Abstract

This study is focused on the effective removal of recalcitrant pollutants hexaclorocyclohexanes (HCHs, isomers α, β, γ, and δ) and chlorobenzenes (CBs) present in a real groundwater coming from a landfill of an old lindane factory. Groundwater is characterized by a total organic carbon (TOC) content of 9 mg L−1, pH0 = 7, conductivity = 3.7 mS cm−1, high salt concentration (SO42−, HCO3−, Cl−), and ferrous iron in solution. The experiments were performed using a BDD anode and a carbon felt (CF) cathode at the natural groundwater pH and without addition of supporting electrolyte. The complete depletion of the four HCH isomers and a mineralization degree of 90% were reached at 4-h electrolysis with a current intensity of 400 mA, the residual TOC (0.8 mg L−1) corresponding mainly to formic acid. A parallel series reaction pathway was proposed: HCHs and CBs are transformed into chlorinated and hydroxylated intermediates that are rapidly oxidized to non-toxic carboxylic acids and/or mineralized, leading to a rapid decrease in solution pH.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The extensive use of technical hexachlorocyclohexane (t-HCH, a mixture of α, β, γ, δ, and ε HCH isomers) and the purified lindane (γ-HCH, the only isomer with insecticidal properties) in the agricultural sector and, in a less extent, for public health purposes (Wang et al. 2009; Chang et al. 2011), has resulted in their occurrence in aquatic, soil, and air environment, generating a contamination problem of global dimensions (Dominguez et al. 2016; Vega et al. 2016; Khan et al. 2017; Madaj et al. 2017). Thus, it is estimated that there are large accumulations of HCHs worldwide (Peng et al. 2015), mainly, in Europe, where the 63% of the total wastes is concentrated (Vijgen et al. 2011). Recently, three of the HCH isomers (α, β, and γ-HCH) have been included in the list of persistent organic pollutants (POPs) in the Stockholm Convention (Vijgen et al. 2011) due to their high refractoriness and adverse effects on ecosystem and human beings (Wacławek et al. 2016). Consequently, sites contaminated by these pollutants need to be addressed as part of the implementation of the aforementioned convention, which implies the irreversible destruction or transformation of POPs into non-POP compounds.

Lindane has been synthetized in Spain at four production plants (all of them in the north of the country), two in the Basque Country, one in Galicia, and the biggest one in Aragon, specifically in a small industrial city located in the Aragonian Pyrenees, Sabiñánigo. This study focuses on the area affected by the old HCH landfill located in Sabiñánigo, named “Sardas landfill,” where INQUINOSA, a lindane manufacturing company, operated from 1975 to 1988 (Fernández et al. 2013). During the production period, the generated HCH wastes were initially sent to France and treated by thermal cracking and later packed in drums and dumped at different locations in the vicinity of the plant (Fernández et al. 2013). It is estimated that this company generated approximately 150,000 t of dumped hazardous organochlorine wastes, mainly composed of HCH waste isomers (Vijgen 2006), which constitutes a serious risk for the environment, especially considering the proximity of the Gállego River. The in situ-conducted assessments have revealed significant contamination of soil, ground, and surface water and the presence of a large volume of dense non-aqueous phase liquid (DNAPL, 4000 t), resulted by the infiltration of liquid wastes and detected at very variable depths. As lindane was obtained from the chlorination of benzene and further purification by distillation with solvents, the DNAPL wastes produced by failure runs and distillation tails contained CBs, solvents, and HCH isomers. The DNAPL (density ≈ 1.5–1.8 g cm-3) migrated in the subsurface resulting in the contamination of the groundwater.

Nowadays, the polluted water collected from the landfill after rainstorms and the groundwater pumped to avoid the contamination of the surface water is treated by physicochemical processes, consisting in coagulation followed by adsorption with activated carbon. Spent activated carbon is currently sent to a hazardous waste incineration company located in France (Fernández et al. 2013), entailing a significant economic expenditure. Concerns over the potential production of secondary contaminants, especially dioxins and furans, have resulted in strong public opposition to the application of this technology (Peng et al. 2015). Therefore, more suitable alternatives able to replace the physicochemical processes currently applied are highly required.

In this study, the treatment of a real groundwater from the Sardas landfill contaminated by HCHs and CBs by electrochemical advanced electrooxidation processes (EAOPs) is presented. These techniques, which include anodic oxidation (AO) and electro-Fenton (EF) processes, constitute environmentally friendly emerging methods based on the direct or indirect electrogeneration of hydroxyl radicals (•OH) (Brillas et al. 2009; Oturan and Aaron 2014; Sirés et al. 2014; Brillas and Martínez-Huitle 2015) and have proved high efficiency in the oxidation of toxic and persistent organic pollutants (Oturan and Brillas 2007; Kesraoui-Abdessalem et al. 2010; Rodrigo et al. 2014).

