Abstract

The efficacy of thiourea dioxide (TUD) as an efficient, inexpensive, and readily accessible organocatalyst for the synthesis of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitrile derivatives via a four-component reaction of ethyl acetoacetate, hydrazine hydrate, aryl aldehydes, and malononitrile is described. Upon completion of the reaction, the product was isolated by filtration, and the remaining aqueous TUD solution could be reused several times with consistent catalytic activity. High yields, simple work-up process, avoiding the use of organic solvents, short reaction time, and recyclable catalyst are the superior advantages of the present protocol.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, the expansions of green protocols that are environmentally benign and pollution free have received substantial levels of consideration because of the increasing tendency of the chemical industry towards greener unit processes. Nowadays, Multi-component reactions (MCRs) have received much attention in the field of organic and medicinal chemistry, because the strategies of MCR offer significant advantages over conventional synthetic methodologies [1]. The average molecular complexity occurred per operation is completely dependent from the length of organic synthesis, which depends in turn on the number of chemical bonds being formed [2]. Therefore, planning reactions that accomplish multi-bond formation in one operation are becoming one of the foremost challenges in the field of green organic synthesis. Synthesis of biological active molecules as well as important organic intermediates through an MCR approach delivers a number of merits over conventional transformations, such as shorter reaction times, higher product yields, lower costs, and environmental wellbeing [3–5].

4H-Pyrans analogue heterocyclic scaffolds signify a fortunate structural motif well distributed in naturally occurring compounds [6, 7]. Furthermore, 4H-pyrane derivatives displays a broad spectrum of biological activities such as anticancer [8], anti-HIV [9], anti-inflammatory [10], antimalarial [11], antimicrobial [12], antiviral [13], and anti-proliferative [14]. These potent outlines of biological activities have encouraged widespread studies for the preparation of 1,4-dihydropyrano[2,3-c]pyrazole derivatives [15]. Condensed pyrazolo derivatives are also biologically important compounds and their chemistry has recently received considerable attention [16]. Several pyrano[2,3-c]pyrazoles are reported to have beneficial biological activities such as anti-inflammatory and analgesic [17]. In addition, the biological activity of fused azoles has led to exhaustive research on their synthesis [18]. Because of the presence of the 1,4-dihydropyrano[2,3-c]pyrazole scaffold in several biologically active compounds, new approaches in the direction of the synthesis of highly functionalized pyrano[2,3-c]pyrazoles are of great attention. Thus, these derivatives were synthesized using different catalysts like maltose [19], saccharose [20], urea [21], lipase [22], meglumine [23], diaminocyclohexane-thiourea [24], isonicotinic acid [25], acetic acid [26], DBU [27], DABCO [28], piperidine and pyridine [29], pyrrolidine [30], citric acid [31], disulfonic acid imidazolium chloroaluminate [32], sodium benzoate [17], nano-titania sulfuric acid (TSA) [33], nano-ZnO [34], CuO–CeO2 nanocomposite [35], nano-titania-supported preyssler-type heteropolyacid [36], nano TiO2 [37], nano-CuFe2O4 [38], nickel nanoparticles [39], nano-CuI [40], Fe3O4 nanoparticles [41], SnO2 quantum dots [42], amberlyst A21 [43], cetyltrimethylammonium chloride (CTACl) [44], NaOH [45], tetraethylammonium bromide (TEABr) [46], CeCl3 [47], CSF [48], poly(4-vinylpyridine) [49], borax [50], silica-supported tetramethylguanidine [51], iodine [52], cerium ammonium nitrate (CAN) [53], and tungstate sulfuric acid [54].

Among the recently developed expansions of interest, the use of catalysis by small organic molecules called organocatalysis has become an extensive area of the research in synthetic organic chemistry, which is one of the most important possibilities for sustainable chemistry. Ambitious because of environmental concerns, there is great need to develop an inexpensive, non-metallic readily accessible, recyclable and reusable, small organic molecule catalyst [55]. Organocatalysis offers numerous advantages including lower activation energy, high stability, metal free environment, reduced toxicity and mild reaction conditions [56–58]. Small molecules such as urea [59–61] and thiourea [62–64] derivatives, due to their strong hydrogen-bonding activity, have also ascended to be potential organocatalysts for the preparation of important organic molecules. Owing to the growing environmental concerns, there is continued pressure on pharmaceutical as well as on chemical industries to reduce chemical waste. In this regard utilization of heterogeneous catalysts may offer the advantages of facile recovery and recycling of the catalyst, which reduces chemical pollution [65–69].

