Abstract

Hexachlorocyclohexane (HCH) isomers represent a family of formerly widely utilized pesticides that are persistent, capable of undergoing long-range transport and tend to bioaccumulate in human and animal tissue. Their widespread global utilization coupled with a propensity to adversely impact human health and the environment translates into an urgent need to develop feasible methodologies by which to treat HCH-impacted groundwater and soil. The present study was conducted to evaluate the efficacy of two persulfate-based oxidants: peroxydisulfate (S2O8 2−, PDS) and peroxymonosulfate (HSO5 −, PMS) activated by electrochemical processes (EC) to treat HCH-impacted environmental media. This research demonstrated that the optimal experimental conditions (oxidant dose and electrical current) were 2 mM PDS and 20 mA for an aqueous solution of 4 μM of summed HCHs (ΣHCH). GC/MS full scan analysis revealed the presence of 2,4,6–trichlorophenol as the only detectable intermediate formed during electro-activated PDS treatment of ΣHCH. The investigated method was tested on leachate from a known HCHs-impacted site in Hajek, Czech Republic which contained 106 μg/l of ΣHCH and 129 μg/l of chlorobenzenes. Results from batch treatment showed positive results for electro-activated PDS but only negligible effectiveness for electro-activated PMS. In addition to explaining the efficacy of the electro-activated PDS, this research also explored the basis for the differing reactivities of these two persulfates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Halogenated organic substances have long been known as one of the most notable classes of environmental pollutants in soils, sediments and groundwater as a result of their widespread use as herbicides, insecticides, fungicides, solvents, plasticizers and intermediates for chemical synthesis over the past century. Due to their ubiquity, toxicity, resistance to degradation and bioaccumulation potential, halogenated compounds have been the subject of considerable regulatory and research attention over the past several decades due to their potential effects on the quality of life (Fetzner and Lingens 1994).

Hexachlorocyclohexanes (HCHs) represent one of the most widely investigated families of chlorinated pesticides and were recently (in 2009) added to the list of persistent organic pollutants (POPs) (Vijgen et al. 2011). In addition to the highly toxic gamma (γ) HCH isomer, also known as lindane, other less toxic but still environmentally-relevant HCH isomers include the alpha (α), beta (β) and delta (δ) isomers (Vijgen et al. 2011). The gamma isomer’s pesticidinal properties were originally discovered by researchers at Imperial Chemical Industries (ICI, UK) in the 1940s (Slade 1945). Since that time, the dominant production method has involved the photochlorination of benzene by UV light. This product, referred to as technical HCH, consisted of a mixture of isomers and, because of its lower cost, was favoured in developing economies. A typical composition for technical HCH is as follows: 60–70 % α-HCH, 10–12 % γ-HCH, 5–12 % β-HCH, 6–10 % δ-HCH and 3–4 % ε-HCH (Iwata et al. 1993). The highly toxic isomer γ-HCH, a pesticide used worldwide for controlling agricultural pests, in seed treatments and in medical applications could be obtained by multiple recrystallizations from technical HCH (Voldner and Li 1995; Willett et al. 1998). The use of high purity lindane treatments tended to be preferred in the developed economies of Western Europe, the USA, and Canada (Ramos et al. 2011).

Considering that approximately 10 million tons of HCHs were utilized globally during the timeframe of 1948–1997, it is reasonable to assume that a significant number of impacted sites require cleanup (Willett et al. 1998). Although the threat is obvious, HCHs are still being used as pesticides in developing as well as developed countries (Li 1999). For example, a mixture of technical HCHs and lindane has been used in India in both pharmaceutical products and agriculture (Central Insecticide Board and Registration Committee 2005) and lindane has been used for seed treatment in Canada and USA (Sang et al. 1999).