In AO process, the simplest EAOP, organic pollutants can be oxidized by direct electron transfer to the anode or by generation of heterogeneous hydroxyl radicals, M(•OH), formed as intermediates of water oxidation at the surface of a high O2-overvoltage anode (M) according to Eq. (1) (Canizares et al. 2009; Panizza and Cerisola 2009; Martinez-Huitle et al. 2015; Bocos et al. 2016):

On the other hand, the EF process, one of the most popular EAOPs (Brillas et al. 2009; Nidheesh and Gandhimathi 2012; Vasudevan and Oturan 2014; Sirés et al. 2014), is based on the in situ electrogeneration of hydrogen peroxide (H2O2) from two-electron reduction of dissolved O2 gas (Eq. 2) at a suitable cathode and its further decomposition into •OH in the presence of ferrous iron (Fe2+) via Fenton reaction (Eq. 3) (Oturan 2000; Martínez-Huitle and Brillas 2009; Nidheesh and Gandhimathi 2012; Yahya et al. 2014). Fe2+ is continuously regenerated (Eq. 4) in the cathode by electroreduction of Fe3+ produced from Fenton reaction. Therefore, the use of a low quantity of Fe2+ (catalyst) allows the electrocatalysis of Fenton reaction (Oturan and Aaron 2014; Nidheesh 2015) avoiding also the accumulation or Fe2+ ion in the reaction medium and thus the production of iron sludge (Komtchou et al. 2015).

The homogeneous (•OH) and heterogeneous (M(•OH)) radicals thus formed are powerful oxidants able to oxidize recalcitrant organic pollutants until their mineralization (Eq. 5) (Brillas et al. 2009; Panizza and Cerisola 2009; Sirés et al. 2014). The EF process has been proved to be powerful for efficient degradation of hazardous pesticides and herbicides (Nidheesh and Gandhimathi 2012).

This paper reports on the feasibility of a technical solution for the treatment of a groundwater pumped from the Sardas landfill, containing organochlorine pesticides from lindane production wastes by EAOPs. Thus, we describe for the first time the electrooxidation of the real groundwater in an undivided electrochemical cell equipped with a BDD anode and a CF cathode. A complete study including the identification of intermediates and the evolution of pH and ecotoxicity during the electrochemical treatment is presented. Finally, a feasible degradation pathway has been proposed.

Materials and methods

Groundwater

The groundwater was pumped from an extraction well located in Sardas landfill, in Sabiñánigo (in the northeast of Spain). The contaminated groundwater was sampled at 11 m below the ground level, corresponding to the saturated zone. The groundwater extraction was carried out by using bladder pumps and flow cells. Samples taken were immediately stored and preserved in glass bottles in a refrigerator at 4 °C.

Reagents

Working standard solutions of the four isomers of HCH (α-HCH, β-HCH, δ-HCH, and γ-HCH, Sigma-Aldrich), potassium hydrogen phthalate (C8H5KO4, Nacalai Tesque), acetic acid (CH3COOH), formic acid (CH2O2), chloroacetic acid (C2H3ClO2), oxalic acid (C2H2O4), and succinic acid (C4H6O4) (all of them from Sigma-Aldrich) were used for gas chromatography-mass spectrometry (CG-MS), total organic carbon (TOC), and ionic chromatography (IC) calibration, respectively.

Other reagents used in the present work (all of analytical grade) were sodium carbonate (Na2CO3, Riedel-de Häen) and sodium bicarbonate (NaHCO3, Fluka). All of the following reagents were provided by Sigma-Aldrich: iron(II) sulfate heptahydrate (FeSO4·7H2O), acetone (C3H6O), methanol (CH3OH), sodium sulfite (Na2SO3), sulfuric acid (H2SO4), sodium hydroxide (NaOH), 4-methylcyclohexanone (C7H12O), and C36H24FeN62+. Synthetic solutions were prepared with high-purity water obtained from a Millipore Direct-Q system (resistivity > 18 MΩ cm at 25 °C).

Electrochemical device

An undivided and cylindrical glass electrolytic cell (V = 230 mL) was used to carry out the experiments at ambient conditions (25 °C, 1 atm) during 6 h. The electrochemical cell was capped during the experiments in order to avoid both water evaporation and the loss of volatile compounds from groundwater during electrolysis time. The cathode, a 3D carbon felt (CF, 18.0 cm × 5.0 cm × 0.5 cm, from Mersen, France), was placed on the inner wall of the cell, covering almost the total internal perimeter, while the anode, a 24-cm2 boron-doped diamond (BDD) thin film deposited on niobium support (from CONDIAS GmbH, Germany), was centered in the electrolytic cell and surrounded by the CF cathode. These electrodes have been selected for their excellent performance in EAOP reactions (Sirés et al. 2007). Compressed air was bubbled through the solutions 10 min before and during the electrochemical experiments to assure saturated O2 content for its reduction to H2O2 on the cathode surface (Eq. 2). The solution was stirred with a magnetic bar (250 rpm) to enhance the mass transport of reactants toward/from the electrodes. Groundwater was treated as received, at its natural pH (≈ 7). The applied current intensity and the potential difference of the electrochemical cell were measured by a DC power supply (HAMEG Instruments, HM 8040-3). The experiments were performed by duplicate being the standard deviation always lower than 5%.