Simply oxidation of thiourea with hydrogen peroxide affords thiourea dioxide (TUD) [70]. TUD is a highly stable material. Moreover, TUD retains the ability to activate organic substrates through hydrogen bonding. Furthermore, TUD can form strong hydrogen bonding interaction and provide higher levels of activation than the corresponding thiourea, because it possesses two extra oxygen atoms. In addition, thiourea dioxide is insoluble in common organic solvents; and, therefore, it can easily be recovered from the reaction and reused several times without significant loss of efficiency. Recently, TUD has emerged as a promising novel organocatalyst in the one-pot synthesis of a library of novel heterocyclic compounds [71], hydrolysis of imines [72], synthesis of naphthopyrans [73], synthesis of pyrano[4,3-b]pyrans [74], synthesis of 4-aryl-2-naphthalen-2-yl-5H-indeno [1,2-b]pyridin-5-ones [75], in oxidation of sulfides to sulfoxides [76], in reduction of aldehydes [77], and synthesis of dihydropyrido[2,3-d]pyrimidine-2,4-diones [78]. Our literature survey exposed that there is no report on the use of TUD as a green organocatalyst in the synthesis of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitriles. Herein, we wish to report the development of an environmentally friendly process for the preparation of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitrile derivatives via the one‐pot, four-component synthesis catalyzed by TUD in aqueous media (Scheme 1).

Experimental

Apparatus and analysis

All chemicals, unless otherwise specified, were purchased from commercial sources and were used at analytical grade. The products were characterized by a comparison of their physical data and melting points with those of known samples or by their spectral data. Melting points were measured on an Optimelt MPA 100 melting point apparatus and are uncorrected. FT-IR spectra were recorded on a Perkin Elmer FT-IR 377 spectrometer using KBr. Proton NMR spectra were recorded on a Bruker AV 400 MHz spectrometer using DMSO as solvent and TMS as the internal reference. Mass spectra were recorded at Advion expression CMS, USA. Acetone is used as the mobile phase, and electron spray ionization (ESI) is used as the ion source. Elemental analysis was performed on a CHN elemental analyzer. The development of reactions was monitored by thin layer chromatography (TLC) analysis on Merck pre-coated silica gel 60 F254 aluminum sheets, visualized by UV light.

Synthesis of thiourea dioxide (Catalyst) [33]

Thiourea (25 g) was dissolved in pure water (250 mL) at 40 °C, and the solution was cooled to 8–10 °C. Hydrogen peroxide solution (aq. 50 wt%, 80 mL) was added slowly at a rate such that the solution temperature was held below10 °C and stirred over a period of 90 min. Thereafter, the solution was cooled to 0 °C. After the crystallization, the resulting solid–liquid mixture was filtered off immediately at 0 °C, and the crystals so obtained were dried at 50 °C, to yield thiourea dioxide 26.0 g (75 %).

General method for the preparation of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitriles (1–15)

In a 25-mL round-bottomed flask, ethyl acetoacetate (1 mmol), hydrazine hydrate (1.5 mmol, 80 %), aromatic aldehydes (1 mmol), and malononitrile (1 mmol) were stirred in the presence of 10 mol% of TUD in 5 mL water at 80 °C for 30–50 min. During the reflux, the progress of the reaction mixture was monitored by TLC analysis. The mixture was then poured into water (10 mL), and the resulting solid was removed by filtration, and washed with water. The remaining aqueous thioureadioxide was collected, water was evaporated under vacuum, and catalyst was dried. This recovered catalyst could be reused four times without significant loss of its efficiency. The crude products were purified by recrystallization from ethanol. The reaction products were identified by comparing their physical and spectral data (i.e., IR, 1H and 13C NMR, and MS) with those reported in the literature.

Spectral data of representative compounds

6-amino-4-(4-methoxyphenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (5)

Light yellow solid, White solid. IR ν max (KBr) cm−1: 3411, 3385 (NH2), 3320 (–NH–), 3070, 3022 (Aromatic), 2933 (–CH3), 2590 (–OCH3), 2206 (–CN), 1482 (–NH–), 812 (Para-NO2). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.79 (s, 3H, CH3), 2.27 (s, 3H, OCH3), 4.55 (s, 1H, 4H), 6.87 (s, 2H, NH2), 7.30–7.32 (d, 2H, J = 7.96 Hz, Ar–H), 7.76–7.78 (d, 2H, J = 8.04 Hz, Ar–H), 12.11 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.86, 27.98, 55.18, 99.32, 111.68, 112.74, 121.11, 128.55, 127.53, 134.45, 135.18, 163.34. MS (ESI) m/z for (282.11): 282.1 (M)+, 283.3 (M + 1)+. Elemental Analysis (CHN): calcd. for C14H11N5O3: C 56.56, H 3.73, N 23.56 %; found: C 56.58, H 3.72, N 23.55 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(4-chlorophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (8)