It is therefore important to develop cost-effective remedial technologies to treat soil, water and waste sites contaminated by HCH isomers and to help speed up the disposal of HCH products. Degradation of HCH can be achieved by various remedial techniques using both biological and chemical reduction methods (Phillips et al. 2005; Boyle et al. 1999; Elliott et al. 2009; Singh et al. 2012; Zinovyev et al. 2004), but according to our knowledge, there have been relatively few investigations on the use of chemical oxidation to degrade HCHs in the literature. Previous studies employing H2O2 for assisted UV photo-degradation of synthetic lindane solutions (Nienow et al. 2008; Nitoi et al. 2013) and various oxidants including H2O2, PDS and permanganate (Usman et al. 2014; Cao et al. 2008) are known. Usman et al. (2014) reported the oxidative treatment of HCH isomers in soil by PDS both activated by Fe2+ and non-activated. Application of soluble Fe2+ showed a negative impact on the reactivity of PDS after 24 h of reaction. The utilization of PDS alone resulted in relatively high degradation of HCH isomers, which decreased in the order γ-HCH (95 %), δ-HCH (92 %), α-HCH (79 %) and β-HCH (43 %) (Usman et al. 2014).

PDS and PMS are among the strongest oxidants used in environmental remediation applications. The standard ORP for the reaction (Eq. 1) is 2.01 V; thus, it is higher than the 1.4 V (Eq. 2) of PMS but lower than that of ozone (2.2 V) (Block et al. 2004; Bajpai 2012).

Furthermore, PDS and PMS can form free radicals analogous to the hydroxyl radical pathways generated by Fenton’s chemistry (Eqs. 3, 4) (Block et al. 2004; Wang and Chu 2012). Yuan et al. (2014) claimed that OH• can be produced from SO4 •– (Eq. 5) and can play a more important role than SO4 •– for degradation of certain contaminants, e.g. VOC.

Sulfate radicals are also very strong aqueous oxidizing species with a redox potential estimated to be 2.6 V, similar to that of the hydroxyl radical, 2.7 V. These radicals are usually generated during the activation of PDS under heat-, photo-, metal-, chelated metal-, quinone-, phenols-, hydrogen peroxide- or alkaline-catalysed conditions (Huang et al. 2002; Block et al. 2004; Fang et al. 2013; Siegrist et al. 2011; Ahmad et al. 2013). Wang and Chu (2012) reported that PMS can be easily activated into highly reactive radicals through homolytic cleavage of the peroxide bond of HSO5 − by photolysis or thermolysis (Eq. 4). However, the activation of PDS and PMS under electrochemical conditions is still not widely known (Yuan et al. 2014; Govindan et al. 2014; Lin et al. 2014). The mechanisms in which iron oxidation plays an important role in the anodic and cathodic reactions can be described by (Eqs. 6 to 9) (Govindan et al. 2014).

Anodic reactions:

Cathodic reaction:

Overall reaction:

The reactions taking place on anodes and cathodes contribute to the activation of oxidants. Fe2+ produced from the iron anode activates oxidants to generate strongly oxidizing SO4 •− and OH• species (Eqs. 10, 5) and the Fe2+ is regenerated from the reduction of Fe3+ on the cathode (Eq. 11) (Lin et al. 2014).

Iron electrodes can be easily introduced into the contaminated zone to control the in situ activation of PDS, thus minimizing potential losses during its injection and transportation in the subsurface (Yuan et al. 2014). For this and many other reasons, the oxidation efficiency of organic and inorganic pollutants can be significantly enhanced by coupling electrochemical processes with PDS and PMS injection (Lin et al. 2014; Govindan et al. 2014).

On the other hand, according to literature, the electrochemically produced Fe2+ can also act as a sulfate radical scavenger at high concentrations as expressed by Eq. (12) (Usman et al. 2014; Cao et al. 2008; Xu and Li 2010). Thus, ferrous iron represents a double-edged sword—it can both catalyse the formation of sulfate radicals and quench them depending upon its concentration.

This study was conducted to evaluate the efficacy of two persulfate-based oxidants, PDS and PMS, activated by electrochemical processes (EC) to degrade HCH isomers in contaminated water. To our knowledge, this represents the first published research concerning the degradation of HCHs by electro-activated persulfates. Following controlled bench-scale experiments, the optimized methodology was demonstrated on groundwater from an HCH-impacted site in the Czech Republic.

