Abstract

A bifunctional acid–base catalyst of CeIII immobilized on ethylenediamine (EDA)-grafted poly(vinyl chloride) (PVC) has been prepared by a simple approach. First, PVC was treated with EDA to afford aminated poly(vinyl chloride) (PVC–EDA). Thereafter, the PVC–EDA were used in the mobilization of CeCl3 to obtain a bifunctional catalyst (PVC–EDA–CeIII) in which a harmonious coexistence of Lewis acid (Ce3+) sites and Lewis base (amine) moieties on PVC was achieved. The obtained PVC–EDA–CeIII complex was characterized by EA, ICP–AES, FT-IR, SEM, EDS, TGA, and DTG techniques. The as-prepared catalyst can efficiently catalyze the one-pot four-component reactions of aromatic aldehydes, malononitrile, ethyl acetoacetate, and hydrazine in ethanol under mild conditions to afford polyfunctionalized 1,4-dihydropyrano[2,3-c]pyrazoles with excellent yields. The high catalytic performance of the PVC–EDA–CeIII bifunctional catalyst is attributed to a synergistic effect of Lewis acid sites (CeIII) and Lewis base sites (amino moieties). The significant features of the present protocol are environmentally benign, simple operation, short reaction time, high yields, and without chromatographic separation. Moreover, the catalyst can easily be separated by simple filtration and reused for five runs without obvious decline or losing its catalytic activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Multicomponent reactions (MCRs) are one-pot processes in which at least three or more readily available reactants react to construct highly functionalized target molecules which incorporate the majority of the atoms in the starting materials. Simplicity, high selectivity, greater bond-forming efficiency, and high atom economy are some of the main advantages of MCRs [1,2,3,4,5,6]. Hence, the development of MCRs for the synthesis of heterocyclic compounds has attracted significant interest from industry and academia. 1,4-dihydropyrano[2,3-c]pyrazoles are very important heterocycles due to their biological activity and pharmaceutical interest. Many of them have been found for applications such as a potential inhibitor of a human Chk1 kinase, [7] as well as antitumor, [8] analgesic, [9] antibacterial, [10] and anti-inflammatory agents [9,10,11]. Due to the biological activity of the 1,4-dihydropyrano[2,3-c]pyrazole derivatives, various MCRs including three-component reactions (3-CRs), four-component reactions (4-CRs), and even five-component reactions (5-CRs) have been reported. 3-CRs of carbonyl compounds, malononitrile, and pyrazolin-5-ones using both a basic catalyst like ionic liquid ([bmim][OH]), [12] ethylenediammonium diformate, [13] 4-dimethylaminopyridine (DMAP), [14] N-methylmorpholine, [15] triethanolamine, [16] Me3N, [17] Et3N, [17] electrogenerated base, [17, 18] etc. and an acidic catalyst including BF3 bonded nano-Fe3O4, [19] [nano-Fe3O4@SiO2@(CH2)3-Imidazole-SO3H]Cl, [20] NH4H2PO4/Al2O3, [21] etc. have been reported. Among the recent developments and expanding interest in MCRs, the use of the catalyst in 4-CRs of aldehydes, malononitrile, ethyl acetoacetate, and hydrazine hydrate have been developed. The basic catalysts have included ionic liquid [DBU][Ac], [22] Amberlyst A21, [23] Et3N, [24] and TBD-anchored mesoporous silica nanoparticles [25], while the acidic catalysts have included ionic liquid [DMDBSI]·2HSO4, [26] isonicotinic acid, [27] and morpholine triflate [28]. More recently, we have established an overall 5-CRs incoorporating Suzuki coupling of 4-bromobenzaldehyde and arylboronic acids with 4-CRs of ethyl acetoacetate, malononitrile, and hydrazine hydrate to synthesize 1,4-dihydropyrano[2,3-c]pyrazoles [29]. Although these reported MCRs have some useful synthetic procedures, several limitations, including high homogeneous catalyst loading, prolonged reaction time, harsh reaction conditions, poor recyclability, low yields, and side reactions, have still remained. For example, the employment of a basic catalyst for this type of MCRs has the potential to accomplish various side reactions, such as the Aldol reaction and the Cannizzaro condensation, to produce unexpected by-products. As a result, the development of simple and efficient MCRs without the use of hazardous solvents and toxic catalysts is highly desirable in the area of synthetic chemistry. Recently, heterogeneous catalysis has appeared as an area of very rapid growth for organic synthesis because it has the advantages of recoverability and recyclability of the catalyst, and is benign to the environment.