Off-white solid, IR ν max (KBr) cm−1: 3400, 3391 (NH2), 3317 (–NH–), 3066, 3017 (Aromatic), 2931 (–CH3), 2211 (–CN), 1488 (–NH–), 1058 (Ar–Cl), 815 (Para-Cl). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.79 (s, 3H, CH3), 4.64 (s, 1H, 4H), 6.96 (s, 2H, NH2), 7.19–7.21 (d, 2H, J = 8.40 Hz, Ar–H), 7.37–7.39 (d, 2H, J = 8.40 Hz, Ar–H), 12.17 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.71, 35.51, 56.68, 97.15, 120.65, 128.43, 129.07, 129.34, 129.70, 130.00, 131.20, 135.67, 143.44, 154.65, 160.87. MS (ESI) m/z for (286.06): 286.1 (M)+, 288.1 (M + 2)+. Elemental Analysis (CHN): calcd. for C14H11ClN4O: C 58.65, H 3.87, N 19.54 %; found: C 58.63, H 3.88, N 19.55 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(4-hydroxy-3,5-dimethoxyphenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (11): (Novel Compound)

Off-white solid. IR ν max (KBr) cm−1: 3452 (C–OH), 3393, 3384 (NH2), 3310 (–NH–), 3059, 3010 (Aromatic), 2925 (–CH3), 2590 (–OCH3), 2205 (–CN), 1481 (–NH–), 742 (Ortho), 772 (Meta), 805 (Para). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.86 (s, 3H, CH3), 3.71 (s, 6H, 2 × OCH3), 4.53 (s, 1H, 4H), 6.43 (s, 2H, NH2), 6.85 (s, 2H, Ar–H), 8.28 (s, 1H, –OH), 12.08 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.88, 36.24, 55.93, 57.32, 97.63, 104.82, 120.89, 134.25, 134.45, 135.66, 147.80, 154.66, 160.73. MS (ESI) m/z for (328.1): 329.1 (M + 1)+, 351.1 (M + Na)+. Elemental Analysis (CHN): calcd. for C16H16N4O4: C 58.53, H 4.91, N 17.06 %; found: C 58.54, H 4.90, N 17.06 %.

6-amino-4-(4-bromophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (12)

White solid. IR ν max (KBr) cm−1: 3405, 3390 (NH2), 3317 (–NH–), 3062, 3028 (Aromatic), 2930 (–CH3), 2205 (–CN), 1626 (=C=N–), 1487 (–NH–), 1069 (Ar–Br), 810 (Para-Br). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 2.15 (s, 3H, CH3), 4.72 (s, 1H, 4H), 6.55 (s, 2H, NH2), 7.44–7.46 (d, 2H, J = 8.48 Hz, Ar–H), 7.56–7.58 (d, 2H, J = 8.48 Hz, Ar–H), 10.93 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.66, 27.2, 40.57, 98.02, 113.88, 113.94, 120.81, 129.95, 131.53, 138.05, 139.18, 158.97. MS (ESI) m/z for (330.0): 330.2 (M)+, 332.3 (M + 2)+. Elemental Analysis (CHN): calcd. for C14H11BrN4O: C 50.77, H 3.35, N 16.92 %; found: C 50.72, H 3.38, N 16.89 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(4-nitrophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (14)

Yellow solid. IR ν max (KBr) cm−1: White solid. IR ν max (KBr) cm−1: 3414, 3389 (NH2), 3323 (–NH–), 3073, 3025 (Aromatic), 2936 (–CH3), 2209 (–CN), 1485 (–NH–), 1354, 1563 (Ar–NO2), 818 (Para-NO2). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.82 (s, 3H, CH3), 4.84 (s, 1H, 4H), 7.08 (s, 2H, NH2), 7.46–7.48 (d, 2H, J = 8.48 Hz, Ar–H), 8.20–8.22 (d, 2H, J = 8.48 Hz, Ar–H), 12.22 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.71, 35.84, 55.84, 96.52, 120.47, 123.87, 128.81, 135.84, 146.34, 152.08, 154.63, 161.11. MS (ESI) m/z for (297.1): 397.2 (M)+, 398.3 (M + 1)+. Elemental Analysis (CHN): calcd. for C14H11BrN4O: C 50.77, H 3.35, N 16.92 %; found: C 50.72, H 3.38, N 16.89 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(3,4,5-trimethoxyphenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (19)

Off-white solid. IR ν max (KBr) cm−1: 3432 (C–OH), 3391, 3382 (NH2), 3316 (–NH–), 3069, 3017 (Aromatic), 2922 (–CH3), 2593 (–OCH3), 2207 (–CN), 1487 (–NH–), 742 (Ortho), 772 (Meta), 805 (Para). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.89 (s, 3H, CH3), 3.55 (s, 9H, 3 × OCH3), 4.61 (s, 1H, 4H), 6.49 (s, 2H, NH2), 6.92 (s, 2H, Ar–H), 12.13 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.91, 36.46, 55.74, 56.84, 59.91, 97.28, 104.49, 105.50, 120.87, 135.73, 136.07, 140.07, 152.76, 153.13, 154.67, 160.95. MS (ESI) m/z for (342.13): 343.1 (M + 1)+, 366.2 (M + Na)+. Elemental Analysis (CHN): calcd. for C17H18N4O4: C 59.64, H 5.30, N 16.37 %; found: C 59.63, H 5.33, N 16.36 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(4-cyanophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (22)