Methodology

Reagents and solutions

All of the chemicals used in the experiments were analytical reagent grade. PMS (Oxone®, 99.0 %) and sodium bicarbonate (99.7 %) were purchased from Sigma–Aldrich, sodium thiosulfate pentahydrate (99.0 %), PDS (sodium persulfate, 99.0 %), potassium iodide (99.5 %) and sodium sulfate were purchased from Lach-Ner. A saturated stock solution of HCH was prepared by dissolving standard mix of HCH isomers (purity >99.3 %; Fluka, Sigma–Aldrich Co.) in deionized water. This was filtered through a 0.45-μm filter after vigorous stirring for 3 days. The stock solution (summed HCH concentration, ΣHCH: 40 μM; pH~6.8; α-HCH (13.6 %), β-HCH (12.4 %), γ-HCH (45.6 %) and δ-HCH (28.4 %)) was then stored in a refrigerator at 5 °C. Deionized water (18.2 MΩ cm−1) was prepared by an ELGA Purelab flex system (ELGA, Veolia Water, Marlow, UK).

A representative sample of contaminated groundwater was taken from the Hajek dump site (Czech Republic). The site is an uncontrolled dump associated with a former uranium and kaoline mine which, in the 1960s, was used for disposal of waste product from lindane and chlorobenzene production by the Spolana, a.s., a chemicals manufacturer in Neratovice, Czech Republic. Approximately 3000 tons of chemicals were disposed in steel barrels, paper bags or loosely at the dump site (Hešnaur and Jech 2001). Seepage water is collected by drainage pipes which flow into an open channel discharging into a nearby lake, where HCH concentrations exceed the appropriate limit (0.02 μg/l). The water from the pipe was collected by a 10-l glass vessel, transferred to the laboratory and stored at 4 °C. The contaminant content was determined prior to the experiments. The water contains a mixture of HCHs (ΣHCH = 106.51 μg/l) and CB at 129.90 μg/l (Table 1).

Analytical

HCH and CB isomers were quantified by a gas chromatograph (Thermo Trace 1310 combined with an MS detector TSQ 8000 triple quadrupole). Headspace solid-phase microextraction (HS-SPME) was utilized for sample preparation and injection (PDMS SPME fibres, Supelco). A TR-Pesticide chromatographic column, 30 m in length, 0.25 mm in diameter was used for gas chromatography. For detection of the polar chlorophenols, as by-products of the oxidation reactions, sample aliquots were derivatized with acetic anhydride. For calibration, standard mixtures of HCH and CB (Neochema, Pesticides Mix 5 and Chlorobenzenes Mix 12) were employed along with deuterated γ-HCH (Ehrenstorfer, GmBH) as an internal standard.

In addition, potential volatile reaction intermediates and products (other than chlorophenols) were qualitatively searched for in the full scan mode of a GC/ion trap MS instrument (Varian Saturn 3800), equipped with a DB-624 column, 60 m in length and 0.25 mm in diameter.

A ultraviolet-visible spectrophotometer HACH DR 6000 (HACH LANGE s.r.o., Czech Republic) with matched 1-cm quartz cells (cuvettes) was used for the determination of PDS and PMS concentration according to the method developed by (Liang et al. 2008) and (Wacławek et al. 2015), respectively. At selected time points, 0.2-ml samples were taken from the reactors, mixed with a 5-ml potassium iodide solution and the resulting mixtures were then measured using the spectrophotometer (characteristic wavelengths of 400 and 395 nm). A calibration curve was established using PDS and PMS solutions ranging from 4 to 40 and 1.35 to 13 mg/l, respectively.

The pH and ORP measurements were determined by a WTW pH-meter equipped with SenTix pH electrodes (MultiLine® Multi 3430 IDS). ORP values are presented as values against a saturated calomel electrode (SCE) and were not corrected to the standard hydrogen electrode (SHE). TOC was analysed by a Multi N/C 3100 analyser (Jena Corporation, Germany).

