Abstract

A convenient one-pot multi-component strategy was conducted successfully under catalyst-free conditions employing water and PEG-400 as the efficient and cheap promoting medium. Three types and nearly 50 2-amino-3-cyano-4H-pyran annulated derivatives were synthesized in good to excellent yields by the condensation of a series of aromatic aldehydes with malononitrile and different 1,3-dicarbonyl compounds. Broad substrate scope, systematic characterization, eliminated catalyst, brief reaction time, and simple purification procedure are the best merits in this process.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Green and sustainable chemistry is a practical and philosophical concept that focuses on the improvement or design of synthetic procedure to eliminate or reduce the impact of potentially hazardous pollutants on the environment [1, 2]. Remarkable efforts have been dedicated to develop new organic reactions in agreement with the principles of green chemistry [3, 4]. In many organic reactions, solvents not only facilitate the intimate contact of reactants and catalysts, but also determine the choice of work-up procedures and disposal strategies [5]. Thus, employing non-toxic, inexpensive, and environment-friendly solvents instead of hazardous organic solvents for chemical synthesis has attracted increasing interest [6, 7] especially without the use of catalyst [8,9,10,11]. Both water [12,13,14] and polyethylene glycol (PEG) [15,16,17,18] are considered to be the popular green reaction mediums and efficient promoters in modern organic synthesis. Also, several reports have used water-PEG as the green solvent for organic reactions [19,20,21,22].

A multi-component reaction (MCR) is a powerful and ideal bond-forming technique in organic, combinatorial, and medicinal chemistry [23,24,25]. This strategy has greater efficiency with respect to structural complexity and atom economy for the synthesis of diverse chemical libraries in one-pot reactions [26, 27]. Development or improvement of the unknown and known MCRs for the synthesis of privileged scaffolds has received significant attention in recent years [28,29,30]. One prominent MCR that produces an interesting class of “privileged heterocyclic compounds” is 4H-pyrans derivatives synthesis [31,32,33]. 4H-pyrans and 4H-pyran-annulated heterocyclic scaffolds (4H-chromene) are the key building blocks of numerous oxygen-containing heterocyclic natural products and represent a “drug-like” structural motif with a broad spectrum of applications in organic synthesis and medicinal chemistry [34,35,36,37,38,39]. In view of these useful properties, a good number of methods have been developed under environmentally friendly conditions to synthesize polyfunctionalized 4H-pyran heterocyclics by the multi-component condensation of aromatic aldehyde, malononitrile (or ethyl cyanoacetate), and diverse enolizable C-H activated acidic compounds [40,41,42,43,44,45]. These reactions can be catalyzed in the presence of various acidic or basic catalysts [46,47,48]. However, the catalysts employed in most of these reactions are not always cheap, simple, and eco-friendly. Consequently, environmental pollution often results when the catalysts contaminate the environment. There is still a great desire for more green, general, efficient, feasible, high yielding, and cost effective methods for the synthesis of this class of compounds [49,50,51,52,53,54].

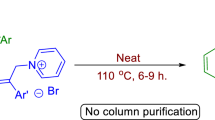

The combination of multi-component technique, use of green reaction media and involvement of no catalyst would be the ideal strategy to develop perfect green synthetic procedure [11, 55, 56]. To the best of our knowledge, there are only a few reports on the oriented catalyst-free synthesis of this type of 4H-pyran-annulated derivative [46, 57,58,59]. A survey of the literature shows that water promotes the condensation of aldehydes with dicarbonyl compounds in the absence of catalyst [60,61,62]; therefore, we speculate that water could also accelerate the multi-component reaction of aldehyde with dimedone and malononitrile under catalyst-free conditions. The major drawback of using water as solvent is its poor ability to solubilize organic reactants [14, 63]. One of the most efficient and versatile methods of increasing the solubility is using an organic co-solvent [64]. Many reactions could perform smoothly in the mixture medium from water and organic solvent without catalyst [55, 65, 66]. Based on this, herein, we wish to report a strategy employing the mixture of water and PEG-400 as green, bio-compatibility, and efficient promoting medium for the three component condensation between aromatic aldehyde, malononitrile, and different dicarbonyl compounds to synthesize 2-amino-3-cyano-4H-pyran derivatives avoiding the addition of a catalyst (Scheme 1).