Analytical methods

Samples at different reaction times were taken from the electrolytic cell and immediately analyzed. The four HCH isomers were identified and quantified by means of GC-MS, using 4-methylcyclohexanone as internal standard (ISTD). Samples were extracted in acetone by using solid-phase (SP) cartridges (C18-E, 55 μm, 70 Å, Phenomenex) and a Varian vacuum manifold 20 port model coupled to a KNF vacuum pump (4.0 bar). Prior to acetone elution, cartridges were vacuum-dried (10 mmHg) to remove water traces. The GC-MS, Thermo Scientific (Trace 1300-ISQ), used in this study is equipped with a TG-5-MS column. Helium was used as carrier gas (1.2 mL min−1). Extracted samples (3 μL) were manually injected. The GC injection port temperature was set at 250 °C. The temperature program started at 40 °C (held during 2 min), and then, the temperature ramp was set at 10 °C min−1 to 280 °C and maintained during 4 min. Analysis was carried out in EI mode (70 eV).

TOC of initial and treated liquid samples was determined by using a Shimadzu TOC-V analyzer as the difference between total carbon (TC) and inorganic carbon (IC). Reproducible TOC values were found by injecting 50 μL aliquots (accuracy of ± 2%).

Aromatic intermediates were identified by high-performance liquid chromatography (HPLC) using a Merck HITACHI Lachrom Liquid chromatography equipped with an L-2310 pump, fitted with a reverse phase column Pursopher RP-18, 5 μm, 25 cm × 4.6 mm (i.d.), and coupled with an L-2400 UV detector set at λ = 238 nm. The temperature of the column was maintained at 40 °C; the injection volume was set at 20 μL, and the eluent (30:70 methanol/water) was pumped to the system at 0.5 mL min−1. Short-chain carboxylic acids were determined by IC with anionic chemical suppression using a conductivity detector. A Metrosep A supp 5-250 column (25 cm long, 4-mm diameter) was used as stationary phase and 0.7 mL min−1 of an aqueous solution 3.2 mM of Na2CO3 and 1 mM of NaHCO3 as mobile phase. Ferrous iron in solution was measured by the o-phenantroline method (Sandell 1959). The pH evolution was measured using a Basic 20-CRISON pH electrode and the conductivity with a Methrom conductimeter.

The toxicity of the groundwater containing organochlorine pesticides and the treated solutions was evaluated by means of the Microtox® method, based on determining the inhibition of the bioluminescence of the marine bacteria Vibrio fischeri (provided by Hach Lange France SAS), according to the standard process (OIN 11348-3). The inhibition percentage was measured after 15 min of exposition of the bacteria to the electrochemically treated solutions at different reaction times and to the untreated groundwater. Prior to the measurements, possible residual H2O2 was removed by the addition of Na2SO3, the osmotic pressure of the samples was adjusted close to 2% NaCl, and the pH between 6.5 and 7.5. The bioluminescence measurements were carried out at 15 °C and by duplicate.

Results and discussion

Groundwater characterization

The groundwater treated in the present work is a colorless liquid with unpleasant odor. Its composition can be explained by the liquid wastes dumped in the landfill (containing HCH isomers and CBs) and the composition of the soil (marls, clays, and sandstones with high content in bicarbonates). A representative analysis of the groundwater is given by pH = 7 ± 0.2, conductivity = 3.7 ± 0.1 mS cm−1, TC = 70 ± 5 mg L−1, and TOC = 9 ± 0.4 mg L−1.

Four isomers of HCH were detected in the groundwater by GC-MS: α-HCH, β-HCH, δ-HCH, and γ-HCH (lindane) being the most abundant. Their concentrations are given in Table 1. Traces of other organochlorine compounds (non-quantified) were also detected: 1-4 dichlorobenzene (1,4-diCB), 1,2,4-trichlorobenzene (1,2,4-triCB), and pentachlorobenzene (PCB) (see Fig. 1).

The groundwater presents high concentration of inorganic salts (Table 2), mainly sulfates (782 mg L−1), chlorides (630 mg L−1), and bicarbonates (325 mg L−1) resulting in a conductivity value high enough (3.7 mS cm−1) to carry out the electrochemical experiments (Canizares et al. 2006). Therefore, the extra addition of supporting electrolyte is apparently not needed, which represents an advantage from the economic and operational point of view.

Among other metallic ions present in solution, collected in Table 2, a special attention has to be paid to iron ions because Fe2+ behaves as catalyst in EF process (Nidheesh and Gandhimathi 2012). This metal decomposes H2O2 into •OH, according to Fenton’s reaction (Eq. 3) and is regenerated electrochemically at the cathode (Eq. 4). Although ferrous iron concentration, [Fe2+]0 = 5.8 mg L−1 (≈ 0.1 mM), is relatively low, it is continuously generated at the cathode and therefore available during all the experiment. In fact, [Fe2+] is within the range commonly used in EF processes (0.05–0.2 mM) (Brillas et al. 2009; Labiadh et al. 2015). In this way, in addition to M(•OH) generated on the anode surface (Eq. 1), homogeneous •OH produced in the bulk can also oxidize the organic matter. Consequently, the EAOP experiments were carried out without extra catalyst addition.