EC experiment setup

EC tests were performed at room temperature in a non-tightened undivided batch electrolytic cell (1.5 l) containing 1 l of electrolyte solution as shown in Fig. 1. Two iron electrodes were employed and were connected in parallel through a DC regulated power supply (HQ POWER PS3010) at an inter-electrode distance of 8 cm in the electrolytic cell. Sodium sulfate at 0.7 mM was used as a background electrolyte. Sample aliquots of 10 ml were taken from the reactor and mixed with sodium thiosulfate to quench the oxidant and stop the reaction. Unless otherwise specified, the reaction conditions were based on a 4-μM ΣHCH mixture, containing 0.5 μM (α-HCH), 0.5 μM (β-HCH), 1.9 μM (γ-HCH) and 1.1 μM (δ-HCH), 2 mM PDS or 6 mM PMS initial concentrations and 20 mA applied current (6 V). The experiment with two separated compartments was conducted in two 2 l reactors separated by an anion-exchange membrane (MemBrain s.r.o., Czech Republic) that transmits anions and blocks the cations and hydrodynamic flow of the solvent. All of the experiments were carried out in duplicate at least.

Results and discussion

Applied electric current significantly changed the concentrations of contaminants and other parameters as well as the solution pH and ORP during the tests. Fe2+ produced from the iron electrode activated the oxidants in solution to generate strongly oxidizing SO4 •− and OH• radicals which subsequently degraded the HCHs. Both SO4 •− and OH• are possibly responsible for the destruction of HCH and either radical may predominate over the other depending on solution pH. The kinetics of pH and ORP changes in the EC, EC + PDS and EC + PMS experimental sets were observed (Fig. 2). According to Liang and Huang (2012), SO4 •− was the predominant radical at acidic solution pH. Both PDS and PMS have the potential to dramatically lower pH and increase ORP in groundwater. Figure 2 shows that after the addition of 2 mM of PDS, the solution pH and ORP changed to about 2.5 standard units and 450 mV, respectively, within 30 min of treatment. By comparison, following the addition of 6 mM of PMS, the solution pH dropped to 2.5 standard units and the ORP increased to 550 mV. Based on these results, PDS and PMS generate similar pH and ORP profiles when combined with EC. According to Anipsitakis and Dionysiou (2004), SO4 •− and OH• exhibit similar reduction potentials under acidic conditions. These radicals are highly reactive to C–H bonds (Lee and von Gunten 2010) located in HCH.

Effect of various oxidant doses on summed HCH isomers degradation

In this study, a pseudo first-order kinetic model (Eq. 13) was applied to evaluate the kinetics of HCHs degradation.

where C and C 0 are the summed HCH isomers concentrations at time (t) and t = 0, respectively, and k is the reaction rate constant.

The effect of PDS and PMS doses on the degradation of summed HCH isomers is shown in Figs. 3, 4 and 5. As the source of radicals, the PDS quantity played an important role in the HCH degradation process with the oxidant dose being directly correlated to the extent of observed HCH degradation. In the presence of electrolysis alone, no significant HCH removal was observed during the 2 h timeframe of the experiment. As increasing PDS concentrations were added into the solution, the degradation of summed HCH isomers appeared. The reaction rate constants for 2 mM PDS concentration equals to 0.045 min−1 and is c.a. 15 times higher than the rate constant for the 0.5 mM dose (0.003 min−1). The variation of PDS dosage from 0.5 to 4 mM resulted in an increased efficiency of HCH loss from 23 to 95 % within 2 h. Because there is no improvement in HCHs degradation between the dosages of 2 and 4 mM (k = 0.045 and 0.032 min−1 respectively), the dosage of 2 mM was taken as being optimal.