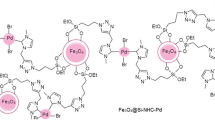

Poly(vinyl chloride) (PVC) is one of the cheapest and most commonly used synthetic polymers in the world. It is well known that PVC is easily functionalized by nucleophilic groups via a displacement reaction directly without chlorormethylation, which means it can be used as a polymeric matrix for a heterogeneous catalyst [30]. Nevertheless, rare examples of using PVC as a support have been reported in the literature. Recently, our group has reported the preparation of Pd nanoparticles supported on 2-aminoethanol functionalized-PVC [31] or a PVC-derived Schiff’s base [32] and their application in the Heck and Suzuki reactions.

The above observations of MCRs promoted by acidic catalysts and/or basic catalysts for the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles has encouraged us to envisage a single catalyst possessing both Lewis acid sites and Lewis base sites, which can activate electrophiles and nucleophiles, respectively, to catalyze 4-CRs as well as having many practical benefits like a synergic effect and so on. For this purpose, we advocated a novel heterogeneous bifunctional acid–base PVC–EDA–CeIII catalyst, with amine-ligated CeIII as the Lewis acid and amine moieties as the Lewis base, for the 4-CRs to the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles. To the best of our knowledge, a PVC–EDA–CeIII catalyst has not yet been used for this purpose.

Experimental

Chemicals and characterizations

FT-IR spectra were recorded on a Nicolet 6700 spectrometer as KBr pellets in the range 4000–400 cm−1. 1H NMR spectra were obtained with a Bruker Advance instrument (300 MHz) with DMSO-d6 as solvent and TMS as an internal standard. The elemental Ce content of polymeric catalyst was determined by a Perkin Elmer Optima 2000DV inductively coupled plasma (ICP). Scanning electron microscopy (SEM) was performed with a Philips XL 30ESEM instrument. X-ray photoelectron spectroscopy (XPS) was performed on a Kratos Axis Ultra DLD spectrometer using an Al X-ray source.

All chemicals are commercially available and used as received without further purification. The PVC powder (MW 4800) was of industrial grade.

Preparation of PVC–EDA–CeIII catalyst

Commercially available PVC powders (20 g, 310 mmol of Cl) were dispersed in EDA (80 mL, 1200 mmol). The mixture was heated at 80 °C with constant stirring for 48 h to afford the corresponding reddish-brown aminated PVC resin. The resulting solid was filtered, washed thoroughly with deionized water until the filtrate was colorless and pH value was neutral, then the powder was dried at 60 °C to a constant weight.

The resulting reddish-brown PVC–EDA powder (2 g) was immersed completely in CeCl3·7H2O (745 mg, 2 mmol) aqueous ethanolic solution (20 mL), and the resulting mixture was stirred for 48 h at room temperature. The resulting black powder-anchored CeIII was filtered and successively washed with deionic water and ethanol and dried at 60 °C to a constant weight to afford the PVC–EDA–CeIII as a black powder. The N contents in the PVC–EDA and PVC–EDA–CeIII by elemental analysis were 6.96 and 6.54 mmol/g, respectively. The Ce content of the PVC–EDA–CeIII was determined to be 0.401 mmol/g by ICP–AES. The molar ratio of N to Ce in the PVC–EDA–CeIII was 16.3:1.

The synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles catalyzed by PVC–EDA–CeIII

A mixture of carbonyl compounds (1 mmol), malononitrile (1 mmol), ethyl acetoacetate (1 mmol), and 80% hydrazine (1 mmol) was stirred in ethanol (5 mL) in a 50-mL round-bottomed flask at 78 °C (reflux temperature) in the presence of PVC–EDA–CeIII (40 mg, 1.6 mol%) for a specific time. The progress of the reaction was monitored by TLC. Upon the completion of the reaction, hot ethanol was added and the mixture was filtered to recover the catalyst. The crude product was obtained after removing the ethanol with a rotary evaporator, and was further purified by recrystallization with absolute ethanol to obtain the pure product. All the products were characterized by melting point and 1H-NMR, which were consistent with the data reported in the literature.

Results and discussion

Synthesis and characterization of PVC–EDA–CeIII

Ethylenediamine-functionalized PVC (PVC–EDA) was obtained by the treatment of commercially available PVC with EDA, which has previously been reported by us [32]. Complexation of the as-prepared PVC–EDA with CeCl3·7H2O solution provides the desired PVC–EDA–CeIII catalyst. The synthetic pathway is depicted in Scheme 1.

Then, PVC–EDA–CeIII was characterized by FT-IR, XRD, SEM, EDS, TGA, DTG, and XPS techniques.

FT-IR spectroscopy is an important tool to investigate the catalyst structure. The FT-IR spectra of PVC (a), PVC–EDA (b), and PVC–EDA–CeIII (c) are shown in Fig. 1. The adsorption peaks located at 611.3 and 692.3 cm−1 in curve (a) are assigned to the C–Cl stretching vibration of PVC. As can be seen from curve (b), peaks at 1656.6 cm−1 are attributed to the stretching vibration of secondary N–H stretching. These peaks negatively shift to 1639.2 cm−1 in curve (c), implying the coordination of CeIII with the nitrogen atoms of the amine. The characteristic peaks of C–Cl become weaker in curve (b) and (c) owing to the chlorine atoms on the PVC molecular chain being replaced by EDA.

SEM images of the fresh and reused catalyst are depicted in Fig. 2. The rough surface of the catalyst can be seen, which facilitates the contact of the catalyst and the substrate. It can be clearly observed that the recovered catalyst after the 5th run is broken into pieces might be caused by the stirring during the course of the reaction.

Energy dispersive X-ray spectroscopy (EDS) analysis provides local information of various elements. The existence of the metallic elements Ce and non-metallic elements C and Cl in the PVC–EDA–CeIII is clearly shown by the EDS (Fig. 3) associated with the SEM analysis. As a result, it is reasonable to assume that the CeIII species was successfully anchored on the PVC–EDA.

The thermal stability of the catalyst has a significant effect on its catalytic activity and recyclability because this MCR is usually performed under heating conditions. Figure 4 shows the TGA (solid line) and DTA (dashed line) curves of PVC–EDA–CeIII under N2 atmosphere varying from 25 to 900 °C. As can be seen from the plot, there is three-step thermal decomposition. The first weight loss was observed around 100 °C responding to the removal of loosely physically adsorbed water. Subsequently, the weight loss which began near 200 °C was likely due to the releasing of HCl from the damaged PVC. The final weight loss occurred around 380 °C and can be attributed to the decomposition of the catalyst. TGA analysis indicates that PVC–EDA–CeIII is stable up to 200 °C. The thermal stability of PVC–EDA–CeIII can satisfy the thermal conditions in this MCR. The DTG curve of PVC–EDA–CeIII shows three peaks at around 100, 200 and 380 °C, which are assigned to the loss of adsorbed water, the releasing of HCl, and the decomposition of catalyst, respectively.

