Abstract

A native bacterial strain with high capability for Cr (VI) removal was isolated from tannery sediments located in Elena (Córdoba Province, Argentina). The strain was characterized by amplification of 16S rRNA gene and identified as Serratia sp. C8. It was able to efficiently remove different Cr (VI) concentrations in a wide range of pHs and temperatures. The addition of different carbon sources as well as initial inoculum concentration were analyzed, demonstrating that Serratia sp. C8 could reduce 80 % of 20 mg/L Cr (VI) in a medium containing glucose 1 g/L, at pH 6–7 and 28 °C as optimal conditions, using 5 % inoculum concentration. The mechanisms involved in Cr (VI) removal were also evaluated. The strain was capable of biosorpting around 7.5–8.5 % of 20 mg/L Cr on its cell surface and to reduce Cr (VI). In addition, approximately a 54 and 46 % of total Cr was detected in the biomass and in the culture medium, respectively, and in the culture medium, Cr (III) was the predominant species. In conclusion, Serratia sp. C8 removed Cr (VI) and the mechanisms involved in decreasing order of contribution were as follows: reduction catalyzed by intracellular enzymes, accumulation into the cells, and biosorption to the microbial biomass. This strain could be a suitable microorganism for Cr (VI) bioremediation of tannery sediments and effluents or even for other environments contaminated with Cr.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Leather industries that extensively employ compounds containing chromium (Cr) (such as Cr (III) salts) in the tanning process usually discharge effluents with high Cr levels into natural water resources, mostly without proper effluent treatment, resulting in anthropogenic contamination (Cheung and Gu 2007; Garg et al. 2012). For this reason, this metal is one of the most common inorganic pollutants present in the surroundings of tanneries. Even though trivalent chromium (Cr (III)) is commonly used for leather processing, the environmental conditions prevailing at the site of discharge, such as high oxygen concentration or the presence of manganese oxide, can promote although in small concentrations the oxidation of Cr (III) to Cr (VI) (Benazir et al. 2010; Oliveira 2012). Thus, we decided to focus in Cr (VI) remediation because of its higher toxicity than Cr (III). Cr toxicity depends on the metal redox state, since Cr (III) is an important micronutrient for cell metabolism that is required as co-factor by some enzymes, while hexavalent form has carcinogenic and teratogenic effects. The major toxicity of Cr (VI) is related with its high solubility, availability, and mobility in soil as well as through biological membranes (Song et al. 2009; Oliveira 2012). Thus, Cr (VI) has been classified by the US Environmental Protection Agency (USEPA) as a contaminant from class A (Benazir et al. 2010; Pajor et al. 2012). As a consequence, there are some reglamentations that establish maximum allowed levels of Cr (VI) in water. For instance, in Argentina, the Food Argentinean code has established 0.05 mg/L of Cr (VI) and 0.5 mg/L of total Cr (Cr III plus Cr VI) as maximum levels in drinking water, while other reglamentations establish 0.2 mg/L Cr (VI) and 2 mg/L of Cr (III) as maximum concentrations allowed in the discharge of sewage collectors, rain ducts, and/or waterways (Romero et al. 2006).

Cr (VI) removal from the environment, mainly from tannery effluents and sediments, is of special concern for Environmental Organizations and researchers. In fact, several physicochemical methods to remove this heavy metal from contaminated areas have been described in the last few years (Hafez et al. 2002; Esmaeili et al. 2005; Ahluwalia and Goyal 2007). Unfortunately, in developing countries, none of these methods have achieved economic viability. Moreover, some of them produce voluminous wastes, whose disposal creates a secondary pollution again. Thus, microbial bioremediation emerges as a cost-competitive strategy, environmentally friendly, and beneficial bioresource for removing Cr and many other hazardous contaminants from tannery and other industrial wastes (Garg et al. 2012). Bioremediation of Cr involves different strategies that include biosorption, bioreduction, and bioaccumulation (Srinath et al. 2002; Focardi et al. 2013). Biosorption is a non-directed physicochemical interaction between metal and the cellular components of biological species. In this context, most of the studies related to Cr biosorption have been carried out using non-living and resting cells of microorganisms. On the other hand, in bioreduction processes, alterations in the oxidation/reduction state of toxic metals occur. As it is well known, Cr (VI) enters the cell through sulfate transport proteins (active transport), due to its ionic and structural similarity. Once into bacterial cells, Cr (VI) is reduced to Cr (III), which is an interesting mechanism of bacteria since it decreases the Cr toxicity to living organisms (Smutok et al. 2011). Cr (VI) reduction can be produced inside cells, in cell surface, or in the surrounding media. The intracellular reduction is carried out by cytoplasmic reductases or other reductases associated to cytoplasmic membranes, whereas reduction associated to cell surfaces occurs at the expense of cell wall compounds with redox potential. Besides, Cr (VI) reduction would be carried out by extracellular reductases secreted by microorganisms in the surrounding medium (Quintelas et al. 2009; Mangaiyarkarasi et al. 2011; Chen et al. 2012). Regarding bioaccumulation, it constitutes a metabolically active process in living organisms that involves adsorption, intracellular accumulation, and bioprecipitation mechanisms.