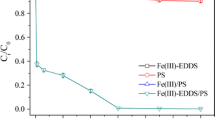

In contrast, the degradation rate of HCH isomers by EC coupled with PMS (up to 9 mM) is negligible during the 2 h of the experiment. This result differs from the data presented by Govindan et al. (2014) in which PMS was shown to be the best electro-activated oxidant for pentachlorophenol removal from groundwater. This phenomenon could be explained by a much lesser reactivity of PMS with Fe2+ in comparison to other transition metals, i.e. Co2+ (Anipsitakis and Dionysiou 2004; Do et al. 2009). Since the effect of PMS on HCH isomer degradation was found to be negligible, no further tests with it were conducted.

Figure 4 shows the kinetics of the degradation of individual isomers by electro-activated PDS. There were no significant differences between the degradation rate constants of the individual isomers 0.026 min−1 (α-HCH), 0.037 min−1 (β-HCH), 0.040 min−1 (γ-HCH) and 0.049 min−1 (δ-HCH). Although α-HCH is known as one of the most reactive isomers, it shows the lowest degradation rate, much smaller compare to β-HCH, considered the most persistent HCH isomer. After 30 min, the β-HCH concentration was approximately a half of the concentration of α-HCH. The final concentration of α-HCH was about 5 % of its initial concentration compared to a maximum of 1 % for the others. In general, compared to the results obtained by Usman et al. 2014, our method shows much higher and faster degradation.

Effect of variable current on HCH degradation and oxidant decomposition

Whereas Fig. 3 shows the effect of increasing PDS concentrations, Fig. 5 shows the effect of variable current with a fixed PDS dose. With increasing applied current, there is a progressive increase of the HCH degradation up to 20 mA. According to (Eq. 10), Fe2+ produced from corroded anode activates PDS to generate strongly oxidizing SO4 •− and OH• radicals. As the current level increases, the production of Fe2+ also increases (Yuan et al. 2014; Govindan et al. 2014) and more oxidizing species are formed from PDS. This is confirmed by measurement of the kinetics of PDS decomposition induced by various currents (Fig. 6). Specifically, the PDS decomposition is faster by higher current density.

Based on the results of the above study, a PDS dose of 2 mM and a current of 20 mA were found to be optimal for our experimental set-up. It has been found that applying higher current can slower reaction kinetics of HCH degradation. One possible reason is that electrochemically produced Fe2+ can act also as a radical scavenger at its elevated concentration.

Membrane separation processes

In the system, the electron donors included not only Fe2+ produced from the electrochemical corrosion but also Fe2+ regenerated from Fe3+ reduction on the cathode (Eq. 11) and the electrons donated by the cathode. To estimate the contributions of these effects, experiments in a split electrolytic system (with two separated compartments) were carried out. Figure 7 depicts the results of the degradation of summed HCHs at the anode and cathode, both with 2 mM of PDS and without added PDS.

When EC tests were performed without the addition of PDS, a significant decrease in HCH concentrations was observed only in the cathodic compartment. This effect is believed to be attributable to the increase of pH from an initial value of 6.6 to 11.4 by water electrolysis. According to literature, when the level of pH rises significantly above 9, the HCH isomers are transformed into chlorobenzenes by base-catalysed hydrolysis (Ren et al. 2006; Li et al. 2011; Homolková et al. 2014). After the introduction of PDS, the degradation of HCH isomers was significant in both the anodic and cathodic compartments and at a far faster rate than was observed for EC alone. These results validate the contribution of Fe2+ produced from the electrochemical corrosion of iron around anode (Eq. 6) and also the impact of the cathodic reactions mentioned above. Degradation in the cathodic compartment reflects the contribution of Fe2+ regenerated from the reduction of Fe3+ on the cathode (Eq. 11) and PDS direct decomposition by electron capture (Lin et al. 2014). These two processes cannot be separated and therefore assessed their contribution.

TOC removal

The products of HCH degradation were investigated using gas chromatography. Derivatization and SPME injection of sample (PDS concentration—2 mM, contact time—30 min) in the GC/MS and its full scan analysis revealed the presence of 2,4,6–trichlorophenol as the only detectable intermediate formed during electro-activated PDS treatment of HCH. The other expected intermediates or final products such as chlorophenols, chlorobenzenes and chlorinated cyclohexanes reported in literature (Cao et al. 2008) were not observed. TOC analysis was performed in order to confirm the complete transformation of HCH to CO2 and H2O. In the case of EC alone, a negligible TOC change was observed during the 5 h of the experiment. However, electro-activated PDS oxidation (20 mA and 2 mM) clearly indicated that the removal efficiency of TOC via PDS oxidation was about 60 % in 1 h, which is in agreement with observed HCH removal (Fig. 3) and PDS decomposition (Fig. 6). The final TOC removal was 92 % after 5 h.

