Abstract

Lactobacillus brevis 3-A5 was isolated and expected to produce mannitol efficiently by regulating pH in batch and fed-batch fermentations. In 48 h batch fermentations with free and constant pH, the optimal pH for cell growth and mannitol production in the first 24 h of incubation was 5.5, whereas that for mannitol production in the second 24 h of incubation was 4.5. To achieve high cell density and mannitol yield simultaneously, a dual-stage pH control strategy was proposed based on the kinetic analysis of mannitol production. The pH value was controlled at 5.5 for the first 12 h of fermentation and subsequently shifted to 4.5 until the fermentation was completed. Under dual-stage pH control fermentation, a 103 g/L yield of mannitol with a volumetric production rate of 3.7 g/L/h was achieved after 28 h. The dual-stage pH control fed-batch fermentation strategy was further developed to improve mannitol yield, wherein the yield increased by 109 % to 215 g/L after 98 h of fermentation. This value is the highest yield of mannitol ever reported using L. brevis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mannitol is a valuable polyol with many applications in confectionery foods, oral care, pharmaceuticals, and chemicals (Akinterinwa et al. 2008). Until now, the industrial production of mannitol has been largely achieved through catalytic hydrogenation (global market, 13.6 million kg/year; US $7.30/kg) (Saha and Racine 2011). However, this chemical hydrogenation process has limitations, including additional costs caused by harsh conditions and separation of mannitol from sorbitol (Song and Vieille 2009). Thus, various alternatives to mannitol production have been proposed and developed. As a promising method, fermentation for mannitol production with lactic acid bacteria (LAB) has gained considerable attention for providing a safer, more eco-friendly production process with enhanced specificity (Ghoreishi and Shahrestani 2009).

LAB are industrially food-grade microorganisms that consume glucose via either homofermentative or heterofermentative pathways. Heterofermentative LAB are preferred over homofermentative LAB for mannitol production because they convert fructose to mannitol by one step (Rodríguez et al. 2012). Moreover, heterofermentative LAB produce mannitol from fructose by an NADH-linked mannitol dehydrogenase (MDH). The NADH is mainly formed via the heterofermentative pathway (Ortiz et al. 2012). In the heterofermentative pathway, 1 mol of glucose is metabolized to 1 mol of lactic acid and 1 mol of acetic acid or ethanol. The organic acids produced by LAB decrease pH, thereby significantly inhibiting LAB growth and reducing fermentation end products. Consequently, pH control serves as an approach to improve mannitol yields. Saha and Racine reported that the optimal pH for mannitol production by Lactobacillus intermedius NRRL B-3693 in pH-controlled fermentation was 5.0 and the mannitol yield was approximately twice that in free pH fermentation (Saha and Racine 2010; Saha and Racine 2011). The effects of pH on microbial growth and product formation vary in different microorganisms and culture conditions (Cao et al. 2012; Wu et al. 2010). The preferable pH for mannitol production may not always be consistent with that for cell growth. Thus, it may not be appropriate for maintaining a constant pH throughout the fermentation process for effective mannitol accumulation. Therefore, a pH stage-controlled fermentation may be a valid strategy for improving mannitol production.

The genera Lactobacillus intermedius and Leuconostoc mesenteroides of the heterofermentative LAB have been well studied for mannitol production, while only a little attention focused on the mannitol production by Lactobacillus brevis owing to its low mannitol yield (von Weymarn 2002; Saha 2006; Patra et al. 2011). In our previous study, L. brevis M1 was selected for its ability to produce mannitol during a screening of seven heterofermentative LAB strains belonging to L. brevis, L. buchneri, and L. mesenteroides (Zhu et al. 2009). After mutation of L. brevis M1, one mutant designated as L. brevis 3-A5, showed high mannitol productivity (Yue et al. 2012). Given that pH plays a key factor in controlling mannitol yield, we first investigated mannitol production by L. brevis 3-A5 in batch fermentations with free and constant pH. Subsequently, a dual-stage pH control strategy suitable for strain 3-A5 was developed. To obtain high mannitol yield and circumvent the limitation that potential damage to the growth of strain 3-A5 caused by high initial concentrations of fructose, a dual-stage pH control fed-batch fermentation strategy was adopted. The mannitol yield of L. brevis 3-A5 was significantly increased, reaching a value close to the maximum production reported using LAB (Saha 2006).

