Abstract

Pd2+/Cu2+ bimetallic catalysts immobilized on ethylenediamine-functionalized poly(vinyl chloride) (PdII/CuII@EDA-PVC) were developed by combining two metallic catalysts that complement rather than inhibit one another. The synthesized PdII/CuII@EDA-PVC were screened for their catalytic activity and found to be excellent in the one-pot sequential synthesis of quinoxalines from 1,2-diphenylacetylenes and o-phenylenediamines. Both Pd2+ and Cu2+ are indispensable and play crucial roles in this transformation. This one-pot sequential reaction proceeds well and tolerates various available substrates to form the desired product in excellent yield. A plausible mechanism was proposed for this conversion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Quinoxalines are one important class of nitrogen-containing heterocyclic compounds with interesting applications in organic chemistry, pharmaceuticals, agriculture, and advanced materials [1,2,3,4,5]. In light of their usefulness, the development of efficient and practical synthetic approaches for quinoxalines has attracted significant attention, and a number of catalytic synthetic methods have been documented [6]. Among these, the common method is the direct condensation of 1,2-dicarbonyl compounds with o-phenylenediamine in the presence of Bronsted acid and Lewis acid catalysts (Scheme 1, path a). Examples of Bronsted acids include sulfamic acid [7], citric acid [8], H6P2W18O62 [9], protic ionic liquids [10], polyaniline-sulfate salt [11], 2-iodoxybenzoic acid (IBX) [12], Montmorillonite K-10 [13], etc. The employed Lewis acids comprise I2 [14,15,16], InCl3 [17], MnCl2 [18], CuSO4 [19], Zn[(L)proline] [20], CAN [21], Ga(OTf)3 [22], sulfonated nanoClay [23], and so on. Another variant to develop quinoxalines involved the condensation of α-hydroxy ketone with o-phenylenediamine via a one-pot tandem oxidation and annulation process (Scheme 1, path b). A variety of catalysts and oxidants such as MnO2 [24, 25], HgI2 [26], Pd(OAc)2 [27], RuCl2(PPh3)3 in diglyme [28], FeCl3/morpholine [29], silica gel coupled with MWI [30], and N-Heterocyclic carbene (NHC) [31] have been employed for this transformation. These documented protocols have their own merits and disadvantages, however most employed substrates are confined to 1,2-diketones or α-hydroxy ketones so they lead to quinoxalines with poor functional group diversity. Recently, several synthetic methods have been reported for the one-pot sequential synthesis of quinoxalines by use of commercially available alkynes and o-phenylenediamines as starting materials should be one of the most efficient and economic strategies toward the formation of quinoxalines (Scheme 1, path c). This type of one-pot sequential reaction combines a two-step reaction in a single vessel that has the advantages of reducing the synthesis route, simplifying the operation, promoting the product outcome, and decreasing the waste output as well. Various oxidants and catalytic systems, including NBS [32], Cu2+/Al3+ [33], PhI(OCOCF3)2/I2 [34], PdCl2/CuCl2/PEG [35], PdI2/DMSO [36], [AuCl(IPr)]/AgNTf [37], [Ru(cymene)Cl2]2/TEMPO [38], Au(I) [39], I2/DMSO [14,15,16], PhI(OAc)2 [40], NH4I/EtOCS2K [41], and others have been reported for the preparation of this type of compound. However, some of these procedures still have several drawbacks such as the use of precious metal catalysts, need of strong oxidants, generation of toxic waste, and conduction under harsh reaction conditions. Moreover, the yields are usually unsatisfactory in some cases. Consequently, the development of a simple, convenient, and general method for the one-pot sequential synthesis of quninoxalines is still a challenge from commercially available alkynes and o-phenylenediamines.