Environmental sample

Contaminated leachate from the Hajek dump site contaminated with HCH isomers was selected in order to test the efficiency of the proposed method on a real-world sample from an HCH-impacted site. Since the degree of the HCH contamination is higher than in previous spiked experiments, higher doses of PDS were applied (Fig. 8).

As shown in Fig. 8, the rapid degradation of CB can be observed by both PDS doses coupled with electro-activation. This can be explained by the high reaction rate between both sulfate and hydroxyl radicals and the aromatic double bonds located in the chlorobenzenes CB (Rickman and Mezyk 2010; Wojnárovits and Takács 2014). In contrast, the HCHs proved to be significantly more recalcitrant. In the test conducted with the lower dose of PDS (4 mM), HCH degradation was negligible even after 8 h of contact, indicating that PDS was probably preferentially consumed by CB oxidation. However, in the experiment with the higher PDS dose (16 mM), both CB and HCH were almost completely eliminated after 6 to 8 h. Even in this case, HCH degradation is slower compared to CB, probably because of the lack of aromatic double bonds. Stated in another way, the prevalence of C–Cl single bonds in the HCHs proved to be more recalcitrant to the studied remedial approach than did the aromatic C–Cl bonds of the chlorobenzenes.

With respect to the results for the individual HCH isomers, interesting trends were observed. In consensus with the literature and contrary to our findings with the spiked HCH samples, β-HCH degradation in the field sample was observed to be significantly slower to the other isomers. While the other isomer concentrations dropped (16 mM PDS) below 1 % of their initial values after 8 h, β-HCH remained at 16 %. Concerning the CBs, no significant difference was observed between individual congener removal rates.

Conclusions

This study confirmed that the Fe2+ ions produced and regenerated in the process of electrolysis can be a suitable reactant for the transformation of PDS into sulfate and hydroxyl radicals for the rapid degradation of HCH isomers. Surprisingly, PMS coupled with EC is ineffective for the removal of HCH isomers (which could be explained by a lesser reactivity of PMS with Fe2+) and therefore was not detailed investigated. The concentration of PDS and the applied current are essential parameters influencing the rate of HCH degradation. Furthermore, it is noteworthy that HCH isomers can be almost completely degraded using an applied current of 20 mA and a PDS concentration of 2 mM. In addition, GC/MS analysis found no hazardous by-products or intermediates after electro-activated PDS treatment. The method was successfully tested on contaminated groundwater containing HCHs and CBs from a former pesticides manufacturing site in the Czech Republic. Although these results are promising, further investigations are needed to thoroughly assess the cost-effectiveness of the remedial approach for removing HCH and CB from groundwater and wastewater.

References

Ahmad M, Teel AL, Watts RJ (2013) Mechanism of persulfate activation by phenols. Environ Sci Technol 47:5864–5871

Anipsitakis GP, Dionysiou DD (2004) Radical generation by the interaction of transition metals with common oxidants. Environ Sci Technol 38:3705–3712

Bajpai P (2012) Environmentally benign approaches for pulp bleaching. 2nd edn. Elsevier, London, pp 59–129

Block PA, Brown RA, Robinson D (2004) Novel activation technologies for sodium persulfate in situ chemical oxidation. Proceedings of the Fourth International Conference on the Remediation of Chlorinated and Recalcitrant Compounds, Monterrey CA

Boyle AW, Häggblom MM, Young LY (1999) Dehalogenation of lindane (γ-hexachlorocyclohexane) by anaerobic bacteria from marine sediments and by sulfate-reducing bacteria. FEMS Microbiol Ecol 29:379–387