Experimental

General information

Unless otherwise stated, all reagents were obtained from commercial sources and were used without further purification. Melting points were determined on Beijing Tech X-5 melting point detector and were uncorrected. The IR spectra were measured with a Bruker Shimadzu IR-460 spectrometer. 1H and 13C NMR spectra were recorded on a Bruker Avance 500 MHz. The chemical shifts (δ) were reported in parts per million (ppm) and coupling constants (J) in Hertz. High resolution mass spectra (HRMS) were obtained on an Agilent G6224A TOF mass spectrometer.

Typical experimental procedure for synthesis of 5 and 6

A mixture of dimedone or 1,3-dioxocyclohexane (0.55 mmol), malononitrile (0.5 mmol), and aromatic aldehyde (0.5 mmol) was stirred in 1 mL H2O and 1 mL PEG-400 at room temperature for 45 min. Then 1 mL 50% EtOH was added and the mixture was vigorously stirred for a moment at 100 °C. After cooling in an ice bath, the precipitate was collected by filtration and washed with 25% cold EtOH to afford the desired product without further purification.

Typical experimental procedure for synthesis of 7

To a 10 mL pressure tube equipped with magnetic bar was added 0.55 mmol 4-hydroxycoumarin, 0.5 mmol malononitrile, 0.5 mmol aromatic aldehyde, and the solvent (1.5 mL H2O and 0.5 mL PEG-400). This solution was stirred at 100 °C for 3.5 h. Then 1 mL 50% EtOH was added and the mixture was vigorously stirred for a moment at 100 °C. After cooling in an ice bath, the precipitate was separated by filtration and washed with 25% cold EtOH to afford the desired product without further purification.

Results and discussion

As the literature reported [46], the separation of products was hard, and a moderate yield was obtained when the reaction took place in 2 mL water or PEG-400, respectively (Table 1, entries 1, 2). With regard to the previous reports, we commenced our work to optimize the reaction condition by using H2O/PEG-400 as the solvent and promoter. First, various volume and ratio of the water and PEG-400 were screened (Table 1, entries 3–7). To our delight, the required pure white product was formed in 93% yield when employing 1 mL H2O and 1 mL PEG-400 as the reaction media (Table 1, entry 4). Only a slight lower yield than the reference which employing aqueous PEG-400 as the medium and 20 mol% Ba(OTf)2 as the catalyst [40]. Next, the temperature evaluation indicated that reacted at room temperature was the best choice. We also investigated the fate of varying the molar ratio of each substrate (Table 1, entries 10–12). A satisfied result was observed with 1:1:1.1 molar ratio of benzaldehyde, malononitrile, and dimedone (Table 1, entry 12). Finally, the reaction time was tested and a higher result was achieved as shorten the time to 45 min (Table 1, entry 14). Therefore, the reaction was optimized using cheap, safe, and environmentally benign reaction medium under catalyst-free conditions.

To probe the generality, as well as the efficiency of our protocol, a number of substituted benzaldehydes were reacted with dimedone and malononitrile under the optimum conditions. As indicated in Table 2, the position of substituent and the electronic density of the aromatic ring did not show dramatic effect on the yield of 2-amimo-3-cyano-4-aryl-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-benzo[b]pyran. All substrates underwent the reaction smoothly to afford the corresponding products in excellent yields in 45 min. In another study 1,3-dioxocyclohexane was applied instead of dimedone in one-pot condensation with malononitrile and different aromatic aldehydes under optimized reaction conditions (Table 3). The trend of reactivity for different aldehydes was similar to that of the reaction with dimedone and good to excellent yields were obtained. The aromatic heterocyclic aldehyde also proceeded smoothly in these two reactions and the corresponding products (5r and 6q) were isolated in excellent yields.