Materials and methods

Microorganism and seed culture conditions

Lactobacillus brevis 3-A5 is a mutant of L. brevis AS 1.7 obtained from China General Microbiological Culture Collection Center (Beijing, China). Prior to being stored at −80 °C, L. brevis 3-A5 was maintained in MRS medium (composition: 10 g/L bacto-peptone, 10 g/L beef extract, 5 g/L yeast extract, 20 g/L glucose, 2 g/L ammonium citrate, 5 g/L sodium acetate, 0.2 g/L magnesium sulfate, 0.05 g/L manganese sulfate, 2 g/L dipotassium phosphate, and 1.0 mL/L Tween 80, pH 6.5) supplemented with glycerol (13 % v/v). MRS medium was also used for seed culture. The medium was sterilized by autoclaving at 121 °C for 15 min. The seed culture was incubated at 30 °C for 24 h with shaking at 150 rpm.

Batch and fed-batch trials

Batch and fed-batch trials were carried out in a 5 L bioreactor at 37 °C. The inoculum size was 10 % (v/v) to give a final optical density of 0.4–0.5 at 600 nm. No aeration was employed, and the agitation speed was fixed at 200 rpm. The pH was controlled by the automatic addition of 10 M NaOH or 4 M HCl.

Batch trials were performed with a working volume of 3 L in simplified production (SP) medium (composition: 20 g/L tryptone, 10 g/L yeast extract, 4 g/L dipotassium phosphate, 0.4 g/L magnesium sulfate, and 0.02 g/L manganese sulfate) after sterilization. The carbon source was composed of 100 g/L fructose and 50 g/L glucose. For the dual-stage pH control experiment, pH was initially controlled at 5.5 for 12 or 16 h. This value was decreased to 4.5 and then controlled at a constant value.

With the dual-stage pH control strategy, fed-batch experiments were initiated with a 2 L working volume in SP medium. The initial concentrations of fructose and glucose were 120 and 57 g/L, respectively. Additional substrate (1 L) containing 480 g fructose, 228 g glucose, 80 g tryptone and 40 g yeast extract was added at a rate of 0.30, 0.45, or 0.60 mL/min after 8 h of inoculation.

All trials were performed twice, and data were reported as mean values.

Analytical methods

To determine the cell dry weight (CDW), cells were harvested and dried at 105 °C for 12 h. The concentrations of glucose, fructose, and mannitol were determined by an HPLC equipped with a pulsed amperometric detector (Dionex, USA) using a PA-10 sugar analytic column (Dionex, USA) eluted with 18 mM NaOH at a flow rate of 1 mL/min. The column was maintained at 30 °C. The concentrations of lactic acid and acetic acid were determined by ion chromatography system ICS 3000 (Dionex, USA) as previously described (Geng et al. 2008). Ethanol was determined using an automatic ethanol analyzer SBA-40E (Biology Institute of Shandong Academy of Sciences, China) equipped with an immobilized enzyme electrode. MDH activity was determined as previously described (Hahn et al. 2003). Cofactor recycling assay was performed to determine intracellular concentrations of NAD(H) as previously described (Zhou et al. 2011).

Calculation of kinetic parameters

The rate equation models for biomass (X) and mannitol (P) were estimated from the experimental data of CDW (g/L) and mannitol production (g/L).

Cell growth kinetics model: the logistic equation is commonly used to describe cell growth rate (Ricklefs 1967; Zhu et al. 2012):

Product synthesis kinetics model: The Luedeking–Piret equation is commonly used to describe the relationship between product synthesis rate and cell growth rate (Luedeking and Piret 1959):

Substrate consumption kinetics model: Substrate consumption is mainly driven by cell growth, cell maintenance, and product synthesis:

The fitted data were obtained by Origin software (Version 8.0).

Results and discussion

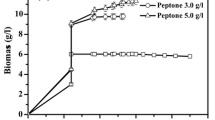

Mannitol production during fermentations with free and constant pH

The effects of free pH (at an initial pH of 6.5) and constant pH (pH 4.5, 5.5 and 6.5) on mannitol production by L. brevis 3-A5 are demonstrated in Fig. 1. In the first 8 h of fermentation with free pH, the pH dramatically decreased from 6.5 to 4.1 and then gradually decreased to 3.1 at the end of the fermentation (Fig. 1A). This decrease in pH may be attributed to the organic acids (such as lactic acid and acetic acid) produced from sugar during fermentation. A significant decrease in pH during the fermentation probably affected cell growth and mannitol production. This finding indicates the importance of determining the effects of pH on mannitol biosynthesis by L. brevis 3-A5.