Treatment of groundwater containing HCHs by EAOPs

The groundwater from lindane production site was treated as received, at circumneutral pH and, as stated above, without extra reagent addition (neither supporting electrolyte nor catalyst). Thereby, it is an efficient and economic process that combines characteristics of EF (generation of homogeneous •OH in the solution bulk through Fenton reaction (Eq. 2) thanks to the reaction between electrochemically generated H2O2 and ferrous iron naturally presents in ground wastewater) and AO (no catalyst is added and the pH is not adjusted).

Oxidative degradation of HCH isomers

The GC-MS chromatogram of the groundwater before the advanced electrochemical treatment is shown in Fig. 1. The main signals correspond to the different HCH isomers at different retention times, i.e., α-HCH (11.60 min), γ-HCH (12.32 min), β-HCH (12.67 min), and δ-HCH (12.79 min). As it can be seen, three CBs 1,4-diCB (5.42 min), 1,2,4-triCB (7.23 min), and PCB (10.47 min) were also detected at low concentrations. The signal corresponding to the ISTD appears at the beginning of the chromatogram (4.79 min), and the additional signals, of minor importance (5.21 and 7.22 min), are associated to the C-18 cartridges used during the extraction process. As observed in Fig. 1, after 60 min of electrochemical treatment at 400 mA current intensity, the chromatographic peaks corresponding to HCHs are greatly reduced. The same occurred for the other organochlorine compounds. After 240-min electrolysis, only trace-level concentrations of the chlorinated compounds are observed, indicating that EAOPs constitute an efficient technology for the destruction of chlorinated pollutants. It should be noted that the concentration of these compounds remains constant at the end of the experiment when no current is applied (data not shown).

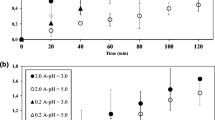

The decay of the normalized concentration of the four HCH isomers present in the groundwater with treatment time is depicted in Fig. 2. The isomers differ from each other in the relative position of the chlorine atoms, containing from three (γ) to six equatorial (β) chlorines and from zero (β) to three (γ) axial chlorines. Isomers with the largest ratio of axial to equatorial chlorines are expected to be more reactive and therefore more easily oxidized, since equatorial chlorine substituents contribute toward lower overall energy than their axial counterparts (Buser and Muller 1995; Elliott et al. 2008). However, the evolution of the four HCH isomers during the electrochemical treatment is quite similar regardless the chlorine position and highlighting their complete oxidation at 4-h electrolysis time.

Mineralization of groundwater polluted by organochlorine compounds

The electrochemical oxidation has proven to be highly effective in the destruction of HCH isomers. However, these compounds represent only around 5% of the initial TOC (0.42 of 9 mg L−1). Therefore, in order to really evaluate the efficiency of the process, information concerning the removal of other organic pollutants is also required. This information can be provided by the mineralization degree of the treated groundwater.

The evolution of normalized TOC concentration in groundwater with electrolysis time is shown in Fig. 3. The results obtained without current intensity are also included for the sake of comparison. As can be seen, TOC concentration remains practically unchanged during the 360 min of experimentation, discarding the volatilization of non-identified organic compounds. When a current intensity of 400 mA is applied to the electrolytic system, the organic carbon content follows a progressive decay with electrolysis time until reaching 90% TOC removal at the end of the experiment. TOC abatement is the consequence of the concomitant effect of hydroxyl radicals generated over the BDD surface (M(•OH)) (Eq. 1) and in the bulk (•OH) through the Fenton reaction (Eq. 3). Moreover, chlorides present in the groundwater can also play an important role in the oxidation of organic matter. When working with BDD anode, Cl− can be progressively oxidized in the anode surface to give different chlorinated species (dissolved Cl2, hypochlorite, chlorite, chlorate, and perchlorate) that could contribute to the oxidation of organic pollutants in the bulk (Mascia et al. 2010; Randazzo et al. 2011). On the other hand, when working with high oxygen overvoltage anode materials such as BDD, persulfate, a weak oxidant (Sirés et al. 2007) can be generated in the presence of sulfate ions (Brillas et al. 2009; Komtchou et al. 2015) and react with free hydroxyl radical to give a strong oxidant reagent (sulfate anion radical, SO4•−) (Criquet and Leitner 2009), which is able to remove organic pollutants from water (Criquet and Leitner 2009; Komtchou et al. 2015).