X-ray photoelectron spectroscopy (XPS) measurements were performed to confirm the chemical oxidation state of the fresh and used PVC–EDA–CeIII catalyst. Figure 5a and b shows the binding energy located at 898.4, 901.1, 903.5, and 907.7 eV belonging to the Ce(III) oxidation state, [33] and the peak at around 917 eV without overlap with any other peaks, which is a fingerprint of the Ce(IV) oxidation state [34]. The results of the XPS analysis suggest that a mixture of Ce(III) and Ce(IV) oxidation states exists in the catalyst, which may be caused by Ce(IV) impurities trapped in the CeCl3 or the oxidation of a small part of Ce(III) ions to Ce(IV) in the process of the catalyst preparation in water under air. The lack of changes in the chemical oxidation states of cerium in the fresh (Fig. 5a) and used catalyst (Fig. 5b) indicates that the reaction has no effect on the valence of the catalyst.

Performance of PVC–EDA–CeIII on multicomponent reaction for the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles

In search of the optimal conditions for the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles, the influences of solvent, base, temperature, and amount of catalyst were carefully explored using the 4-CR of 4-chlorobenzaldehyde, malononitrile, ethyl acetoacetate, and hydrazine as a model reaction (Scheme 1). The results are summarized in Table 1.

Initially, various protic and aprotic solvents with varying polarities were explored in the model reaction. As shown in Table 1, the rate of reaction and the yield of the product were significantly influenced by the used solvent. Among the solvents screened, we found that the use of EtOH as the solvent gave the highest yield of 95% (Table 1, entry 3).

Subsequently, we examined the effect of the amount of catalyst ranging from 0.0 to 2.0 mol% of Ce on the model reaction. It was found that this reaction could proceed efficiently even with a low amount of the catalyst (0.4 mol% Ce) with 59% yield at 78 °C (Table 1, entry 15). With increasing the amount of Ce from 0.4 to 1.6 mol%, the reaction yield increased from 59 to 95% (Table 1, entries 15–17, 3). Further increasing the amount of catalyst to 2.0 mol% had no apparent effect on the product yield (Table 1, entry 18). Therefore, 1.6 mol% of CeIII is sufficient to drive the reaction to completion in a short time. Recall that, in the absence of a catalyst, the model reaction proceeded with a prolonged reaction time and a lower yield (Table 1, entry 12).

Then, the effect of reaction temperature was evaluated on the model reaction. As shown from Table 1, the product yield decreased from 95 to 26% and the reaction time increased from 15 to 120 min when the temperature was dropped from reflux to room temperature (Table 1, entries 18–22). Therefore, the reflux temperature was the optimum temperature for this reaction.

Finally, to further evaluate the catalytic activity of the PVC–EDA–CeIII catalyst, a comparison was made with the CeCl3·7H2O (Table 1, entry 13) and PVC–EDA (Table 1, entry 14) in the model reaction. It can be seen that the PVC–EDA–CeIII is superior over the CeCl3·7H2O Lewis acid catalyst and the PVC–EDA Lewis base catalyst in terms of product yields and reaction times under similar reaction conditions. The enhanced catalytic activity of PVC–EDA–CeIII may be attributed to the synergic effect of Lewis acidic sites and Lewis basic sites formed in the PVC–EDA–CeIII catalyst. Moreover, the elemental analysis result (molar ratio of N/Ce is 16.3/1) indicates that the number of amino groups is sufficient to anchor CeIII and to serve as a Lewis base in the reaction.

Synthesis of dihydropyrano[2,3-c]pyrazoles with different substrates

Under the optimum conditions, the scope and generality of the 4-CRs of various carbonyl compounds, hydrazine, ethyl acetoacetate, and malononitrile were investigated. As shown in Table 2, in all cases, the nature of functional groups on the aryl ring of aldehyde exerted a slight influence on the reaction. A series of substituted aromatic aldehydes carrying either electron–donating or electron–withdrawing groups proceeded smoothly to afford the desired products with excellent yields (75–95%) in short times (15–25 min) (Table 2, entries 1–15, 17, 22). Notably, the aromatic ketones showed sluggish reactions and gave slightly lower yields with prolonged reaction times (35–48 min) (Table 2, entries 18–21).