Time course of growth and mannitol production by L. brevis with free and constant pH: A Free pH; B pH 4.5; C pH 5.5; D pH 6.5. The symbols used: CDW (filled square), mannitol concentration (filled triangle), fructose concentration (filled inverted triangle), glucose concentration (open square), pH (dash dot line)

After 48 h of incubation with free pH, 42.5 % of the initial glucose and 32.1 % of the initial fructose were not consumed. However, little sugar remained in the medium at the end of the fermentation with constant pH. These findings indicate that substrate consumption is affected by pH increase or decrease, i.e., pH deviation from the ideal value reduces carbohydrate metabolism. The kinetic parameters were calculated based on Fig. 1. As shown in Table 1, X m (5.825 g/L) and μ max (0.179/h) with free pH were the lowest. However, the final mannitol yield on the biomass (Y P/X , 12.655 ± 0.615 g mannitol/g biomass) and the final mannitol yield on the sugar (Y P/S , 0.724 ± 0.098 g mannitol/g sugar) with free pH were the highest for the assayed fermentation conditions. Among constant pH fermentations, X m (7.863 g/L) and μ max (0.199/h) were the lowest at pH 4.5. However, Y P/X (11.587 ± 1.771 g mannitol/g biomass), Y P/S (0.613 ± 0.084 g mannitol/g sugar), and the volumetric productivity of mannitol (Q P , 1.860 ± 0.103 g/L/h) were the highest at pH 4.5. These data suggest that although low pH (pH ≤ 4.5) hampers cell growth, it (pH 4.5) seems to be preferable for mannitol production. The optimum pH for initial cell growth was found to be 5.5, as confirmed by the highest μ max (0.338/h) achieved at this pH. The Luedeking–Piret model values of α and β with free pH were 9.701 and 0.111/h, respectively, indicating that the process was partially growth coupled and that mannitol production was mainly associated with cell growth. Under constant pH fermentation conditions, the values of α were non-zero, whereas those of β were close to zero, showing that these processes were growth coupled. These results reveal that pH plays a vital role in mannitol production and cell growth. Moreover, the optimum pH for mannitol biosynthesis may be different from that for cell growth. Similar results were reported in rhamnolipids formation (Zhu et al. 2012), succinic acid biosynthesis (Liu et al. 2008), and cyclic adenosine monophosphate fermentation (Cao et al. 2012).

Lactobacillus brevis is a heterofermentative LAB that uses glucose to produce lactic acid, CO2, and acetic acid and/or ethanol in equimolar amounts through alternative external electron acceptors (Wisselink et al. 2002). As an electron acceptor, fructose is reduced to mannitol in a single enzymatic conversion with an NADH-linked MDH, leading to the conversion of acetyl phosphate into acetate instead of ethanol, accompanied by the generation of ATP (Zaunmüller et al. 2006). Therefore, the MDH activities and available NADH may be varied under different pH conditions and thus affect the mannitol production. After 12 h of incubation, the highest specific MDH activity on the biomass [Y MDH/X , 0.415 ± 0.088 U/mg protein/(g/L biomass)] was obtained at pH 4.5, and the ratio of NADH to NAD showed no significant difference under the experimental conditions used (Table 2). The specific mannitol formation rate (q P , 2.538/h) and ratio of mannitol to organic acids (lactic acid and acetic acid) and ethanol [P/(L + A + E), 1.039] were the highest at pH 4.5. These data suggest that constant pH at 4.5 favors mannitol production by L. brevis 3-A5 probably because of high MDH activity. The highest specific fructose consumption rate (q SF , 2.378/h), specific glucose consumption rate (q SG , 1.118/h), specific mannitol formation rate (q P , 2.538/h), specific lactic acid formation rate (q L , 0.581/h), and specific acetic acid formation rate (q A , 0.393/h) were obtained at pH 4.5. This result indicates that constant pH at 4.5 is applicable for substrate consumptions and main product formations, and that the substrate consumptions are mainly used for product formation instead of cell growth. The highest specific cell growth rate (μ, 0.176/h) was achieved at pH 5.5, indicating that constant pH at 5.5 was the optimum pH for cell growth.