As can be seen, the removal of TOC is more pronounced in the early stages of the electrochemical reaction, until 120 min, where a mineralization degree of around 80% is achieved. After that, TOC elimination becomes more gradual, providing an insight into the higher refractoriness of the generated intermediate compounds during the treatment, in particular, short-chain carboxylic acids which are well known to be resistant to hydroxyl radicals compared to other organics (Brillas et al. 2009; Oturan and Aaron 2014). The residual TOC (0.8 mg L−1) remaining at the end of electrolysis is formed by these acids, in particular by formic acid. On the other hand, the production of parasitic reactions between hydroxyl radicals and the inorganic anions present in the groundwater (both chlorides and carbonates) is not negligible, becoming more important at the end of the treatment, when the concentration of organic matter is weak.

These results highlighted the effectiveness of EAOPs not only in the destruction of the highly toxic organochlorine pesticides but also in the mineralization of the solution thus ensuring the disposal of other potentially harmful contaminants contained in groundwater.

Evolution of pH

The evolution of pH during electrolysis time is shown in Fig. 4. As can be seen, the pH increases slightly in the first minutes of treatment until reaching a maximum value around pH = 8 at 10 min. After that, the pH rapidly decreases from 8 to acid values, around 3, at about 60-min electrolysis time. From this moment, the pH remains basically stable until the end of the experiment. Besides the acidification caused by anodic water oxidation and the alkalization caused by cathodic water reduction (Canizares et al. 2009), the changes observed in the pH during the treatment can be associated to the changes in the water composition. Therefore, the pH decrease may be related to the progressive oxidation of chloride ions releasing H+ and the formation of short-chain carboxylic acids (Figs. 5 and 6) during oxidation of HCH isomers and other organics present in the groundwater (Sirés et al. 2014; Martinez-Huitle et al. 2015). Thus, several carboxylic acids (acetic, formic, chloroacetic, succinic, and oxalic acids) have been detected (some of them in non-negligible concentrations) in the treated solutions.

Identification of intermediated compounds and proposed oxidation pathway

Samples taken at different electrolysis times were analyzed by chromatographic techniques such as GC-MS, reversed-phase HPLC, and IC in order to identify as much as possible the intermediate compounds formed during the electrooxidation of organochlorine compounds by M(•OH)/•OH. The identification of organic compounds by GC-MS was assessed using the NIST database library. Analyses by HPLC and IC were conducted by comparison of the retention time of chromatographic peaks with those of standard compounds. In order to make easier the identification of certain compounds at short reaction times, additional experiments at lower current intensity of 100 mA were performed. In this way, the oxidative degradation of HCHs and their reaction intermediates slows down, and therefore, the accumulation of these compounds in the reaction medium is favored. Moreover, prior to GC-MS analyses, samples were pre-concentrated.

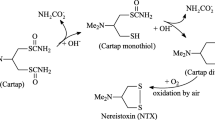

In addition to the four isomers of HCH and CBs, identified in the starting groundwater, other chlorinated aliphatics (penta- and tetra-chlorocyclohexene) and aromatics (CB, 1,4-diCB, 1,2,3,5-, and 1,2,4,5-tetraCB) were detected in low concentrations by GC-MS from the beginning of the treatment. Moreover, three hydroxylated compounds were also identified by HPLC (2,4-dichlorophenol, 1,2,4-trichlorophenol, and hydroxyquinol) in trace level. Some carboxylic acids (acetic, chloroacetic, formic, oxalic, and succinic acids) were identified and quantified by IC also from the earliest stages of the process. The evolution of these compounds with electrolysis time is shown in Fig. 5. Acetic acid appears in high concentration from the beginning of the treatment and reaches its maximum concentration (14.5 mg L−1) at 10 min. Then, its concentration progressively decreases until practically complete disappearance at 240 min. Chloroacetic acid was detected at small concentration (maximum around 1 mg L−1 at 30 min) and thereafter is quickly mineralized. Formic acid is also generated from the beginning of the process, reaching the maximum concentration (around 3 mg L−1) at about 30 min and then remains practically constant until the end of treatment, due to its weak reactivity toward •OH (Bocos et al. 2016). Thus, this acid represents the main cause of the residual TOC at the end of the treatment. On the other hand, oxalic and succinic acid were detected in trace amounts (< 0.1 mg L−1).

Based on the identified intermediate compounds by the different techniques and TOC removal results, the parallel series reaction pathway shown in Fig. 6 was proposed for the oxidation of organochlorine pesticides by M(•OH)/•OH produced in a BDD/CF electrochemical cell. Firstly, aromatic and non-aromatic chlorinated compounds and chlorinated and hydroxylated cyclic compounds appear as a consequence of dechlorination reactions via chlorine and hydrogen abstraction reactions (Wacławek et al. 2016) and •OH addition reactions (hydroxylation) from HCHs and CBs, respectively. All these compounds are more easily oxidized by hydroxyl radicals than the former (Peng et al. 2015), and they rapidly disappear from the reaction medium to generate carboxylic acids (acetic, chloroacetic, formic, succinic, and oxalic acids). These compounds were identified from the earliest stages of the process, suggesting that (i) HCHs can be simultaneously attacked by M(•OH)/•OH in different positions, yielding carboxylic acids upon ring opening or, more likely (ii) some organic compounds present in the starting groundwater and non-identified by the analysis used in the present work are rapidly oxidized by the action of M(•OH)/•OH to short-chain organic acids. Finally, these compounds are slowly transformed into carbon dioxide, chloride, and water. It should be noted the release of chlorides in the sequential steps of the oxidation reactions.