In order to develop an efficient system for Cr (VI) bioremediation, microorganisms belonging to polluted sites are preferred. This is due to they will be able to tolerate it and, probably, they could develop some mechanisms that allow them to remove this pollutant. Moreover, some native microorganisms could even have the ability to remove several pollutants at once (Tripathi et al. 2011; Chandra et al. 2011). Therefore, we have isolated, selected, identified, and characterized a bacterial strain with high tolerance and ability for Cr (VI) removal, from tannery effluent and sediments. The optimization of several growth parameters for the improvement of Cr (VI) removal process was studied. In addition, the main mechanisms involved in Cr bioremediation by this microorganism as well as the final localization of Cr (VI) were determined. This study will contribute to the knowledge related to the ability of Cr (VI) bioremediation of a native microorganism, in order to estimate its ability to reduce Cr levels in the environment and, hence, its potential use to minimize the environmental impact of this metal in soils and aquifers.

Materials and methods

Samples collection and isolation of Cr (VI) tolerant strains

Several samples were obtained from effluents and contaminated sediments from a tannery located in Elena (Córdoba Province), Argentina. To select Cr (VI) tolerant strains, samples were appropriately diluted and spread on agar plates with TY medium [(g/L): 5 tryptone; 3 yeast extract; 0.65 CaCl2; 13 agar] supplemented with 100 mg/L Cr (VI) as Cr2O7K2 (Sigma). After 7 days of incubation at 28 ± 2 °C, morphologically different colonies growing in the plates were isolated and selected for following assays.

Evaluation of Cr (VI) tolerance

The isolated bacteria were spread on solid TY medium supplemented with different Cr (VI) concentrations (100 to 500 mg/L) in order to determine their maximum tolerance to this heavy metal. It was established as the highest concentration of the contaminant at which bacterial growth could be appreciated after 10 days of incubation at 28 ± 2 °C and it was expressed as maximum tolerated concentration (MTC).

One strain isolated from sediments, named C8 until its identification, with capability to tolerate high Cr (VI) concentrations was selected, characterized, and identified for further Cr (VI) removal studies.

Characterization and identification of C8 isolate

C8 isolate was characterized based on its morphological, physiological, and biochemical features. Thus, it was stained using a Gram staining kit (Britania) and observed using an Axiopot (Carl Zeiss) microscope. The oxidase activity was determined using oxidase disks (Britania), and catalase activity was evaluated through O2 production by transferring one single colony onto a microscopy slide and adding a drop of 3 % hydrogen peroxide solution.

All the biochemical tests were performed using a commercial kit (API 20 E from BioMerieux® SA). The kit was used following the manufacturer’s instructions. Results of the biochemical tests were analyzed with API web program that allowed identification of the microorganism.

Identification of C8 strain through molecular methods was also carried out. For this, 16S rDNA gene was amplified and sequenced using forward (5′ -CCAGCAGCCGCGGTAATACG -3′) and reverse (5′ -TACCAGGGTATCTAATCC- 3′) primers after genomic DNA extraction and the corresponding PCR. All the procedures were carried out by “MacroGen” company (Seoul, Korea). The sequence was compared and identified using BLAST program (Altschul et al. 1997, http://www.ncbi.nlm.lih.gov) and deposited in GenBank, under accession number JX258135.

Cr (VI) removal assays

Cr (VI) removal studies were carried out to establish the potential of C8 strain to remediate this metal. For these assays, the bacterial strain was grown on TY liquid medium during 24 h, until late exponential phase. Then, this strain was inoculated (at 7.5 % V/V) in Erlenmeyer flasks containing 20 mL of TY medium with different Cr (VI) concentrations (5, 20, 35, 50, and 100 mg/L). The flasks were placed in a shaker at 150 rpm and 28 ± 2 °C. Samples were taken each 24 h, and bacterial biomass and Cr (VI) removal were analyzed during 5 days, as it is described below. All the experiments were carried out in triplicate. No inoculated media but with the same characteristics of the conditions tested were performed as abiotic control.

Factors affecting Cr (VI) removal

Optimum culture conditions for C8 strain were determined in order to maximize its removal capability. The experiments were performed as it was above described. A selected Cr (VI) concentration (20 mg/L) was added to TY medium and the following conditions were evaluated:

-

(a)

Carbon sources: 1 g/L of glucose, citrate, sodium acetate, or sucrose. Besides, glucose 0.5 and 1.5 g/L were also assayed

-

(b)

pH: from 4 to 9

-

(c)

Temperature: cultures were incubated at temperatures from 20 to 37 °C

-

(d)

Initial inoculum concentration: varied between 1 and 10 % V/V

All the assays were performed during 5 days. At this time, Cr (VI) removal was tested, as it is described below. Different abiotic controls were carried out for each condition (carbon sources, pH, and temperatures).