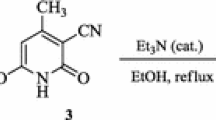

With these results in hand, we further investigated the substrate scopes and limitations of the present procedure by using 4-hydroxycoumarin as the enolic component to synthesize 2-amino-3-cyano-pyrano[3,2-c]chromen-5(4H)-one derivatives (Scheme 2). Similar to the above optimization, the solvent and temperature used in the reaction for synthesis of compound 7 were also evaluated to optimize the reaction conditions. We found that employing 1.5 mL H2O and 0.5 mL PEG-400 as media was the best option. Increasing the reaction temperature and prolonging the reaction time led these uncatalyzed one-pot condensations to proceed with high yields. This may be attributed to the lower acidity and activity of C–H bond of 4-hydroxycoumarin. As it is shown in Table 4, the substituent on the aromatic ring had a minor influence on the reactivity of the aldehyde too. This evaluation employing 4-hydroxycoumarin as the substrate only afforded a slightly lower yields than the previous reactions of dimedone or 1,3-dioxocyclohexane.

After successfully synthesizing these three classes of 2-amino-3-cyano-4H-pyran derivatives in good to excellent yields, a paper published online employing PEG-600 as the promoting media [59]. Compared to this method, our protocol that using water as solvent and PEG-400 as co-solvent performed more effective. The research was systematic, the substrate scope was broad, the yields were relatively higher, and the reaction time was mercifully brief.

Conclusions

The simplification of reaction approach is an important concept in synthetic chemistry. Herein, this improved protocol removes the catalyst and unnecessary reagents, avoids the problems associated with using hazardous organic solvents, and eliminates the tedious work up, isolation, and purification procedures. Three types and nearly 50 2-amino-3-cyano-4H-pyran derivatives have been successfully synthesized and characterized. The isolation is simply a filtration after suspension in 50% aqueous ethanol to remove the impurities and PEG-400. Most of the target compounds need no further purification. Employing water in combination with mild, nontoxic, and commercially available PEG-400 as the accelerant without adding catalyst is found to highly applicable to get a satisfactory outcome.

References

U. Balijapalli, S. Munusamy, K.N. Sundaramoorthy, S.K. Iyer, Synth. Commun. 44, 943 (2014)

L.A. Polindara-García, E. Juaristi, Eur. J. Org. Chem. 2016, 1095 (2016)

H.-J. Li, K. Deng, D.-H. Luo, D.-H. Liu, J.-L. Wang, C.-H. Lin, Y.-C. Wu, RSC Adv. 4, 26316 (2014)

B. Paplal, S. Nagaraju, P. Veerabhadraiah, K. Sujatha, S. Kanvah, B.V. Kumar, D. Kashinath, RSC Adv. 4, 54168 (2014)

X. Zhang, R. Zou, J. Deng, W. Zhou, J. Wang, Chin. J. Org. Chem. 35, 1238 (2015)

A. Solhy, A. Elmakssoudi, R. Tahir, M. Karkouri, M. Larzek, M. Bousmina, M. Zahouily, Green Chem. 12, 2261 (2010)

M.G. Dekamin, M. Eslami, Green Chem. 16, 4914 (2014)

J. Liu, M. Lei, L. Hu, Green Chem. 14, 2534 (2012)

H. Yang, W. Hu, S. Deng, T. Wu, H. Cen, Y. Chen, D. Zhang, B. Wang, New J. Chem. 39, 5912 (2015)

D.A. Alonso, A. Baeza, R. Chinchilla, G. Guillena, I.M. Pastor, D.J. Ramón, Eur. J. Org. Chem. 2016, 612 (2016)

M.B. Gawande, V.D.B. Bonifácio, R. Luque, P.S. Branco, R.S. Varma, Chem. Soc. Rev. 42, 5522 (2013)