The above documented methodologies were brought to our attention and inspired us to develop an affordable alternative catalytic system for this conversion. We envisioned that a novel heterogeneous PdII/CuII dual catalyst merged the preponderance of both Pd2+ and Cu2+ catalytical properties that would definitely be of potential interest to promote one-pot two-step sequential reactions of alkynes with o-phenylenediamines for the synthesis of quninoxalines (Scheme 1, path c). In this integrated heterogeneous bimetallic catalyst, the combined Pd2+/Cu2+ catalytic species can greatly activate the C≡C bond of the alkyne [42] to facilitate the conversion of diphenylacetylene into dikentones via Wacker-type oxidation [43], as well as it can efficiently mediate the subsequently condensation of dikentones formed in situ and o-phenylenediamines. Poly(vinyl chloride)(PVC) is one of the cheapest and most commercially available synthetic polymers which is used extensively in the academic and industrial communities. It is well known that PVC which possesses chlorine on its molecular backbone is easily functionalized by replacement of chlorine with nucleophilic groups [44]. Palladium and copper can form stable complexes with a wide variety of organic ligands with P, N, O, and S atoms because of its pronounced coordination properties. PVC-EDA bearing –NH2 groups on its molecular skeleton, PVC-EDA possesses the potential to act as an excellent ligand to chelate Pd2+ and Cu2+, which makes it a suitable polymeric carrier for immobilization of bimetallic catalyst. Our group has been interested in utilizing efficient, heterogeneous catalysts based on the functionalized PVC for many catalysis applications and reported PVC-EA-Pd0 [45], PVC-EDA-SA-Pd0 [46], PVC-EDA-CuII [47], PVC-EDA-CeIII [48] and their applications in Suzuki couplings, Heck reactions, CuAAC reaction, and multicomponent reactions.

On the basis of the described properties and our previous works, we herein wish to advocate the successful attempt on a PdII/CuII@EDA-PVC in which PVC not only is serving as supporting material but also acting as a N-ligand to coordinate to PdII/CuII bimetallic cations for one-pot consequential construction of quinoxalines (Scheme 2). To the best of our knowledge, a PdII/CuII@EDA-PVC bimetallic catalyst has not yet been used for this purpose.

Experimental

Chemicals and reagents

All chemicals were used directly as received. Melting points were recorded on a X5 digital apparatus. The infrared spectrum of products is recorded using a Perkin Elmer PE-1600-FTIR. The 1H NMR (300 MHz) and 13C NMR (75 MHz) were run on a Bruker Avance spectrometer. Mass spectra were recorded on a Shimadzu GC MS-QP 1000 EX 85 apparatus. The known products were identified by comparison of their melting points and spectral data with those reported in the literature. Progress of the reactions was monitored by TLC using silica gel HF 254 plates.

General procedure for one-pot synthesis of quinoxalines

A mixture of 1,2-diphenylethyne (1 mmol), o-phenylenediamine (1 mmol), DMSO (2 mL), and PdII/CuII@EDA-PVC (0.14 mmol) was charged into a sealed vessel at 140 °C with vigorously stirring. The progress was tracked by TLC. Upon the end of the reaction, the mixture was cooled to room temperature, extracted with ethyl acetate (10 mL × 3) to separate the product. The organic fraction was successively washed with dilute HCl, brine, and dried on anhydrous sodium sulfate. After evaporating the organic solvent, the solid residue was recrystallized by a mixture of ethanol and water to give the pure product.

Result and discussion

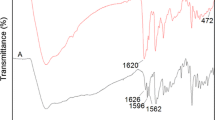

Following the procedure of our previous work, PVC was partially converted into aminated PVC (PVC-EDA) with the use of ethylenediamine at 80 °C. Complexation of the as-prepared PVC-EDA with equivalent of PdCl2 and CuCl2 solution provides the desired PdII/CuII@EDA-PVC bimetallic catalyst. The content of Pd and Cu was determined to be 1.0 mmol/g and 0.005 mmol/g in the catalyst by ICP-AES. The synthetic pathway is depicted in Scheme 3.