Determination of the mechanisms involved in Cr (VI) removal

To understand the mechanisms involved in Cr (VI) removal by C8 strain, different experiments were carried out, including metal biosorption on bacterial biomass, chromate reductase activity, and intracellular accumulation.

Biosorption assays

Two methodologies were used based on biosorption of Cr (VI) on bacterial cells exposed to acidic conditions (Volesky 1999) and bacterial cells treated by heating. To carry out the former methodology, C8 strain was grown in liquid TY medium during 24 h and then centrifuged at 12,000 rpm at 4 °C for 15 min. The obtained pellet (around 30 mg) was washed twice with 0.9 % NaCl and inoculated in Erlenmeyer flasks containing 10 mL of TY medium with Cr (VI) 20 mg/L and adjusted to acidic pH (pH 2). The flasks were placed in a shaker at 150 rpm, 28 °C for 5 days and then used for Cr (VI) removal determination. These assays were performed in quadruplicate. Controls consisting of TY medium (pH 2) supplemented with Cr (VI) 20 mg/L but without bacteria were also evaluated.

The same procedure was carried out to evaluate the biosorption of Cr (VI) into bacterial biomass inactivated by heating. The strain grown in TY medium (pH 7) and then the autoclaved cells were incubated during 5 days in TY medium with 20 mg/L Cr (VI). For both assays, the concentration of residual Cr (VI) was determined as it is described in “Cr (VI) determination.”

Cr (VI) reduction by cell free supernatant and cell free extract

This assay was performed in order to determine the involvement of intracellular or extracellular reductases in Cr (VI) removal. For that, the procedure described by Bopp and Ehrlich (1988) was used with some modifications as described below. Cr (VI) reduction was determined by measuring its disappearance from supernatants or extracts.

Erlenmeyer flasks containing 50 mL of TY medium supplemented with 20 mg/L Cr (VI) were inoculated at 7.5 % V/V with a 24-h C8 strain culture. The flasks were incubated in an orbital shaker at 150 rpm, 28 °C for 24 h. Then, the cultures were centrifuged at 12,000 rpm at 4 °C for 15 min. The supernatants were centrifuged again under the same conditions and filtered using 0.22-μm Millipore filters (Bedford, USA) to remove remaining bacterial cells and were called cell-free supernatants (CFSs).

The pellets were washed twice with 0.9 % NaCl and they were homogenized with phosphate buffer saline (PBS) (1 mL/100 mg of wet weight). The pellet was disrupted at 4 °C for 3 cycles of 2 min each, with a gap of 6 s between the cycles, using a Sonic&Materials VibraTMCells sonicator. Unbroken cells and cell debris were removed by centrifugation at 12,000 rpm at 4 °C for 15 min. The supernatant was filtered with 0.22-μm Millipore filters and named as cell-free extract (CFE).

Both CFS and CFE were placed in tubes containing TY medium supplemented with 10 mg/L of Cr (VI) (in triplicate), and were incubated in an orbital shaker at 150 rpm and 28 °C during 24 h. Controls containing CFS and CFE were placed in thermostatic bath at 100 °C for 30 min to inactivate intra and extracellular reductases. In addition, for each treatment, cell-free controls were prepared to monitor whether abiotic Cr (VI) reduction occurred. Residual Cr (VI) was determined in all samples, after 24 h, as described in “Cr (VI) determination.”

Cr accumulation

Total Cr and Cr (VI) concentrations were determined in the supernatant as well as in the bacterial biomass. For that, a culture of C8 strain was grown in TY medium supplemented with 20 mg/L of Cr (VI) and glucose (1 g/L). After 5 days, this culture was centrifuged to obtain the supernatant and the biomass. In these fractions, Cr (VI) and total Cr were determined by diphenylcarbazide method (APHA 1998 modified method) and atomic absorption spectrophotometry (AAS), respectively. AAS determinations were made in a specialized laboratory (FARESTAIE laboratory (Mar del Plata, Argentina, using SHIMADZU AA-6800 Analyst). Cr (III) concentration was calculated as the difference between total Cr and Cr (VI).

Cr (VI) determination

Cr (VI) was determined by diphenylcarbazide method in acid solution, and the absorbance was measured at 540 nm. The reaction mixture contained 500 μL of each sample, 500 μL of H2SO4 0.2 N, 200 μL of diphenylcarbazide (5 mg/mL), and distilled water to complete a final volume of 5 mL (APHA 1998 modified method). The absorbance data were converted to Cr (VI) concentrations using a calibration curve.