Off-white solid, IR ν max (KBr) cm−1: 3402, 3394 (NH2), 3314 (–NH–), 3067, 3020 (Aromatic), 2931 (–CH3), 2213 (Ar–CN), 1486 (–NH–), 817 (Para-CN). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 1.79 (s, 3H, CH3), 4.76 (s, 1H, 4H), 7.04 (s, 2H, NH2), 7.38–7.40 (d, 2H, J = 8.12 Hz, Ar–H), 7.79–7.81 (d, 2H, J = 8.08 Hz, Ar–H), 12.20 (s, 1H, NH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.69, 36.10, 55.97, 96.61, 109.60, 118.76, 120.52, 128.56, 132.57, 135.77, 150.02, 154.66, 161.10. MS (ESI) m/z for (277.28): 277.2 (M)+, 278.1 (M + 1)+. Elemental Analysis (CHN): calcd. for C15H11N5O: C 64.97, H 4.00, N 25.26 %; found: C 64.93, H 4.02, N 25.23 %. The spectroscopic data is in full agreement with the reported literature data.

6-amino-4-(2-hydroxy-5-nitrophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (23): (Novel Compound)

Yellow solid, IR ν max (KBr) cm−1: 3436 (C–OH), 3406, 3397 (NH2), 3317 (–NH–), 3065, 3024 (Aromatic), 2935 (–CH3), 2217 (–CN), 1488 (–NH–), 1355, 1566 (Ar–NO2), 744 (Ortho), 774 (Meta), 803 (Para). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 2.10 (s, 3H, CH3), 4.77 (s, 1H, 4H), 6.99 (s, 2H, NH2), 7.20–7.22 (d, 1H, J = 7.44 Hz, Ar–H), 7.88 (s, 1H, Ar–H), 8.05–8.07 (d, 1H, J = 6.28 Hz, Ar–H), 10.67 (s-broad, 2H, NH and OH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.80, 18.50, 28.66, 54.91, 56.01, 104.35, 117.05, 120.15, 123.45, 124.71, 124.96, 136.80, 143.46, 153.05, 159.20, 160.04. MS (ESI) m/z for (313.27): 313.3 (M)+, 314.1 (M + 1)+. Elemental Analysis (CHN): calcd. for C14H11N5O4: C 53.68, H 3.54, N 22.36 %; found: C 53.66, H 3.52, N 22.33 %.

6-amino-4-(2-hydroxy-5-bromophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (24): (Novel Compound)

Light yellow solid, IR ν max (KBr) cm−1: 3440 (C–OH), 3411, 3399 (NH2), 3319 (–NH–), 3068, 3028 (Aromatic), 2937 (–CH3), 2218 (–CN), 1491 (–NH–), 1062 (Ar–Br), 740 (Ortho), 773 (Meta), 810 (Para). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 2.06 (s, 3H, CH3), 4.64 (s, 1H, 4H), 6.65 (s, 2H, NH2), 6.95–6.97 (d, 1H, J = 6.2 Hz, Ar–H), 7.09 (s, 1H, Ar–H), 7.34–7.36 (d, 1H, J = 8.68 Hz, Ar–H), 10.58 (s-broad, 2H, NH and OH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 9.79, 18.55, 28.63, 54.94, 56.03, 104.39, 117.02, 120.18, 123.44, 124.74, 124.93, 136.81, 143.44, 153.07, 159.22, 160.06. MS (ESI) m/z for (347.17): 347.2 (M)+, 349.1 (M + 2)+. Elemental Analysis (CHN): calcd. for C14H11BrN2O2: C 48.43, H 3.19, N 16.14 %; found: C 48.46, H 3.18, N 16.13 %.

6-amino-4-(2-hydroxy-5-bromophenyl)-3-methyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (25): (Novel Compound)

Brown Solid, IR ν max (KBr) cm−1: 3447 (C–OH), 3416, 3396 (NH2), 3314 (–NH–), 3062, 3025 (Aromatic), 2939 (–CH3), 2214 (–CN), 1492 (–NH–), 1062 (Ar–Cl), 740 (Ortho), 773 (Meta), 810 (Para). 1H NMR (400 MHz, DMSO-d 6): δ H (ppm) 2.06 (s, 3H, CH3), 4.64 (s, 1H, 4H), 6.65 (s, 2H, NH2), 6.95–6.97 (d, 1H, J = 6.2 Hz, Ar–H), 7.09 (s, 1H, Ar–H), 7.34–7.36 (d, 1H, J = 8.68 Hz, Ar–H), 10.58 (s-broad, 2H, NH and OH). 13C NMR (100 MHz, DMSO-d 6): δ C (ppm) 10.56, 32.99, 34.79, 92.98, 112.95, 113.27, 114.99, 125.64, 125.83, 127.19, 127.94, 131.24, 137.40, 140.89, 145.62, 156.34, 157.53. MS (ESI) m/z for (337.07): 337.1 (M)+, 338.2 (M + 1)+. Elemental Analysis (CHN): calcd. for C17H12ClN5O: C 60.45, H 3.58, N 20.73 %; found: C 60.46, H 3.55, N 20.77 %.