To explore the feasibility of our strategy, we began our investigation by exerting 1,2-diphenylethyne and o-phenylenediamine as a model reaction in the presence of different amounts of PdII/CuII@EDA-PVC at the range of room temperature to 140 °C in various solvents. The results are shown in Table 1. At the beginning, the effect of the amount of PdII/CuII@EDA-PVC on the model reaction was investigated in DMSO at 140 °C. As shown in Table 1, it was found that the yield of the desired product was reached up to 95% when the model reaction was carried out in the presence of PdII/CuII@EDA-PVC (3 mol% Pd, 0.02 mol% Cu) (Table 1, entry 3). This result encouraged us to optimize the dosage of PdII/CuII@EDA-PVC on the catalytic performance. Increasing the amount of Pd/Cu from 3/0.02 to 4.5/0.03 mol%, even to 6/0.04 mol% had no apparent improvement in yield at all (Table 1, entries 4–5). Lowering the amount of the Pd/Cu to 2/0.013 mol% still allowed the reaction to proceed smoothly, decreasing the desired product in 91% yield respectively (Table 1, entry 2). Further decreasing the amount of the Pd/Cu to 1/0.007 mol%, the product yield dramatically dropped to 44% (Table 1, entry 1). Next, the effect of reaction temperature was evaluated on the model reaction. Remarkably, the temperature had an apparent impact on the model reaction. The highest yield of the product was obtained when the reaction was carried out DMSO at 140 °C (Table 1, entry 3), and the yield of the product decreased from 95 to 43, 17, 11, and 0% as the temperature was decreased from 140 to 120, 100, 80, 60 °C and even to room temperature (Table 1, entries 5–10). Finally, the used solvents were explored. Among the various screened solvents, DMSO was identified as most effective for the model reaction under the catalytic system. Replacement of DMSO with other solvents such as DMF, acetonitrile, 1,4-dioxane, THF, toluene, and dichloromethane resulted in no product detected (Table 1, entries 11–16). Taken together, optimal conditions for this model reaction were identified by employing 1,2-diphenylacetylene (1 mmol), o-phenylenediamine (1 mmol), and PdII/CuII@EDA-PVC (3 mol% of Pd and 0.02 mol% of Cu) in DMSO at 140 °C, which yielded 95% of the desired product.

Upon the optimal reaction conditions in hand, we tested the scope of internal alkynes and o-phenylenediamine. As shown in Table 2, a variety of 1,2-disubstituted alkynes and o-phenylenediamine proceeded smoothly in this reaction to afford the corresponding quinoxalines in excellent yields. It should be noted that both electron-donating and electron-withdrawing substitution such as –OMe, –OEt, –Me, –Cl, –NO2 on the aromatic ring of internal alkynes and o-phenylenediamine were tolerated in the reaction to give the corresponding products in good yields.

Recyclability of the catalyst was examined upon the model reaction. After completion of the reaction, the reaction mixture was extracted with ethyl acetate to separate the product. The left catalyst was washed with EtOAc thoroughly, and reused for the next run without additional treatment. The catalyst can be reused at least four times with satisfying yield (Fig. 1).

To gain further insights into the reaction mechanism, some control experiments have been explored (Scheme 4). Initially, the Wacker-type reaction of diphenylacetylene was performed in the absence and presence of CuII@EDA-PVC, PdII@EDA-PVC, and PdII/CuII@EDA-PVC separately in DMSO under optimal conditions. As can be seen from Scheme 4a, the Wacker-type reaction did not process under catalyst-free conditions (Scheme 4a, i). Also, the CuII@EDA-PVC is null and void when it was employed as a catalyst for this transformation (Scheme 4a, ii). When PdII@EDA-PVC was used as a catalyst, the moderate yield (48%) of the corresponding benzil was obtained (Scheme 4a, iii), which indicates PdII@EDA-PVC has certain catalytic performance. Remarkably, PdII/CuII@EDA-PVC afforded the highest yield (97%) of the desired benzil under the standard conditions (Scheme 4a, iv). These results clarify that both of the Pd(II) and Cu(II) species are indispensable and played a critical role in the Wacker-type reaction. These findings may contribute to the synergic effect of Pd(II) and Cu(II). [33, 35, 42, 43]. Subsequently, the condensation of benzil and o-phenylenediamine was investigated (Scheme 4b). All the catalyst of CuII@EDA-PVC, PdII@EDA-PVC, and PdII/CuII@EDA-PVC gave the desired quinoxaline in excellent yields.