Statistical analysis

In all experiments, three replicate experiments were performed for each sample. Results are presented as the mean and the standard error. The statistical significance of differences among values was assessed using Student’s t test and ANOVA. The post hoc Tukey test was applied to determine significant differences between treatments. Results were considered statistically significant when p < 0.05. The STATISTICA 6.0 (Statsoft, Inc., Tulsa, OK, USA) software was used.

Results and discussion

Isolation, characterization, and identification of C8 strain

Eight isolates resistant to Cr (VI) were obtained from tannery effluent and sediment samples and selected for tolerance assays. Among them, one isolate denominated C8, which showed a MTC of 180 mg/L Cr (VI) was selected for further studies. It is important to note that these native microorganisms could contribute to reduce Cr levels in the environment, from which they were isolated and therefore could minimize the environmental impact of this metal in soils and aquifers.

The isolated C8 strain was characterized as Gram-negative bacillus, catalase positive, and oxidase negative. Subsequently, based on biochemical characterization obtained through API 20E, the strain was identified as Serratia sp. Results of 16S rRNA gene amplification and sequencing indicated that it has a 99 % similarity with species closely related to Serratia genus; thus, the isolate was designated Serratia sp. C8. The ability of Serratia species to remediate Cr-polluted sites has been described by some authors (Srivastava and Thakur 2007; Beadregard et al. 2010; Zhang and Li 2011).

Cr (VI) removal assays

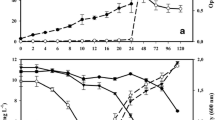

The effect of initial Cr (VI) concentrations (5 to 100 mg/L) on the overall rate of removal and cell growth was investigated after 5 days (Fig. 1).

The biomass was affected compared to the control when Cr (VI) concentrations were increased in the medium. The presence of 100 mg/L Cr (VI), the highest tested concentration, produced an approximately 50 % of growth inhibition. Regarding Cr (VI) removal efficiencies achieved by C8 strain, they varied between 75 and 16 % when the concentrations were increased from 5 to 100 mg/L Cr (VI), respectively. This trend was also observed in Acinetobacter sp. and Pseudomonas sp. (Farag and Zaki 2010). However, it must be emphasized that resistance to chromate is not a common property of Serratia sp., since normal enterobacteria cannot tolerate the presence of high levels of chromate (Wang et al. 1989).

The biomass diminution could be due to the high toxicity produced by high Cr (VI) concentrations that would affect the active metabolism, involving enzymatic activities and/or bioaccumulation. Besides, the lower growth observed with high Cr (VI) concentration would results in a lower adsorption surface for the binding of the contaminant, and consequently, a low removal was observed in this condition.

Based on the obtained results, 20 mg/L Cr (VI) was selected for further studies since a 50 % of removal was achieved and values close to this concentration are frequently found in wastewaters.

Factors affecting Cr (VI) removal

Microorganisms can remove metals through several mechanisms, which can be affected for different environmental or medium conditions.

Effect of the addition of different carbon sources and glucose concentrations

The addition of different carbon sources is of great importance in Cr (VI) removal studies since they could be used by the microorganisms as electron source to achieve Cr (VI) reduction and hence producing an improvement in the removal efficiency (Dey and Paul 2012). Thus, glucose, citrate, sodium acetate, and sucrose (1 g/L) were added to the culture medium containing 20 mg/L Cr (VI) (Fig. 2a). The removal efficiencies achieved by Serratia sp. C8 in TY medium containing citrate and acetate (48 %) did not showed significant differences compared with the control (without extra carbon source), after 5 days (p > 0.05). However, when the strain was grown in media containing glucose and sucrose, removal efficiencies significantly increased (p < 0.05), compared to the control (75 and 56 %, respectively). The observed differences in removal efficiencies suggest that Cr (VI) would be reduced to Cr (III) by the presence of chromate reductases. This process could involve electron transfer from a compound with lower redox potential (carbon source) to another with higher potential, such as Cr (VI). Moreover, it has been shown that Cr (VI)-reducing microorganism’s stimulation may be possible through the addition of relatively economical fermentable sources, such as molasses which was the by-product of sucrose production (Zhang and Li 2011). Therefore, a supplementary carbon source allowed a significant increase in Cr (VI) removal, being a simple and economic strategy that could be used at industrial level.