Although pH is important for mannitol production, other factors (e.g., product concentration) also affect cell growth, mannitol production, and sugar consumption. The activities of some enzymes involved in the biosynthesis of mannitol and biomass may be partially inhibited with increasing product concentration. Similar results were reported in sorbitol fermentation (Wang et al. 2009). Mannitol production is closely related to cell growth, and the optimum pH for mannitol formation and cell growth may be different. Thus, simultaneously achieving high biomass and mannitol yield may not be possible in the fermentation with constant pH. A dual-stage pH control strategy may accomplish the maximum accumulation of mannitol.

Dual-stage pH control fermentations

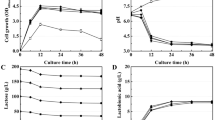

The specific cell growth rate and yield of mannitol were higher at pH 5.5 in the initial stage of incubation; however, the mannitol yield was higher at pH 4.5 after 28 h of fermentation (Figs. 1B, C). A dual-stage pH control strategy was developed according to the above results. The pH was maintained at 5.5 in the earlier fermentation period, and then adjusted to 4.5 to rapidly reach the maximum mannitol yield. Two time points for pH change were selected during the fermentation. At the 12th hour, the cell growth rate reached the maximum at a constant pH of 5.5. At the 16th hour, the cell growth tended to stabilize at a constant pH of 5.5 (Fig. 1C).

As shown in Fig. 2, the maximum biomass values were 11.119 ± 0.243 g/L (pH change at the 12th hour) and 7.700 ± 0.106 g/L (pH change at the 16th hour), respectively. In the 48 h fermentation process, the pH change at the 12th hour gave the maximum mannitol yield of 103.281 ± 1.505 g/L, whereas that at the 16th hour produced the maximum mannitol yield of only 86.009 ± 2.670 g/L. These results reveal that different time points for changing pH significantly affect cell growth and mannitol yields. The maximum ethanol yield after the pH change at the 12th hour (2.585 ± 0.135 g/L) was less than that after the pH change at the 16th hour (4.200 ± 0.224 g/L). By contrast, the mannitol yield showed the opposite tendency. These data suggest that the yields of mannitol and ethanol were inversely correlated. Similar results were found by von Weymarn (2002). Compared with the optimal results in the fermentation with constant pH, the mannitol concentration and CDW of the dual-stage pH control fermentation (pH change at the 12th hour) increased by 15.7 and 20.5 %, respectively. These results show that the proposed dual-stage pH control strategy not only enhances the accumulation of mannitol but also improves cell growth. Thus, it is an effective strategy for mannitol production. For further studies, we recommend the pH change at the 12th hour because of the higher yield and productivity of mannitol under this condition.

Time course of growth and mannitol production by L. brevis using dual-stage pH control strategy: A pH change at the 12th hour; B pH change at the 16th hour. The symbols used: CDW (filled square), mannitol concentration (filled triangle), fructose concentration (filled inverted triangle), glucose concentration (open square)

Dual-stage pH control fed-batch fermentations

The concentration of mannitol was an important factor for separating mannitol from the broth at the end of fermentation. Up to 180 g/L mannitol can be readily recovered from the broth simply through cooling crystallization (Saha and Nakamura 2003). To improve mannitol production and reduce the inhibitory effect of high substrate concentrations during the initial stages of fermentations, a dual-stage pH control fed-batch fermentation strategy was adopted.

To obtain the maximum mannitol production, various flow rates of feeding were tested. The highest mannitol yield was 215.025 g/L, which was lower than 5.7 % of the maximum production by LAB when the feeding flow rate and fermentation time were 0.30 mL/min and 98 h, respectively (Fig. 3). This study is the first to report such a high mannitol yield by L. brevis, which seems to be a good candidate for efficient mannitol production. A comparison of mannitol production parameters with LAB was listed in Table 3. Mannitol could be readily crystallized from fermentation broth based on dual-stage pH control fed-batch fermentation because its yield exceeded 180 g/L, which facilitated the subsequent purification of mannitol.