Results and discussion

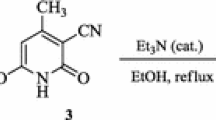

The main objective of the current work was to develop an efficient and green protocol for the synthesis of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitriles in a non‐toxic solvent like water. In the beginning, the reaction of equimolar quantities of ethyl acetoacetate (1 mmol), hydrazine hydrate (1.5 mmol, 80 %), aromatic aldehydes (1 mmol), and malononitrile (1 mmol) was used as a model reaction to identify suitable conditions for the transformation using TUD as a catalyst. To optimize the reaction conditions and evaluate the catalytic activity of TUD compared with other catalysts for the formation of compound 1, comparative experiments were performed, and the data are shown in Table 1. Different catalysts were tested, including FeCl3·6H2O, InCl3, ZnCl2, Sulfamic acid, p‐TSA, Ceric ammonium nitrate (CAN), and TUD. However, TUD was found to be the most efficient in terms of the reaction time and yield of the product (Table 1, Entries 1–6).

The model reaction was used to identify suitable conditions, including solvents, amounts of catalyst, and temperatures. The results are summarized in Table 2. In this transformation, catalyst loadings in the range of 0–15 % were tested. From the result table, we concluded that the lower yield of the product was observed in the absence of the catalyst (Table 2, Entry 1). In addition, it was discovered that the reaction was rather slow and resulted in poor yield (29 %) in the absence of the catalyst when the reaction was carried out in refluxing water for 60 min (Table 2, Entry 2), which demonstrates that the catalyst is essential for formation of the product in high yield. The yields of product were also increased slightly by adding 5 and 10 mol% of TUD to the reaction mixture at room temperature (Table 2, Entries 3, 4).

To evaluate the effects of different solvents on the reaction, the model reaction was conducted in a range of different solvents, including methanol, ethanol, acetonitrile, dichloromethane, ethyl acetate, chloroform, and water under reflux conditions in the presence of 10 mol% TUD catalyst (Table 2, Entries 6–11). Aprotic solvents gave the desired product in lower yields, whereas protic solvents gave the product in good to excellent yields. Water was clearly identified as the solvent of choice, because it provided the highest yield of the desired product, as well as being the most cost‐effective and environmental acceptable of the solvents tested (Table 2, Entry 12). On the other hand, a mixture of EtOH:H2O (1:1, v/v) afforded a moderate yield of the desired product 5a under similar conditions (Table 2, Entry 5). Having optimized the solvent for the reaction, we proceeded to investigate the use of different temperatures including room temperature and 50, 60, 70, and 80 °C (Table 2, Entries 12–15). Increasing the temperature of the reaction from room temperature to 80 °C led to a reduction in the reaction time. The greatest yield in the shortest reaction time was obtained in water at 80 °C (Table 2, Entry 12). In the next step, the reaction was carried out with various amounts of catalyst in water at 80 °C. It was found that, by increasing the amount of catalyst from 2.5 to 10 mol% under reflux conditions, the yield of 6-amino-3-methyl-4-phenyl-1,4-dihydropyrano[2,3-c]pyrazole-5-carbonitrile (1) was improved (Table 2, Entries 8 and 16–18). In addition, higher amounts of catalyst, that is 12.5 mol%, can not improve product yields and the reaction times (Table 2, Entry 19). Hence, the best results were obtained by performing the reaction in the presence of 10 mol% of TUD in refluxing water.

To evaluate the scope of this catalytic transformation, the optimized reaction conditions were subsequently applied to the reaction of ethyl acetoacetate, hydrazine hydrate, and malononitrile with a variety of different aromatic aldehydes (Table 3, Entries 1–24). A wide range of aromatic aldehydes bearing either electron‐releasing or electron-withdrawing substituents reacted successfully to give the corresponding products in high to excellent yields over short reaction times. In all cases, the reaction was found to be selective and afforded the desired products in high purity without any evidence of the formation of any side products. In addition, heterocyclic aldehyde like 2-furfuraldehyde and 2-thienyl could also reacted efficiently, which afforded product in excellent yields (Table 3, Entries 10 and 20).

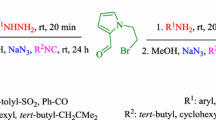

To broaden the scope of the reaction, we have prepared quinoline hybride pyrano[2,3-c]pyrazolo derivative efficiently using TUD as a green organocatalyst. For this synthesis, we used 2-chloroquinoline-3-carbaldehyde, which was synthesized from the acetanilide via a Vilsmeier-Haack reaction [82]. Here, we achieved 92 % of product yield within 32 min (Mp = 270–272 °C) (Scheme 2).