Based in the maximum Cr (VI) removal achieved with glucose addition, different concentrations of this carbon source were assayed (Fig. 2b). When glucose 1 and 1.5 g/L were added to the medium, the removal efficiencies showed similar values (around 75 %). However, lower removal efficiency was detected using glucose 0.5 g/L compared to the other assayed concentrations. These results confirm that glucose could be related with Cr (VI) removal process. The Cr (VI) removal rate of Serratia sp. C8 was high at 6 h (1.14 mg/L.h), whereas it was decreasing (0.3 and 0.02 mg/L h) at 24 and 96 h, respectively. However, the removal rate achieved by Serratia sp. C8 at 6 h was several times higher than the maximum reduction rate achieved by other strains, such as Serratia sp. Cr-10, growing in similar conditions (0.16 mg/L h) (Zhang and Li 2011).

Effect of pH and temperature

The pH is another important factor to be considered in Cr removal process because it determines its oxidation state (Mohan and Pittman 2006). Figure 3a shows that removal efficiency varied from 52 to 68 % when the pH range was 5 to 9 and no significant differences were observed between them (p > 0.05). However, the highest efficiency was obtained at pH 6 that was selected for following assays. On the contrary, at pH 4, the lowest Cr (VI) removal was observed. This could be explained since extreme pH, such as 4, can alter macromolecules integrity, making microorganisms susceptible to this acidic pH. Therefore, this destabilization would produce both structural and functional alterations that lead to cell death and, consequently, low removal efficiencies (Madigan et al. 2004).

Effect of temperature on Cr (VI) reduction was also studied and the highest efficiency was obtained at 28 °C (Fig. 3b). The removal efficiencies were significantly lower (p < 0.05) than that obtained at 28 °C (from 30 to 55 %) at temperatures below and above 28 °C. These differences in Cr (VI) removal could be related to Cr (VI) reduction mediated by enzymes, since pH and temperature changes may affect the enzyme ionization rate and the protein folding, consequently affecting enzyme activity (Zhang and Li 2011). Optimum pH and temperatures for Serratia sp. C8 are included among those described for microorganism growing in Cr (VI)-polluted sites (Chaturvedi 2011; Dey and Paul 2012). Moreover, it is important to note that microorganisms belong to Serratia genus are capable of growing in a wide range of pH (5–9) and temperatures (5–40 °C), and therefore, they are capable of removing Cr (VI) in these conditions. This capability is very interesting from an industrial point of view, since it allows future application for the treatment of environments with different characteristics.

Effect of inoculum concentration

The study was conducted using 20 mg/L Cr (VI) and inoculum concentrations from 1 to 10 %. The highest removal efficiency (70 %) was obtained when 5 % inoculum was used; however, similar and no significant differences in removal efficiency were obtained when the inoculum was 1, 7.5, and 10 % (Fig. 3c). This is another relevant parameter to consider in the removal of contaminants since not always a high inoculum concentration leads to a greater contaminant removal (Rajendran et al. 2012).

The factors that affected Cr (VI) reduction studied here (pH, temperature, inoculum size) are important environmental factors affecting remediation strategies for ecosystems polluted with natural or anthropogenic Cr (VI).

Determination of the mechanisms involved in Cr (VI) removal

Biosorption assays

A possible mechanism involved in Cr (VI) removal is the biosorption. This process depends on the external bacterial structure, and it is also affected by the presence of capsule, flagellums, and pills as well as the pH of the medium. For this reason, different adsorption values have been described for fungal and Gram-negative or Gram-positive bacteria (Li and Ramakrishna 2011). Different methods are used for the pre-treatment of cells to study biosorption including heat treatment, detergent washing, employ of acids, alkalis, enzymes, etc. We assayed two different treatments (acidic pH and heat), obtaining similar percentages of Cr biosorption (7.8 and 8.3 %), respectively, and no significant differences were observed between them (Fig. 4a). Gadd (1988) described that heat treatment exposes additional metal-binding groups in cells surface while, as it is well know, pH modifies the membrane cell charges. Thus, at pH 2, some sites of the cell membrane or cell wall are positively charged due to the excessive amount of H+ ions within the medium. This causes a strong attraction between these sites and negatively charged HCrO4 − ions; therefore, negative metal adsorption significantly increases. When pH value enhances, the surface of the adsorbent becomes neutral and a decrease in the adsorption is observed. This behavior is specific for Cr ions and it is different for divalent metals (El-Shafey 2005). However, the biosorption capability of Serratia sp. C8 would not depend on the pH of the medium, since similar results were obtained independently of the applied methodology.