M. Bhardwaj, S. Sahi, H. Mahajan, S. Paul, J.H. Clark, J. Mol. Catal. A: Chem. 408, 48 (2015)

G. Brahmachari, ACS Sustain. Chem. Eng. 3, 2350 (2015)

J. Xiao, H. Wen, L. Wang, L. Xu, Z. Hao, C.-L. Shao, C.-Y. Wang, Green Chem. 18, 1032 (2016)

N.R. Candeias, L.C. Branco, P.M.P. Gois, C.A.M. Afonso, A.F. Trindade, Chem. Rev. 109, 2703 (2009)

X.-C. Wang, G.-J. Yang, Z.-J. Quan, P.-Y. Ji, J.-L. Liang, R.-G. Ren, Synlett 11, 1657 (2010)

M.V. Reddy, J.S. Kim, K.T. Lim, Y.T. Jeong, Tetrahedron Lett. 55, 6459 (2014)

M.N. Khan, S. Karamthulla, L.H. Choudhury, M.S.H. Faizi, RSC Adv. 5, 22168 (2015)

M.A. Kumar, M.F.S. Babu, K. Srinivasulu, Y.B. Kiran, C.S. Reddy, J. Mol. Catal. A: Chem. 265, 268 (2007)

J. Engel-Andreasen, B. Shimpukade, T. Ulven, Green Chem. 15, 336 (2013)

A. Nagaraju, B.J. Ramulu, G. Shukla, A. Srivastava, G.K. Verma, K. Raghuvanshi, M.S. Singh, Green Chem. 17, 950 (2015)

J. Zhang, J. Yao, J. Liu, S. Xue, Y. Li, C. Wang, RSC Adv. 5, 48580 (2015)

S. Anvar, I. Mohammadpoor-Baltork, S. Tangestaninejad, M. Moghadam, V. Mirkhani, A.R. Khosropour, A.L. Isfahani, R. Kia, ACS Comb. Sci. 16, 93 (2014)

K. Aswin, S.S. Mansoor, K. Logaiya, S.P.N. Sudhan, V.S. Malik, H. Ramadoss, Res. Chem. Intermed. 40, 2583 (2014)

S. Zheng, S. Zhong, Z. Chen, W. Chen, Q. Zhu, ACS Comb. Sci. 18, 475 (2016)

X. Feng, J.-J. Wang, J.-J. Zhang, C.-P. Cao, Z.-B. Huang, D.-Q. Shi, Green Chem. 17, 973 (2015)

L. Aguirre-Diaz, F. Gandara, M. Iglesias, N. Snejko, E. Gutierrez-Puebla, M. Monge, J. Am. Chem. Soc. 137, 6132 (2015)

Y. Gu, Green Chem. 14, 2091 (2012)

G. Brahmachari, B. Banerjee, ACS Sustain. Chem. Eng. 2, 411 (2014)

M.V. Reddy, G.C.S. Reddy, Y.T. Jeong, Tetrahedron Lett. 57, 1289 (2016)

M.G. Dekamin, M. Eslami, A. Maleki, Tetrahedron 69, 1074 (2013)

B. Karami, M. Kiani, Monatsh. Chem. 147, 1117 (2016)

M.A. Zolfigol, M. Safaiee, N. Bahrami-Nejad, New J. Chem. 40, 5071 (2016)

R.L. Magar, P.B. Thorat, V.B. Jadhav, S.U. Tekale, S.A. Dake, B.R. Patil, R.P. Pawar, J. Mol. Catal. A: Chem. 374–375, 118 (2013)

S. Tabassum, S. Govindaraju, R. Khan, M.A. Pasha, Ultrason. Sonochem. 24, 1 (2015)

P.P. Bora, M. Bihani, G. Bez, RSC Adv. 5, 50597 (2015)

M.A. Zolfigol, M. Yarie, S. Baghery, Synlett 27, 1418 (2016)