Conclusions

The results of this study indicate that pH plays an important role in mannitol production. A dual-stage pH control fermentation strategy was developed to effectively improve mannitol production. The mannitol yield reached 215.025 g/L in dual-stage pH control fed-batch fermentation, with the approximate maximum mannitol yield to LAB described previously. This method is valid for enhancing mannitol formation and may be used in large-scale, highly efficient mannitol production.

Abbreviations

- X :

-

Cell dry weight, g/L

- X m :

-

Maximum cell dry weight, g/L

- μ :

-

Specific cell growth rate, 1/h

- μ max :

-

Maximum specific cell growth rate, 1/h

- t :

-

Time, h

- P :

-

Product concentration, g/L

- Q P :

-

Volumetric productivity of mannitol, g/L/h

- α :

-

Growth associated constant for product formation

- β :

-

Non-growth associated constant for product formation, 1/h

- q P :

-

Specific mannitol formation rate, 1/h

- q L :

-

Specific lactic acid formation rate, 1/h

- q A :

-

Specific acetic acid formation rate, 1/h

- q E :

-

Specific ethanol formation rate, 1/h

- P/(L + A + E):

-

Ratio of mannitol to organic acids (lactic acid and acetic acid) and ethanol

- S :

-

Substrate concentration, g/L

- Y X/S :

-

Cell yield coefficient on substrate, g biomass/g sugar

- Y P/X :

-

Product yield coefficient on biomass, g mannitol/g biomass

- Y P/S :

-

Product yield coefficient on substrate, g mannitol/g sugar

- m s :

-

Energy maintain constant, 1/h

- q SF :

-

Specific fructose consumption rate, 1/h

- q SG :

-

Specific glucose consumption rate, 1/h

- Y MDH/X :

-

Specific mannitol dehydrogenase activity on the biomass, U/mg protein/(g/L biomass)

- NADH/NAD:

-

Ratio of NADH to NAD

References

Akinterinwa O, Khankal R, Cirino PC (2008) Metabolic engineering for bioproduction of sugar alcohols. Curr Opin Biotechnol 19:461–467

Cao JM, Chen XC, Ren HJ, Zhang JD, Li L, Chen Y, Xiong J, Bai JX, Ying HJ (2012) Production of cyclic adenosine monophosphate by Arthrobacter sp. A302 using fed-batch fermentation with pH-shift control. World J Microbiol Biotechnol 28:121–127

Fontes C, Honorato T, Rabelo M, Rodrigues S (2009) Kinetic study of mannitol production using cashew apple juice as substrate. Bioprocess Biosys Engin 32:493–499

Geng X, Zhang S, Wang Q, Zhao ZK (2008) Determination of organic acids in the presence of inorganic anions by ion chromatography with suppressed conductivity detection. J Chromatogr A 1192:187–190

Ghoreishi SM, Shahrestani RG (2009) Innovative strategies for engineering mannitol production. Trends Food Sci Technol 20:263–270

Hahn G, Kaup B, Bringer-Meyer S, Sahm H (2003) A zinc-containing mannitol-2-dehydrogenase from Leuconostoc pseudomesenteroides ATCC 12291: purification of the enzyme and cloning of the gene. Arch Microbiol 179:101–107

Liu YP, Zheng P, Sun ZH, Ni Y, Dong JJ, Wei P (2008) Strategies of pH control and glucose-fed batch fermentation for production of succinic acid by Actinobacillus succinogenes CGMCC1593. J Chem Technol Biotechnol 83:722–729

Luedeking R, Piret EL (1959) A kinetic study of the lactic acid fermentation. Batch process at controlled pH. J Biochem Microbiol Technol Eng 1:393–412

Ortiz ME, Fornaguera MJ, Raya RR, Mozzi F (2012) Lactobacillus reuteri CRL 1101 highly produces mannitol from sugarcane molasses as carbon source. Appl Microbiol Biotechnol 95:991–999

Patra F, Tomar SK, Rajput YS, Singh R (2011) Characterization of mannitol producing strains of Leuconostoc species. World J Microbiol Biotechnol 27:933–939

Racine FM, Saha BC (2007) Production of mannitol by Lactobacillus intermedius NRRL B-3693 in fed-batch and continuous cell-recycle fermentations. Process Biochem 42:1609–1613

Ricklefs RE (1967) A graphical method of fitting equations to growth curves. Ecology 48:978–983