We have also proposed a possible mechanism for the building of final products (1–15) (Scheme 3). The nitrile anion (E) was formed by the removal of acidic hydrogen from malononitrile (D) catalyzed by TUD. Finally, the arylidene nitrile intermediates (Knoevenagel adducts, F) are formed through the Knoevenagel condensation reaction of the intermediate nitrile anion (E) with aldehydes (C). On other hand, the reaction of ethyl acetoacetate and hydrazine hydrate afforded compound (G), which was enolised in the presence of TUD to formed compound (H). Subsequently, the enolizable compound (H) condensed with the Knoevenagel adducts (F) via Michael addition, which results in the in situ formation of intermediate (I) (Michael adducts). Then there is subsequent intramolecular nucleophilic cyclization (Thorpe–Ziegler type reaction) and tautomerization to afford the desired compounds (1–15).

Next, we checked the recyclability of the catalyst by performing the reaction of ethyl acetoacetate, hydrazine hydrate, benzaldehyde, and malononitrile in the presence of a catalytic amount of 10 mol% of TUD in water. After completion of the reaction, the reaction mixture was diluted with water (10 mL), and the resulting solid was removed by filtration, and washed with water. The remaining aqueous thiourea dioxide was collected, water was evaporated under vacuum, and the obtained catalyst was washed with ethyl acetate and dried. The recycling ability of the TUD was tested for four runs, which providing 96–90 % of the desired product yield in a similar reaction time. The results of recycling experiments are given in Fig. 1.

Conclusion

In summary, we have established a green and highly efficient one‐pot four‐component protocol for the preparation of various 6-amino-1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitriles catalyzed by TUD. The TUD catalyst was easily prepared by the oxidation of thiourea with hydrogen peroxide. There are numerous striking features to this protocol, including high yield of products with high purity, a simple work-up process, avoidance of the use of hazardous organic solvents, aqueous conditions, and a simple work-up procedure make the present method a valuable contribution in agreement with green chemistry principles. The use of TUD as an inexpensive, reusable, and non‐volatile catalyst makes the method environmentally friendly, green, and economically viable.

References

A. Domling, I. Ugi, Angew. Chem. Int. Ed. 39, 3168 (2000)

J. Zhu, H. Bienayme, Multicomponent Reactions (Wiley, Weinheim, 2006)

N.P. Prajapati, R.H. Vekariya, H.D. Patel, Synth. Commun. (2015). doi:10.1080/00397911.00392015.01045986

D.M. D’Souza, T.J. Mueller, Chem. Soc. Rev. 36, 1095 (2007)

M.S. Singh, S. Chowdhury, RSC Adv. 2, 4547 (2012)

G. Feuer, G. Ellis, G. West, Ed. Ellis, GP and West, GB, North Holland Publishing Co., New York, 10, 85 (1974)

A. Goel, V.J. Ram, Tetrahedron 65, 7865 (2009)

J.Y.C. Wu, W.F. Fong, J.X. Zhang, C.H. Leung, H.L. Kwong, M.S. Yang, D. Li, H.Y. Cheung, Eur. J. Pharmacol. 473, 9 (2003)

M. Rueping, E. Sugiono, E. Merino, Chem. Eur. J. 14, 6329 (2008)

D.O. Moon, K.C. Kim, C.Y. Jin, M.H. Han, C. Park, K.J. Lee, Y.M. Park, Y.H. Choi, G.Y. Kim, Int. Immunopharmacol. 7, 222 (2007)

V.F. de Andrade-Neto, M.L.O. Goulart, J.F. da Silva Filho, M.J. da Silva, F. Maria do Carmo, A.V. Pinto, M.G. Zalis, L.H. Carvalho, A.U. Krettli, Bioorg. Med. Chem. Lett. 14, 1145 (2004)

L.R. Morgan, B.S. Jursic, C.L. Hooper, D.M. Neumann, K. Thangaraj, B. LeBlanc, Bioorg. Med. Chem. Lett. 12, 3407 (2002)

A. Martínez-Grau, J. Marco, Bioorg. Med. Chem. Lett. 7, 3165 (1997)

A. Venkatesham, R.S. Rao, K. Nagaiah, J. Yadav, G. RoopaJones, S. Basha, B. Sridhar, A. Addlagatta, Med. Chem. Comm. 3, 652 (2012)