TOC balance

The TOC value calculated from the identified compounds (HCHs) in the starting groundwater (0.42 mg L−1) represents only the 5% of the experimental measure (9 mg L−1), highlighting the occurrence of other non-identified organic compounds in non-negligible concentrations. Once the electrochemical oxidation process begins, the value of TOC calculated from the identified compounds (TOCHCHs + TOCcarboxylic acids) is greatly increased, and it was fairly close to the experimental TOC measurements from 30-min electrolysis time until the end of the experiment. The time profile of these measures is provided in Fig. 7, in addition to the percentage of identified TOC. It is noteworthy that practically 100% of the TOC is identified from 60-min electrolysis time.

Ecotoxicity assays

The evolution of ecotoxicity of the groundwater during the treatment by electrochemical oxidation with the BDD/CF system at 400 mA is depicted in Fig. 8. The toxicity is measured by Microtox® method from inhibition of luminescence of bacteria Vibrio fischeri. As can be observed, the luminescence inhibition increases strongly at the initial stages of the treatment (from 30% for the starting solution to 100% at 10-min electrolysis time), indicating the quick formation of intermediate products rather more toxic than the parent pollutants (Dirany et al. 2011). The cyclic compounds appearing in the first step of the treatment (see Fig. 6) seem to be the responsible of this increased bioluminiscence inhibition. However, after 15-min electrolysis time, the toxicity of the solution exhibits an important decrease (10% from 120-min reaction time), highlighting the complete and rapid destruction of these toxic intermediates. Although the toxicity of the electrochemically treated solution is not completely removed (8% of inhibition at the end of the treatment), it is significantly lower than that corresponding to the starting groundwater. The low residual toxicity at the end of the process could be attributed to the presence of formic acid (the last end-product remained in the solution), chloride ions, and/or their oxidation products (Cl2, hypochlorite, chlorite, chlorate, and perchlorate).

Conclusions

This paper shows that EAOPs constitute a highly efficient technology for the treatment of polluted groundwater containing organochlorine pesticides such as lindane and other HCH isomers as well as CBs. Thanks to the versatility of this technology, it can be also applied to the decontamination of polluted water from “pump and treat,” leachates, lixiviates from rainstorm, etc.

Taking advantage of the natural characteristics of the groundwater from lindane production site (conductivity = 3.7 mS cm−1 and [Fe2+] = 5.8 mg L−1), the electrochemical treatment can be carried out without any reagent addition (electrolyte, catalyst, pH adjusters), which greatly simplifies the process and reduces the operation cost. Using a BDD anode and CF cathode, the complete elimination of all the organic compounds identified in the starting groundwater (four isomers of HCH and several CBs) and 90% of TOC removal is achieved at 4-h electrolysis time with a current intensity of 400 mA. The starting compounds are transformed in a first stage into chlorinated and hydroxylated intermediates that are rapidly oxidized to non-toxic carboxylic acids (mainly acetic, chloroacetic, and formic acids) and/or mineralized. Despite the large difference between the measured and calculated TOC for the starting groundwater, the carbon balance is fully accomplished after the treatment. Further studies, including the effect of current intensity, the role of chloride ions during electrooxidation, and the cost evaluation of the process would be very valuable toward an effective implementation of the treatment.

References

Bocos E, Oturan N, Sanromán MÁ, Oturan MA (2016) Elimination of radiocontrast agent diatrizoic acid from water by electrochemical advanced oxidation: kinetics study, mechanism and mineralization pathway. J Electroanal Chem 772:1–8. https://doi.org/10.1016/j.jelechem.2016.04.011

Brillas E, Martínez-Huitle CA (2015) Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods. An updated review. Appl Catal B-Environ 166:603–643

Brillas E, Sirés I, Oturan MA (2009) Electro-Fenton process and related electrochemical technologies based on Fenton’s reaction chemistry. Chem Rev 109(12):6570–6631. https://doi.org/10.1021/cr900136g

Buser HR, Muller MD (1995) Isomer and enantioselective degradation of hexachlorocyclohexane isomers in sewage-sludge under anaerobic conditions. Environ Sci Technol 29(3):664–672. https://doi.org/10.1021/es00003a013

Canizares P, Hernández-Ortega M, Rodrigo M, Barrera-Díaz C, Roa-Morales G, Sáez C (2009) A comparison between conductive-diamond electrochemical oxidation and other advanced oxidation processes for the treatment of synthetic melanoidins. J Hazard Mater 164(1):120–125. https://doi.org/10.1016/j.jhazmat.2008.07.134