Rodríguez C, Rimaux T, Fornaguera MJ, Vrancken G, de Valdez GF, Vuyst LD, Mozzi F (2012) Mannitol production by heterofermentative Lactobacillus reuteri CRL 1101 and Lactobacillus fermentum CRL 573 in free and controlled pH batch fermentations. Appl Microbiol Biotechnol 93:2519–2527

Saha BC (2006) Production of mannitol from inulin by simultaneous enzymatic saccharification and fermentation with Lactobacillus intermedius NRRL B-3693. Enzyme Microb Technol 39:991–995

Saha BC, Nakamura LK (2003) Production of mannitol and lactic acid by fermentation with Lactobacillus intermedius NRRL B-3693. Biotechnol Bioeng 82:864–871

Saha BC, Racine FM (2010) Effects of pH and corn steep liquor variability on mannitol production by Lactobacillus intermedius NRRL B-3693. Appl Microbiol Biotechnol 87:553–560

Saha BC, Racine FM (2011) Biotechnological production of mannitol and its applications. Appl Microbiol Biotechnol 89:879–891

Soetaert W, Buchholz K, Vandamme EJ (1995) Production of D-mannitol and D-lactic acid by fermentation with Leuconostoc mesenterroides. Agro Food Ind Hi Tech 6:41–44

Song SH, Vieille C (2009) Recent advances in the biological production of mannitol. Appl Microbiol Biotechnol 84:55–62

von Weymarn N (2002) Process development for mannitol production by lactic acid bacteria, PhD Thesis. Helsinky University of Technology, Finland

von Weymarn N, Hujanen M, Leisola M (2002) Production of D-mannitol by heterofermentative lactic acid bacteria. Process Biochem 37:1207–1213

Wang RB, Zhang HZ, Qiu HY, Gao SY, Kan B (2009) Proteins involved in difference of sorbitol fermentation rates of toxigenic and nontoxigenic Vibrio cholerae EI T or strains revealed by comparative proteome analysis. BMC Microbiol 9:135

Wisselink HW, Weusthuis RA, Eggink G, Hugenholtz J, Grobben GJ (2002) Mannitol production by lactic acid bacteria: a review. Int Dairy J 12:151–161

Wu Q, Xu H, Ying HJ, Ouyang PK (2010) Kinetic analysis and pH-shift control strategy for poly (gamma-glutamic acid) production with Bacillus subtilis CGMCC 0833. Biochem Eng J 50:24–28

Yue M, Cao HL, Li SG, Yang FL, Zhang JP, Du YG (2012) Mutation breeding of lactic acid bacteria for high yield of mannitol from saccharified Jerusalem artichoke. China Brew 31:53–56

Zaunmüller T, Eichert M, Richter H, Unden G (2006) Variations in the energy metabolism of biotechnologically relevant heterofermentative lactic acid bacteria during growth on sugars and organic acids. Appl Microbiol Biotechnol 72:421–429

Zhou YJ, Wang L, Yang F, Lin XP, Zhang SF, Zhao ZB (2011) Determining the extremes of the cellular NAD(H) level by using an Escherichia coli NAD+-auxotrophic mutant. Appl Environ Microbiol 77:6133–6140

Zhu Y, Cao HL, Yue M, Li SG, Bai XF, Zhao XM, Du YG (2009) The primary study of production of mannitol from saccharified jerusalem artichoke juice with several lactic acid bacteria. Acta Agric Boreali Occident Sin 18:137–141, 175

Zhu LQ, Yang X, Xue CY, Chen Y, Qu L, Lu WY (2012) Enhanced rhamnolipids production by Pseudomonas aeruginosa based on a pH stage-controlled fed-batch fermentation process. Bioresour Technol 117:208–213

Acknowledgments

This research was financially supported by the Main Direction Program of Knowledge Innovation of the Chinese Academy of Science (Grant No. KSCX2-EW-G-5), the National High Technology Research and Development Program of China (863 Program) (Grant No. 2012AA021205) and National Science and Technology Support Program (Grant No. 2012BAD32B09). We thank Dr. Haidong Tan for critical reading of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yue, M., Cao, H., Zhang, J. et al. Improvement of mannitol production by Lactobacillus brevis mutant 3-A5 based on dual-stage pH control and fed-batch fermentations. World J Microbiol Biotechnol 29, 1923–1930 (2013). https://doi.org/10.1007/s11274-013-1357-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-013-1357-6