A plausible mechanism based on the control experimental results and previous literatures is outlined in Scheme 5. The Pd2+ combined with Cu2+ to form a Pd2+/Cu2+-π-complex intermediate (I) should greatly activate C≡C bond of the alkyne through coordination to generate the acceptors of DMSO [42]. The nucleophilic addition of DMSO to the as-generated π-complex intermediate (I) followed by the release of Me2S and the addition of another DMSO produces a ketoalcohol-like intermediate (II), which proceeds to afford the corresponding 1,2- diphenyldiketone along with the Pd2+/Cu2+ bimetallic species and Me2S. Noticeably, the Pd2+/Cu2+-π-complex leads to a more efficient nucleophilic attack of DMSO onto the activated C≡C bond of the alkyne than Pd2+ alone, thus affording more efficient alkyne Wacker-type oxidation [43]. Subsequently, condensation reaction of 1,2-dikentone with o-phenylenediamine catalyzed by PdII/CuII of the catalysts affords the desired quinoxaline.

Conclusion

In conclusion, we have developed a PdII/CuII@EDA-PVC bimetallic catalyst in a simple and efficient way by the treatment of a solution of Pd and Cu salts with PVC-EDA which could be easily achieved by a substitution reaction of PVC and EDA. The experimental results demonstrate that PdII/CuII@EDA-PVC bimetallic catalysts possess a good catalytic activity in the synthesis of a broad variety of quinoxaline derivatives. This approach undergoes through one-pot sequential reaction of Wacker-type oxidation of alkyne giving 1,2-dikentones, which are then condensed with o-phenylenediamine smoothly affording substituted quinoxaline derivatives in excellent yields. High reactivity, wide substrate scope, short reaction time, and reusability of the catalyst are the merits of this practical catalytic process.

References

J.A. Pereira, A.M. Pessoa, M.N.D.S. Cordeiro, R. Fernandes, C. Prudêncio, J.P. Noronha, M. Vieira, Eur. J. Med. Chem. 97, 664 (2015)

T.-C. Lin, Y.-J. Huang, B.-R. Huang, Y.-H. Lee, Tetrahedron Lett. 52, 6748 (2011)

D. Aldakov, P. Anzenbacher Jr., Chem. Commun. (12), 1394 (2003)

C.B. Black, B. Andrioletti, A.C. Try, C. Ruiperez, J.L. Sessler, J. Am. Chem. Soc. 121, 10438 (1999)

D. Aldakov, M.A. Palacios, P. Anzenbacher Jr., Chem. Mater. 17, 5238 (2005)

O.O. Ajani, Eur. J. Med. Chem. 85, 688 (2014)

H.R. Darabi, S. Mohandessi, K. Aghapoor, F. Mohsenzadeh, Catal. Commun. 8, 389 (2007)

R. Mahesh, A.K. Dhar, T.V.N.V. Tara Sasank, S. Thirunavukkarasu, T. Devadoss, Chin. Chem. Lett. 22, 389 (2011)

M.M. Heravi, K. Bakhtiari, F.F. Bamoharram, M.H. Tehrani, Monatsh. Chem. 138, 465 (2007)

A.G. Mulik, D.R. Chandam, D.R. Patil, P.P. Patil, G.N. Mulik, S.T. Salunkhe, M.B. Deshmukh, Res. Chem. Intermed. 41, 10085 (2015)

C. Srinivas, C.N.S.S.P. Kumar, V.J. Rao, S. Palaniappan, J. Mol. Catal. A-Chem. 265, 227 (2007)

M.M. Heravi, K. Bakhtiari, M.H. Tehrani, N.M. Javadi, H.A. Oskooie, Arkivoc (16), 16 (2006)

T.-K. Huang, R. Wang, L. Shi, X.-X. Lu, Catal. Commun. 9, 1143 (2008)

C. Xie, Z. Zhang, B. Yang, G. Song, H. Gao, L. Wen, C. Ma, Tetrahedron 71, 1831 (2015)

K.K.D.R. Viswanadham, M. Prathap Reddy, P. Sathyanarayana, O. Ravi, R. Kant, S.R. Bathula, Chem. Commun. 50, 13517 (2014)

J. Zi, D.-W. Gu, Y. Zhang, Z.-Y. Hu, X.-Q. Zhang, X.-X. Guo, Synth. Commun. 48, 915 (2018)

P. Hazarika, P. Gogoi, D. Konwar, Synth. Commun. 37, 3447 (2007)

M.M. Heravi, K. Bakhtiari, H.A. Oskooie, S. Taheri, Heteroatom Chem. 19, 218 (2008)

M.M. Heravi, S. Taheri, K. Bakhtiari, H.A. Oskooie, Catal. Commun. 8, 211 (2007)