H. Kiyani, M.S. Jalali, Heterocycles 92, 75 (2016)

E. Abbaspour-Gilandeh, M. Aghaei-Hashjin, A. Yahyazadeh, H. Salemi, RSC Adv. 6, 55444 (2016)

A. Kumar, M.S. Rao, Green Chem. Lett. Rev. 5, 283 (2012)

Y. Sarrafi, E. Mehrasbi, A. Vahid, M. Tajbakhsh, Chin. J. Catal. 33, 1486 (2012)

J. Safari, Z. Zarnegar, J. Mol. Struct. 1072, 53 (2014)

A. Chaskar, Lett. Org. Chem. 11, 480 (2014)

B. Amirheidari, M. Seifi, M. Abaszadeh, Res. Chem. Intermed. 42, 3413 (2016)

M.G. Dekamin, S.Z. Peyman, Z. Karimi, S. Javanshir, M.R. Naimi-Jamal, M. Barikani, Int. J. Biol. Macromol. 87, 172 (2016)

H.R. Safaei, M. Shekouhy, S. Rahmanpur, A. Shirinfeshan, Green Chem. 14, 1696 (2012)

V.M. Joshi, R.L. Magar, P.B. Throat, S.U. Tekale, B.R. Patil, M.P. Kale, R.P. Pawar, Chin. Chem. Lett. 25, 455 (2014)

J. Albadi, A. Mansournezhad, Res. Chem. Intermed. 42, 5739 (2016)

D.M. Pore, K.A. Undale, B.B. Dongare, U.V. Desai, Catal. Lett. 132, 104 (2009)

J.M. Khurana, B. Nand, P. Saluja, Tetrahedron 66, 5637 (2010)

A. Hasaninejada, M. Shekouhy, N. Golzar, A. Zare, M.M. Doroodmand, Appl. Catal. A 402, 11 (2011)

Y. Ren, W. Zhang, J. Lu, K. Gao, X. Liao, X. Chen, RSC Adv. 5, 79405 (2015)

J.K. Rajput, P. Arora, G. Kaur, M. Kaur, Ultrason. Sonochem. 26, 229 (2015)

F. Shirini, O. Goli-Jolodar, M. Akbari, M. Seddighi, Res. Chem. Intermed. 42, 4733 (2016)

F. Nemati, S.H. Nikkhah, A. Elhampour, Chin. Chem. Lett. 26, 1397 (2015)

S. Singh, M. Saquib, M. Singh, J. Tiwari, F. Tufail, J. Singh, J. Singh, New J. Chem. 40, 63 (2016)

S. Khaksar, A. Rouhollahpour, S.M. Talesh, J. Fluorine Chem. 141, 11 (2012)

M.N. Elinson, F.V. Ryzhkov, T.A. Zaimovskaya, M.P. Egorov, Mendeleev Commun. 25, 185 (2015)

D.N. Survase, H.V. Chavan, S.B. Dongare, V.B. Helavi, Synth. Commun. 46, 1665 (2016)

F. Bigi, S. Carloni, L. Ferrari, R. Maggi, A. Mazzacani, G. Sartori, Tetrahedron Lett. 42, 5203 (2001)

R. Maggi, F. Bigi, S. Carloni, A. Mazzacani, G. Sartori, Green Chem. 3, 173 (2001)

T.-S. Jin, A.-Q. Wang, X. Wang, J.-S. Zhang, T.-S. Li, Synlett 5, 871 (2004)

P. Liu, J.-W. Hao, L.-P. Mo, Z.-H. Zhang, RSC Adv. 5, 48675 (2015)

K. Venkatesan, S.S. Pujari, K.V. Srinivasan, Synth. Commun. 39, 228 (2009)

H.M. Bachhav, S.B. Bhagat, V.N. Telvekar, Tetrahedron Lett. 52, 5697 (2011)

S. Ghosh, J. Das, S. Chattopadhyay, Tetrahedron Lett. 52, 2869 (2011)

Acknowledgements

We are grateful for financial support from the National Natural Science Foundation of China (21403100), Natural Science Foundation of Liaoning Province (20141100), and Department of Education of Liaoning Province (L2014421).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lü, CW., Wang, JJ., Li, F. et al. Efficient synthesis of 2-amino-3-cyano-4H-pyran derivatives via a non-catalytic one-pot three-component reaction. Res Chem Intermed 44, 1035–1043 (2018). https://doi.org/10.1007/s11164-017-3151-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-017-3151-9