Cao J, Zhang W-X, Brown DG, Sethi D (2008) Oxidation of lindane with Fe(II)-activated sodium persulfate. Environ Eng Sci 25:221–228

Central Insecticide Board and Registration Committee (2005) Dept. of Plant Protection and Quarantine, Ministry of Agriculture, India

Do S-H, Jo J-H, Jo Y-H, Lee H-K, Kong S-H (2009) Application of a peroxymonosulfate/cobalt (PMS/Co(II)) system to treat diesel-contaminated soil. Chemosphere 77(8):1127–1131

Elliott DW, Lien H, Zhang W (2009) Degradation of lindane by zero-valent iron nanoparticles. J Environ Eng 135(5):317–324

Fang G, Gao J, Dionysiou DD, Liu C, Zhou D (2013) Activation of persulfate by quinones: free radical reactions and implication for the degradation of PCBs. Environ Sci Technol 47:4605–4611

Fetzner S, Lingens F (1994) Bacterial dehalogenases: biochemistry, genetics, and biotechnological applications. Microbiol Rev 58:641–685

Govindan K, Raja M, Noel M, James EJ (2014) Degradation of pentachlorophenol by hydroxyl radicals and sulfate radicals using electrochemical activation of peroxomonosulfate, peroxodisulfate and hydrogen peroxide. J Hazard Mater 272:42–51

Hešnaur L, Jech J (2001) Řešení problematiky důlních vod z výsypky lomu Hájek, kontaminovaných uloženými odpady z výroby organochlorových insekticidů. DIAMO, s. p., o. z. SUL Příbram

Homolková M, Hrabák P, Kolář M, Černík M (2014) Degradability of hexachlorocyclohexanes in water using ferrate (VI). Water Sci Technol 71(3):405–411

Huang KC, Couttenye RA, Hoag GE (2002) Kinetics of heat-assisted persulfate oxidation of methyl tert-butyl ether (MTBE). Chemosphere 49:413–420

Iwata H, Tanabe S, Sakal N, Tatsukawa R (1993) Distribution of persistent organochlorines in the oceanic air and surface seawater and the role of ocean on their global transport and fate. Environ Sci Technol 27:1080–1098

Lee Y, von Gunten U (2010) Oxidative transformation of micropollutants during municipal wastewater treatment: comparison of kinetic aspects of selective (chlorine, chlorine dioxide, ferrate VI, and ozone) and non-selective oxidants (hydroxyl radical). Water Res 44:555–566

Li YF (1999) Global technical hexachlorocyclohexane usage and its contamination consequences in the environment: from 1948 to 1997. Sci Total Environ 232:121–158

Li S, Elliott DW, Spear ST, Ma L, Zhang W-X (2011) Hexachlorocyclohexanes in the environment: mechanisms of dechlorination. Crit Rev Environ Sci Technol 41:1747–1792

Liang CJ, Huang SC (2012) Kinetic model for sulfate/hydroxyl radical oxidation of methylene blue in a thermally-activated persulfate system at various pH and temperatures. Sustain Environ Res 22(4):199–208

Liang C, Huang C-F, Mohanty N, Kurakalva RM (2008) A rapid spectrophotometric determination of persulfate anion in ISCO. Chemosphere 73:1540–1543

Lin H, Zhang H, Hou L (2014) Degradation of C. I. acid orange 7 in aqueous solution by a novel electro/Fe3O4/PDS process. J Hazard Mater 276:182–191

Nienow AM, Bezares-Cruz JC, Poyer IC, Hua I, Jafvert CT (2008) Hydrogen peroxide-assisted UV photodegradation of Lindane. Chemosphere 72:1700–1705

Nitoi I, Oncescu T, Oancea P (2013) Mechanism and kinetic study for the degradation of lindane by photo-Fenton process. J Ind Eng Chem 19(1):305–309

Phillips TM, Seech AG, Lee H, Trevors JT (2005) Biodegradation of hexachlorocyclohexane (HCH) by microorganisms. Biodegradation 16:363–392

