Aggregation of methylene blue in frozen aqueous solutions studied by absorption spectroscopy. J Phys Chem A 109:6702–6709. https://doi.org/10.1021/jp050439j

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95:69–96. https://doi.org/10.1021/cr00033a004

Hong G-B, Jiang C-J (2017) Synthesis of SnO2 nanoparticles using extracts from Litsea cubeba fruits. Materials Letters 194:164–167. https://doi.org/10.1016/j.matlet.2017.02.058

Houari M, Hamdi B, Bouras O, Bollinger J-C, Baudu M (2014) Static sorption of phenol and 4-nitrophenol onto composite geomaterials based on montmorillonite, activated carbon and cement. Chem Eng J 255:506–512. https://doi.org/10.1016/j.cej.2014.06.065

Hu JQ, Ma XL, Shang NG, Xie ZY, Wong NB, Lee CS, Lee ST (2002) Large-scale rapid oxidation synthesis of SnO2 nanoribbons. J Phys Chem B 106:3823–3826. https://doi.org/10.1021/jp0125552

Ibarguen CA, Mosquera A, Parra R, Castro MS, Rodríguez-Páez JE (2007) Synthesis of SnO2 nanoparticles through the controlled precipitation route. Mater Chem Phys 101:433–440. https://doi.org/10.1016/j.matchemphys.2006.08.003

Jeong K-E, Kim H-D, Kim T-W, Kim J-W, Chae H-J, Jeong S-Y, Kim C-U (2014) Hydrogen production by aqueous phase reforming of polyols over nano- and micro-sized mesoporous carbon supported platinum catalysts. Catalysis Today 232:151–157. https://doi.org/10.1016/j.cattod.2014.02.005

Jia X, Liu Y, Wu X, Zhang Z (2014) A low temperature situ precipitation route to designing Zn-doped SnO2 photocatalyst with enhanced photocatalytic performance. Appl Surf Sci 311:609–613. https://doi.org/10.1016/j.apsusc.2014.05.118

Jiang J, Oberdörster G, Elder A, Gelein R, Mercer P, Biswas P (2008) Does nanoparticle activity depend upon size and crystal phase? Nanotoxicology 2:33–42. https://doi.org/10.1080/17435390701882478

Jung S-H, Oh E, Lee K-H, Yang Y, Park CG, Park W, Jeong S-H (2008) Sonochemical preparation of shape-selective ZnO nanostructures. Crystal Growth & Design 8:265–269. https://doi.org/10.1021/cg070296l

Kamal T, Khan SB, Asiri AM (2016) Synthesis of zero-valent Cu nanoparticles in the chitosan coating layer on cellulose microfibers: evaluation of azo dyes catalytic reduction. Cellulose 23:1911–1923. https://doi.org/10.1007/s10570-016-0919-9

Kar A, Patra A (2014) Recent development of core-shell SnO2 nanostructures and their potential applications. Journal of Materials Chemistry C 2:6706–6722. https://doi.org/10.1039/C4TC01030B

Kawashima N, Zhu QY, Gerson AR (2012) The selective growth of rutile thin films using radio-frequency magnetron sputtering. Thin Solid Films 520:3884–3891. https://doi.org/10.1016/j.tsf.2012.01.021

Kennedy MK, Kruis FE, Fissan H, Mehta BR, Stappert S, Dumpich G (2002) Tailored nanoparticle films from monosized tin oxide nanocrystals: particle synthesis, film formation, and size-dependent gas-sensing properties. J Appl Phys 93:551–560. https://doi.org/10.1063/1.1525855

Kharissova OV, Dias HVR, Kharisov BI, Pérez BO, Pérez VMJ (2013) The greener synthesis of nanoparticles. Trends Biotechnol 31:240–248. https://doi.org/10.1016/j.tibtech.2013.01.003

Kim SP, Choi MY, Choi HC (2016) Photocatalytic activity of SnO2 nanoparticles in methylene blue degradation. Mater Res Bull 74:85–89. https://doi.org/10.1016/j.materresbull.2015.10.024

Kim, J., 2014. Ti-based nanostructured materials for lithium-ion batteries

Konstantin Stanislavsky – Bella Merlin – Google Books [WWW Document], n.d. URL https://books.google.ca/books?hl=en&lr=&id=kWJgDwAAQBAJ&oi=fnd&pg=PT10&dq=Merlin+et+al.,+2018&ots=TSHIGPu9Xr&sig=UZaGaYQPcc3X8B5jEW5d–cyczoc#v=onepage&q&f=false (accessed 5.26.20).

Kostedt WL IV, Ismail AA, Mazyc DW (2008) Impact of heat treatment and composition of ZnO-TiO2 nanoparticles for photocatalytic oxidation of an azo dye. Ind Eng Chem Res 47:1483–1487. https://doi.org/10.1021/ie071255p

Krishnakumar T, Pinna N, Kumari KP, Perumal K, Jayaprakash R (2008) Microwave-assisted synthesis and characterization of tin oxide nanoparticles. Mater Lett 62:3437–3440. https://doi.org/10.1016/j.matlet.2008.02.062

Król A, Pomastowski P, Rafińska K, Railean-Plugaru V, Buszewski B (2017) Zinc oxide nanoparticles: synthesis, antiseptic activity and toxicity mechanism. Adv Coll Interface Sci 249:37–52. https://doi.org/10.1016/j.cis.2017.07.033

Lang C, Mission EG, Fuaad AA, Shaalan AM (2021) Nanoparticle tools to improve and advance precision practices in the Agrifoods Sector towards sustainability – a review. J Clean Prod 293:126063. https://doi.org/10.1016/j.jclepro.2021.126063