Canizares P, Martínez L, Paz R, Saez C, Lobato J, Rodrigo MA (2006) Treatment of Fenton-refractory olive oil mill wastes by electrochemical oxidation with boron-doped diamond anodes. J Chem Technol Biot 81(8):1331–1337. https://doi.org/10.1002/jctb.1428

Chang C, Lian F, Zhu L (2011) Simultaneous adsorption and degradation of gamma-HCH by nZVI/Cu bimetallic nanoparticles with activated carbon support. Environ Pollut 159(10):2507–2514. https://doi.org/10.1016/j.envpol.2011.06.021

Criquet J, Leitner NKV (2009) Degradation of acetic acid with sulfate radical generated by persulfate ions photolysis. Chemosphere 77(2):194–200. https://doi.org/10.1016/j.chemosphere.2009.07.040

Dirany A, Efremova-Aaron S, Oturan N, Sirés I, Oturan MA, Aaron JJ (2011) Study of the toxicity of sulfamethoxazole and its degradation products in water by a bioluminescence method during application of the electro-Fenton treatment. Anal Bioanal Chem 400(2):353–360. https://doi.org/10.1007/s00216-010-4441-x

Dominguez CM, Parchão J, Rodriguez S, Lorenzo D, Romero A, Santos A (2016) Kinetics of lindane dechlorination by zero valent iron microparticles: effect of different salts and stability study. Ind Eng Chem Res 55(50):12776–12785. https://doi.org/10.1021/acs.iecr.6b03434

Elliott DW, Lien H, Zhang W (2008) Zerovalent iron nanoparticles for treatment of ground water contaminated by hexachlorocyclohexanes. J Environ Qual 37(6):2192–2201. https://doi.org/10.2134/jeq2007.0545

Fernández J, Arjol M, Cacho C (2013) POP-contaminated sites from HCH production in Sabiñánigo, Spain. Environ Sci Pollut Res 20(4):1937–1950. https://doi.org/10.1007/s11356-012-1433-8

Kesraoui-Abdessalem A, Bellakhal N, Oturan N, Dachraoui M, Oturan MA (2010) Treatment of a mixture of three pesticides by photo-and electro-Fenton processes. Desalination 250(1):450–455. https://doi.org/10.1016/j.desal.2009.09.072

Khan S, Han C, Khan HM, Boccelli DL, Dionysiou DD (2017) Efficient degradation of lindane by visible and simulated solar light-assisted S-TiO2/peroxymonosulfate process: kinetics and mechanistic investigations. J Mol Catal A-Chem 428:9–6. https://doi.org/10.1016/j.molcata.2016.11.035

Komtchou S, Dirany A, Drogui P, Bermond A (2015) Removal of carbamazepine from spiked municipal wastewater using electro-Fenton process. Environ Sci Pollut Res 22(15):11513–11525. https://doi.org/10.1007/s11356-015-4345-6

Labiadh L, Oturan MA, Panizza M, Hamadi NB, Ammar S (2015) Complete removal of AHPS synthetic dye from water using new electro-Fenton oxidation catalyzed by natural pyrite as heterogeneous catalyst. J Hazard Mater 297:34–41. https://doi.org/10.1016/j.jhazmat.2015.04.062

Madaj R, Sobiecka E, Kalinowska H (2017) Lindane, kepone and pentachlorobenzene: chloropesticides banned by Stockholm convention. Int J Environ Sci Technol:1–10. https://doi.org/10.1007/s13762-017-1417-9), https://doi.org/10.1007/s13762-017-1417-9)

Martínez-Huitle CA, Brillas E (2009) Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods: a general review. Appl Catal B-Environ 87(3-4):105–145. https://doi.org/10.1016/j.apcatb.2008.09.017

Martinez-Huitle CA, Rodrigo MA, Sires I, Scialdone O (2015) Single and coupled electrochemical processes and reactors for the abatement of organic water pollutants: a critical review. Chem Rev 115(24):13362–13407. https://doi.org/10.1021/acs.chemrev.5b00361

Mascia M, Vacca A, Polcaro AM, Palmas S, Ruiz JR, Da Pozzo A (2010) Electrochemical treatment of phenolic waters in presence of chloride with boron-doped diamond (BDD) anodes: experimental study and mathematical model. J Hazard Mater 174(1-3):314–322. https://doi.org/10.1016/j.jhazmat.2009.09.053

Nidheesh PV (2015) Heterogeneous Fenton catalysts for the abatement of organic pollutants from aqueous solution: a review. RSC Adv 5(51):40552–40577. https://doi.org/10.1039/C5RA02023A

Nidheesh PV, Gandhimathi R (2012) Trends in electro-Fenton process for water and wastewater treatment: an overview. Desalination 299:1–15. https://doi.org/10.1016/j.desal.2012.05.011

Oturan MA (2000) An ecologically effective water treatment technique using electrochemically generated hydroxyl radicals for in situ destruction of organic pollutants. Application to herbicide 2,4-D. J Appl Electrochem 30:477–482