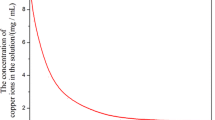

The cyclic performance of PVC–EDA–CeIII catalyst

For practical applications, the reusability of a catalyst is highly desirable for a catalytic process. To explore this aspect of the catalyst, catalytic recycling experiments were performed using the model reaction under the optimized conditions. The cyclic recovery of the catalyst was simple. After the completion of the reaction, hot ethanol was added to the reaction mixture and the catalyst was easily recovered from the mixture by filtering, and then could be used directly in a consecutive run after washing with ethanol and drying at room temperature. As demonstrated in Fig. 6, the catalyst could be reused for at least five runs without obvious loss of its catalytic activity.

Plausible mechanism for synthesis of dihydropyrano[2,3-c]pyrazoles derivatives catalyzed by PVC–EDA–CeIII

We have proposed a plausible synergic catalytic mechanism for the synthesis of 1,4-dihydropyrano[2,3-c]pyrazole derivatives in the presence of PVC–EDA–CeIII in accordance with the literature shown in Scheme 2 [35, 36]. First, the pyrazolone A was produced via the condensation between hydrazine and ethyl acetoacetate activated by CeIII. Simultaneously, the formation of 2-benzylidene malononitrile B from a Knoevenagel condensation of malononitrile and aryl aldehyde catalyzed by the amino groups of the catalyst occurred. Then, Michael addition of pyrazolone A onto α,β-unsaturated compound B facilitates the formation of Michael adduct C which subsequently transformed to intermediate D via intramolecular cyclization in the presence of the catalyst. Finally, intermediate D undergoes tautomerization to give the desired product pyrano[2,3-c]pyrazole.

Conclusions

The catalyst PVC–EDA–CeIII was synthesized in a simple and efficient way by the treatment of CeCl3·7H2O with PVC–EDA which could be achieved by a substitution reaction of PVC and EDA. It has been proven that PVC–EDA–CeIII has a good performance to catalyze 4-CRs of carbonyl compounds, ethyl malononitrile, acetoacetate, and hydrazine for the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles with excellent yields. The high catalytic activity of PVC–EDA–CeIII can be attributed to the synergic catalytic effect of its Lewis acid sites and Lewis base sites. High reactivity, wide substrate scope, short reaction time, mild conditions, and reusability of the catalyst are the merits of this practical catalytic process for the synthesis of structurally diverse 1,4-pyrano[2,3-c]pyrazole derivatives.

References

B.H. Rotstein, S. Zaretsky, V. Rai, A.K. Yudin, Chem. Rev. 114, 8323 (2014)

E. Ruijter, R. Scheffelaar, R.V.A. Orru, Angew. Chem. Int. Ed. 50, 6234 (2011)

R.C. Cioc, E. Ruijter, R.V.A. Orru, Green Chem. 16, 2958 (2014)

B. Jiang, T. Rajale, W. Wever, S.-J. Tu, G. Li, Chem-Asian. J. 5, 2318 (2010)

T. Zarganes-Tzitzikas, A.L. Chandgude, A. Dömling, Chem. Rec. 15, 981 (2015)

G. van der Heijden, E. Ruijter, R.V.A. Orru, Synlett 24, 666 (2013)

N. Foloppe, L.M. Fisher, R. Howes, A. Potter, A.G.S. Robertson, A.E. Surgenor, Bioorgan. Med. Chem. 14, 4792 (2006)

J.-L. Wang, D. Liu, Z.-J. Zhang, S. Shan, X. Han, S.M. Srinivasula, C.M. Croce, E.S. Alnemri, Z. Huang, Proc. Natl. Acad. Sci. USA 97, 7124 (2000)

S.C. Kuo, L.J. Huang, H. Nakamura, J. Med. Chem. 27, 539 (1984)

S.R. Mandha, S. Siliveri, M. Alla, V.R. Bommena, M.R. Bommineni, S. Balasubramanian, Bioorg. Med. Chem. Lett. 22, 5272 (2012)

M.E.A. Zaki, H.A. Soliman, O.A. Hiekal, A.E. Rashad, Z. Naturforsch. C. 61, 1 (2006)