S. Hatakeyama, N. Ochi, H. Numata, S. Takano, Chem. Commun. 17, 1202 (1988)

F. Karcı, F. Karcı, Dyes Pigments 76, 97 (2008)

H. Kiyani, H. Samimi, F. Ghorbani, S. Esmaieli, Curr. Chem. Lett. 2, 197 (2013)

D. Shi, J. Mou, Q. Zhuang, L. Niu, N. Wu, X. Wang, Synth. Commun. 34, 4557 (2004)

M. Kangani, N. Hazeri, M.T. Mghsoodlou, S.M. Habibi-khorasani, S. Salahi, Res. Chem. Intermed. 41, 2513 (2015)

M. Kangani, N. Hazeri, M.T. Maghsoodlou, K. Khandan-Barani, M. Kheyrollahi, F. Nezhadshahrokhabadi, J. Iran. Chem. Soc. 12, 47 (2015)

G. Brahmachari, B. Banerjee, A.C.S. Sustain, Chem. Eng. 2, 411 (2013)

P.P. Bora, M. Bihani, G. Bez, J. Mol. Catal. B Enzym. 92, 24 (2013)

R.Y. Guo, Z.M. An, L.P. Mo, S.T. Yang, H.X. Liu, S.X. Wang, Z.H. Zhang, Tetrahedron 69, 9931 (2013)

H.F. Zhang, Z.Q. Ye, G. Zhao, Chin. Chem. Lett. 25, 535 (2014)

M.A. Zolfigol, M. Tavasoli, A.R. Moosavi-Zare, P. Moosavi, H.G. Kruger, M. Shiri, V. Khakyzadeh, RSC Adv. 3, 25681 (2013)

V.L. Gein, T.M. Zamaraeva, I.V. Kozulina, Russ. J. Org. Chem. 50, 691 (2014)

S. Bhavanarushi, V. Kanakaiah, E. Yakaiah, V. Saddanapu, A. Addlagatta, J. VatsalaRani, Med. Chem. Res. 22, 2446 (2013)

A. Keyume, Z. Esmayil, L. Wang, F. Jun, Tetrahedron 70, 3976 (2014)

L.K. Katariya, G.J. Kharadi, Int. J. Pharm. Res. Sch. 3, 627 (2014)

W. Liju, K. Ablajan, Curr. Org. Synth. 11, 310 (2014)

P.B. Pawar, S.D. Jadhav, B.M. Patil, R.V. Shejwal, S. Patil, Arch. Appl. Sci. Res. 6, 150 (2014)

A.R. Moosavi-Zare, M.A. Zolfigol, E. Noroozizadeh, M. Tavasoli, V. Khakyzadeh, A. Zare, New J. Chem. 37, 4089 (2013)

D. Azarifar, S.M. Khatami, M.A. Zolfigol, R. Nejat-Yami, J. Iran. Chem. Soc. 11, 1223 (2013)

S.U. Tekale, S.S. Kauthale, K.M. Jadhav, R.P. Pawar, J. Chem. 2013, 1 (2013). doi:10.1155/2013/840954

J. Albadi, A. Mansournezhad, Z. Derakhshandeh, Chin. Chem. Lett. 24, 821 (2013)

D. Azarifar, S.M. Khatami, R. Nejat-Yami, J. Chem. Sci. 126, 95 (2014)

H.R. Shaterian, K. Azizi, Mild Res. Chem. Intermed. 40, 661 (2014)

K. Pradhan, S. Paul, A.R. Das, Catal. Sci. Technol. 4, 822 (2014)

J.M. Khurana, K. Vij, Synth. Commun. 43, 2294 (2013)

J. Safaei-Ghomi, A. Ziarati, M. Tamimi, Acta Chim. Slov. 60, 403 (2013)

M.A. ElAleem, A.A. El-Remaily, Tetrahedron 70, 2971 (2014)

S. Paul, K. Pradhan, S. Ghosh, S.K. De, A.R. Das, Tetrahedron 70, 6088 (2014)

M. Bihani, P.P. Bora, G. Bez, H. Askari, A.C.S. Sustain, Chem. Eng. 1, 440 (2013)

M. Wu, Q. Feng, D. Wan, J. Ma, Synth. Commun. 43, 1721 (2013)

A.I. Ilovaisky, M.G. Medvedev, V.M. Merkulova, M.N. Elinson, G.I. Nikishin, J. Heterocycl. Chem. 51, 523 (2014)

G.S. Kumar, C. Kurumurthy, B. Veeraswamy, P.S. Rao, P.S. Rao, B. Narsaiah, Org. Prep. Proced. Int. 45, 429 (2013)

K. Ablajan, L.J. Wang, Z. Maimaiti, Y.T. Lu, Monatsh. Chem. 145, 491 (2014)

V.N. Bhosale, J.A. Angulwar, G.S. Khansole, G.S. Waghmare, J. Chem. Pharm. Res. 6, 733 (2014)

J. Albadi, A. Mansournezhad, F. Akbari Blout-Bangan, Acta Chim. Slov. 61, 185 (2014)

H. Adibi, L. Hosseinzadeh, S. Farhadi, F. Ahmadi, J. Repor. Pharm. Sci. 2, 116 (2013)

A.B. Atar, J.T. Kim, K.T. Lim, Y.T. Jeong, Synth. Commun. 44, 2679 (2014)