Oturan MA, Aaron JJ (2014) Advanced oxidation processes in water/wastewater treatment: principles and applications. A review. Crit Rev Environ Sci Technol 44(23):2577–2641. https://doi.org/10.1080/10643389.2013.829765

Oturan MA, Brillas E (2007) Electrochemical advanced oxidation processes (EAOPs) for environmental applications. Port Electrochim Acta 25(1):1–18. https://doi.org/10.4152/pea.200701001

Panizza M, Cerisola G (2009) Direct and mediated anodic oxidation of organic pollutants. Chem Rev 109(12):6541–6569. https://doi.org/10.1021/cr9001319

Peng L, Deng D, Guan M, Fang X, Zhu Q (2015) Remediation HCHs POPs-contaminated soil by activated persulfate technologies: feasibility, impact of activation methods and mechanistic implications. Sep Purif Technol 150:215–222. https://doi.org/10.1016/j.seppur.2015.07.002

Randazzo S, Scialdone O, Brillas E, Sirés I (2011) Comparative electrochemical treatments of two chlorinated aliphatic hydrocarbons. Time course of the main reaction by-products. J Hazard Mater 192(3):1555–1564. https://doi.org/10.1016/j.jhazmat.2011.06.075

Rodrigo MA, Oturan N, Oturan MA (2014) Electrochemically assisted remediation of pesticides in soils and water: a review. Chem Rev 114(17):8720–8745. https://doi.org/10.1021/cr500077e

Sandell EB (1959) Colorimetric determination of traces of metals. Interscience Publishers Inc., New York, Vol. 59, No. 6, p. 481

Sirés I, Brillas E, Oturan MA, Rodrigo MA, Panizza M (2014) Electrochemical advanced oxidation processes: today and tomorrow. A review. Environ Sci Pollut Res 21(14):8336–8367. https://doi.org/10.1007/s11356-014-2783-1

Sirés I, Garrido JA, Rodriguez RM, Brillas E, Oturan N, Oturan MA (2007) Catalytic behavior of the Fe+3/Fe+2 system in the electro-Fenton degradation of the antimicrobial chlorophene. Appl Catal B-Environ 72(3-4):382–394. https://doi.org/10.1016/j.apcatb.2006.11.016

Vasudevan S, Oturan MA (2014) Electrochemistry as cause and cure in water pollution. An overview. Environ Chem Lett 12(1):97–108. https://doi.org/10.1007/s10311-013-0434-2

Vega M, Romano D, Uotila E. (2016) Lindane (persistent organic pollutant) in the EU. Directorate General for Internal Policies. Policy Department C: Citizens’ Rights and Constitutional Affairs. Petitions (PETI). PE 571.398

Vijgen J (2006) The legacy of lindane HCH isomer production. Main report. International HCH & Pesticides Association, Holte, January

Vijgen J, Abhilash P, Li YF, Lal R, Forter M, Torres J, Singh N, Yunus M, Tian C, Schäffer A (2011) Hexachlorocyclohexane (HCH) as new Stockholm convention POPs—a global perspective on the management of Lindane and its waste isomers. Environ Sci Pollut Res 18(2):152–162. https://doi.org/10.1007/s11356-010-0417-9

Wacławek S, Antoš V, Hrabák P, Černík M, Elliott D (2016) Remediation of hexachlorocyclohexanes by electrochemically activated persulfates. Environ Sci Pollut Res 23(1):765–773. https://doi.org/10.1007/s11356-015-5312-y

Wang Z, Peng P, Huang W (2009) Dechlorination of gamma-hexachlorocyclohexane by zero-valent metallic iron. J Hazard Mater 166(2-3):992–997. https://doi.org/10.1016/j.jhazmat.2008.11.106

Yahya MS, Oturan N, El Kacemi K, El Karbane M, Aravindakumar CT, Oturan MA (2014) Oxidative degradation study on antimicrobial agent ciprofloxacin by electro-Fenton process: kinetics and oxidation products. Chemosphere 117:447–454. https://doi.org/10.1016/j.chemosphere.2014.08.016

Acknowledgments

The authors acknowledge Université Paris-Est Marne-la-Vallée (France) for research facilities. Carmen M. Dominguez acknowledges the Spanish MINECO for “Juan de la Cierva” post-doctoral grant (FJCI-2014-20732) and the “José Castillejo” mobility program (CAS16/00255).

Funding

The authors acknowledge financial support from Comunidad Autonoma of Madrid (Project S2013-MAE-2739 CARESOIL-CM) and from the Spanish MINECO (Project CTM2013-43794-R and CTM2016-77151-C2-1-R).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Vítor Pais Vilar

Rights and permissions

About this article

Cite this article

Dominguez, C.M., Oturan, N., Romero, A. et al. Removal of organochlorine pesticides from lindane production wastes by electrochemical oxidation. Environ Sci Pollut Res 25, 34985–34994 (2018). https://doi.org/10.1007/s11356-018-1425-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-1425-4