Different mechanisms involved in Cr (VI) removal by Serratia sp. C8. a Biosorption. b Residual Cr (VI) determined after CFS and CFE treatment. c Biomass accumulation of total Cr and Cr distribution in supernatant [Cr (VI) and Cr (III)]. The assays were performed after 5 days of culture, with Cr (VI) 20 mg/L and glucose 1 g/L

Cr (VI) reduction by cell free supernatant and cell free extract

The localization of chromate reductase activity was carried out using CFS and CFE. In CFS, residual Cr (VI) was 100 % (Fig. 4b), suggesting that Serratia sp. C8 would not release such enzymes to the culture medium. On the contrary, only 18 % of residual Cr (VI) was found when CFE fraction was used, indicating the presence of intracellular reductases involved in Cr (VI) reduction. Thus, the location of enzymes involved in Cr (VI) reduction would be mainly associated with the soluble fraction of the cytoplasm of bacterial cells. Heated CFE, used as control, failed to reduce Cr (VI), confirming the obtained results. Bacterial chromate reductases have been located either in the membrane fraction (Cheung et al. 2006) or in the cytoplasm fractions of Cr (VI)-reducing bacteria (Desai et al. 2008). However, both enzyme localizations were described in some microorganisms such as Escherichia coli ATCC 33456 (Bae et al. 2005), Streptomyces sp. MC1 (Polti et al. 2010), and different Bacillus strains (Iftikhar et al. 2007; Sau et al. 2010). In this sense, Soni et al. (2012) demonstrated that the major chromate reductase activity is present in cytosolic fraction of different Bacillus strains, even though these enzymes could be also released to extracellular medium. On the contrary, despite chromate reductases have both extracellular and intracellular localization in Serratia sp. Cr-10, the main reductase activity was detected in the extracellular medium (Zhang and Li 2011).

In other enterobacteria, such as Pseudomona sp., the capability of Cr (VI) reduction constitutes an important mechanism to tolerate this pollutant, and the location of chromate reductases is restricted to the cytoplasm or, possibly, the periplasm. In this sense, soluble reductases activity may be enhanced by the addition of an electron donor, which has been reported previously with glucose in Pseudomonas fluorescens (Bopp and Ehrlich 1988). Similarly, this study showed a greater reduction of Cr (VI) by Serratia sp. C8, when glucose was added to the culture medium. In view of the obtained results, the main mechanism involved in Cr (VI) removal by Serratia sp. C8 would be the enzymatic reduction, due to the removal efficiency detected was 80 %.

Chromium accumulation

To elucidate if Cr accumulation could be another possible mechanism carried out by Serratia sp. C8 to remove this pollutant, concentrations of Cr (III) and Cr (VI) in supernatant and cell biomass were analyzed (Fig. 4c). The results showed that 46.3 % of Cr was in the supernatant, corresponding 30 % to Cr (III) and 16.3 % to Cr (VI). On the other hand, total Cr detected in biomass was around 53.7 % and it could corresponds to intracellular Cr as well as biosorpted Cr at the cell surface. Considering the high Cr (VI) reduction observed and its high toxicity, we would suggest that Cr accumulated in the biomass would be Cr (III). In this context, Polti et al. (2010) reported that Streptomyces sp. was able to accumulate Cr (1.48 mg/g) when microorganisms were grown in presence of 50 mg/L Cr (VI); however, Cr (VI) was not detected in the biomass, suggesting that total Cr would correspond to the Cr (III) form. In addition, Srivastava and Thakur (2007) detected Cr accumulation in E. coli PCP1, Pseudomonas aeruginosa PCP2, and Acinetobacter sp. PCP3, whereas Essahale et al. (2012) demonstrated chromate accumulation within Acinetobacter AB1 bacterial cells growing in presence of Cr (VI). It has been described that surface functional groups (e.g., carboxyl, phosphoryl, and hydroxyl) play a major role in bio-accumulation of metals. Moreover, Cr (VI) uptake is carried out by the sulfate transport pathway based on the chemical similarity between CrO4 2− and SO4 2− ions (Mabbett and Macaskie 2001). However, Gadd (1988) described that heavy-metal ions can be entrapped in the cellular structure and subsequently biosorpted onto its binding sites.

Therefore, the main mechanisms of Serratia sp. C8 for Cr (VI) removal would involve the uptake of toxic Cr (VI), then its subsequent reduction by intracellular reductases into less toxic Cr (III), and finally its accumulation into cells. However, biosorption is another mechanism that contributes to the overall removal process. It should be note that the reduction of Cr (VI) to Cr (III) is an important mechanism for Cr (VI) removal, considering the lower toxicity of Cr (III).

Conclusion

Serratia sp. C8 isolated from a tannery sediment was able to tolerate and remove high Cr (VI) concentrations. The optimal conditions to obtain the maximum removal were established, and approximately 80 % Cr (VI) removal efficiency was reached, at pH 6 and 28 °C. The mechanisms of Cr (VI) removal detected in Serratia sp. C8 would include biosorption, reduction of Cr (III) carried out by intracellular chromate reductases, and finally, bioaccumulation. This native strain could be used as a biotechnological tool to mitigate Cr (VI) pollution sites.