Ramos J, Gavilán A, Romero T, Ize I (2011) Mexican experience in local, regional and global actions for lindane elimination. Environ Sci Pol 14:503–509

Ren M, Peng P, Huang W, Liu X (2006) Kinetics of base-catalyzed dehydrochlorination of hexachlorocyclohexanes: I. homogeneous systems. J Environ Qual 35:880–888

Rickman KA, Mezyk SP (2010) Kinetics and mechanisms of sulfate radical oxidation of β-lactam antibiotics in water. Chemosphere 81:359–365

Sang S, Petrovic S, Cuddeford V (1999) Lindane—a review of toxicity and environmental fate. WWF, Canada

Siegrist RL, Crimi M, Simpkin TJ (2011) In situ chemical oxidation for groundwater remediation. Springer, New York, pp 147–191

Singh R, Misra V, Mudiam MKR, Chauhan LKS, Singh RP (2012) Degradation of γ-HCH spiked soil using stabilized Pd/Fe0 bimetallic nanoparticles: pathways, kinetics and effect of reaction conditions. J Hazard Mater 237–238:355–364

Slade RE (1945) The γ-isomer of hexachlorocyclohexane (gammexane): an insecticide with outstanding properties. Chem Ind 40:314–319

Usman M, Tascone O, Faure P, Hanna K (2014) Chemical oxidation of hexachlorocyclohexanes (HCHs) in contaminated soils. Sci Total Environ 476–477:434–439

Vijgen J, Abhilash PC, Li YF, Lal R, Forter M, Torres J, Singh N, Yunus M, Tian C, Schäffer A, Weber R (2011) Hexachlorocyclohexane (HCH) as new Stockholm Convention POPs—a global perspective on the management of Lindane and its waste isomers. Environ Sci Pollut Res 18:152–162

Voldner EC, Li Y-F (1995) Global usage of selected persistent organochlorines. Sci Total Environ 160–161:201–210

Wacławek S, Grübel K, Černík M (2015) Simple spectrophotometric determination of monopersulfate. Spectrochim Acta A Mol Biomol Spectrosc 149:928–933

Wang YR, Chu W (2012) Photo-assisted degradation of 2,4,5-trichlorophenoxyacetic acid by Fe(II)-catalyzed activation of oxone process: the role of UV irradiation, reaction mechanism and mineralization. Appl Catal B 123–124:151–161

Willett KL, Ulrich EM, Hites RA (1998) Differential toxicity and environmental fates of hexachlorocyclohexane isomers. Environ Sci Technol 32:2197–2207

Wojnárovits L, Takács E (2014) Rate coefficients of hydroxyl radical reactions with pesticide molecules and related compounds: a review. Radiat Phys Chem 96:120–134

Xu X-R, Li X-Z (2010) Degradation of azo dye Orange G in aqueous solutions by persulfate with ferrous ion. Sep Purif Technol 72:105–111

Yuan S, Liao P, Alshawabkeh AN (2014) Electrolytic manipulation of persulfate reactivity by iron electrodes for trichloroethylene degradation in groundwater. Environ Sci Technol 48:656–663

Zinovyev SS, Shinkova NA, Perosa A, Tundo P (2004) Dechlorination of lindane in the multiphase catalytic reduction system with Pd/C, Pt/C and Raney-Ni. Appl Catal B 47:27–36

Acknowledgments

The research presented in this article was supported by the Ministry of Education, Youth and Sports in the framework of the projects KONTAKT II (LH14067), the National Programme for Sustainability I (LO1201) and the OPR&DI project “Centre for Nanomaterials, Advanced Technologies and Innovation”, CZ.1.05/2.1.00/01.0005. We would also like to thank the state enterprise DIAMO for providing samples of HCH from the Hajek site.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Wacławek, S., Antoš, V., Hrabák, P. et al. Remediation of hexachlorocyclohexanes by electrochemically activated persulfates. Environ Sci Pollut Res 23, 765–773 (2016). https://doi.org/10.1007/s11356-015-5312-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5312-y