M.M. Heravi, M.H. Tehrani, K. Bakhtiari, H.A. Oskooie, Catal. Commun. 8, 1341 (2007)

S.V. More, M.N.V. Sastry, C.-F. Yao, Green Chem. 8, 91 (2006)

J.-J. Cai, J.-P. Zou, X.-Q. Pan, W. Zhang, Tetrahedron Lett. 49, 7386 (2008)

M. Tajbakhsh, M. Bazzar, S.F. Ramzanian, M. Tajbakhsh, Appl. Clay Sci. 88, 178 (2014)

S.A. Raw, C.D. Wilfred, R.J.K. Taylor, Chem. Commun. (18), 2286 (2003)

S.A. Raw, C.D. Wilfred, R.J.K. Taylor, Org. Biomol. Chem. 2, 788 (2004)

S.A. Kotharkar, D.B. Shinde, Bull. Korean Chem. Soc. 27, 1466 (2006)

R.S. Robinson, R.J.K. Taylor, Synlett (6), 1003 (2005)

C.S. Cho, S.G. Oh, Tetrahedron Lett. 47, 5633 (2006)

W. Song, P. Liu, M. Lei, H. You, X. Chen, H. Chen, L. Hu, Synth. Commun. 42, 236 (2012)

V. Jeena, R.S. Robinson, Tetrahedron Lett. 55, 642 (2014)

L. Gao, R. Liu, C. Yu, C. Yao, T. Li, Z. Xiao, Res. Chem. Intermed. 40, 2131 (2014)

C.-K. Chan, M.-Y. Chang, Synthesis 48, 3785 (2016)

A.V. Nakhate, K.B. Rasal, G.P. Deshmukh, S.S.R. Gupta, L.K. Mannepalli, J. Chem. Sci. 129, 1761 (2017)

M. Tingoli, M. Mazzella, B. Panunzi, A. Tuzi, Eur. J. Org. Chem. (2), 399 (2011)

S. Chandrasekhar, N.K. Reddy, V.P. Kumar, Tetrahedron Lett. 51, 3623 (2010)

C. Mousset, O. Provot, A. Hamze, J. Bignon, J.-D. Brion, M. Alami, Tetrahedron 64, 4287 (2008)

S. Shi, T. Wang, W. Yang, M. Rudolph, A.S.K. Hashmi, Chem-Eur. J. 19, 6576 (2013)

Y. Xu, X. Wan, Tetrahedron Lett. 54, 642 (2013)

Y. Liu, X. Chen, J. Zhang, Z. Xu, Synlett 24, 1371 (2013)

C.-Y. Chen, W.-P. Hu, M.-C. Liu, P.-C. Yan, J.-J. Wang, M.-I. Chung, Tetrahedron 69, 9735 (2013)

S. Jiang, Y. Li, X. Luo, G. Huang, Y. Shao, D. Li, B. Li, Tetrahedron Lett. 59, 3249 (2018)

J.-W. Xue, M. Zeng, X.-F. Hou, Z.-Q. Chen, G.-C. Yin, Asian. J. Org. Chem. 7, 212 (2018)

W. Ren, Y. Xia, S.-J. Ji, Y. Zhang, X. Wan, J. Zhao, Org. Lett. 11, 1841 (2009)

S. Moulay, Prog. Polym. Sci. 35, 303 (2010)

X.-J. Huang, F. Dong, L. Chen, Y.-Q. Li, Monatsh. Chem. 139, 1447 (2008)

J. Liu, Y.-Q. Li, W.-J. Zheng, Monatsh. Chem. 140, 1425 (2009)

Y. Zhang, Z. Zhang, Y. Chen, Y. Li, Res. Chem. Intermed. 43, 7307 (2017)

T. Zhang, J. Zhou, Y. Chen, Y. Li, Res. Chem. Intermed. 44, 5329 (2018)

Acknowledgements

We are grateful to the National Natural Science Foundation of China (No 21372099) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jiang, W., Sun, W., Zhou, Y. et al. Integration of Pd and Cu on polymer: a powerful bimetallic heterogeneous catalyst for sequential synthesis of quinoxalines. Res Chem Intermed 45, 5535–5547 (2019). https://doi.org/10.1007/s11164-019-03918-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-03918-w