References

Ahluwalia SS, Goyal D (2007) Microbial and plant derived biomass for removal of heavy metals from waste water. Bioresour Technol 98:2243–2257

Altschul SF, Madden TL, Schäffer AA, Zhang J, Zhang Z, Miller W, Lipman DJ (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25:3389–3402

APHA (1998) (American Public Health Association), AWWA (American Water Works Association) and WEF (American Environment Federation) Standard methods for the examination of water and wastewaters (20th Ed.), Washington DC, USA

Bae WC, Lee HK, Choe YC, Jahng DJ, Lee SH, Kim SJ, Lee JH, Jeong BC (2005) Purification and characterization of NADPH-dependent Cr(VI) reductase from Escherichia coli ATCC 33456. J Microbiol 43:21–27

Beadregard DA, Yong P, Macaskie LF, Johns ML (2010) Using non invasive magnetic resonance imaging (MRI) to assess the reduction of Cr(VI) using a biofilm-palladium catalyst. Biotechnol Bioeng 107:11–20

Benazir JF, Suganthi R, Rajvel D, Pooja MP, Mathithumilan B (2010) Bioremediation of chromium in tannery effluent by microbial consortia. Afr J Biotechnol 9(21):3140–3143

Bopp LH, Ehrlich HL (1988) Chromate resistance and reduction in Pseudomonas fluorescens strain LB 300. Arch Microbiol 150:426–431

Chandra R, Bharagava RN, Kapley A, Purohit HJ (2011) Bacterial diversity, organic pollutants and their metabolites in two aeration lagoons of common effluent treatment plant (CETP) during the degradation and detoxification of tannery wastewater. Bioresour Technol 102:2333–2341

Chaturvedi MK (2011) Studies on chromate removal by chromium-resistant Bacillus sp. isolated from tannery effluent. J Environ Prot 2:76–82

Chen Z, Huang Z, Cheng Y, Pan D, Pan X, Yu M, Pan Z (2012) Cr(VI) uptake mechanism of Bacillus cereus. Chemosphere 87(3):211–216

Cheung KH, Gu JD (2007) Mechanism of hexavalent chromium detoxification by microorganisms and bioremediation application potential: a review. Int Biodeterior Biodegrad 59:8–15

Cheung KH, Lai HY, Gu JD (2006) Membrane-associated hexavalent chromium reductase of Bacillus magaterium TK W3 with induced expression. J Microbiol Biotechnol 16:855–862

Desai C, Jain K, Madamwar D (2008) Hexavalent chromate reductase activity in cytosolic fractions of Pseudomonas sp. G1DM21 isolated from Cr (VI) contaminated industrial landfill. Process Biochem 43:713–721

Dey S, Paul AK (2012) Optimization of cultural conditions for growth associated chromate reduction by Arthrobacter sp. SUK 1201 isolated from chromite mine overburden. J Hazard Mater 213–214:200–206

El-Shafey EI (2005) Behaviour of reduction-sorption of chromium (VI) from an aqueous solution on a modified sorbent from Rice Husk. Water Air Soil Pollut 163:81–102

Esmaeili A, Nia AM, Vazirinejad R (2005) Chromium (III) removal and recovery from tannery wastewater by precipitation process. Am J Appl Sci 2(10):1471–1473

Essahale A, Malki M, Marin I, Moumni M (2012) Hexavalent chromium reduction and accumulation by Acinetobacter AB1 isolated from Fez Tanneries in Morocco. Indian J Microbiol 52(1):48–53

Farag S, Zaki S (2010) Identification of bacterial strains from tannery effluent and reduction of hexavalent chromium. J Environ Biol 31(5):877–882

Focardi S, Pepi M, Focardi SE (2013) Microbial reduction of hexavalent chromium as a mechanism of detoxification and possible bioremediation applications. In: Chamy R, Rosenkranz F (eds) Agricultural and biological sciences, biodegradation-life of science. Vol 12, pp 321-347

Gadd GM (1988) Accumulation of metal by microorganisms and algae. In: Rehm H (ed) Biotechnology: a comprehensive complete treatise, vol 6B, special microbial process, vol 4. Verlagsgesellschaft, Weinheim, pp 401–403

Garg SK, Tripathi M, Srinath T (2012) Strategies for chromium bioremediation of tannery effluent. In: Whitacre DM (ed) Reviews of environmental contamination and toxicology. Springer, Berlin, p 217

Hafez AI, El-Manharawy MS, Khedr MA (2002) RO membrane removal of unreacted chromium from spent tanning effluent. Desalination 144(1–3):237–242

Iftikhar S, Faisal M, Hasnain S (2007) Cytosolic reduction of toxic Cr(VI) by indigenous microorganisms. Res J Environ Sci 1:77–81

Li K, Ramakrishna W (2011) Effect of multiple metal resistant bacteria from contaminated lake sediments on metal accumulation and plant growth. J Hazard Mater 189:531–539

Mabbett AN, Macaskie LE (2001) A novel isolate of Desulfovibrio sp. With enhanced ability to reduce Cr(VI). Biotechnol Lett 23:683–687