M. Parshad, V. Verma, D. Kumar, Monatsh. Chem. 145, 1857 (2014)

K. Ablajan, W. Liju, Y. Kelimu, F. Jun, Mol. Divers. 17, 693 (2013)

M. Farahi, B. Karami, I. Sedighimehr, H.M. Tanuraghaj, Chin. Chem. Lett. 25, 1580 (2014)

R. Heydari, F. Shahrekipour, Res. Chem. Intermed. 7, 4581 (2015)

C.F. Barbas, Angew. Chem. Int. Ed. 120, 44 (2008)

C.F. Barbas, Angew. Chem. Int. Ed. 47, 42 (2008)

S. Bertelsen, K.A. Jorgensen, Chem. Soc. Rev. 38, 2178 (2009)

K.L. Kimmel, M.T. Robak, J.A. Ellman, J. Am. Chem. Soc. 131, 8754 (2009)

S. Tanaka, K. Nagasawa, Synlett, 667 (2009). doi:10.1055/s-0028-1087811

E.M. Fleming, C. Quigley, I. Rozas, S.J. Connon, J. Org. Chem. 73, 948 (2008)

F. Wang, X. Liu, X. Cui, Y. Xiong, X. Zhou, X. Feng, Chem. Eur. J. 15, 589 (2009)

A. Peschiulli, Y. Gun’k, S.J. Connon, J. Org. Chem. 73, 2454 (2008)

Q.H. Wu, Y.J. Gao, Z. Li, Chin. J. Org. Chem. 27, 1491 (2007)

M. Nandi, J. Mondal, K. Sarkar, Y. Yamauchi, A. Bhaumik, Chem. Commun. 47, 6677 (2011)

R.H. Vekariya, H.D. Patel, Synth. Commun. 45, 1031 (2014)

R.H. Vekariya, H.D. Patel, ARKIVOC 1, 70 (2015)

R.H. Vekariya, H.D. Patel, ARKIVOC 1, 136 (2015)

R.H. Vekariya, H.D. Patel, RSC Adv. 5, 49006 (2015)

O. Ohura, O. Fujimoto, in Process for preparing thiourea dioxide. U.S. Patents, 11 Nov., (1980)

S. Verma, S. Kumar, S.L. Jain, B. Sain, Org. Biomol. Chem. 9, 6943 (2011)

S. Kumar, S.L. Jain, B. Sain, RSC Adv. 2, 789 (2012)

S. Verma, S.L. Jain, Tetrahedron Lett. 53, 6055 (2012)

M. Ghashang, S.S. Mansoor, K. Aswin, Chin. J. Catal. 35, 127 (2014)

M. Ghashang, S.S. Mansoor, K. Logaiya, K. Aswin, Res. Chem. Intermed. 40, 1135 (2014)

S. Kumar, S. Verma, S.L. Jain, B. Sain, Tetrahedron Lett. 52, 3393 (2011)

S. Sambher, C. Baskar, R.S. Dhillon, Synth. Commun. 38, 2150 (2008)

S. Verma, S.L. Jain, Tetrahedron Lett. 53, 2595 (2012)

H. Mecadon, M.R. Rohman, M. Rajbangshi, B. Myrboh, Tetrahedron Lett. 52, 2523 (2011)

K. Kanagaraj, K. Pitchumani, Tetrahedron Lett. 51, 3312 (2010)

M.B.N. Amin, A.R. Parikh, H. Parikh, M.V. Gudaparthi, Sch. Acad. J. Pharm. 3, 208 (2014)

B.F. Abdel-Wahab, R.E. Khidre, A.A. Farahat, ARKIVOC 1, 196 (2011)

Acknowledgments

The authors are thankful to the Department of Chemistry, Gujarat University Ahmedabad, for providing the necessary facilities. UGC-Info net and INFLIBNET Gujarat University are acknowledged for providing the e-resource facilities, NFDD Centre for proton NMR and carbon NMR and Synzeal laboratory for mass spectroscopy. R.H.V. is thankful to UGC-BSR [F.7-74/2007 (BSR)] for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

11164_2015_2308_MOESM1_ESM.doc

Supplementary data of representative compounds (Spectroscopic analytical data 1H, 13C NMR and Mass Spectra) associated with this article can be found online (DOC 1368 kb)

Rights and permissions

About this article

Cite this article

Vekariya, R.H., Patel, K.D. & Patel, H.D. A green and one-pot synthesis of a library of 1,4-dihydropyrano[2,3-c]-pyrazole-5-carbonitrile derivatives using thiourea dioxide (TUD) as an efficient and reusable organocatalyst. Res Chem Intermed 42, 4683–4696 (2016). https://doi.org/10.1007/s11164-015-2308-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2308-7