R.S. Aliabadi, N.O. Mahmoodi, RSC Adv. 6, 85877 (2016)

J. Feng, K. Ablajan, A. Sali, Tetrahedron 70, 484 (2014)

A. Thakur, M. Tripathi, U.C. Rajesh, D.S. Rawat, RSC Adv. 3, 18142 (2013)

F. Lehmann, M. Holm, S. Laufer, J. Comb. Chem. 10, 364 (2008)

R.Gr. Redkin, L.A. Shemchuk, V.P. Chernykh, O.V. Shishkin, S.V. Shishkina, Tetrahedron 63, 11444 (2007)

A.M. Shestopalov, Y.M. Emeliyanova, A.A. Shestopalov, L.A. Rodinovskaya, Z.I. Niazimbetova, D.H. Evans, Tetrahedron 59, 7491 (2003)

A.M. Shestopalov, Y.M. Emeliyanova, M. Yuliya, A.A. Shestopalov, L.A. Rodinovskaya, Z.I. Niazimbetova, D.H. Evans, Org. Lett. 4, 423 (2002)

M. Abdollahi-Alibeik, A. Moaddeli, K. Masoomi, RSC Adv. 5, 74932 (2015)

M.A. Zolfigol, R. Ayazi-Nasrabadi, S. Baghery, V. Khakyzadeh, S. Azizian, J. Mol. Catal. A-Chem. 418, 54 (2016)

B. Maleki, S.S. Ashrafi, RSC Adv. 4, 42873 (2014)

H.R. Shaterian, M. Sedghipour, E. Mollashahi, Res. Chem. Intermed. 40, 2721 (2014)

M. Bihani, P.P. Bora, G. Bez, H. Askari, ACS Sustain. Chem. Eng. 1, 440 (2013)

Y.M. Litvinov, A.A. Shestopalov, L.A. Rodinovskaya, A.M. Shestopalov, J. Comb. Chem. 11, 914 (2009)

B. Karmakar, Aust. J. Chem. 69, 1117 (2016)

M. Zakeri, M.M. Nasefl, T. Kargaran, A. Ahmad, E. Abouzari-Lotf, J. Asadi, Res. Chem. Intermed. 43, 717 (2017)

M.A. Zolfigol, M. Tavasoli, A.R. Moosavi-Zare, P. Moosavi, H.G. Kruger, M. Shiri, V. Khakyzadeh, RSC Adv. 3, 25681 (2013)

C.-F. Zhou, J.-J. Li, W.-K. Su, Chin. Chem. Lett. 27, 1686 (2016)

Z. Lu, J. Xiao, D. Wang, Y. Li, Asian J. Org. Chem. 4, 487 (2015)

S. Moulay, Prog. Polym. Sci. 35, 303 (2010)

X.-J. Huang, F. Dong, L. Chen, Y.-Q. Li, Monatsh. Chem. 139, 1447 (2008)

J. Liu, Y.-Q. Li, W.-J. Zheng, Monatsh. Chem. 140, 1425 (2009)

E. Bêche, P. Charvin, D. Perarnau, S. Abanades, G. Flamant, Surf. Interface Anal. 40, 264 (2008)

Y. Bu, C.J. Weststrate, J.W. Niemantsverdriet, H.O.A. Fredriksson, ACS Catal. 6, 7994 (2016)

M. Babaie, H. Sheibani, Arab. J. Chem. 4, 159 (2010)

R.H. Vekariya, K.D. Patel, H.D. Patel, Res. Chem. Intermed. 42, 4683 (2016)

Acknowledgements

We are grateful to the National Natural Science Foundation of China (No 21372099) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, T., Zhou, J., Chen, Y. et al. Ce(III) immobilized on aminated poly(vinyl chloride): high-performance synergistic bifunctional acid–base catalyst for one-pot synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles. Res Chem Intermed 44, 5329–5344 (2018). https://doi.org/10.1007/s11164-018-3425-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-018-3425-x