Madigan TM, Martinko MJ, Parker J, Brock TD (2004) Biology of microorganisms, 10ma edition. Ed Pearson Prentice Hall 6:158–170

Mangaiyarkarasi MS, Vincent S, Janarthanan S (2011) Bioreduction of Cr(VI) by alkaliphilic Bacillus subtilis and interaction of the membrane groups. Saudi J Biol Sci 18:157–167

Mohan D, Pittman CU (2006) Activated carbons and low cost adsorbents for remediation of tri- and hexavalent chromium from water. J Hazard Mater 137(2):762–811

Oliveira H (2012) Chromium as an environmental pollutant: insights on induced plant toxicity. J Bot 2012:1–8

Pajor F, Póti P, Bodnár Á, Bárdos L (2012) Accumulation of some heavy metals (Pd, Cd and Cr) in milk of grazing sheep in north-east Hungary. J Microbiol Biotechnol Food Sci 2(1):389–394

Polti M, Amoroso MJ, Abate CM (2010) Intracellular chromium accumulation by Streptomyces sp. MC1. Water Air Soil Pollut 214:49–57

Quintelas C, Fonseca B, Silva B, Figueiredo H, Tavares T (2009) Treatment of chromium (VI) solutions in a pilot-scale bioreactor through a biofilm of Arthrobacter viscosus supported on GAC. Bioresour Technol 100(1):220–226

Rajendran R, Karthik Sundaram S, Sridevi BV, Prabhavathi P, Gopi V (2012) Biodetoxification of azo dye containing textile effluent through adapted fungal strains. J Environ Sci Technol 5:29–41

Romero CH, Pellerano RG, Acevedo HA, Vázquez FA (2006) Standarization of preliminary conditions for chromium determination in environment samples. Universidad Nacional del Nordeste, Cientific and technology comunication 2006

Sau GB, Chatterjee S, Mukherjee SK (2010) Chromate reduction by cell-free extract of Bacillus firmus KUCr1. Pol J Microbiol 59(3):185–190

Smutok O, Broda D, Smutok H, Dmytruk K, Gonchar M (2011) Chromate-reducing activity of Hansenula polymorpha recombinant cells over-producing flavocytochrome b2. Chemosphere 83(4):449–454

Song H, Liu Y, Xu W, Zeng G, Aibibu N, Xu L, Chen B (2009) Simultaneous Cr (VI) reduction and phenol degradation in pure cultures of Pseudomonas aeruginosa CCTCC AB91095. Bioresour Technol 100(21):5079–5084

Soni SK, Singh R, Awasthi A, Singh M, Kalra A (2012) In vitro Cr (VI) reduction by cell-free extracts of chromate-reducing bacteria isolated from tannery effluent irrigated soil. Environ Sci Pollut Res 20(3):1661–1674

Srinath T, Verma T, Ramteke PW, Garg SK (2002) Chromium (VI) biosorption and bioaccumulation by chromate resistant bacteria. Chemosphere 48(4):427–435

Srivastava S, Thakur IS (2007) Evaluation of biosorption potency of Acinetobacter sp. for removal of hexavalent chromium from tannery effluent. Biodegradation 18(5):637–646

Tripathi M, Vikram S, Jain RK, Garg SK (2011) Isolation and growth characteristics of chromium (VI) and pentachlorophenol tolerant bacterial isolate from treated tannery effluent for its possible use in simultaneous bioremediation. Indian J Microbiol 51(1):61–69

Volesky B (1999) Biosorption for the next century. In: Amils R, Ballester A (eds) Biohydrometallurgy and the environment toward the mining of the 21st century. Elsevier, Amsterdam, pp 161–170

Wang P, Mori T, Komori K, Ohtake H (1989) Isolation and characterization of an Enterobacter cloacae strain that reduces hexavalent chromium under anaerobic conditions. Appl Environ Microbiol 55:1665–1669

Zhang K, Li F (2011) Isolation and characterization of a chromium-resistant bacterium Serratia sp. Cr-10 from chromate-contaminated site. Appl Microbiol Biotechnol 90:1163–1169

Acknowledgments

P.S.G, M.A.T, and E.A. are members of the research career from Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) (Argentina). L.F.A and C.E.P have a fellowship from CONICET. We wish to thank PPI (SECyT-UNRC), CONICET, PICT (FONCyT), and MinCyT Córdoba for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Robert Duran

Rights and permissions

About this article

Cite this article

González, P.S., Ambrosio, L.F., Paisio, C.E. et al. Chromium (VI) remediation by a native strain: effect of environmental conditions and removal mechanisms involved. Environ Sci Pollut Res 21, 13551–13559 (2014). https://doi.org/10.1007/s11356-014-3311-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-3311-z